Combustion type steel component oriented cutting device

A technology for cutting devices and components, applied in aluminothermic welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unsafety, poor orientation, high energy consumption, etc., and achieve fast combustion reaction speed, fast cutting rate, and energy consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

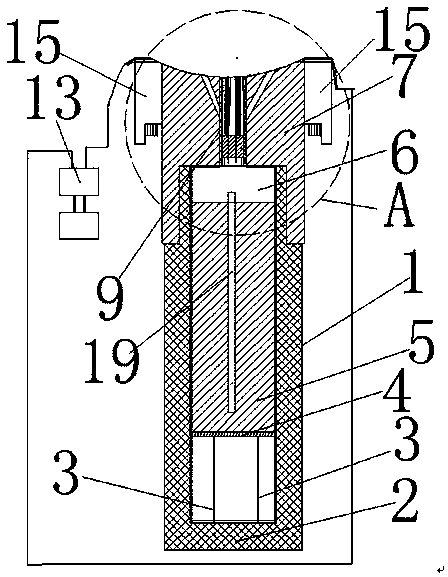

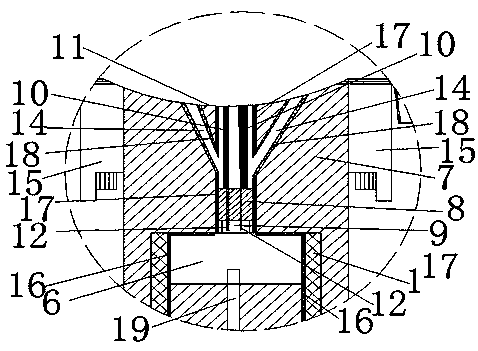

[0036] Example 1. Such as Figure 1-8 As shown, a directional cutting device for combustion-shaped steel members is characterized in that: it includes a charge barrel 1, and the charge barrel 1 is sequentially provided with a bottom support sleeve 3, a top plate 4 with a circular cross section, and a cutting agent Layer 5, igniting agent layer 6, the central axis of the bottom support sleeve 3 coincides with the central axis of the charge barrel 1; the radial outer peripheral surface of the top plate 4 is close to the radial inner peripheral surface of the charge barrel 1; the top plate 4 is placed on On the bottom support sleeve 3; the bottom support sleeve 3 is placed on the barrel bottom 2 of the charge barrel 1; the top cover 7 that can seal the top opening of the charge barrel 1 is installed on the top of the charge barrel 1; the diameter of the top cover 7 The outer peripheral surface is provided with a fixing device 15 for fixing the top cover 7 on the object 20 to be ...

Embodiment 2

[0047] Example 2. Such as Figure 9-10 As shown, the difference between this embodiment and Embodiment 1 is that the fixing device 15 is a plurality of mounting ears provided on the top cover 7 , and each mounting ear is provided with a magnet 21 . The cross section of the object 20 to be punched is rectangular. The object 20 to be punched is a metal plate.

Embodiment 3

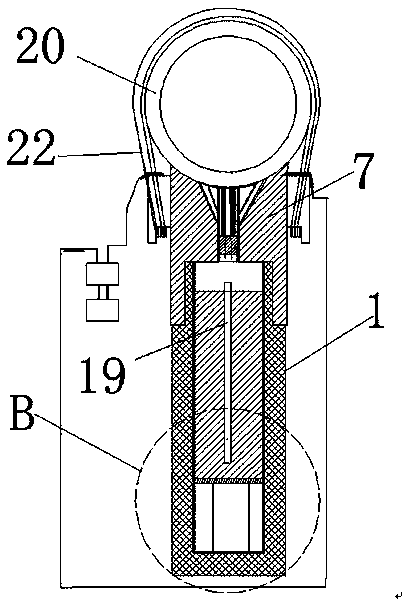

[0048] Example 3. Such as Figure 12-13 As shown, the difference between this embodiment and Embodiment 1 is that the fixing device 15 is a plurality of mounting ears provided on the top cover 7 , and each mounting ear is connected to the object 20 to be punched through a wire rope 22 . The cross section of the object 20 to be punched is rectangular. The object 20 to be punched is a metal plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com