Boiler in-furnace desulfurization, denitration solid mercury integrated method

A technology for desulfurization, denitrification, and boiler furnaces, applied in the field of control, can solve the problems of low pollutant removal efficiency and high pollutant cost by dry method, and achieve the effects of accelerating combustion reaction speed, broad market prospects, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

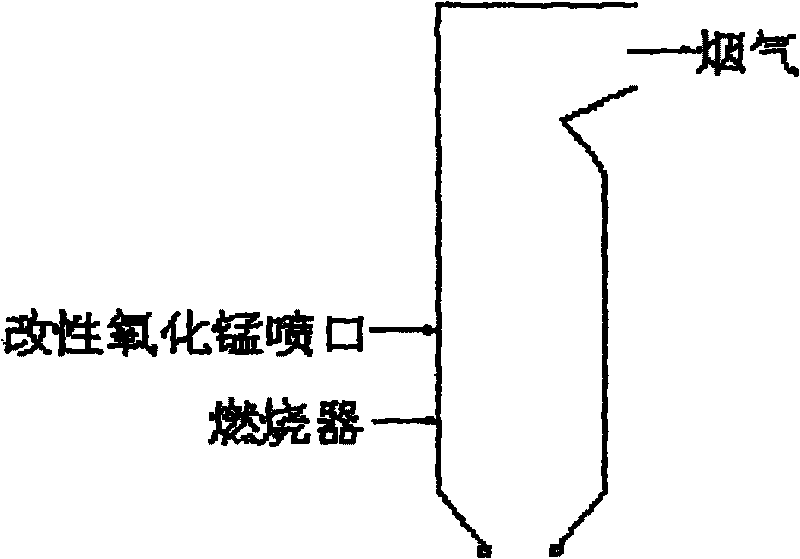

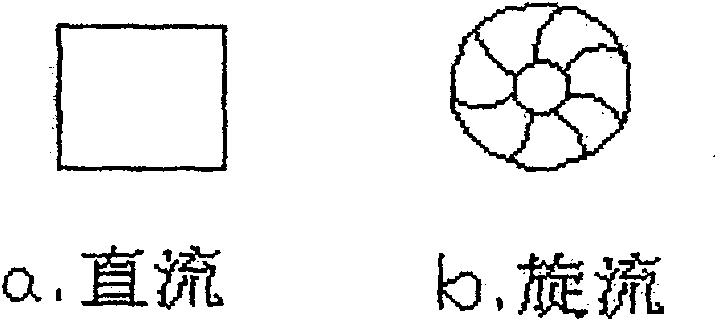

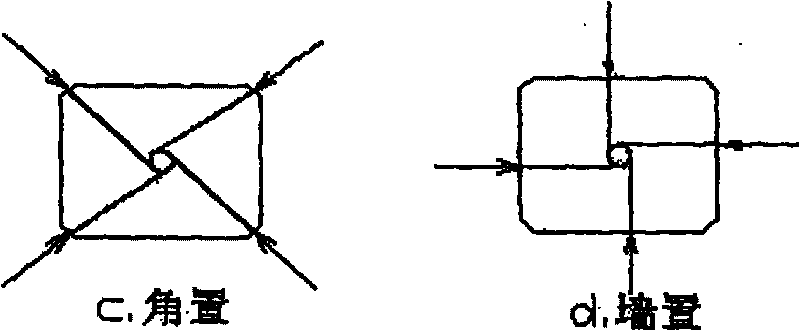

[0022] Such as Figure 1-3 As shown, in the area above the burner where the temperature is 1100°C to 1400°C, a number of (4 or 12) modified manganese oxide nozzles are arranged in a corner or wall, inversely cut or opposed. Modified manganese oxide powder contains MnO, Mn 2 o 3 and MnO 2 , where the highly active component MnO 1.7-1.9 It accounts for more than 90% of the total amount, and the modified component CaO and the like account for 1-10% of the total amount. Manganese oxide powder with an average particle size of 65 μm is carried by air and sprayed at a direct jet velocity of 50 m / s, and its swirl intensity is 1 to 4.5. It is disposed in a position with a temperature of 1000-1400°C by means of continuous spraying, and the product of the manganese absorbent is collected by the boiler dust collector. The removal rates of nitrogen oxides, sulfur oxides and mercury can respectively reach more than 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com