Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Fast combustion reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

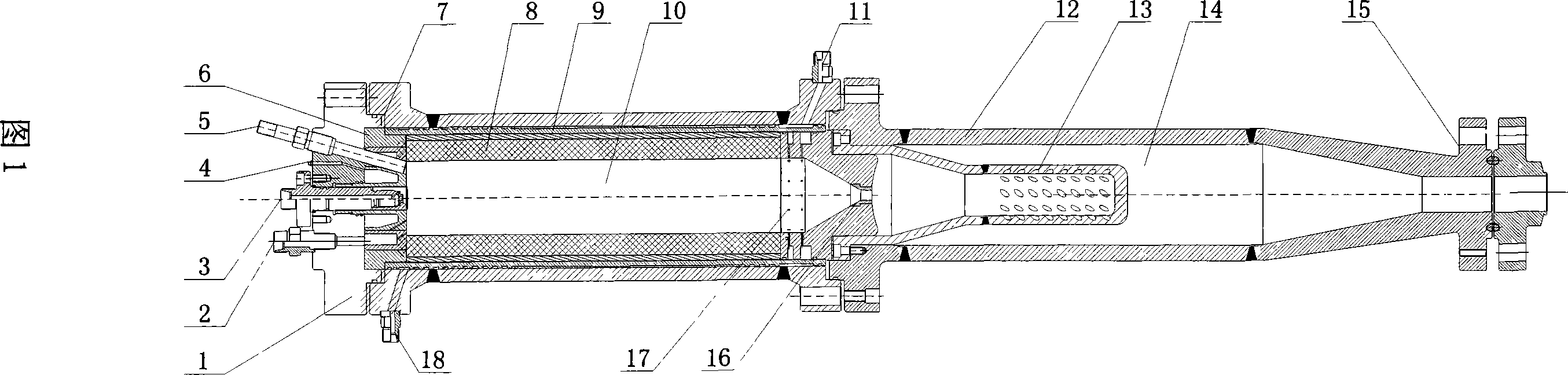

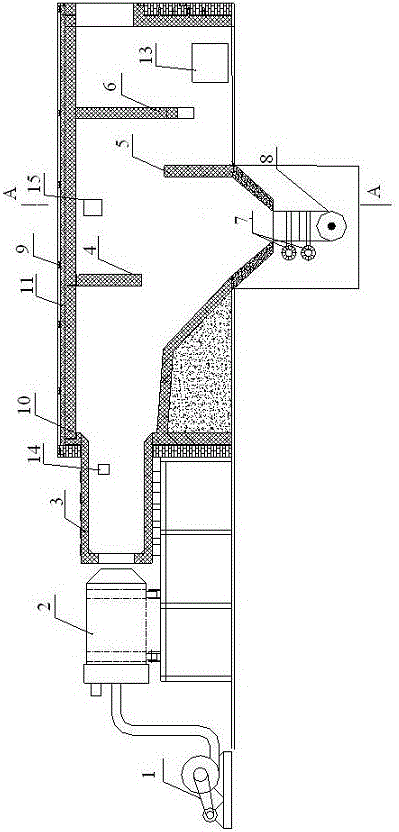

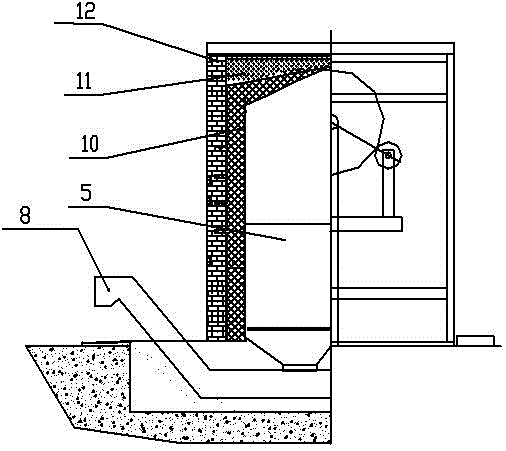

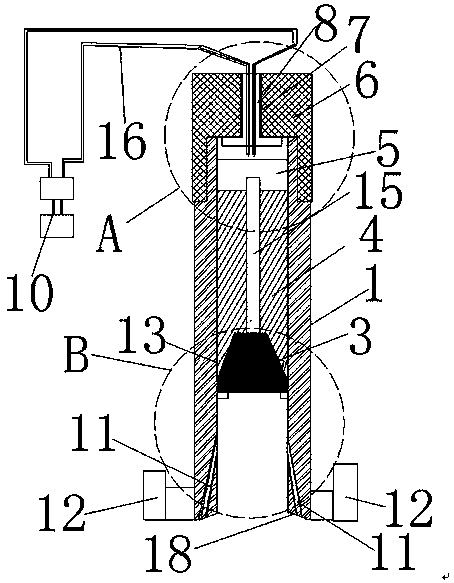

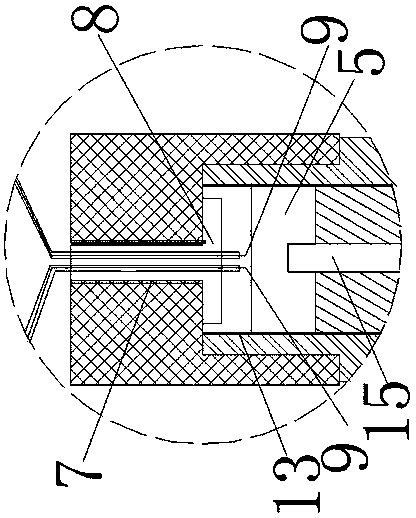

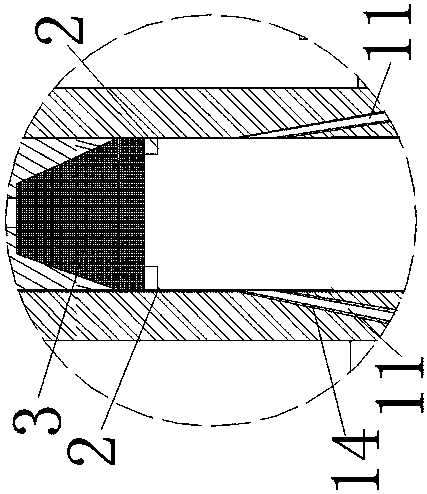

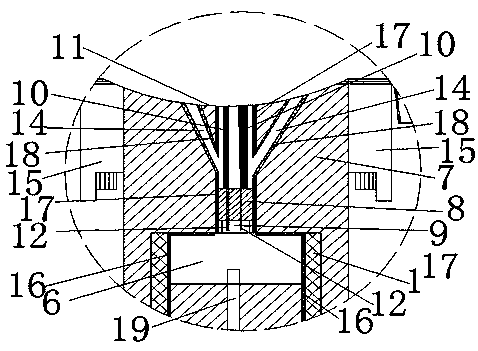

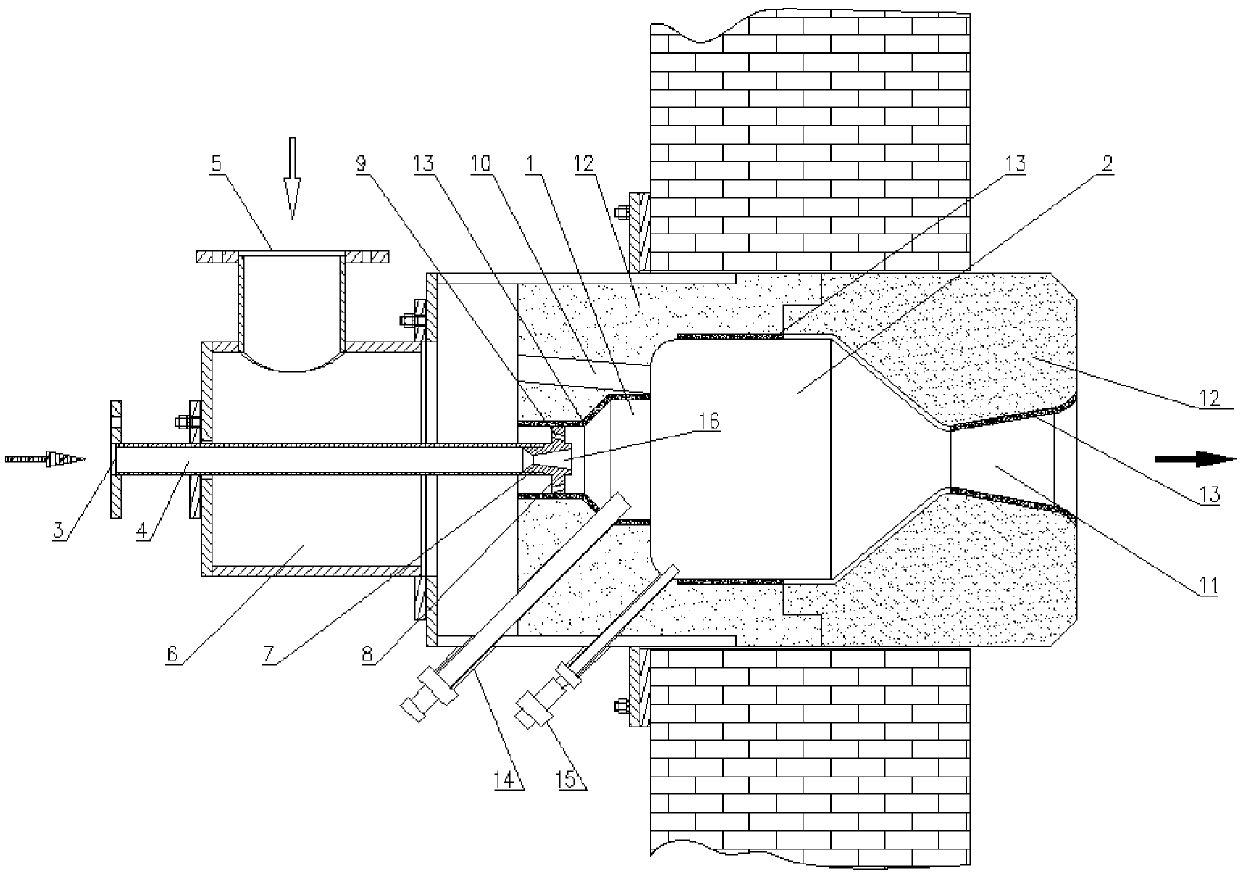

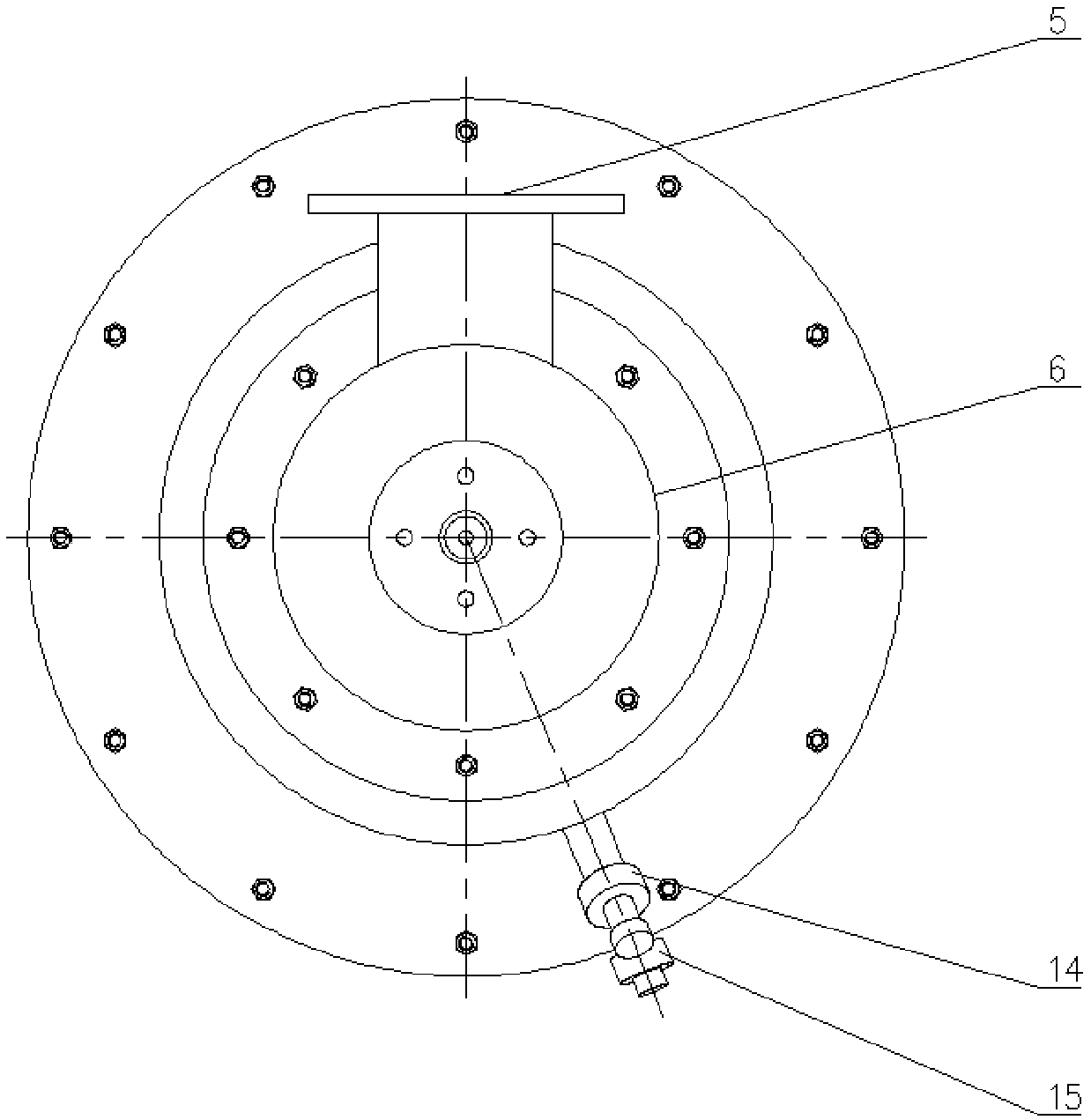

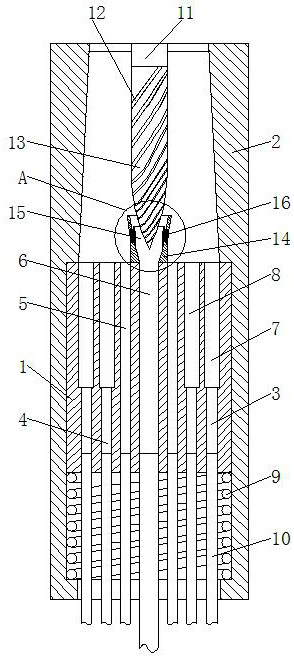

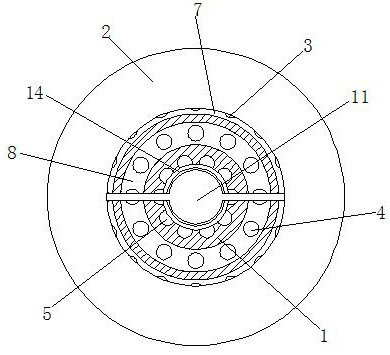

High-pressure mixed gas generator used for petroleum thermal recovery gas injection machine

ActiveCN101067372ALower working temperatureImprove job stabilityFluid removalCombustion chamberWater vapor

The present invention relates to one kind of mixed gas generator for thermal petroleum extraction. The mixed gas generator consists of a head, a combustion section and a mixing section. It features the spiral cooling chamber structure inside the cooling water cap to cool the head effectively, the heat isolating cover and the cooling water jacket with multiple functions of heat insulating, preheating and cooling the combustion section, and the necked bush of the temperature regulator capable of ensuring the sufficient pressure field in the combustor to raise the combustion reaction speed. The mixed gas generator is for burning diesel oil with compressed air as the oxidant to produce high temperature and high pressure fume and spraying water to regulate temperature so as to generate mixed gas of N2, CO2 and water vapor injected into well for thermal petroleum extraction. The present invention is used in oil field to replace steam petroleum extraction.

Owner:江苏神速石油装备有限公司

Environment protection coal-saving agent for cement vertical kiln

The invention provides an environmental-friendly coal-saving agent for a cement shaft kiln, comprising the following raw materials by weight portion: 3-7 portions of a coal combusting low-temperature modifying agent, 2-6 portions of a compound sulphur-fixing agent, 0.5-0.96 portion of a combusting inductive agent, 3-7 portions of a raising agent, 56-96 portions of a combusting poising agent, and 5-15 portions of a highly-efficient sulphur-fixing agent. The coal combusting low-temperature modifying agent can be potassium permanganate, potassium chlorate, potassium perchlorate, sodium chlorate, sodium nitrate and the like; the compound sulphur-fixing agent can be sodium carbonate, calcium oxide and the like; the raising agent can be waste liquor of paper mill containing Na or / and Ca sulphonate and the like; and the combusting poising agent can be a chemical waste reducing substance containing sodium chloride and the like. The method solves the problems of environmental pollution and resource waste in the prior art, uses compatibility of multiple chemical raw material of 6-10 percent and chemical waste to prepare the coal-saving agent with small dosage and fast effect to be added to the production of the cement shaft kiln in trace quantity, and has the advantages of resource conservation by using waste, coal conservation and consumption reduction, and reduction of dust and SO2 discharge and environmental pollution.

