Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

146results about How to "Ensure dynamic balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

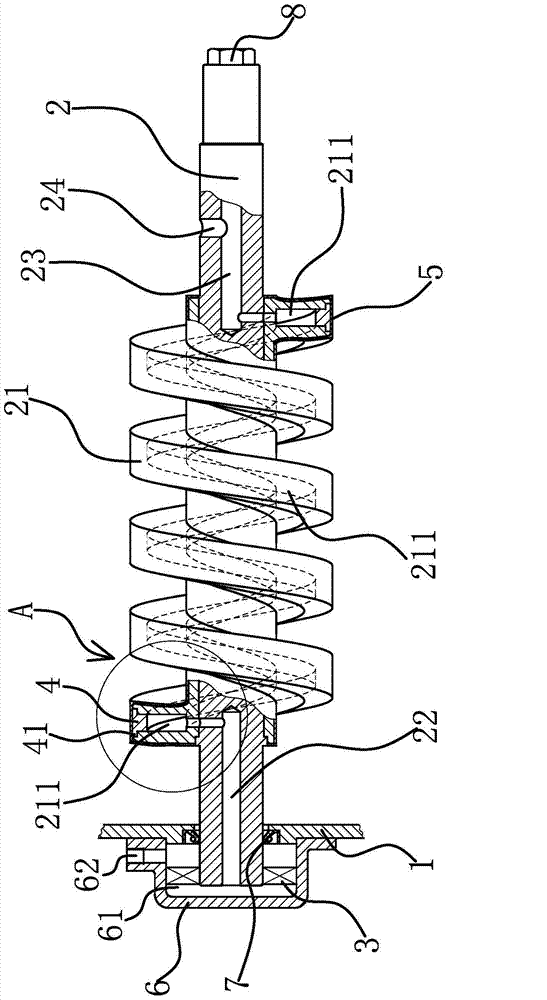

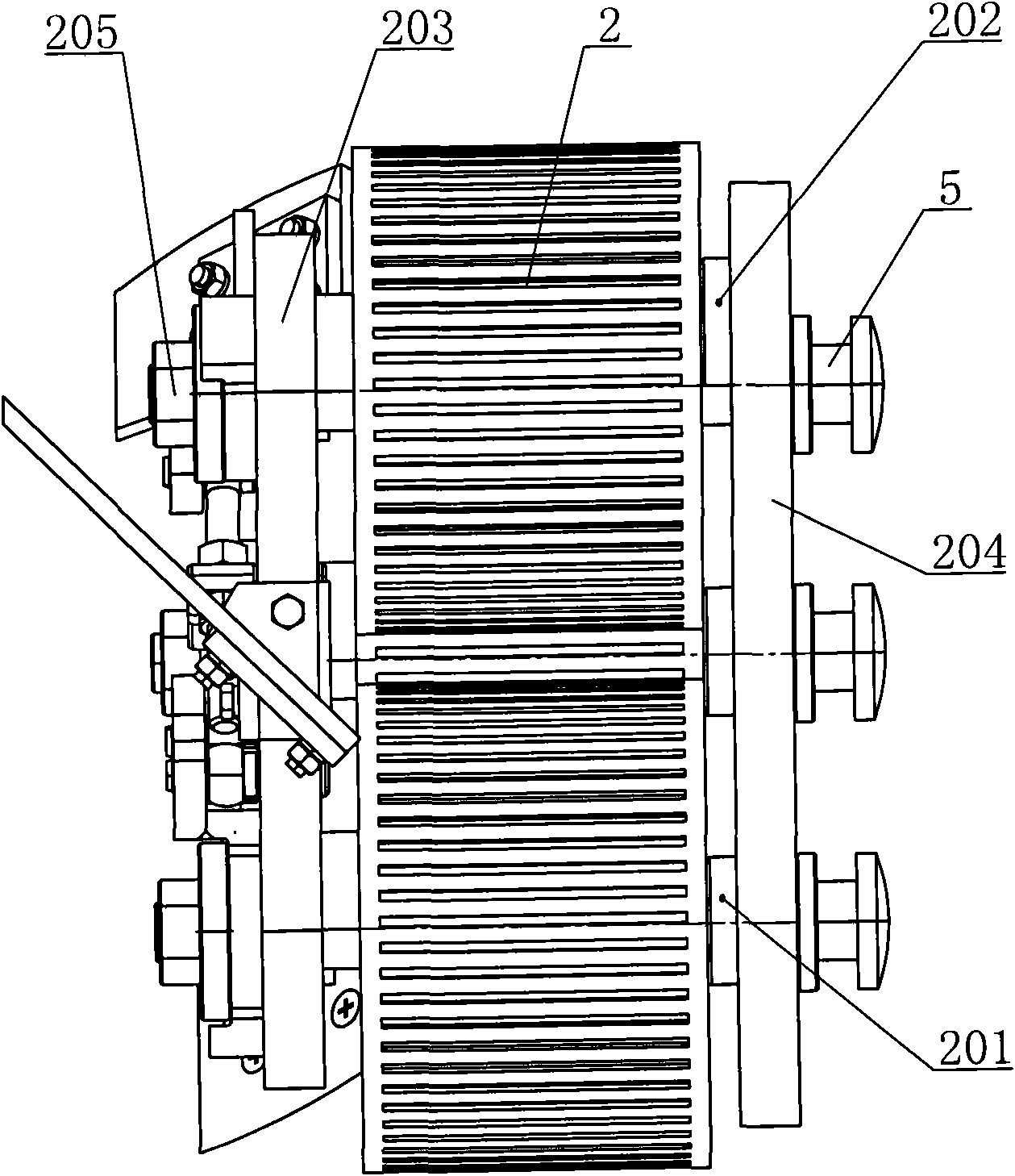

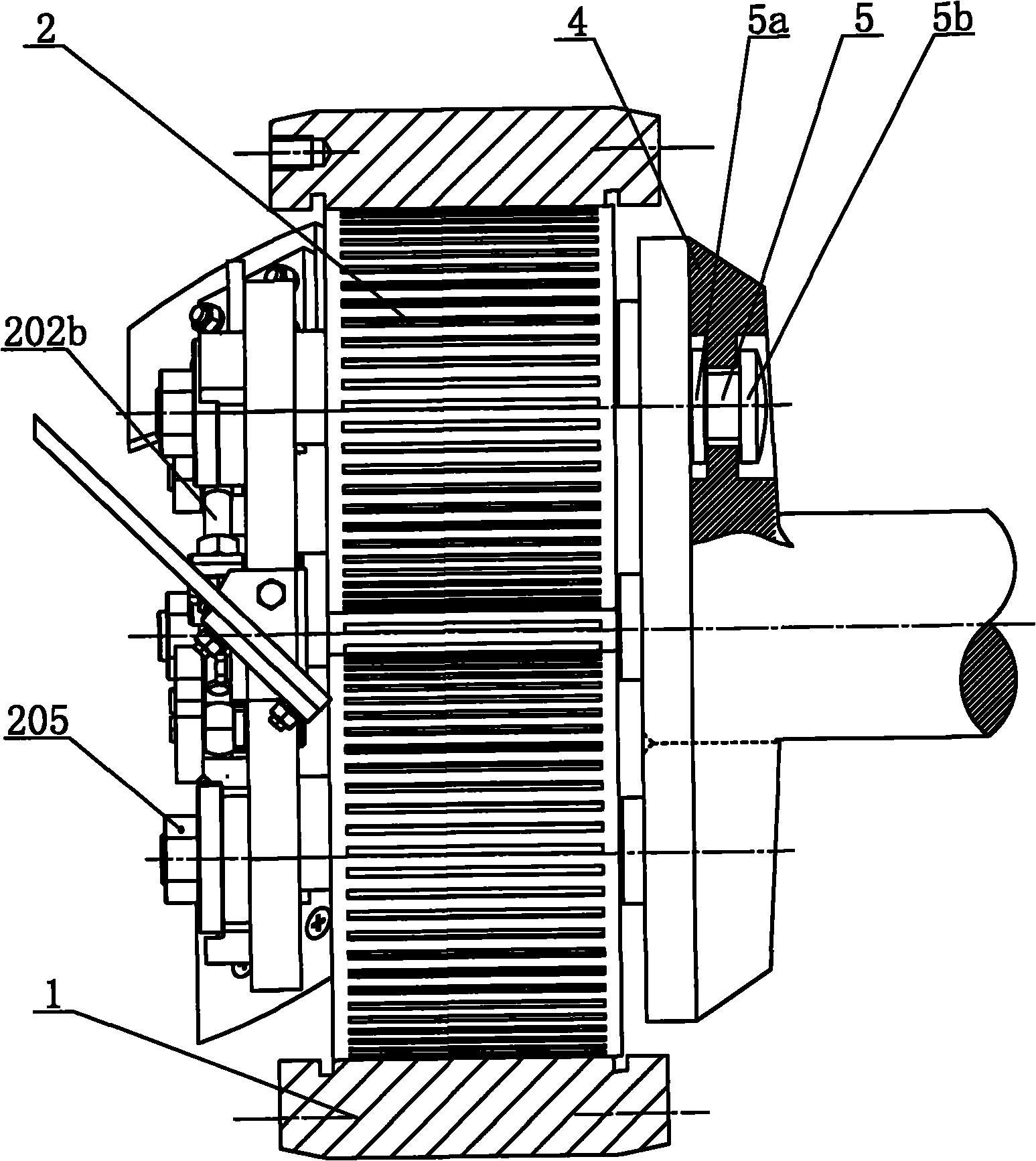

Screw rotor cooling device of screw vacuum pump

ActiveCN104329257AImprove cooling effectEasy to monitorRotary piston pumpsRotary piston liquid enginesCooling effectHydraulic pump

The invention provides a screw rotor cooling device of a screw vacuum pump, belonging to the technical field of pumps and solving the problems that an existing screw rotor cooling device of the screw vacuum pump is poor in cooling effect and inconvenient to machine. The screw rotor cooling device comprises a hydraulic pump and a cooling liquid tank; a helical tooth is arranged on a screw rotor, a cooling liquid channel is formed in the helical tooth along the helical direction, an opening opened relative to the outside is formed in the upper surface of the cooling liquid channel, and an insert matched with the shape of the opening is fixed at the opening of the cooling liquid channel; the helical tooth is externally coated by an engineering plastic attaching layer, and the engineering plastic attaching layer covers the joint of the insert and the opening; a liquid inlet end of the cooling liquid channel is communicated with the cooling liquid tank through the hydraulic pump, and a liquid outlet end of the cooling liquid channel is communicated with the cooling liquid tank. According to the screw rotor cooling device of the screw vacuum pump, the cooling liquid channel is formed in the helical tooth of the screw rotor, so that the cooling effect of the screw rotor is relatively good.

