A kind of 4-s-5-br-2', 3', 5'-o-triacetyl uridine synthesis method

A 4-s-5-br-2, triacetyl uridine technology, applied in chemical instruments and methods, bulk chemical production, sugar derivatives, etc. Long time and other problems, to achieve the effect of simple and convenient post-reaction treatment, improved vulcanization efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

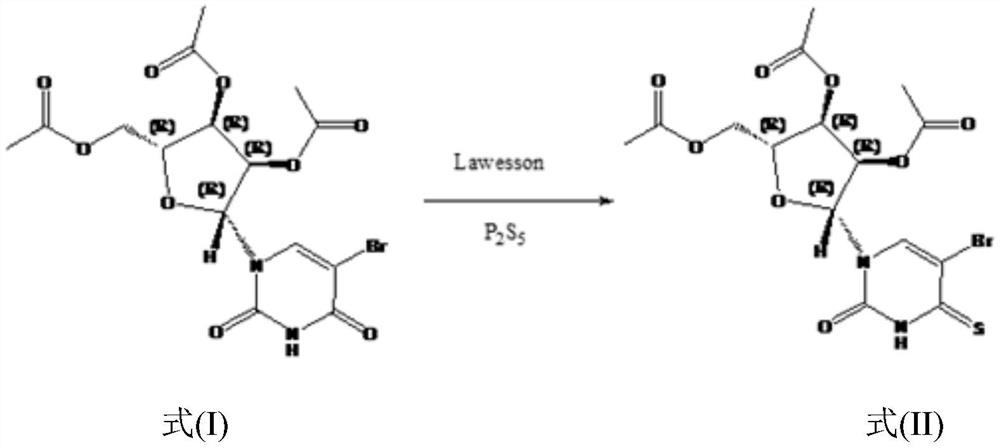

[0043] Dissolve 5-Br-2',3',5'-O-triacetyluridine (1.00g, 2.20mmol) in 50mL of 1,4-dioxane, stir at room temperature to fully dissolve, Subsequently, different molar ratios of P were added 2 S 5 (0.391g, 1.76mmol) and Lawesson (0.356g, 0.88mmol) as vulcanizing agent, the reaction temperature was 95°C, the reaction was monitored by TLC, the starting point disappeared in 1.3h, which proved that the reaction was complete, and steamed under reduced pressure at 55°C Solvent, the crude product was subjected to column separation (PE:EA=6:1; 4:1), after separation, mixed with absolute ethanol and petroleum ether for recrystallization, suction filtration and drying to obtain solid 4-S-5-Br-2' ,3',5'-O-triacetyluridine 0.90g, the yield is 88%.

Embodiment 2

[0045] Dissolve 5-Br-2',3',5'-O-triacetyluridine (1.00g, 2.20mmol) in 50mL of 1,4-dioxane, stir at room temperature to fully dissolve, Subsequently, different molar ratios of P were added 2 S 5 (0.439g, 1.98mmol) and Lawesson (0.267g, 0.66mmol) as vulcanizing agents, the reaction temperature was 95°C, the reaction was monitored by TLC, the starting point disappeared in 1.3h, which proved that the reaction was complete, and steamed under reduced pressure at 55°C Solvent, the crude product was subjected to column separation (PE:EA=6:1; 4:1), after separation, mixed with absolute ethanol and petroleum ether for recrystallization, suction filtration and drying to obtain solid 4-S-5-Br-2' ,3',5'-O-triacetyluridine 0.92g, the yield is 90%.

Embodiment 3

[0047] Dissolve 5-Br-2',3',5'-O-triacetyluridine (1.00g, 2.20mmol) in 50mL of 1,4-dioxane, stir at room temperature to fully dissolve, Subsequently, different molar ratios of P were added 2 S 5 (0.488g, 2.2mmol) and Lawesson (0.178g, 0.44mmol) as vulcanizing agents, the reaction temperature was 95°C, the reaction was monitored by TLC, the raw material point disappeared in 1.3h, which proved that the reaction was complete, steamed out under reduced pressure at 55°C Solvent, the crude product was subjected to column separation (PE:EA=6:1; 4:1), after separation, mixed with absolute ethanol and petroleum ether for recrystallization, suction filtration and drying to obtain solid 4-S-5-Br-2' ,3',5'-O-triacetyluridine 0.93g, the yield is 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com