Owner:陶小勇

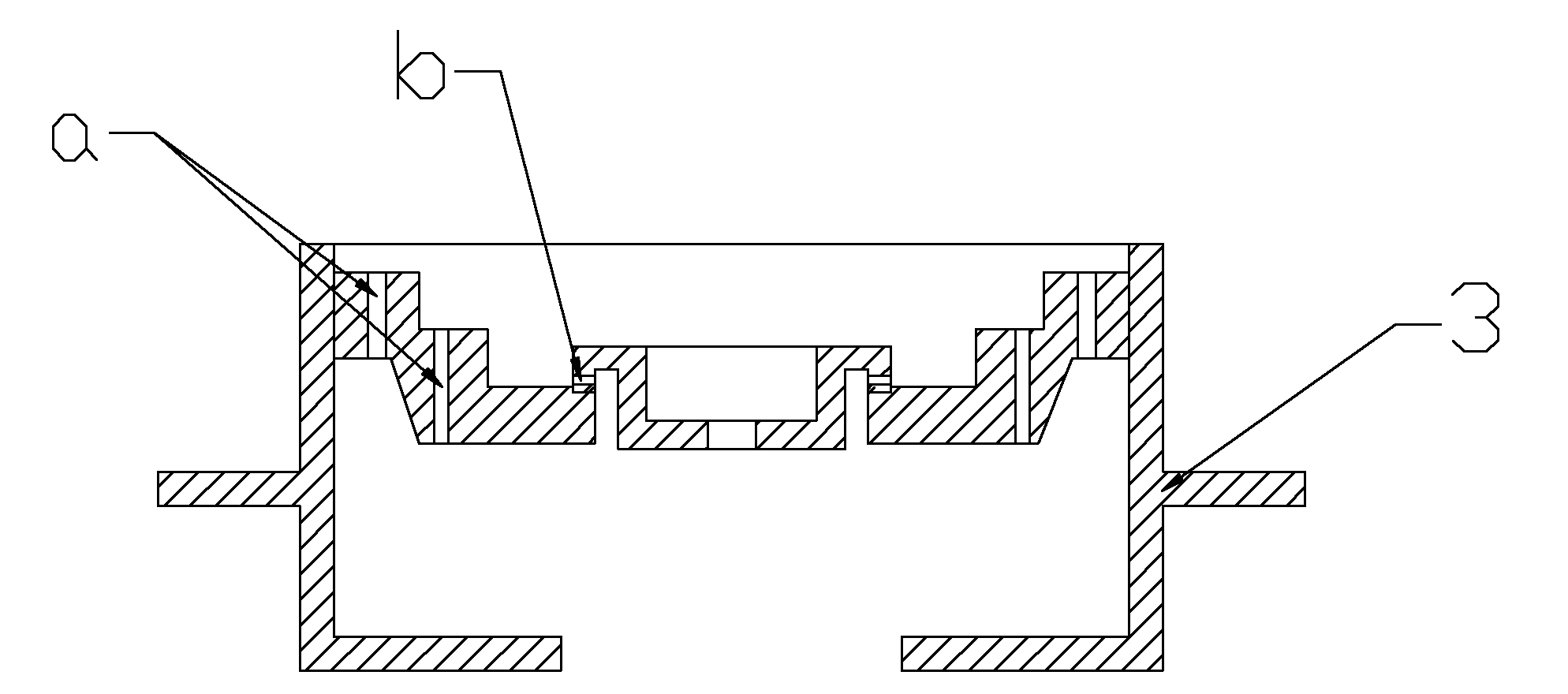

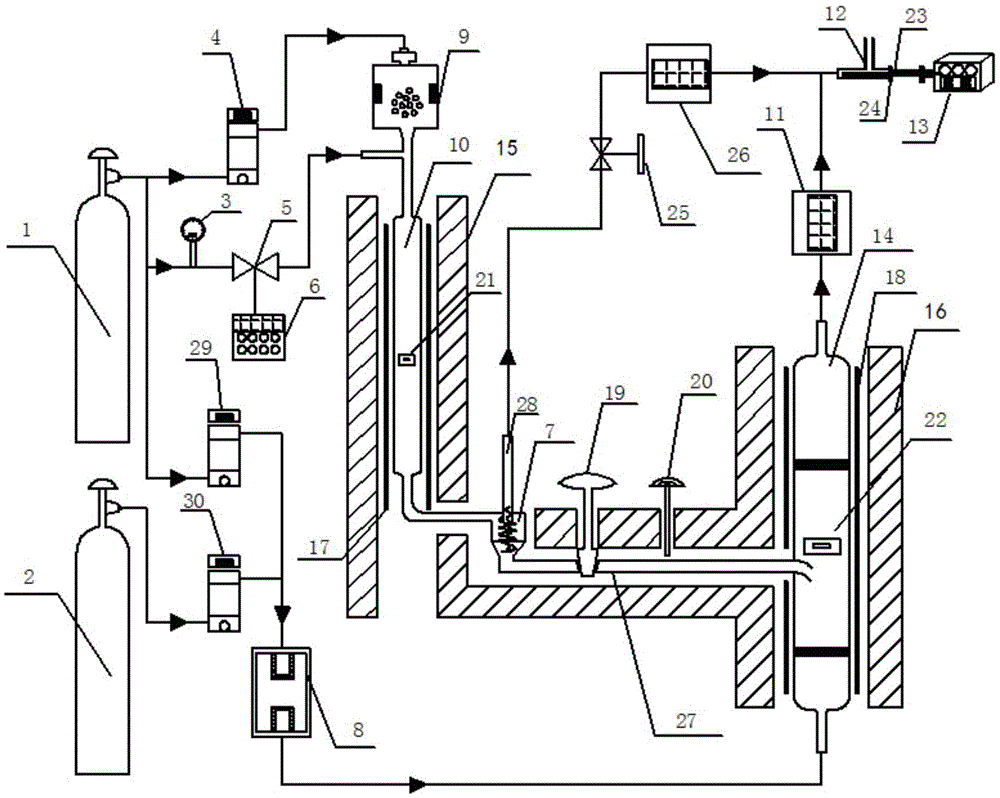

Micro double-bed solid fuel decoupling combustion reaction dynamic analyzer

ActiveCN103543237AAchieve pyrolysisRealize the coke combustion processChemical analysis using combustionAir atmosphereGas detector

The invention provides a micro double-bed solid fuel decoupling combustion reaction dynamic analyzer which comprises a fuel pyrolytic reaction generation device, a residual coke combustion reaction generation device, a double-bed high-temperature coupling device, a gas path device and an analysis test device, wherein solid fuel is firstly pyrolyzed under an inert atmosphere in a micro gas flow bed; then residual cokes enter the micro gas flow bed for combustion test under an air atmosphere; a quick gas detector is used for judging a reaction mechanism by measuring a generation sequence and a generation quantity characteristic of gas components in a fuel pyrolysis process and a coke combustion process, so that reaction dynamic parameters can be calculated. According to the micro double-bed solid fuel decoupling combustion reaction dynamic analyzer, the combustion dynamic parameters of the solid fuel can be tested through direct decoupling combustion through independent and quick switching of the atmospheres and the temperature; the pyrolyzed residual cokes are directly subjected to the combustion test without a cooling process; the temperature rising rates of the gas flow bed and a fluidized bed are high, so that a combustion condition in an actual boiler can be well simulated; the measured reaction dynamic parameters are close to intrinsic reaction dynamic parameters.

Owner:HUAZHONG UNIV OF SCI & TECH

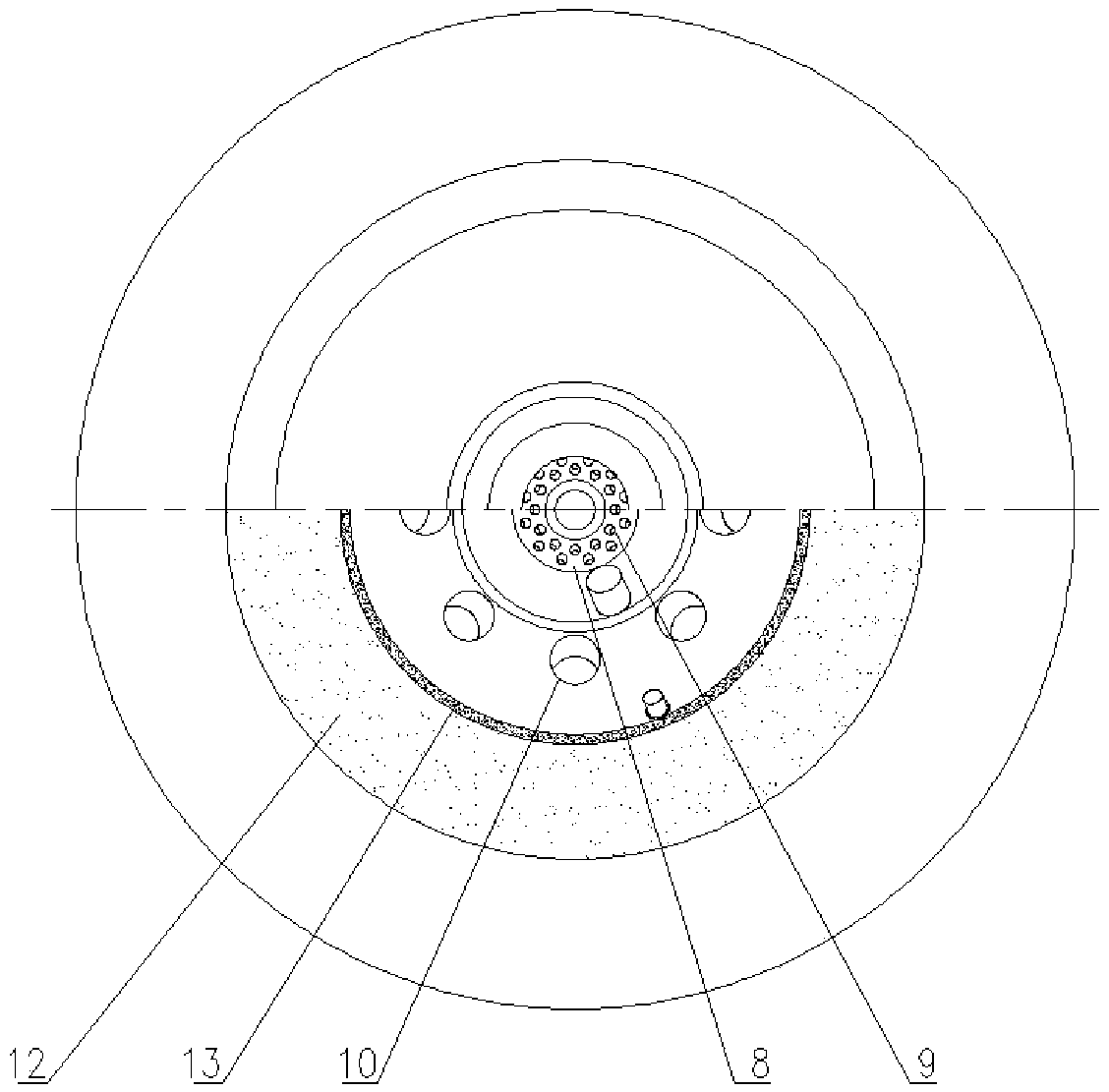

Stove gas burner

InactiveCN102012026AImprove heat exchange capacityStable combustionGaseous fuel burnerEngineeringReaction speed

The invention discloses a stove gas burner, which comprises a centrifugal axial flow fan. The upper part of the centrifugal axial flow fan is provided with a fan air outlet; the fan air outlet is provided with a cyclone wind deflector; a main fire and long open fire burning supply assembly, a burning head and a fire stabilizing ring are arranged in turn above the cyclone wind deflector along the longitudinal direction; and a wind collecting plate, a main fire plate and a long open fire bowel are arranged in the burning head. The whole burner integrates air supply, gas mixing and burning; the flame passages of various working conditions are combined by adopting a unique main and secondary fire hole grouping mode and an independent stable middle long open fire system; and the flame is stable, the burning reaction speed is high, and the energy conservation has qualitative breakthrough.

Owner:赵秀君

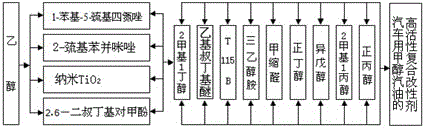

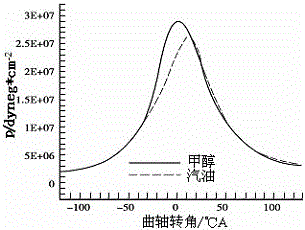

High-activity compound modified additive of methanol gasoline for automobile and preparation process thereof

InactiveCN104745252AMeet the output powerFrequent replacementLiquid carbonaceous fuelsAntioxidantSolvent

The invention relates to a high-activity compound modified additive of methanol gasoline for an automobile. The additive is prepared from the following components in percentage by weight: 12% of ethanol as a solvent, 0.1% of 2-methyl-1-butanol as an antidetonant, 0.5% of sulfurized calcium alkyl as an adjustor, 1.5% of triethanolamine as an engine carbon deposition preventer and an anticorrosive agent, 2.5% of methylal as a combustion improver, 59% of normal butanol as an active mutual solvent, 0.1% of 3-methyl-1-butanol as a synthetic solvent, 10% of 2-methyl-1-propanol as a synthetic solvent, 10% of normal propyl alcohol as a synthetic solvent, 0.1% of ethyl tert butyl ether as an antidetonant, 2% of 1-phenyl-5-mercapto-tetrazole as a corrosion inhibitor, 1% of 2-mercapto benzimidazole as a corrosion inhibitor, 20.6% of nano TiO as a protective coating and 0.6% of 2, 6-ditert-butyl p-cresol as an antioxidant. The additive can be widely applied to additives of methanol and methanol motor gasoline.