Owner:MADEBAO VACUUM EQUIP GRP

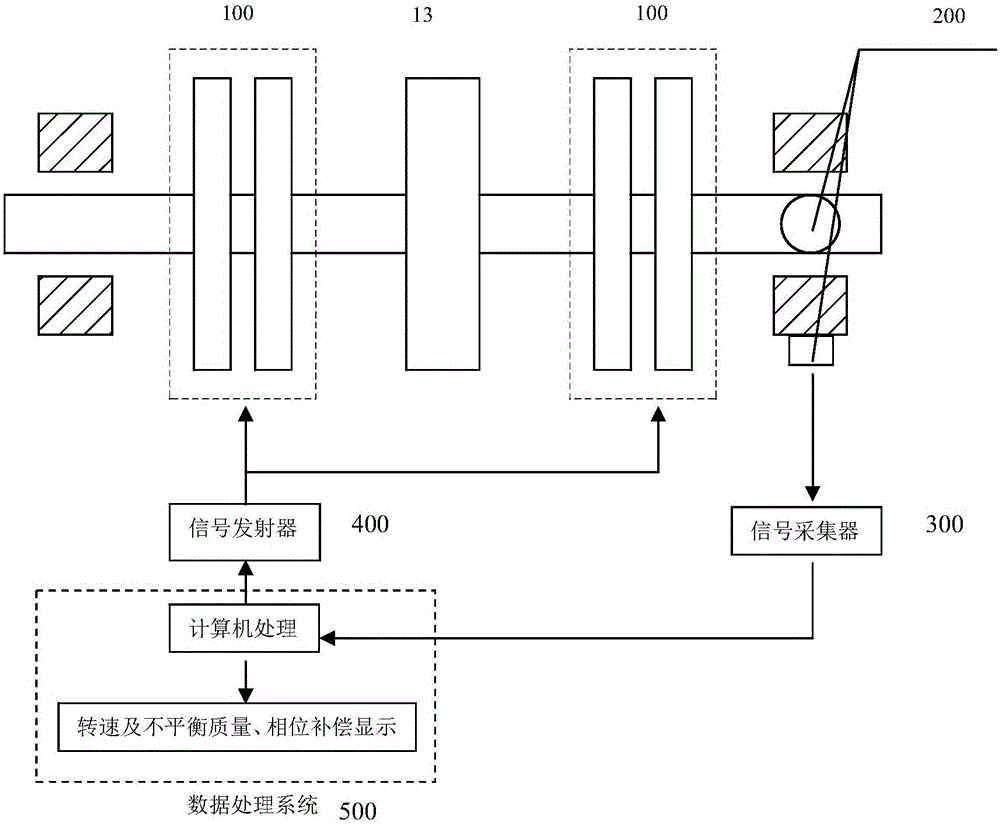

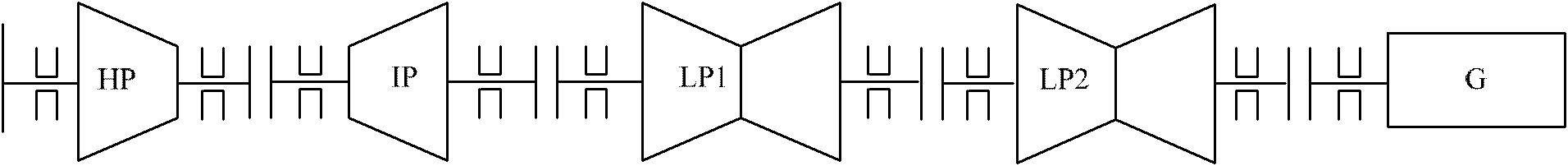

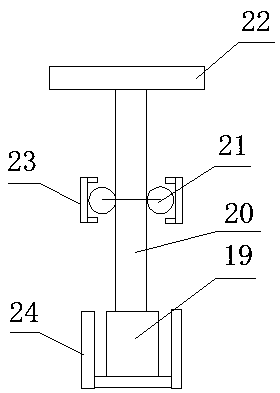

Rotor system on-line dynamic balancing system and rotor system on-line dynamic balancing method

ActiveCN106168526AAchieve dynamic balanceReduce production capacityStatic/dynamic balance measurementData processing systemDynamic balance

The invention provides a rotor system on-line dynamic balancing system and a rotor system on-line dynamic balancing method. The rotor system on-line dynamic balancing system comprises a signal sensor, a signal acquirer, a data processing system, a signal transmitter, and a balance adjuster. The signal sensor is used to acquire unbalanced vibration information of a rotor system, and is used to convert the unbalanced vibration information into an analog signal, which is transmitted to the signal acquirer. The signal acquirer is used to convert the analog signal into a digital signal, and is used to transmit the digital signal into the data processing system after the denoising and the filtering process of the digital signal. The data processing system is used to calculate and process the received digital signal, and is used to acquire the unbalanced mass and the phase information of the rotor system, and is used to generate a motion signal, which is transmitted to the signal transmitter. The signal transmitter is used to transmit the motion signal to the balance adjuster. The balance adjuster is used to generate a motion in the adjuster, and is used to adjust the unbalanced mass of the rotor system, and then the on-line dynamic balancing of the rotor system is realized. The dynamic balancing of the rotor system is completed without requiring shutdown, and repeated starting and stopping steps of a conventional dynamic balancing experiment are saved, and therefore the rotor system on-line dynamic balancing system and the rotor system on-line dynamic balancing method are suitable for systems, which are not suitable for being shut down, and then economic losses caused by the shutdown are reduced.

