Vertical distribution structure applicable to treatment of oil-containing drillings in offshore oil-gas development

A vertical arrangement and drilling cuttings technology, which is applied in earthwork drilling, wellbore/well components, flushing wellbore, etc., can solve the problems of inapplicability to large-scale promotion and application, inapplicability to offshore working conditions, and high processing costs. Achieve the effect of improving thermal efficiency and heat utilization rate, meeting requirements, and green treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and example the present invention will be further described:

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the present invention is a vertical layout structure suitable for oily drilling cuttings treatment in offshore oil and gas development, including three parts: electromagnetic heating system, vertical hammer mill assembly, sealing and support system.

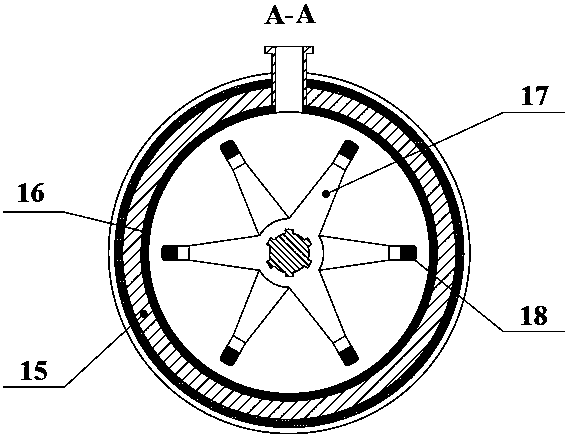

[0020] The vertical hammer mill assembly includes axial hammer mill blades 12, radial hammer mill blades 17, transmission shaft 11, vertical hammer mill cylinder 15, end cover 2, spoiler 4, axial hammer mill blades 12 It is installed on the transmission shaft 11 in the way of spline connection, and the axial hammer mill blade 12 is installed on the bottom end of the transmission shaft 11 through the limit screw 14; the axial blade base 20 of the axial hammer mill blade 12 is a six-blade structure , the hammer mill bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com