Owner:王军

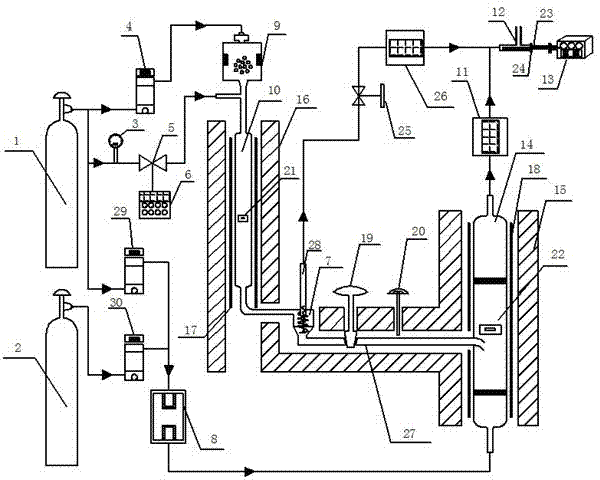

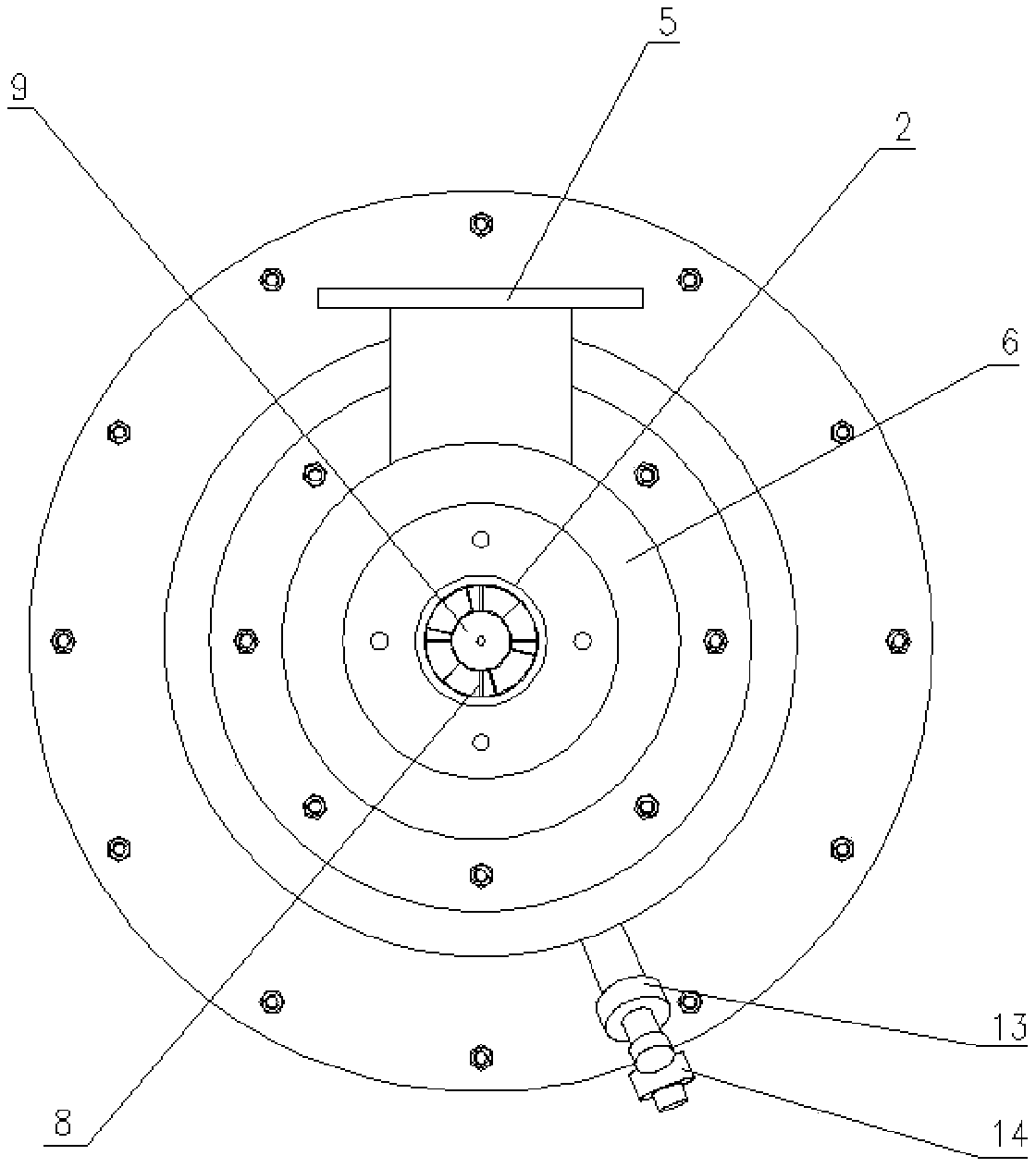

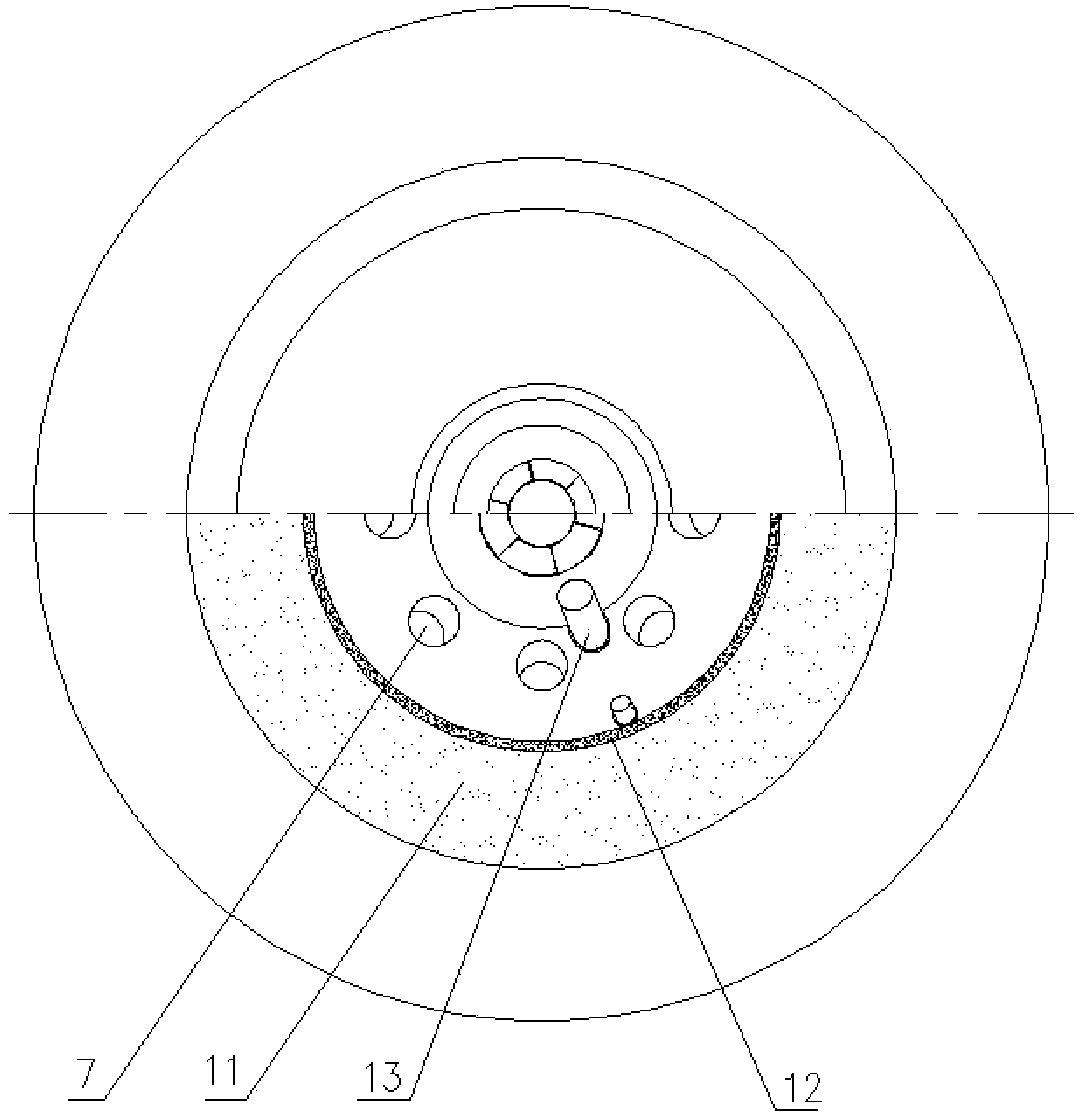

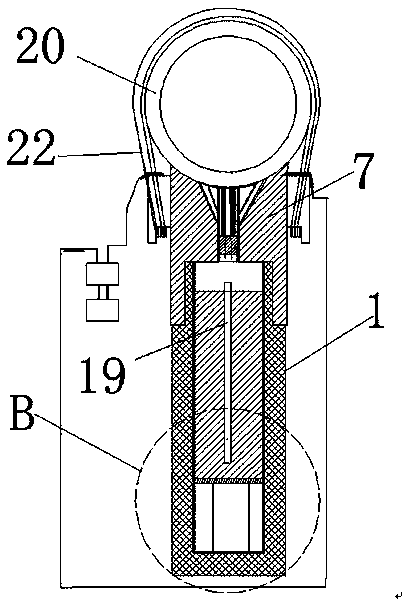

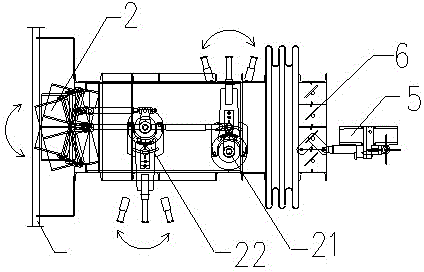

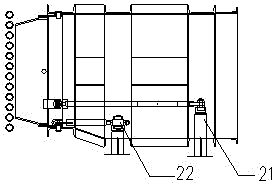

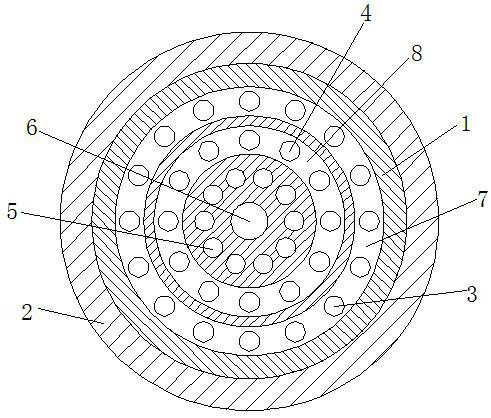

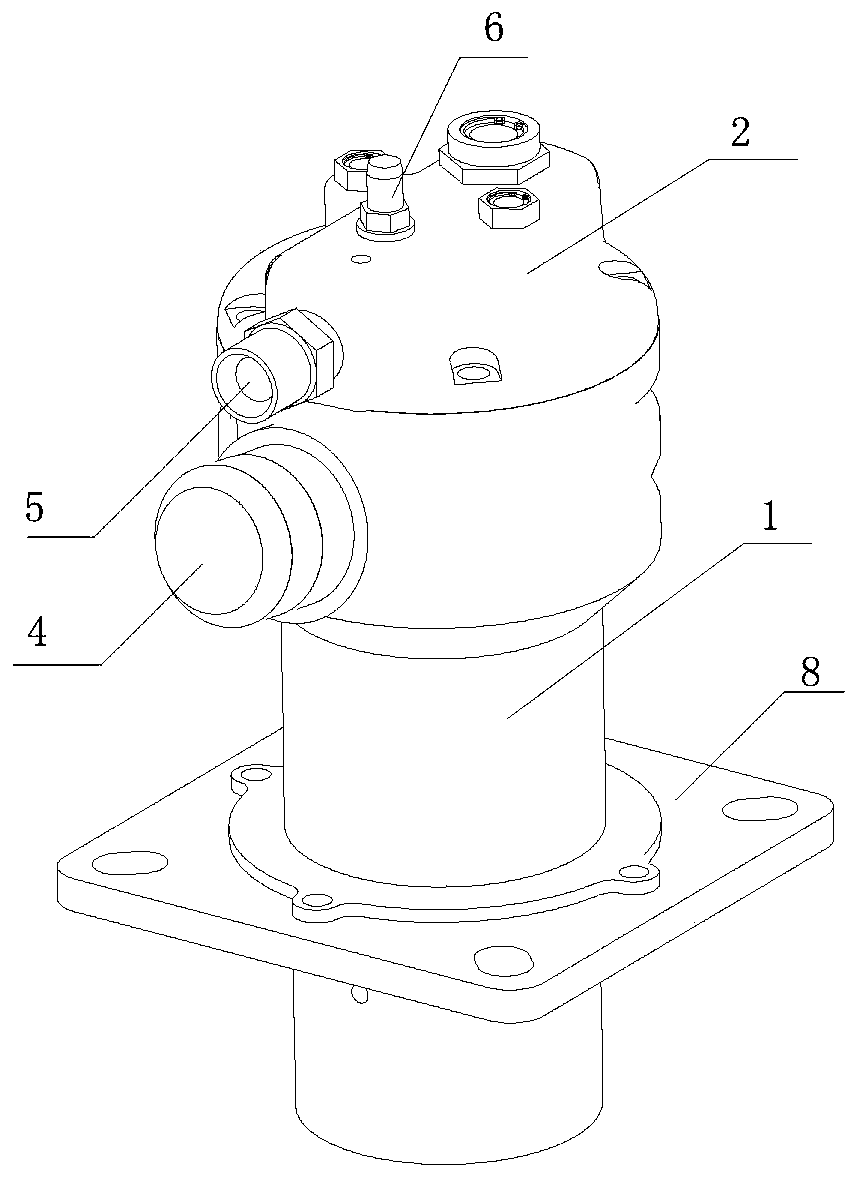

Steam generator used for thickened oil exploitation

InactiveCN103527162AEliminate heat lossShort injection timeSteam generation using pressureFluid removalSpray nozzleEvaporation

The invention discloses a steam generator used for thickened oil exploitation. The steam generator used for thickened oil exploitation comprises a cylindrical barrel body, a dual-ring hydrocyclone, a flame tube, a water film generator and an evaporation converter, wherein the dual-ring hydrocyclone, the flame tube, the water film generator and the evaporation converter are located in the barrel body and are arranged in a coaxial mode in the gas flowing direction in sequence, an end cover provided with a fuel gas inlet connecting pipe and a forced air inlet connecting pipe is fixed at the gas inlet end of the barrel body, forced air is divided into an inner eddy current and an outer eddy current by the dual-ring hydrocyclone fixedly arranged at the position of an inlet of the flame tube, the inner eddy current and the outer eddy current enter the internal space and external space of the flame tube respectively, the forced air entering the flame tube is mixed with fuel gas and then burns to form flame currents, part of the forced air entering a ring runner between the flame tube and the barrel body enters the flame currents through a through-flow hole in the wall surface of the flame tube, most of the forced air entering the ring runner between the flame tube and the barrel body flows out through an outlet, the water film generator is composed of at least one circle of pressure water nozzles arranged on the inner wall of the barrel body, and the evaporation converter is a section of runner with the inner cavity contracting gradually at first and expanding gradually afterwards. The steam generator used for thickened oil exploitation has the advantages of being reasonable in structure, high in reliability, long in service life, saving in energy, and high in efficiency.

Owner:CHENGDU ENGINE GROUP

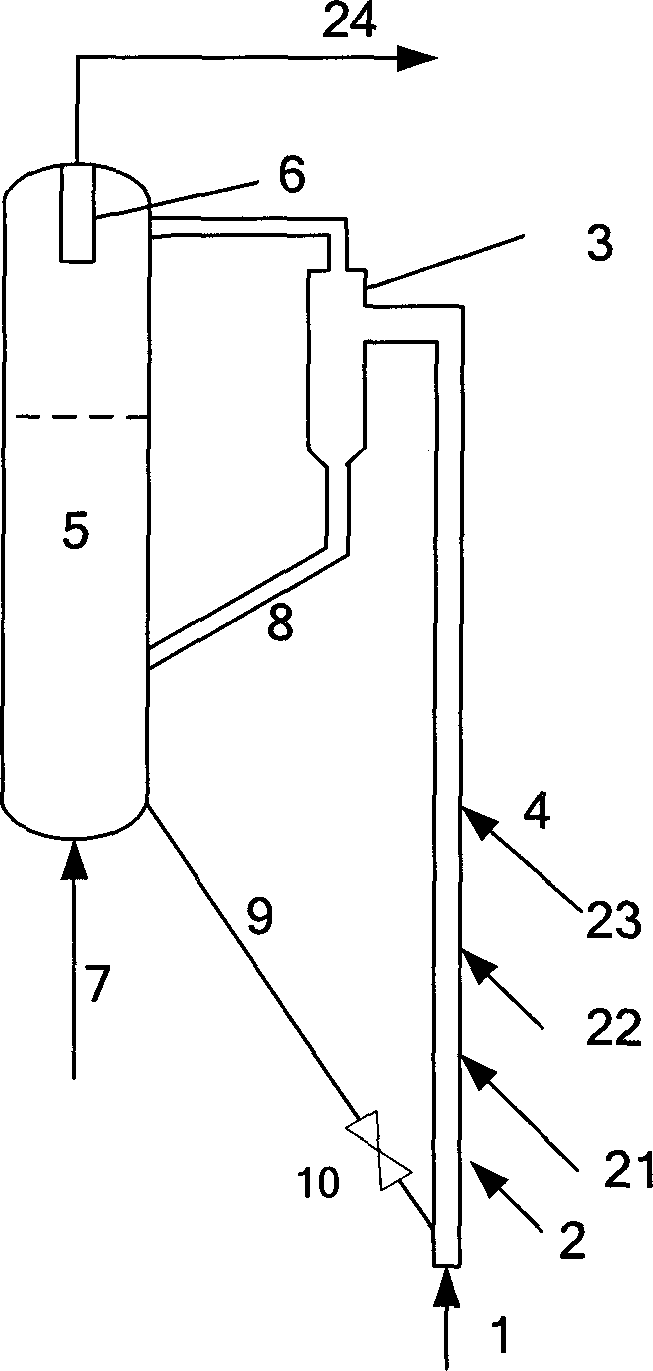

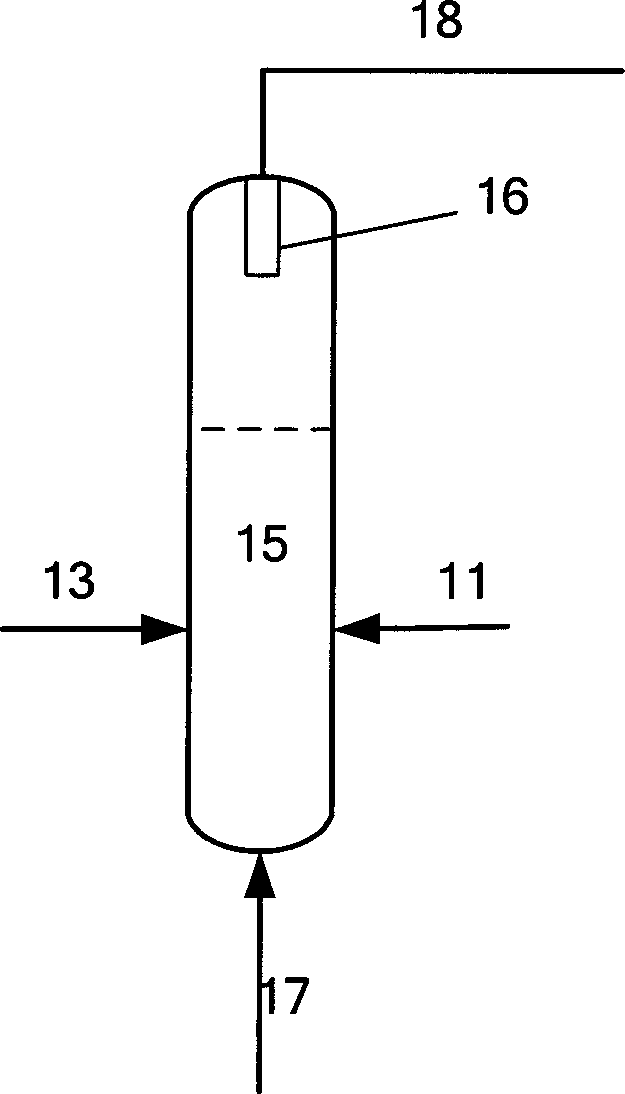

Method and equipment for quickly stabilizing activity of catalytic cracking catalyst

ActiveCN102950031ASmall sizeFast combustion reactionCatalytic crackingCatalyst protectionChemistryGas separation

The invention provides a method and equipment for quickly stabilizing the activity of a catalytic cracking catalyst. The method comprises the following steps that: (1) the catalyst enters the bottom of a dilute phase combustion tube via a fluidized bed reactor, is mixed with an oxygen-containing gas and fuels and then is combusted and flows upward, and the gas and the catalyst enter the fluidized bed reactor via a distributor at the outlet of the dilute phase combustion tube; (2) water vapor is injected into the fluidized bed reactor and is contacted with the high-temperature catalyst to carry out hydrothermal reaction to reduce the activity of the catalyst, the catalyst and the gas are separated at the top of the fluidized bed reactor, the separated gas is exhausted from the device and the separated catalyst returns to the fluidized bed reactor; and (3) operation is stopped and the catalyst is unloaded when the activity of the catalyst is reduced to the appropriate level. The invention also provides a catalyst ager implementing the aging method. By adopting the aging method and equipment provided by the invention, the operating conditions of the combustion reaction and the hydrothermal reaction can be controlled respectively, the activity of the aged catalyst is distributed uniformly and distribution of the products used for catalytic cracking reaction of hydrocarbon oil is obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pulverized coal hot blast stove for drying grain

InactiveCN105757976AReduce generationTemperature controlFood processingDrying gas arrangementsCombustion chamberAir volume

The invention relates to a pulverized coal hot blast stove for drying grain and belongs to the technical field of drying hot blast stoves.A flour mill is connected with one end of a cyclone type pulverized coal combustor, a combustion chamber is connected with the other end of the cyclone type pulverized coal combustor and connected with a stove body, a first fire baffle wall and a third fire baffle wall are fixedly connected with the upper portion of the stove body, an electric insertion plate is arranged blow an ash settling chamber and an ash accumulation hopper at the bottom of the combustion chamber, a screw conveyor is arranged below the electric insertion plate, a second fire baffle wall is fixedly connected with the bottom of the stove body, an inspection opening and an ash removing opening are located below the side face of the stove body, a first air supplementing opening is located in the side face of the combustion chamber, and a second air supplementing opening is located in the side face of the upper portion of the stove body.The pulverized coal hot blast stove for drying grain has the advantages that the structure is novel, the energy-saving effect is remarkable, a combustion reaction is complete, and important significance on environment protection is achieved; besides, cost can be reduced, and economic benefits can be improved; furthermore, the coal feeding amount and the air feeding amount can be adjusted, the temperature and pressure in the combustion chamber can be conveniently and stably controlled, and drying work in a drying tower can be stably carried out.

