Metal component field high-energy thermal cutting and hole forming device

A metal component and hole-forming device technology, which is applied in the field of high-energy thermal cutting hole-forming devices for metal components in the field, can solve problems such as unsafety, poor orientation, and high energy consumption, and achieve fast combustion reaction speed, fast cutting rate, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

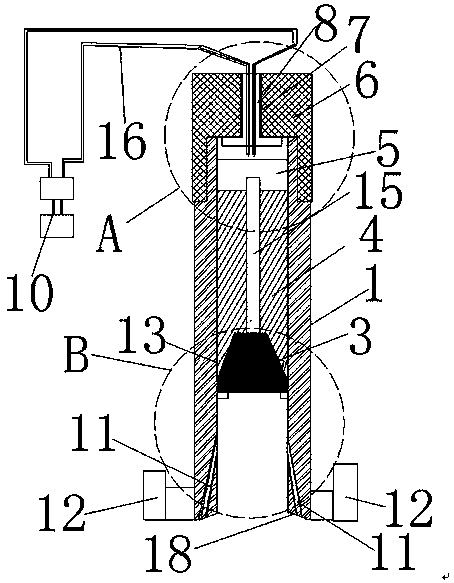

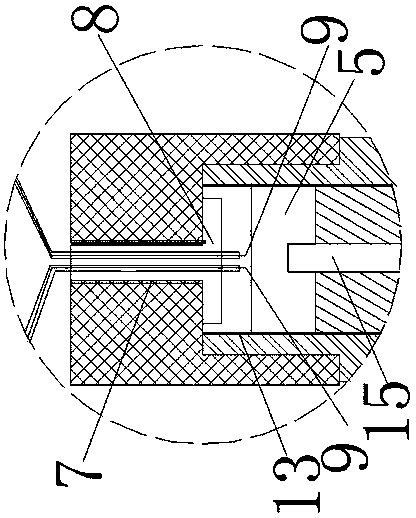

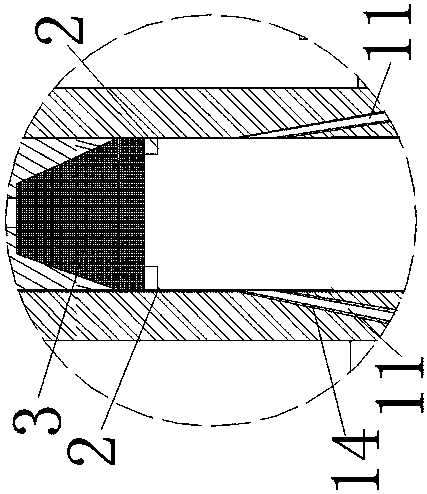

[0036] Example 1. Such as Figure 1-7 As shown, an outdoor high-energy thermal cutting hole-forming device for metal components is characterized in that: it includes a charge barrel 1, and the charge barrel 1 is sequentially provided with an aluminum body whose central axis coincides with the center axis of the charge barrel 1 from bottom to top. The retaining ring 2, the frustum-shaped frustum plug 3, the thermite layer 4, and the ignition agent layer 5 made of ceramics or graphite, the radial outer peripheral surface of the bottom of the frustum plug 3 are tight Mount the radially inner peripheral surface of the drug barrel 1 and the bottom surface of the cone plug 3 is connected to the top surface of the retaining ring 2; the retaining ring 2 is connected to the radially inner peripheral surface of the middle part of the charge barrel 1 and its top surface is perpendicular to The central axis of the charging barrel 1; the top of the charging barrel 1 is equipped with a top...

Embodiment 2

[0048] Example 2. Such as Figure 8-9 As shown, the difference between this embodiment and Embodiment 1 is that the insulating plug installation through hole 7 and the insulating plug 8 are all in the shape of a truncated cone with a small upper part and a larger lower part; the insulating plug 8 is threadedly connected with the insulating plug installation through hole 7.

Embodiment 3

[0049] Example 3. Such as Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that the fixing device 12 includes connecting ears, and the connecting ears are connected to the object 17 to be punched through a wire rope 20. The object 17 to be punched is plate-shaped.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com