Owner:吉林省允祥环保设备有限公司

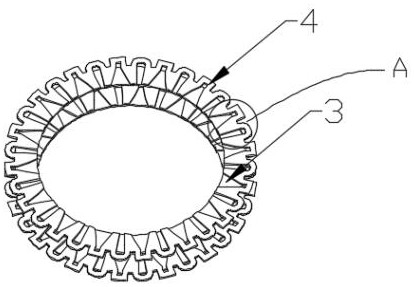

Metal component field high-energy thermal cutting and hole forming device

PendingCN109664041ARapid Emergency Thermal CuttingIncrease energy densityWelding apparatusPunchingCombustion

The invention discloses a metal component field high-energy thermal cutting and hole forming device. The device comprises a charging barrel; an aluminum-made retainer ring, a frustum plug, a thermitelayer and an ignition agent layer are arranged in the charging barrel in sequence from bottom to top; a top cover is mounted at the top end of the charging barrel; a mounting through hole is vertically formed in the center of the top cover; an insulation plug is mounted in the mounting through hole; two ignition electrodes are vertically mounted on the insulation plug; multiple punching holes areformed in the lower part of the side wall of the charging barrel; multiple fixing devices for fixing the charging barrel on objects to be punched are arranged on the radial outer peripheral surface ofthe charging barrel; and a support sleeve is arranged between the frustum plug in the charging barrel and the objects to be punched. The hole forming device is high in energy density, high in combustion temperature, high in cutting pressure and suitable for quick emergency thermal cutting and underwater cutting of various steel structural parts in fields or battlefields under the conditions of noelectricity, no gas and no cutting equipment.

Owner:ARMY ENG UNIV OF PLA

Low NOx emission combustor

PendingCN109489035ASmall volumeCompact structureIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberCombustor

The invention discloses a low NOx emission combustor. The low NOx emission combustor comprises a combustion chamber; the front end of the combustion chamber is provided with a fuel gas inlet through afuel gas channel, a flue gas nozzle is arranged at the rear end of the combustion chamber, an air channel with an air inlet is formed in the outer side of the fuel gas channel, and the air channel isin communication with the combustion chamber through air nozzles arranged in the air channel; and the rear end of the fuel gas channel is provided with a gas guide cone through a supporting rod. Thedevice is simple and compact in structure, small in occupied space and easy to install and maintain, the volume of the combustion chamber is smaller than that of a heating furnace hearth of a common combustor, and the volume heat strength is large and can reach 6*10<8> kJ / m3.h; the width of the adjusting range can reach 1:50, while the common combustor is only 1:10, and automatic regulation and control are easy; and in addition, the air can be preheated by high-temperature, high combustion temperature can be obtained with low-heating-value fuel gas, the combustion temperature of the combustionchamber is high and close to 2000 DEG C, and therefore the combustor can be applied to most industrial furnaces.

Owner:中冶京诚(扬州)冶金科技产业有限公司

Combustion type steel component oriented cutting device

ActiveCN109623136AFull combustion reactionAvoid meltdownAlumino-thermic welding apparatusElectricityPunching

The invention discloses a combustion type steel component oriented cutting device. A bottom support sleeve, a top plate with a circular cross section, a cutting agent layer and an igniting agent layerare arranged in a charging barrel in sequence from bottom to top; a fixing device for fixing a top cover on objects to be punched is arranged on the radial peripheral surface of the top cover; a cylindrical through hole is formed in the center of the top cover; a cylindrical insulation plug is mounted in the through hole; the insulation plug is vertically provided with a top sleeve; two ignitionelectrodes are mounted in the center of the insulation plug, and are connected with electric ignition devices; and the top cover is provided with multiple punching holes. The cutting device is high inenergy density, high in combustion temperature, high in cutting speed and suitable for quick emergency hot cutting and underwater cutting of various steel structural parts under the conditions without electricity, gas and equipment in the fields or battlegrounds.

Owner:ARMY ENG UNIV OF PLA

Environment protection coal-saving agent for cement vertical kiln

The invention provides an environmental-friendly coal-saving agent for a cement shaft kiln, comprising the following raw materials by weight portion: 3-7 portions of a coal combusting low-temperature modifying agent, 2-6 portions of a compound sulphur-fixing agent, 0.5-0.96 portion of a combusting inductive agent, 3-7 portions of a raising agent, 56-96 portions of a combusting poising agent, and 5-15 portions of a highly-efficient sulphur-fixing agent. The coal combusting low-temperature modifying agent can be potassium permanganate, potassium chlorate, potassium perchlorate, sodium chlorate, sodium nitrate and the like; the compound sulphur-fixing agent can be sodium carbonate, calcium oxide and the like; the raising agent can be waste liquor of paper mill containing Na or / and Ca sulphonate and the like; and the combusting poising agent can be a chemical waste reducing substance containing sodium chloride and the like. The method solves the problems of environmental pollution and resource waste in the prior art, uses compatibility of multiple chemical raw material of 6-10 percent and chemical waste to prepare the coal-saving agent with small dosage and fast effect to be added to the production of the cement shaft kiln in trace quantity, and has the advantages of resource conservation by using waste, coal conservation and consumption reduction, and reduction of dust and SO2 discharge and environmental pollution.

Owner:陶小勇

Micro double-bed solid fuel decoupling combustion reaction dynamic analyzer

ActiveCN103543237BHigh simulationAchieving the purpose of measuring reactivity in situChemical analysis using combustionAir atmosphereGas detector

The invention provides a micro double-bed solid fuel decoupling combustion reaction dynamic analyzer which comprises a fuel pyrolytic reaction generation device, a residual coke combustion reaction generation device, a double-bed high-temperature coupling device, a gas path device and an analysis test device, wherein solid fuel is firstly pyrolyzed under an inert atmosphere in a micro gas flow bed; then residual cokes enter the micro gas flow bed for combustion test under an air atmosphere; a quick gas detector is used for judging a reaction mechanism by measuring a generation sequence and a generation quantity characteristic of gas components in a fuel pyrolysis process and a coke combustion process, so that reaction dynamic parameters can be calculated. According to the micro double-bed solid fuel decoupling combustion reaction dynamic analyzer, the combustion dynamic parameters of the solid fuel can be tested through direct decoupling combustion through independent and quick switching of the atmospheres and the temperature; the pyrolyzed residual cokes are directly subjected to the combustion test without a cooling process; the temperature rising rates of the gas flow bed and a fluidized bed are high, so that a combustion condition in an actual boiler can be well simulated; the measured reaction dynamic parameters are close to intrinsic reaction dynamic parameters.

Owner:HUAZHONG UNIV OF SCI & TECH

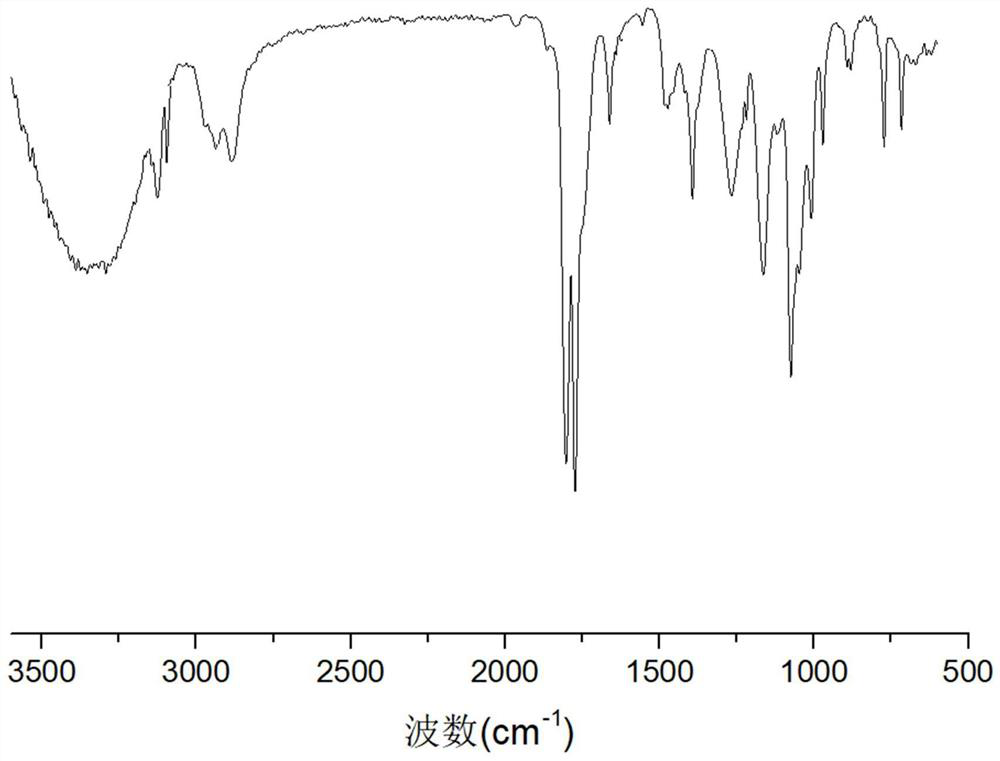

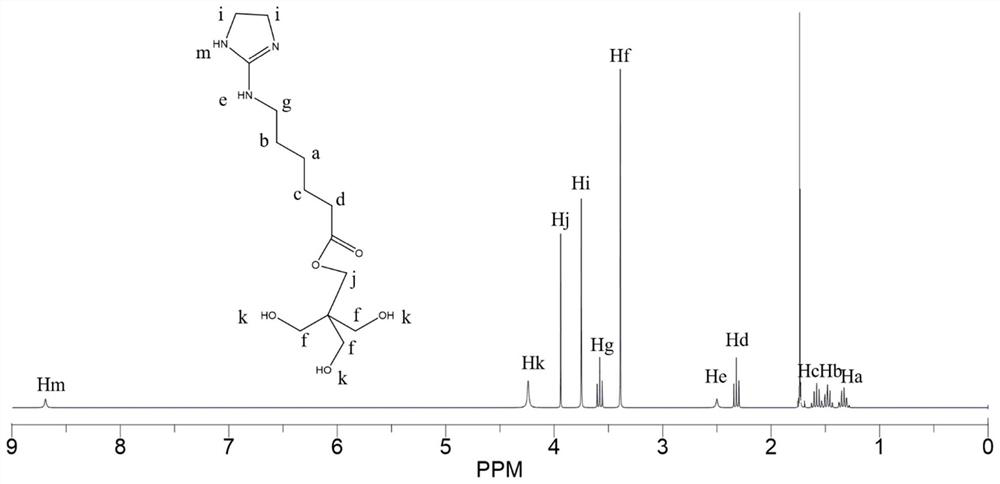

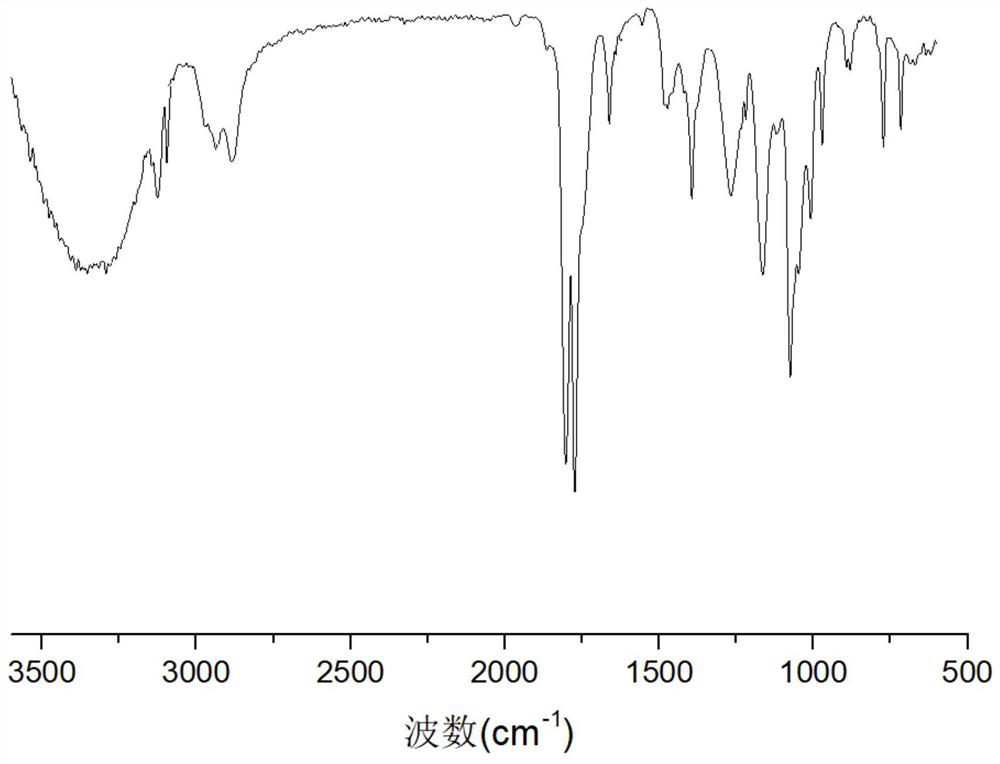

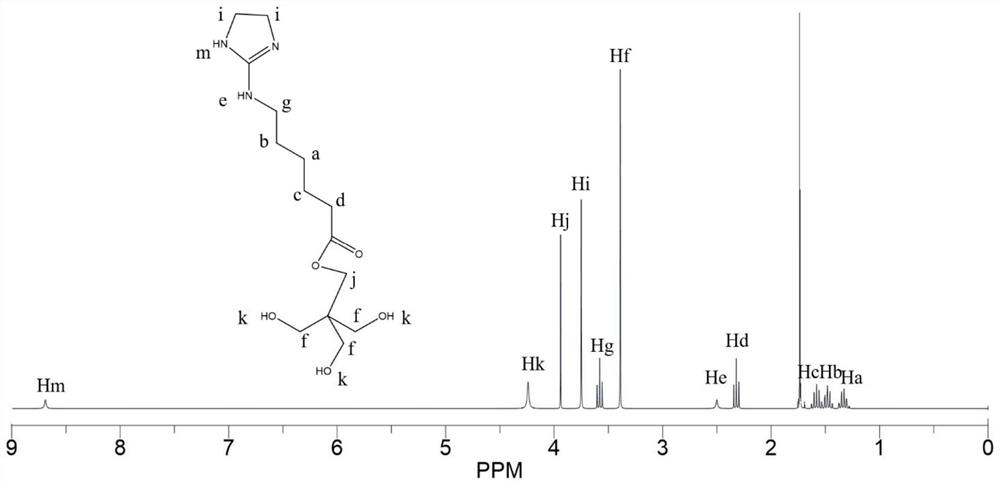

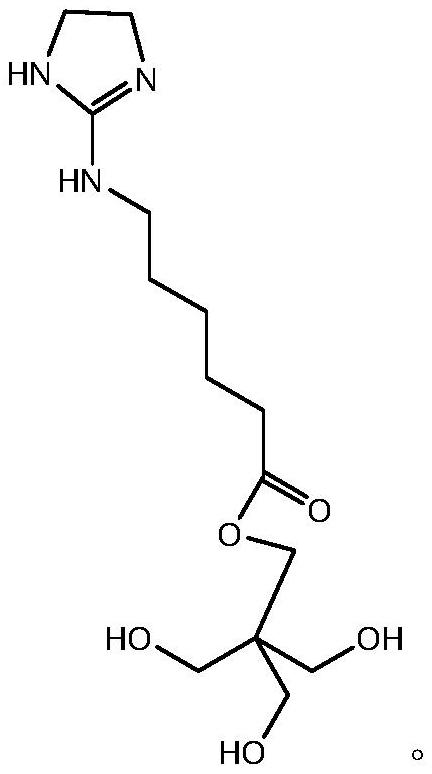

A kind of methanol gasoline additive and preparation method thereof

ActiveCN108893147BImprove solubilityEvenly dispersedLiquid carbonaceous fuelsFuel additivesMethanol fuelPhysical chemistry

The invention belongs to the technical field of methanol fuel for vehicles and in particular relates to a methanol gasoline additive and a preparation method thereof. The structural formula is as shown in the specification. According to the methanol gasoline additive and the preparation method thereof disclosed by the invention, the methanol gasoline additive and methanol are easy to dissolve, dispersion is uniform, the stability is excellent, and no other special process needs to be increased for treatment; due to polyhydroxy groups and imidazole groups contained in the additive structure, the water resistance and metal corrosion resistance of methanol gasoline can be greatly improved, chain paraffin is capable of resisting low-temperature phase separation, low-temperature easily startingis realized, and air resistance is avoided at a high temperature; and the methanol gasoline additive is simple and easily operable in preparation method, low in cost and energy consumption, environment-friendly, pollution-free and suitable for industrial production.

Owner:中新科技投资控股有限公司

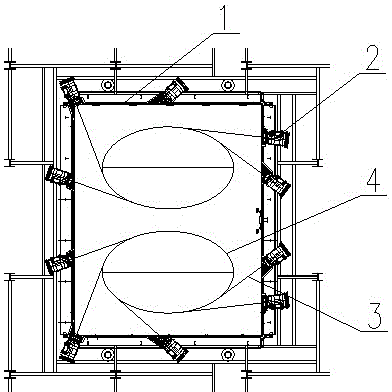

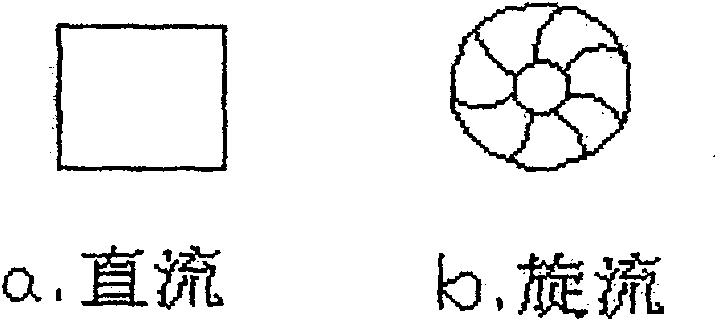

Over-fire air distribution manner in front and back wall opposed firing boiler

The invention discloses an over-fire air distribution manner in a front and back wall opposed firing boiler; a boiler firing method is in the form of front and back wall opposed firing, and over-fire air is fed by using a tangent circle method. The front and back wall opposed firing boiler comprises a front and back wall opposed firing boiler; with a symmetric central line of a long edge of the boiler as boundary, the over-fire air is divided into two groups; 4-5 over-fire air nozzles are arranged in each group; central lines of the over-fire air sprayed by the over-fire air nozzles in each group are tangential to the same imaginary ellipse; rotation directions of the ellipses in the two groups are reverse to each other; and one ellipse rotates in an anticlockwise direction and the other ellipse rotates in a clockwise direction. The over-fire air is high speed direct current over-fire air; and the over-fire air nozzles swing up and down and from left to right in a full-swinging form. The over-fire air distribution manner in the front and back wall opposed firing boiler, disclosed by the invention, is beneficial for enhancing the mixing of the over-fire air and rising flue gas and increasing the travel of the flue gas and prolonging the staying time of a fuel in the oven, and has the advantages that NOx emission of the boiler is obviously reduced and the increase of carbon content in boiler fly ash and the increase of the temperature-reduction water quantity are effectively suppressed.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

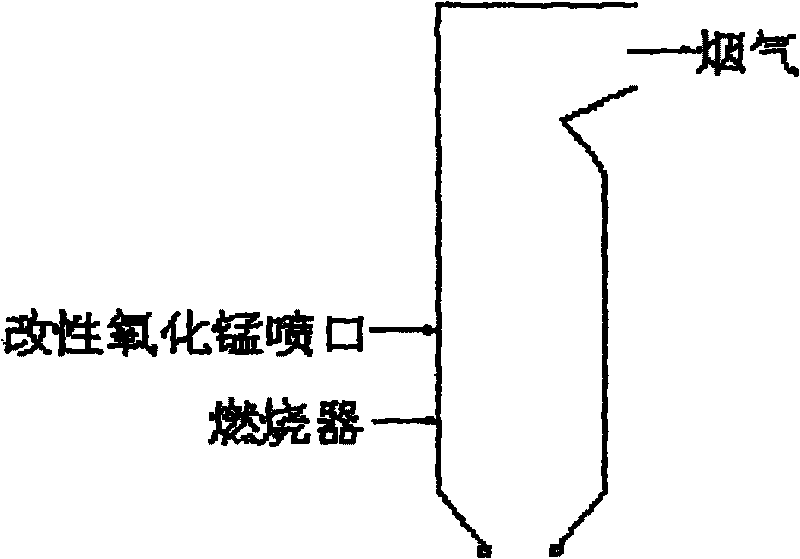

Boiler in-furnace desulfurization, denitration solid mercury integrated method

InactiveCN101209395BLess investmentIncrease turbulent kinetic energyDispersed particle separationAir quality improvementParticulatesNitrogen oxides

The invention discloses an integrated technique of desulfidation, denitration and mercury solidification in a boiler stove, and the invention injects modified MnO2 (manganese dioxide) into a boiler furnace and synthetically removes sulfur dioxide, nitrogen oxide and mercury by using the strong oxidizing property of manganese oxide; meanwhile, as the reaction of removing various infectants with modified MnO2 (manganese dioxide) is favorable for the conglobation of micro dust particles, the method can also reduce the exhaustion of inhalable particulates of PM2.5 from boilers.

Owner:TONGJI UNIV

Fire coal boiler liquid combustion improver

InactiveCN103254960AThe pyrolysis process is acceleratedFast combustion reactionSolid fuelsEngineeringCupric nitrate

The invention provides a fire coal boiler liquid oxidant, which is used as a liquid additive for improving heat efficiency of fire coal boiler and realizing combustion supporting and coal saving, thereby minimizing the circulating fluidized bed boiler volume, reducing boiler height, adapting to the status of circulation ratio in our country, accelerating reaction speed of coal combustion, achieving fire coal efficiency and forming a high efficiency combustion method. The invention is used for fluidized bed boiler and chain-grate boiler. The invention employs a principle of catalysis combustion and gasification combustion of coal, and provides a method for adding liquid oxidant in fuel, thereby realizing high efficiency combustion of the fluidized bed boiler in the low temperature condition. The invention is composed of five substances such as potassium nitrate, sodium carbonate, cupric nitrate, magnesium nitrate and manganous nitrate. The invention has the beneficial effects that after the additive is added, the material ratio is decreased with the same output, thereby the coal saving is increased, wherein, the coal saving rate is about 5%, and the boiler output is increased and the boiler thermal efficiency is increased by 2-3%.

Owner:陈颖通

Highly active composite modified additive for methanol gasoline for automobiles and its preparation process

InactiveCN104745252BMeet the output powerFrequent replacementLiquid carbonaceous fuelsTetrazoleAntioxidant

The invention relates to a high-activity compound modified additive of methanol gasoline for an automobile. The additive is prepared from the following components in percentage by weight: 12% of ethanol as a solvent, 0.1% of 2-methyl-1-butanol as an antidetonant, 0.5% of sulfurized calcium alkyl as an adjustor, 1.5% of triethanolamine as an engine carbon deposition preventer and an anticorrosive agent, 2.5% of methylal as a combustion improver, 59% of normal butanol as an active mutual solvent, 0.1% of 3-methyl-1-butanol as a synthetic solvent, 10% of 2-methyl-1-propanol as a synthetic solvent, 10% of normal propyl alcohol as a synthetic solvent, 0.1% of ethyl tert butyl ether as an antidetonant, 2% of 1-phenyl-5-mercapto-tetrazole as a corrosion inhibitor, 1% of 2-mercapto benzimidazole as a corrosion inhibitor, 20.6% of nano TiO as a protective coating and 0.6% of 2, 6-ditert-butyl p-cresol as an antioxidant. The additive can be widely applied to additives of methanol and methanol motor gasoline.

Owner:王军

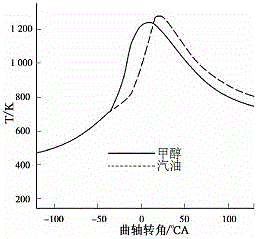

Fire distributor with two variable fire hole airway characteristics

PendingCN111853779AFast flowClosely intertwinedIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberDistributor

The invention relates to the technical field of gas stove fire distributors, and particularly discloses a fire distributor with two variable fire hole airway characteristics. The spacing between the top of a second comb tooth groove and the root of the second comb tooth groove gradually widens, the spacing between the top of a first comb tooth groove and the root of the first comb tooth groove gradually narrows, the gas flowing out of a second gas outlet has low pressure and low flow rate, the gas flowing out of a first gas outlet has high pressure and high flow rate, the mixed gas with lowerpressure and low flow rate burns near the inner wall of the fire distributor, the mixed gas with high pressure and high flow rate burns in a combustion chamber away from the fire distributor, the combustion flame is in the shape of mountain peaks and valleys and is in a high-low staggered form, and the high-low staggered flame and the swirling resident heat are intertwined and integrated more closely. The contact strength and contact surface between the mixed gas flow and the heat released by combustion are increased, the heat utilization efficiency is high, the combustion reaction space utilization rate of the combustion chamber is higher, and thus the combustion reaction speed, combustion reaction temperature and reaction intensity are improved.

Owner:浙江惠厨节能科技有限公司

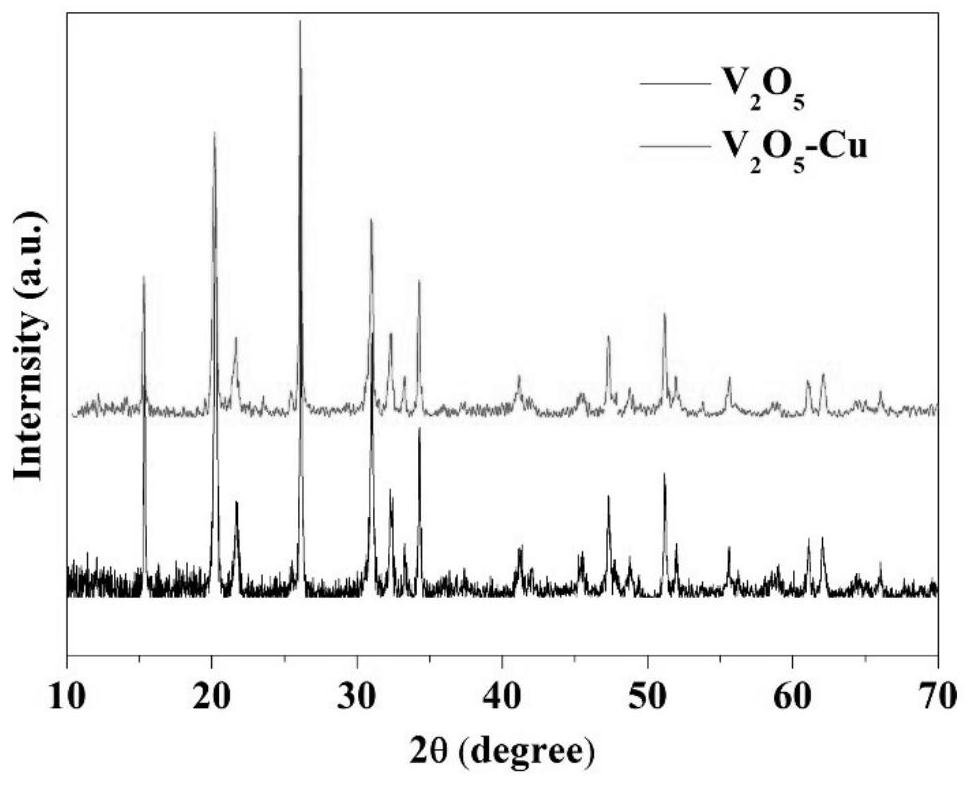

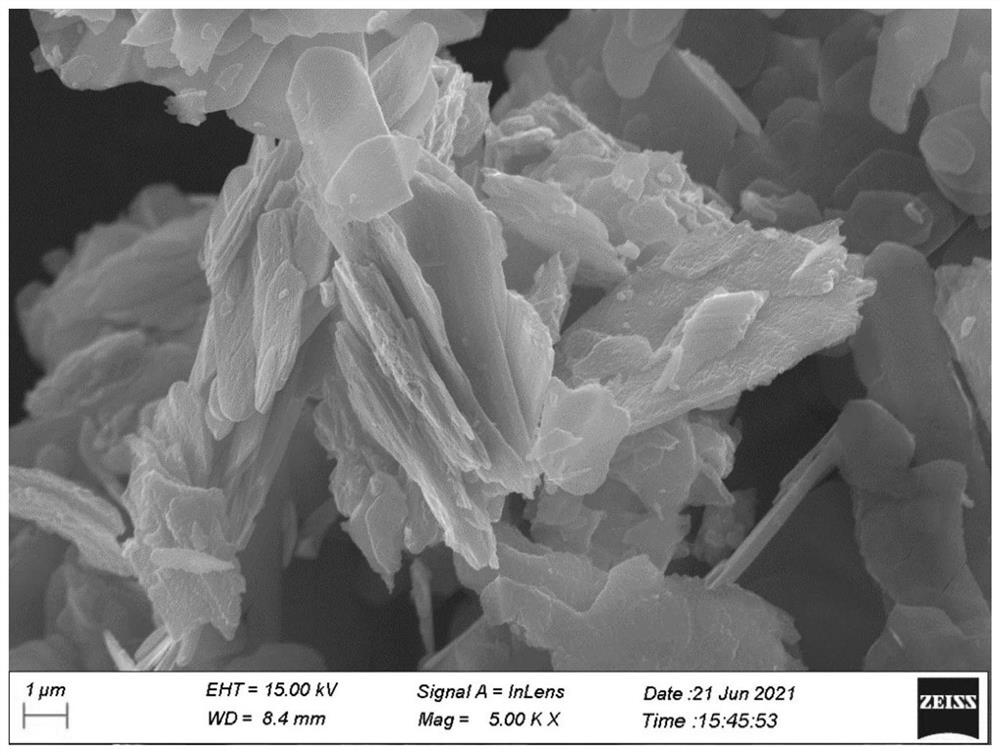

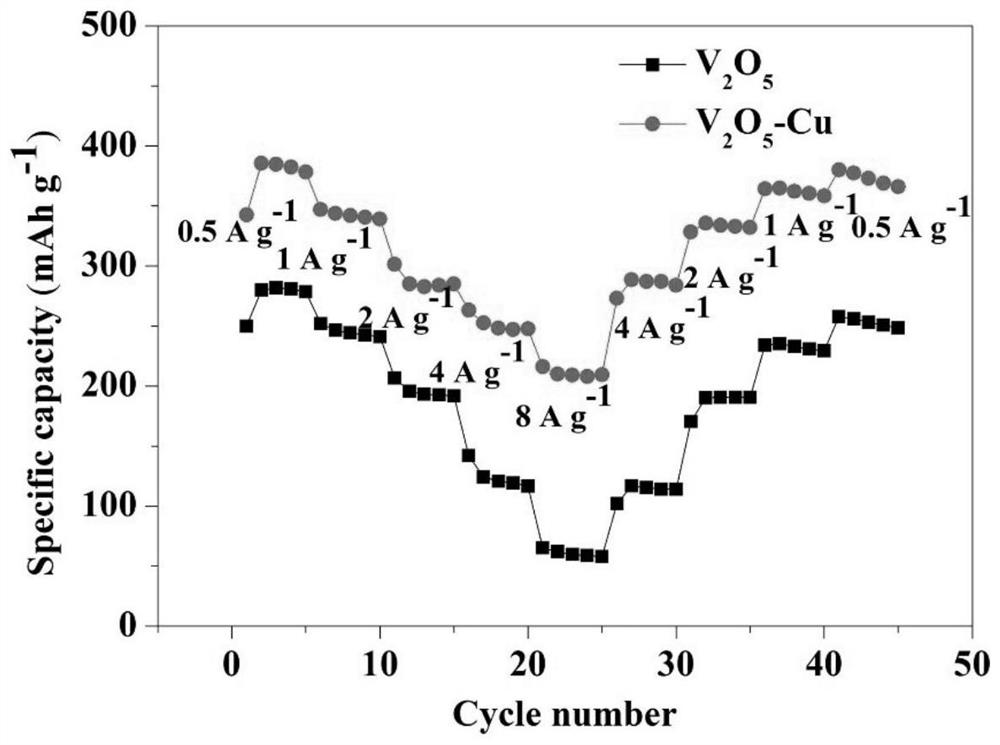

Preparation method of zinc ion battery doped positive electrode material, zinc ion battery doped positive electrode material and zinc ion battery

PendingCN113782727AReduce energy consumptionFast responseCell electrodesSecondary cellsElectrode materialZinc ion

The invention discloses a preparation method of a zinc ion battery doped positive electrode material, the zinc ion battery doped positive electrode material and a zinc ion battery, and relates to the field of zinc ion batteries. The preparation method comprises the following steps: dissolving a vanadium source, an oxidant, a fuel and a cation doping raw material in water, uniformly mixing to obtain a mixed phase, and carrying out low-temperature combustion reaction on the mixed phase to obtain the zinc ion battery doped positive electrode material, wherein the vanadium source comprises NH4VO3, the oxidant comprises NH4NO3, the fuel includes at least one of CO(NH2)2 and C2H5O2N, the cation doping raw material comprises M(NO3)n, and M comprises at least one of Li, Na, K, Ag, Ca, Mg, Zn, Al, Ni, Mn and Cu. The positive electrode material is obtained through the method, and the zinc ion battery adopts the positive electrode material. According to the invention, the process is simple and efficient, the cost is low, and the rate capability of the zinc ion battery is improved.

Owner:XIAMEN UNIV OF TECH

High-speed combustor

PendingCN109539252ASmall volumeCompact structureIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberCombustor

The invention discloses a high-speed combustor. The high-speed combustor comprises a first combustion chamber at the front end and a second combustion chamber at the rear end. The indoor volume of thesecond combustion chamber is larger than that of the first combustion chamber. The front end of the first combustion chamber communicates with a fuel gas channel with a fuel gas inlet. An air channelwith an air inlet is formed in the outer side of the fuel gas channel. A fuel gas nozzle is arranged at the inner end of the fuel gas channel. The high-speed combustor is simple and compact in structure, small in occupied space and easy to install and maintain. The volumes of the combustion chambers are smaller than the volume of a heating furnace hearth of a common combustor; the volume rate ofcombustion is large and can reach 6*108 kJ / m3*h; and the adjusting range is wide, can reach 1:50 and is easy to automatically adjust, while the adjusting range of the common combustor is only 1:10. Moreover, high-temperature preheated air can be used by the high-speed combustor, so that high combustion temperature can be obtained through low-heating-value fuel gas. The combustion temperatures of the combustion chambers are high and close to 2000 DEG C, so that the high-speed combustor can be applied to most industrial furnaces.

Owner:中冶京诚(扬州)冶金科技产业有限公司

A corrosion-resistant, water-resistant methanol gasoline

ActiveCN108865294BImprove solubilityEvenly dispersedLiquid carbonaceous fuelsWater methanolMaterials science

The invention belongs to the technical field of methanol fuel for vehicles, and specifically relates to anti-corrosion and water-proof methanol gasoline. The anti-corrosion and water-proof methanol gasoline is prepared from the following raw materials in percentage by mass: 30 to 75 percent of base oil, 10 to 15 percent of component oil, 10 to 50 percent of methanol and 1 to 10 percent of an additive, wherein the base oil is one of national standard gasoline No.90, national standard gasoline No.93 and national standard gasoline No.97. The anti-corrosion and water-proof methanol gasoline disclosed by the invention has the advantages that the intersolubility of all components is good, the dispersion is uniform, the stability is better, and other special technologies are not required for treating; all components are remarkable in synergistic effect, a water-proof effect is good, no delamination is generated when the water content reaches 5 percent or below, a metal anti-corrosion effect is strong, the oxidation resistance is good, low temperature phase separation can be resisted, the vehicles are easy to start at a low temperature and cannot generate air resistance at a high temperature, combustion is sufficient, and the power performance can be greatly increased; all component raw materials are easy to obtain and low in cost and are energy-saving and environment-friendly.

Owner:谢爱丽

Method and apparatus for rapidly stabilizing catalyst activity by heavy fuel oil

ActiveCN102950033BBurn fullyFacilitate control of combustion temperatureCatalytic crackingCatalyst protectionPtru catalystFluidized bed

A method and equipment for rapidly stabilizing catalyst activity using heavy fuel oil, comprising: (1) The catalyst enters the bottom of a dilute-phase combustion tube from a fluidized bed reactor, and the dilute-phase combustion tube is provided with two or more feed ports from bottom to top , spraying oxygen-containing gas and heavy fuel oil in sequence, the catalyst first mixes with oxygen-containing gas and flows upwards, then mixes with heavy fuel oil, and then replenishes oxygen-containing gas; (2) the high-temperature gas and catalyst after combustion reaction The outlet of the dilute phase combustion tube enters the fluidized bed reactor; (3) the high temperature catalyst in the fluidized bed reactor reacts with water vapor to reduce the activity, and the catalyst separated from the top of the catalyst aging device returns to the fluidized bed reactor; (4) the catalyst is aged After completion, shut down and unload the catalyst. and a device for implementing the method. By adopting the aging method and equipment provided by the invention, the activity of the catalyst can be quickly reduced to a stable level, the activity of the aged catalyst is evenly distributed, and the distribution of products used for catalytic cracking reaction of hydrocarbon oil is obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

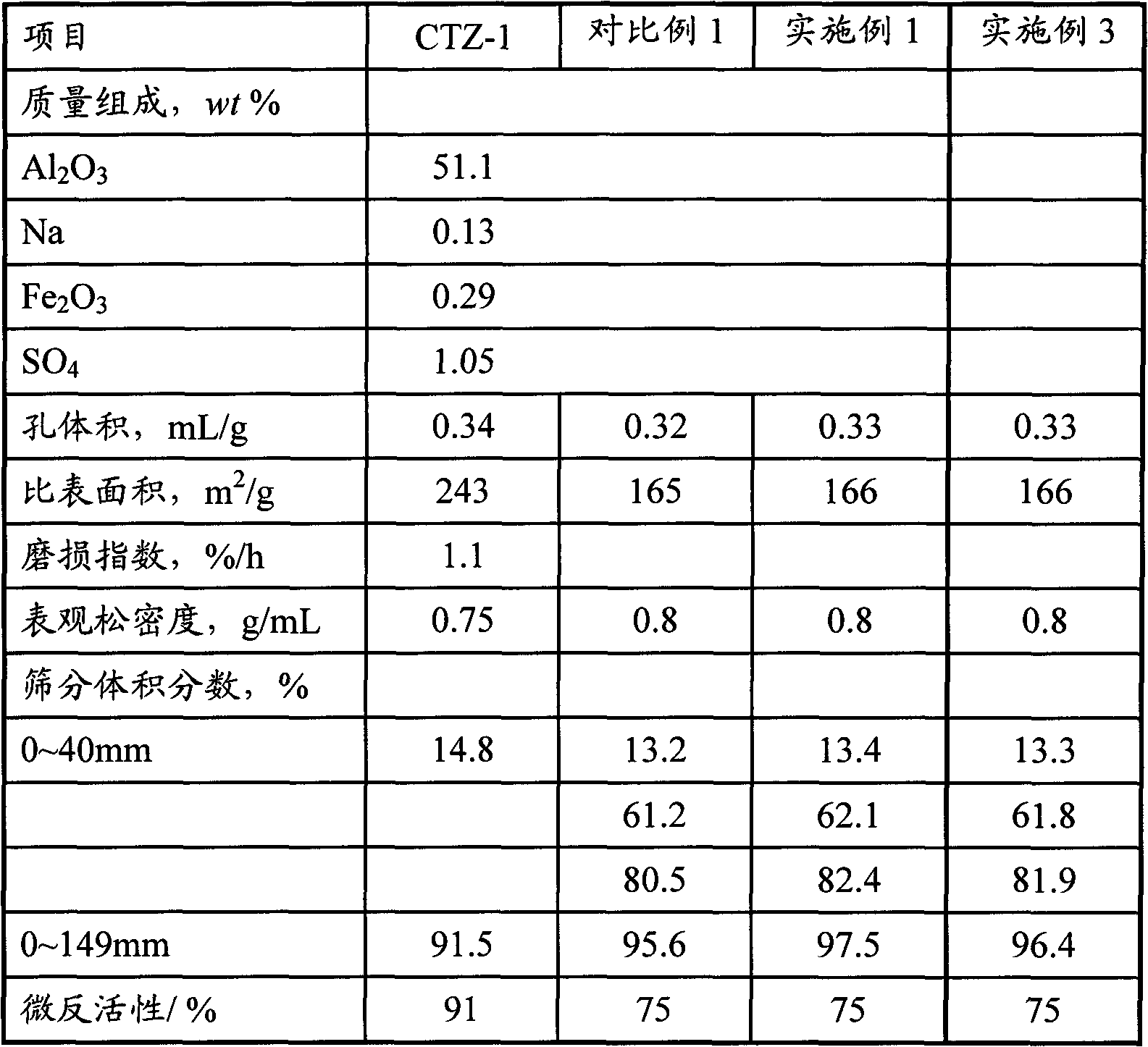

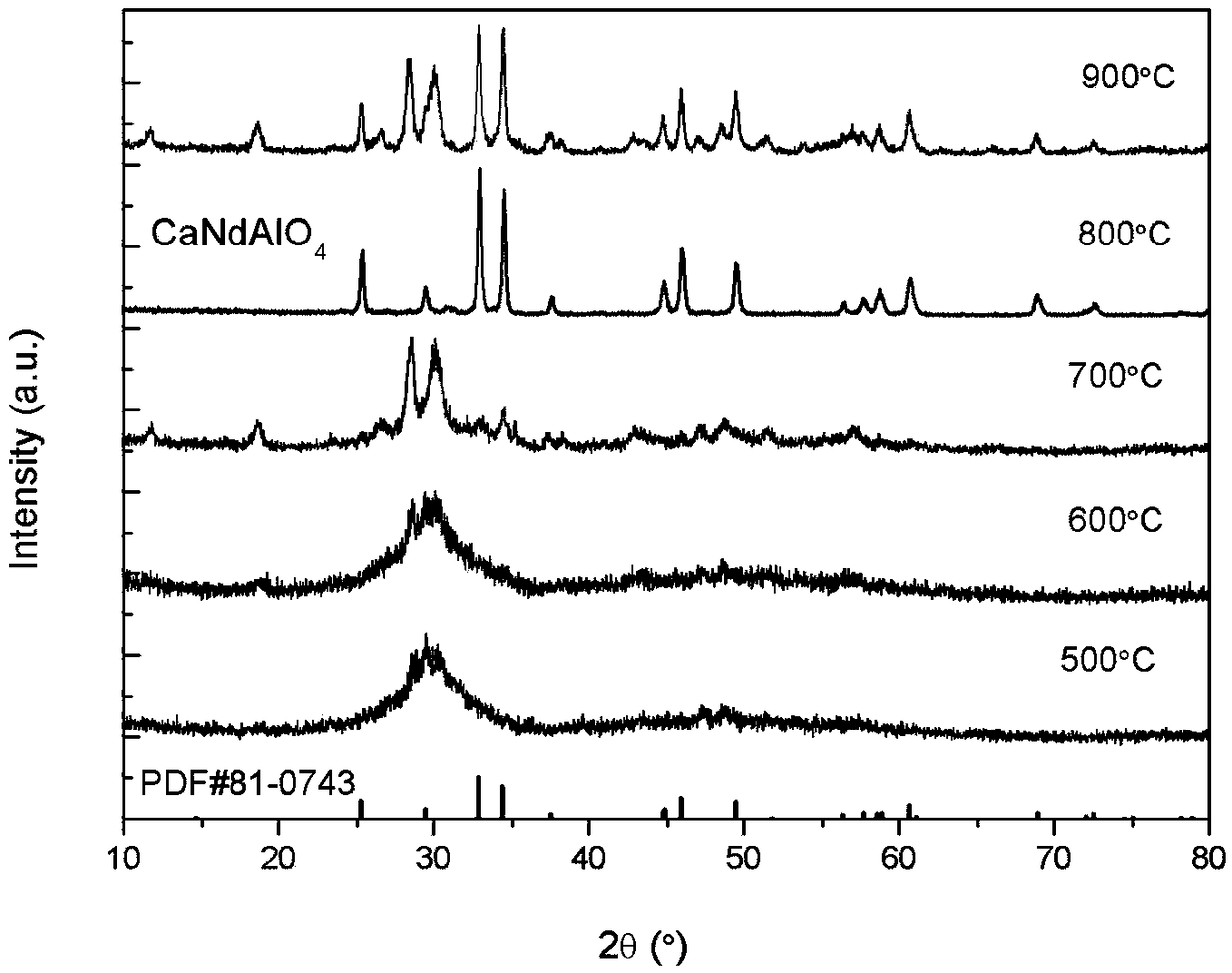

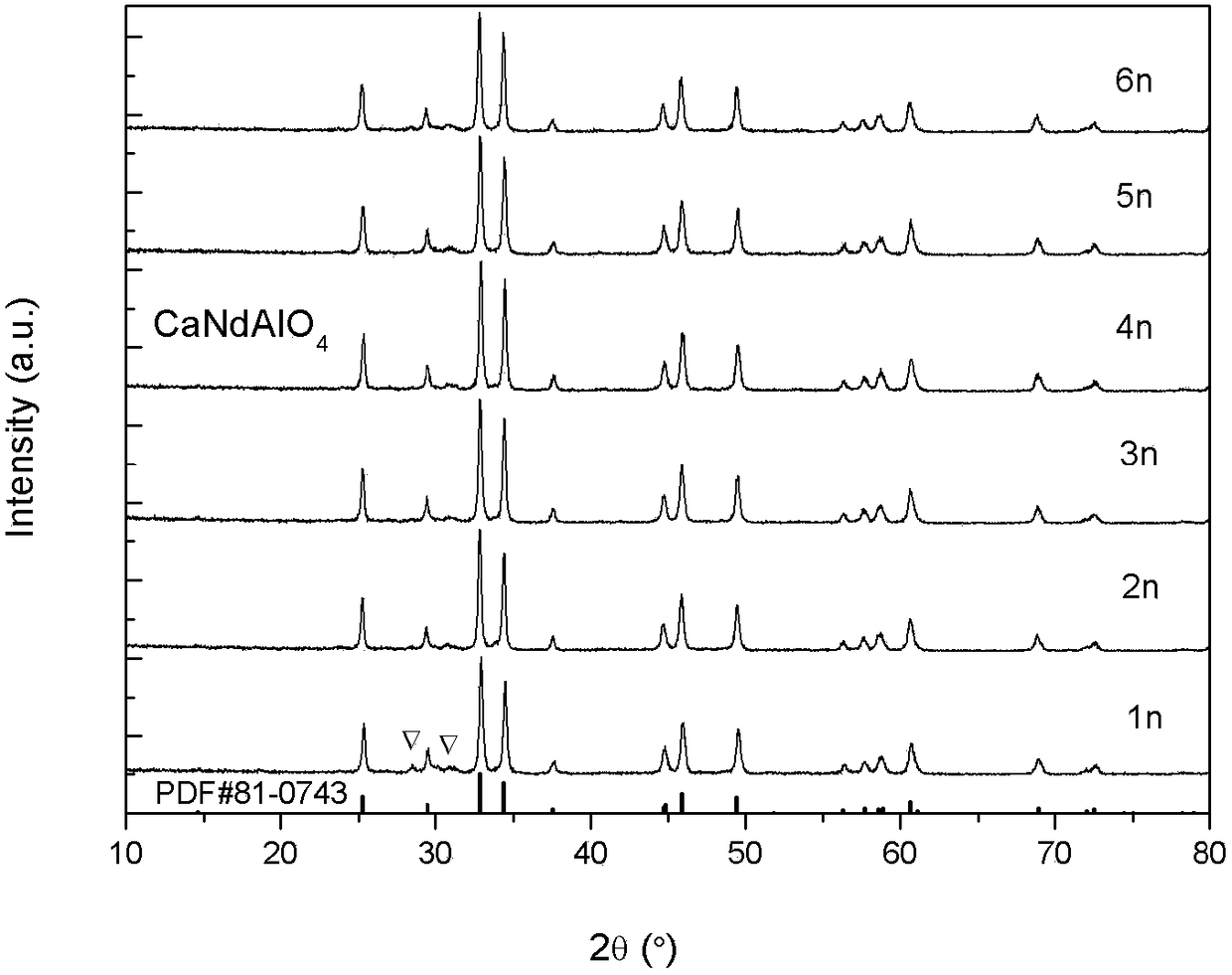

Preparation method of neodymium calcium aluminate

InactiveCN108238626AReduce the temperatureSolve the problem of high synthesis temperatureRare earth metal compoundsAluminateNitrate

The invention discloses a preparation method of neodymium calcium aluminate. The preparation method comprises the following steps: in stoichiometric ratio of metal elements in CaNdAlO4, respectively weighing compounds containing Ca, Nd and Al as raw materials, preparing into mixed solution of nitrates containing Ca<2+>, Nd<3+> and Al<3+>, adding organic fuel and a complexing agent into the mixed solution of nitrates, wherein molar ratio of the organic fuel to Ca<2+> in the mixed solution of nitrates is (1-6):1, uniformly mixing, then igniting the mixed solution at the temperature of 800-900 DEG C, and obtaining neodymium calcium aluminate after the mixed solution is burned up. According to the technical scheme, neodymium calcium aluminate is synthesized at a certain temperature and a certain raw material ratio, so that the problems of high synthesis temperature and long preparation time are solved; the complexing agent is added and can be complexed with metal ions to form an intermediate, temperature for synthesizing neodymium calcium aluminate is lowered, the complexing agent can enable the raw materials to be uniformly mixed and can be expanded in a burning process, a loose product is produced, and the phenomenon that the product is agglomerated and caked can be avoided.

Owner:YANGTZE UNIVERSITY

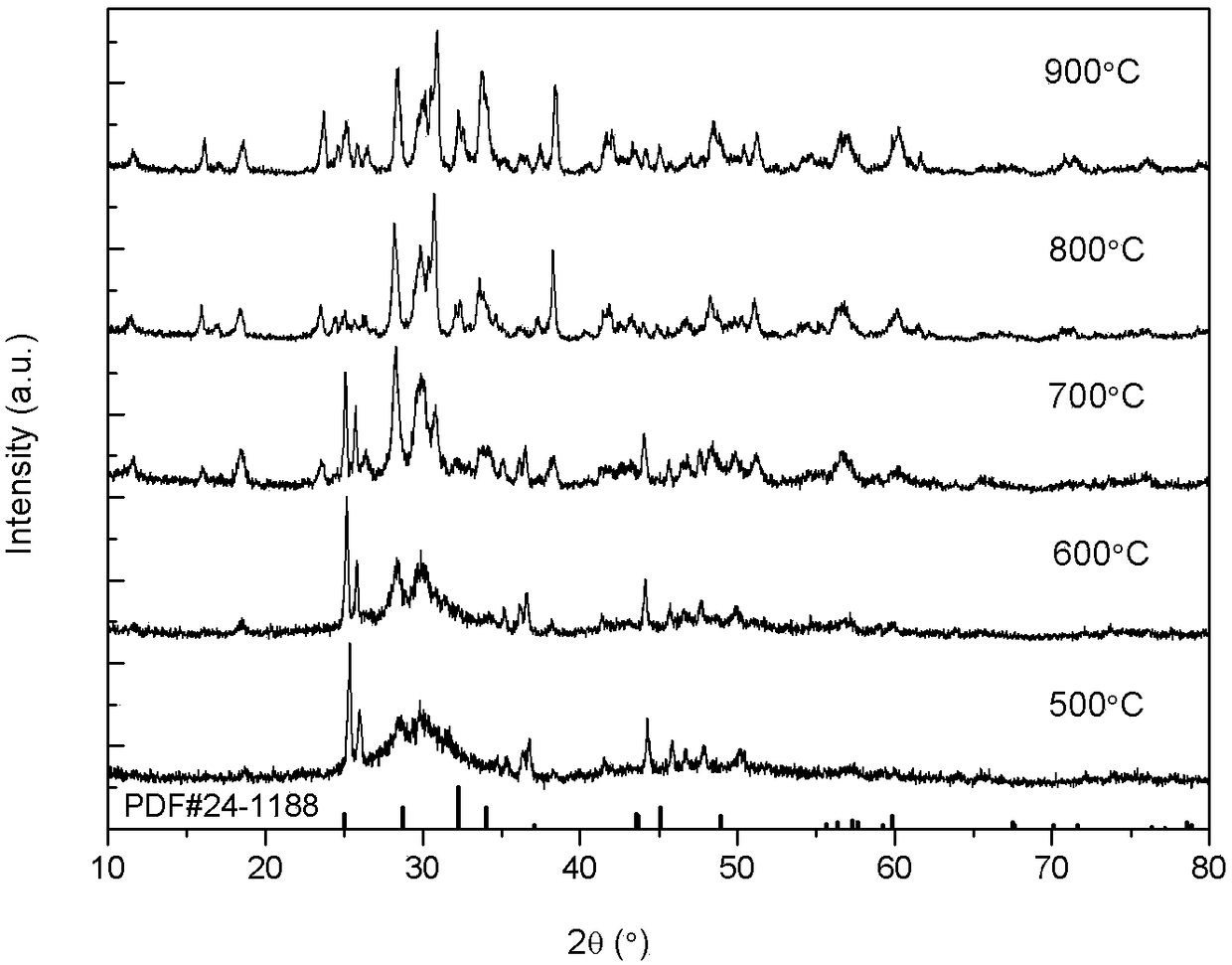

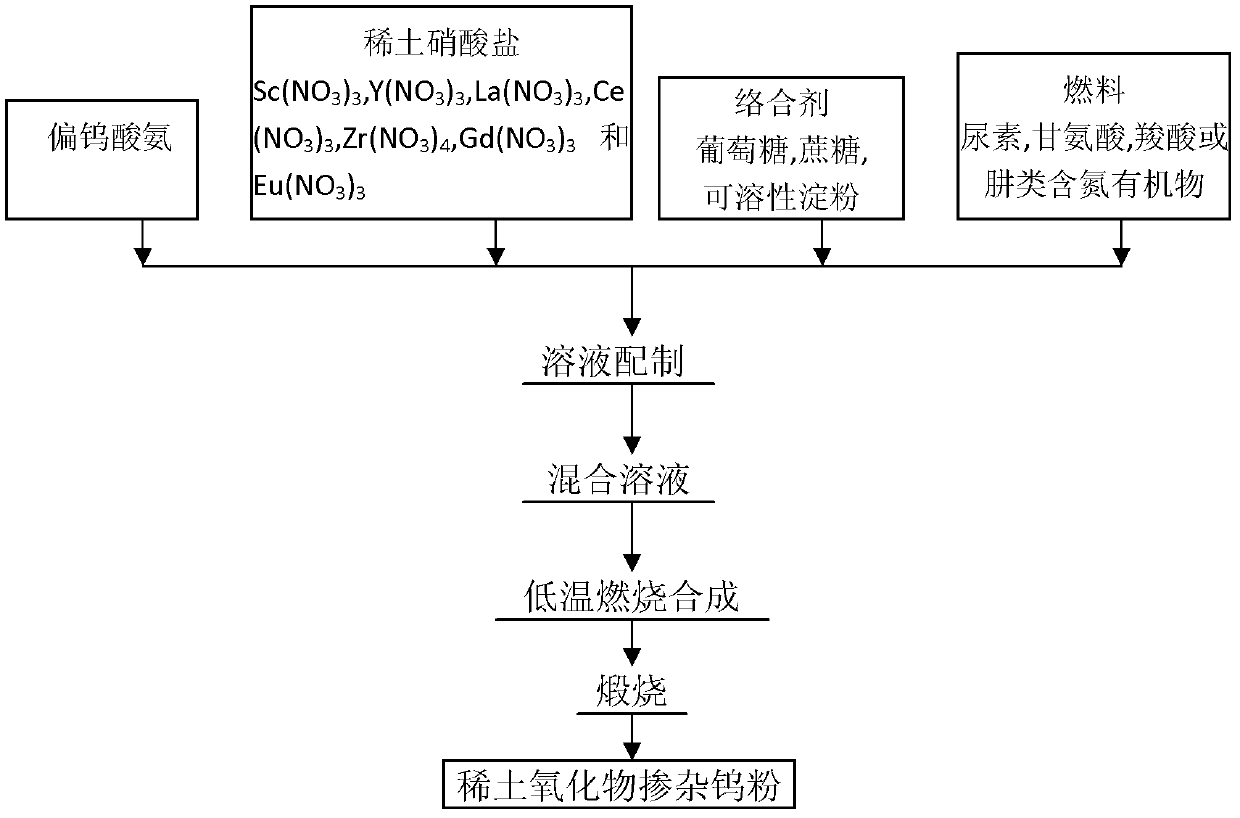

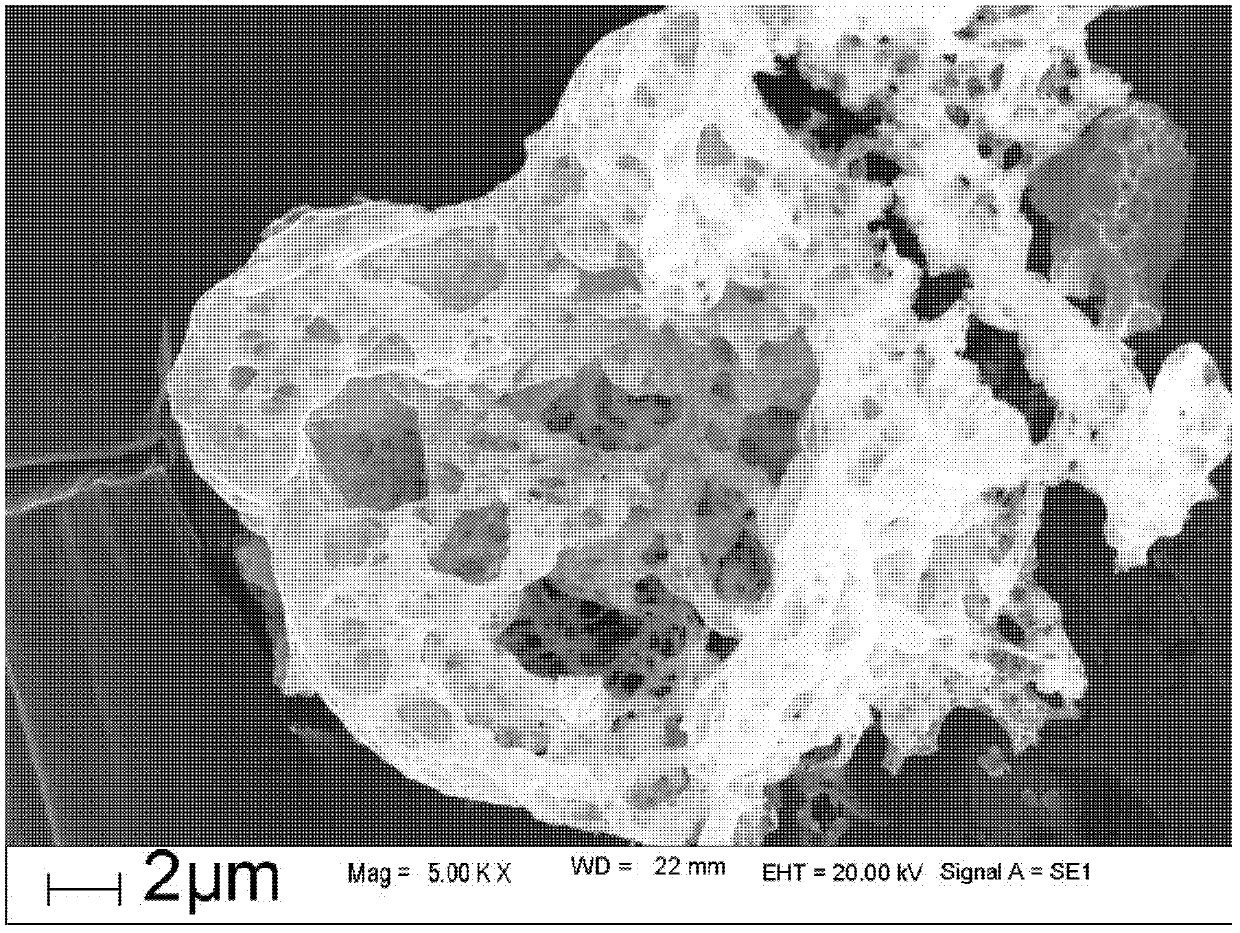

Preparation method for rare earth oxide doped tungsten powder

The invention provides a preparation method of rare earth oxide doped tungsten powder, belonging to a technical field of rare earth refractory metal material. The process flow is that: firstly, a precursor powder is obtained by adopting low-temperature combustion synthesis, wherein the precursor powder is a uniform mixture of rare earth oxide (at least one of Sc2O3, Y2O3, La2O3, CeO2, ZrO2, Gd2O3 and Eu2O3) and tungsten oxide; secondly, the precursor powder undergoes calcination in a muffle furnace; lastly, two-step reduction is carried out in the atmosphere of hydrogen or dissociated ammonia. Easy-reduction tungsten oxide is reduced to tungsten matrix powder, and the rare earth oxide that can not be reduced is reserved, thereby the rare earth oxide doped tungsten powder is obtained. The content of the rare earth oxide in the rare earth oxide doped tungsten powder is 0.05-35 wt%. The advantage of the invention is that target element and organic carbon source are capable of forming a highly dispersed system, and particle sizes of the obtained oxide are uniform and fine. The method is suitable for industrialization production because of low cost of raw materials, quick reaction speed, low energy consumption and simple technology.

Owner:UNIV OF SCI & TECH BEIJING

Blast burner for manufacturing optical fiber preform

PendingCN113860721AIncrease the diameterImprove plateau timeGlass making apparatusSilicon tetrachlorideSilicon oxide

The invention relates to the technical field of optical fiber preparation, and discloses a blast burner for manufacturing an optical fiber preform. The blast burner comprises a distribution ring, the distribution ring is movably sleeved with a lamp sleeve, and an outer ring in the distribution ring is annularly provided with an air hole 1. According to the blast burner for manufacturing the optical fiber preform, an annular groove I and an annular groove II communicate and are matched with the air hole I and an air hole II, so that oxygen and hydrogen conveyed from the air hole I and the air hole II are annularly sprayed out and mixed after being completely loaded in the annular groove I and the annular groove II, and are combusted to generate water which is mixed and reacted with silicon tetrachloride to generate silicon dioxide particles. Silicon dioxide particles are accumulated in the annular groove I and the annular groove II, silicon tetrachloride is liquid, friction force between the silicon tetrachloride and the silicon dioxide particles is larger, and the silicon tetrachloride is not prone to being accumulated in liquid holes, and the annular groove I and the annular groove II are annular grooves, so that the time needed for influencing the discharge amount of the silicon tetrachloride is longer when the silicon dioxide particles cause blocking, and the diameter stable state time can be prolonged when the equipment is used for preparing the preform.

Owner:许平

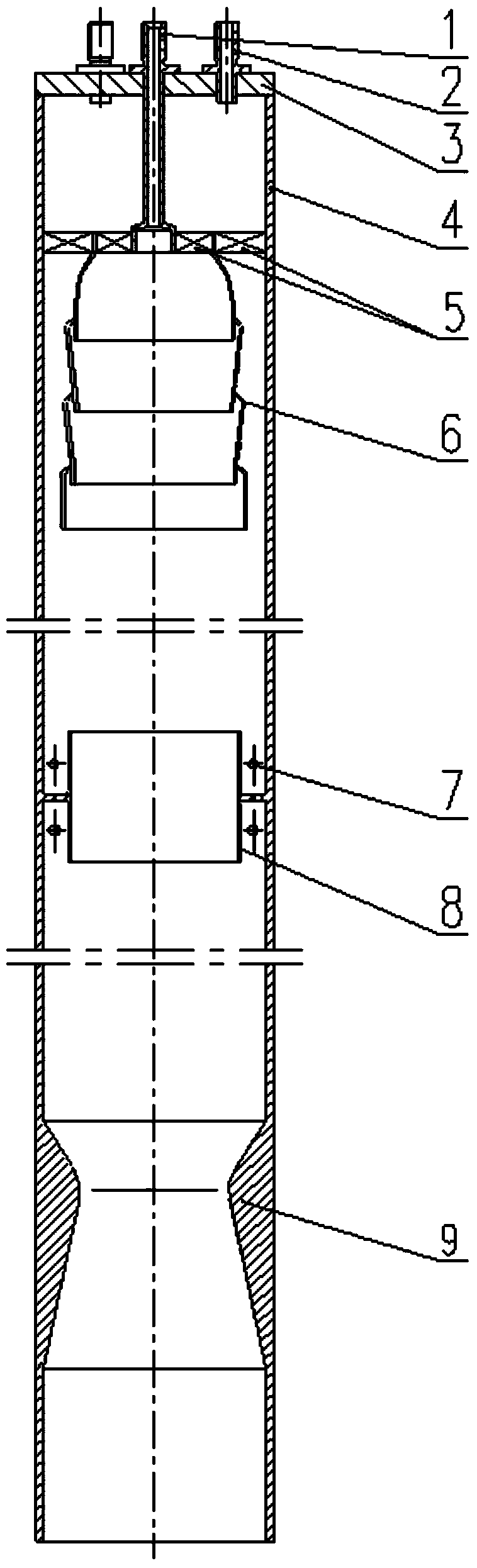

Burning lance and energy-saving and environment-friendly kiln

PendingCN110657427AFast combustion reactionBurn fullyFurnace typesIndirect carbon-dioxide mitigationFuel tankFuel gas

The invention specifically relates to a burning lance and an energy-saving and environment-friendly kiln. The burning lance comprises a lance sleeve, a lance core and a lance head. The lance sleeve isarranged on the outer side of the lance core in a sleeving manner. The lance core and the lance head are fixedly connected. A wind blocking sheet is fixed to the portion, close to the lance head, ofthe outer wall of the lance core. Combustion-supporting air holes are formed in the wind blocking sheet. Fuel gas holes are further formed in the portion, close to the lance head, of the side wall ofthe lance core and are located between the lance head and the wind blocking sheet. The burning lance is high in combustion reaction speed and sufficient in combustion, and the energy consumption is reduced. The energy-saving and environment-friendly kiln comprises a kiln body, burning lances, a fuel tank, a heat exchanger and a combustion-supporting draught fan; the burning lances penetrate through the side wall of a high-temperature section of the kiln body; fuel gas inlets are connected with the fuel tank; combustion-supporting air inlets are connected with an outlet of the combustion-supporting draught fan; combustion-supporting air heating and heat exchanging pipes are arranged on the top of a slow-cooling section of the kiln body and are connected with the inlet end of the heat exchanger; and the outlet end of the heat exchanger is connected with an inlet of the combustion-supporting draught fan. Waste heat of the energy-saving and environment-friendly kiln is sufficiently utilized, and the use amount of fuel is decreased.

Owner:山东狮王陶瓷有限公司

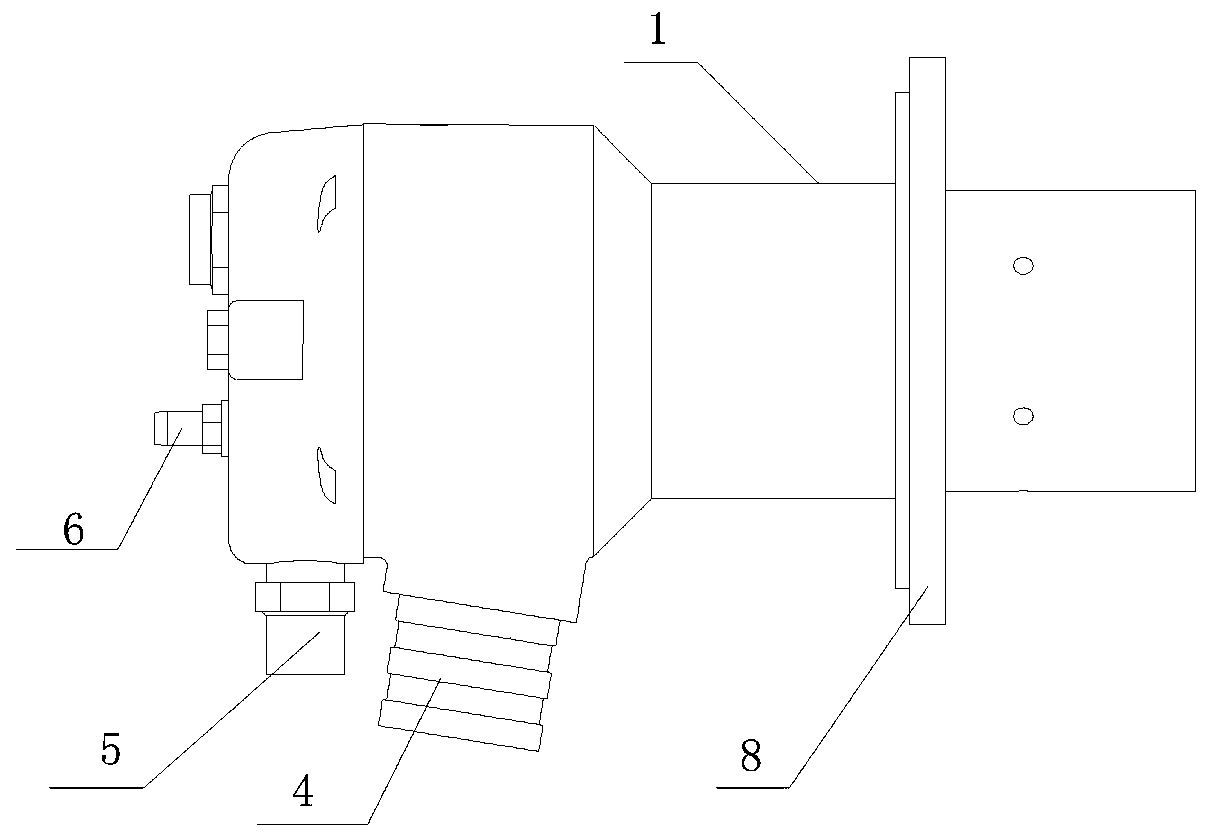

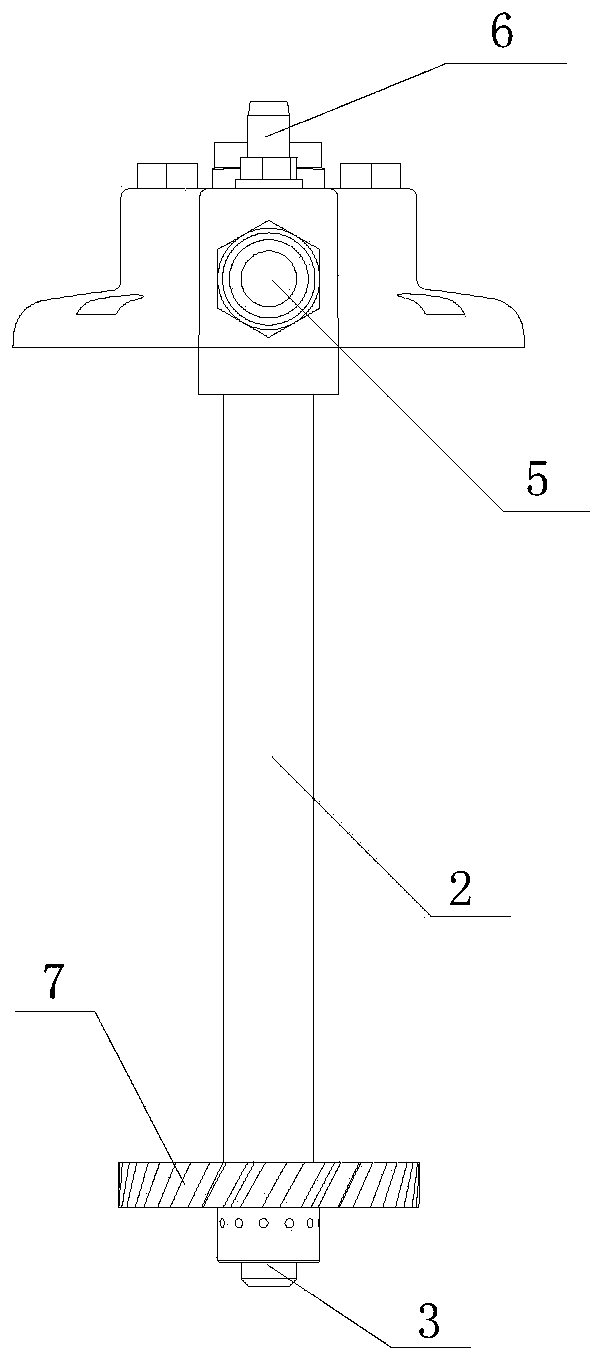

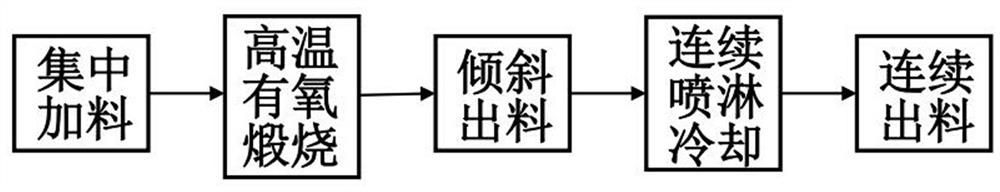

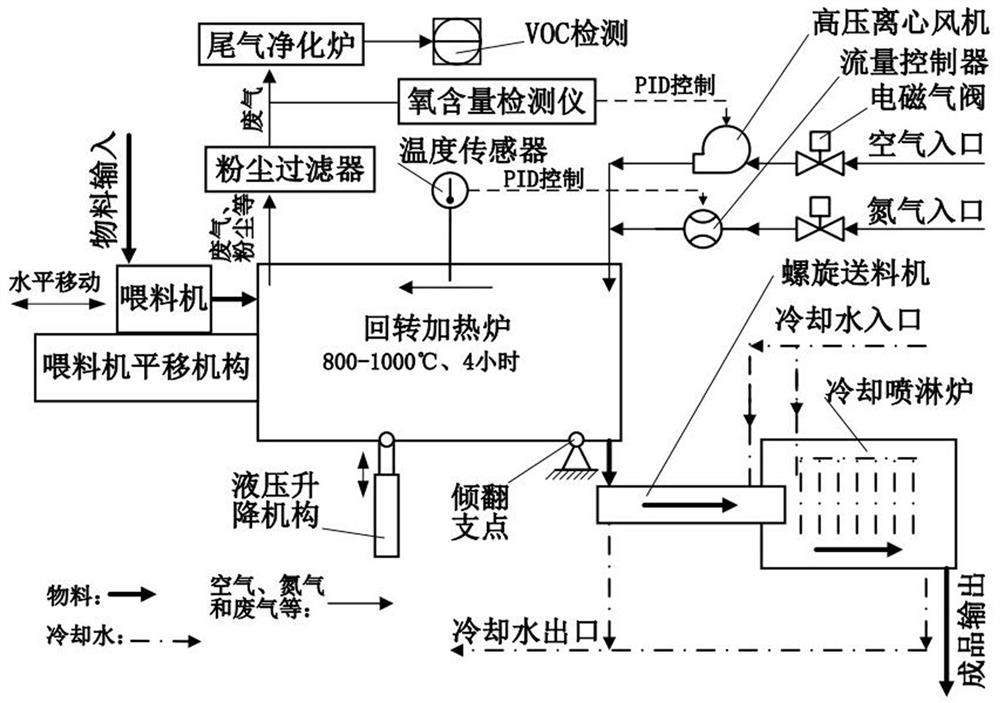

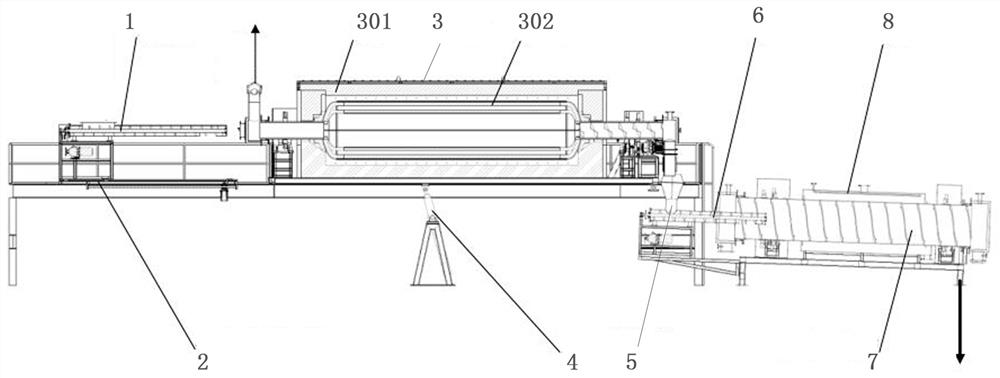

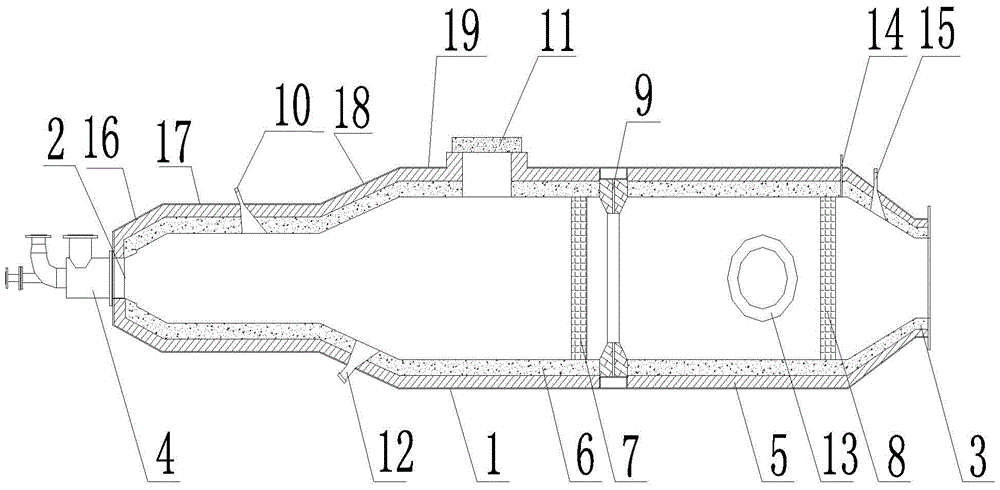

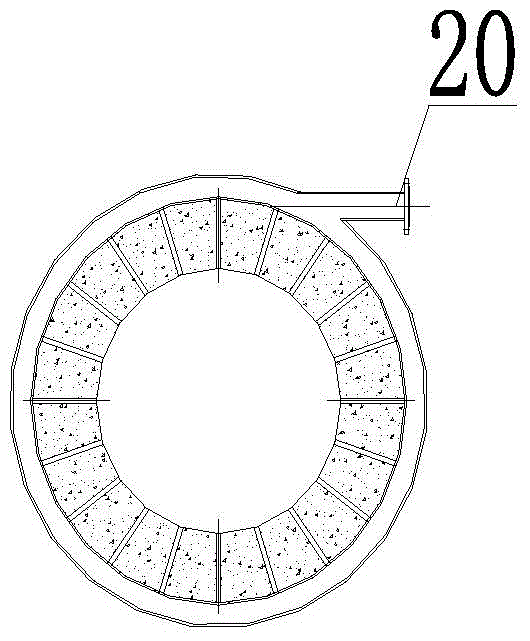

Filler recovery device for thermosetting plastic waste and recovery method

PendingCN112642844AAchieve recyclingReduce pollutionHuman health protectionDispersed particle filtrationPlastic wasteNitrogen gas

The invention provides a filler recovery device for thermosetting plastic waste and a recovery method. The filler recovery device mainly comprises a feeder, a feeder translation device, a rotary heating furnace, a spiral feeder, a cooling spray furnace, a dust filter, a tail gas purification furnace, a VOC detection device, a hydraulic lifting mechanism, a water cooling system, an air input system, a nitrogen input system, an electrical control system and the like. Organic matter in the thermosetting plastic waste is removed through a long-time high-temperature aerobic combustion method, filler in waste is recycled and can be reused for production of thermosetting plastic, cyclic utilization of the waste is achieved, and therefore the production cost is reduced, environmental pollution is reduced, and economic benefits are improved; and moreover, the production process of centralized feeding, high-temperature aerobic calcining, inclined discharging, continuous spraying cooling and continuous discharging is adopted, the device is compact in structure and high in production efficiency, and continuous batch production can be achieved.

Owner:洛阳炬星窑炉有限公司

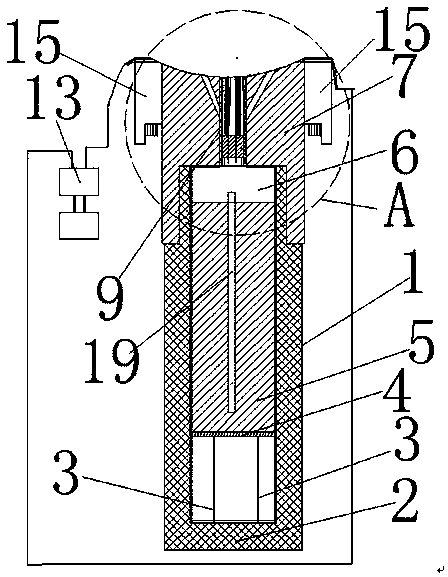

A hydrogen sulfide incinerator

ActiveCN103868082BImprove the mixing effectSmall pressure lossIncinerator apparatusHydrogenInsulation layer

The invention relates to a novel sulfuretted hydrogen incineration furnace which comprises a cavity furnace shell. An air inlet is formed in one end of the cavity furnace shell, an air outlet is formed in the other end of the cavity furnace shell, a sulfuretted hydrogen nozzle is formed in the outer end of the air inlet, a heat insulation layer is arranged on the inner wall of the cavity furnace shell, a fire retardant layer is arranged on the inner wall of the heat insulation layer, two heat storage walls are arranged in the cavity furnace shell, one heat storage wall close to the sulfuretted hydrogen nozzle is the first heat storage wall, the other heat storage wall is the second heat storage wall, the cavity furnace shell is divided into three sections by the two heat storage walls, a secondary temperature adjustment and oxygen supplementary air pipe is arranged at the position, close to the end of the first heat storage wall, between the two heat storage walls, a combustion channel flame detection device, an explosion door and a fire observation hole are arranged on the first section of the cavity furnace shell, a maintenance door is arranged on the second section of the cavity furnace shell, and a negative pressure transmitter and a smoke outlet flame detection device are arranged on the third section of the cavity furnace shell. The novel sulfuretted hydrogen incineration furnace is full in combustion, stable in flame in the furnace, safe and reliable, and saves cost.

Owner:JIANGSU DAXIN ENVIRONMENTAL SCI & TECH

Gas mixed clean fuel

The invention discloses a gas mixed clean fuel, and belongs to the technical field of fuel combustion. The purpose of the invention is to provide the clean fuel containing multiple mixed gases and having a high combustion efficiency and a low production cost. The fuel comprises, by mass, 36-42% of natural gas, 24-32% of water gas, 2-6% of liquefied petroleum gas and 25-35% of methyl ether. The natural gas, water gas, liquefied petroleum gas and dimethyl ether are mixed according to a reasonable ratio, so the advantage complementation of all above fuels is well achieved, the combustion efficiency is obviously improved, and the gas mixed clean fuel also has the advantages of no environmental pollution during combustion, facilitation of atmospheric environmental protection, reduction of the overall cost, and significant commercial and economic benefits.

Owner:武威福民汇科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com