Owner:SHANGHAI JIAO TONG UNIV

Explosion-proof and anti-skid emergency wheel for motor vehicle

The invention discloses an explosion-proof and anti-skid emergency wheel for a motor vehicle. The wheel consists of a tire, an explosion-proof emergency wheel, an inner wheel hub seat, explosion-proof emergency wheel retaining semicircular keys, an emergency wheel conical surface mounting steel bowl, an anti-skid spacer, a retaining nut, an outer wheel hub seat, a charging connector, an overpressure control valve, a minimum air pressure alarm and an anti-skid device, wherein the explosion-proof emergency wheel retaining semicircular keys are arranged in three semicircular key grooves of the outer wheel hub seat; the explosion-proof emergency wheel is built in an emergency wheel conical surface mounting groove on the outer wheel hub seat through the explosion-proof emergency wheel retaining semicircular keys, and the anti-loose spacer and the retaining nut are arranged; the charging connector, the overpressure control valve and the minimum air pressure alarm are arranged on the outer wheel hub seat; and the inner wheel hub seat is arranged on the outer wheel hub seat. In the wheel, when a tire burst accident is suddenly encountered, the tire is instantly substituted by the emergency wheel to run so as to avoid accidents; the anti-skid device can prevent the accidents from being produced by skidding of the tire; tire demounting equipment is not required for repairing the tire; resources and energy are saved; and pollution emission is reduced.

Owner:刘红旗

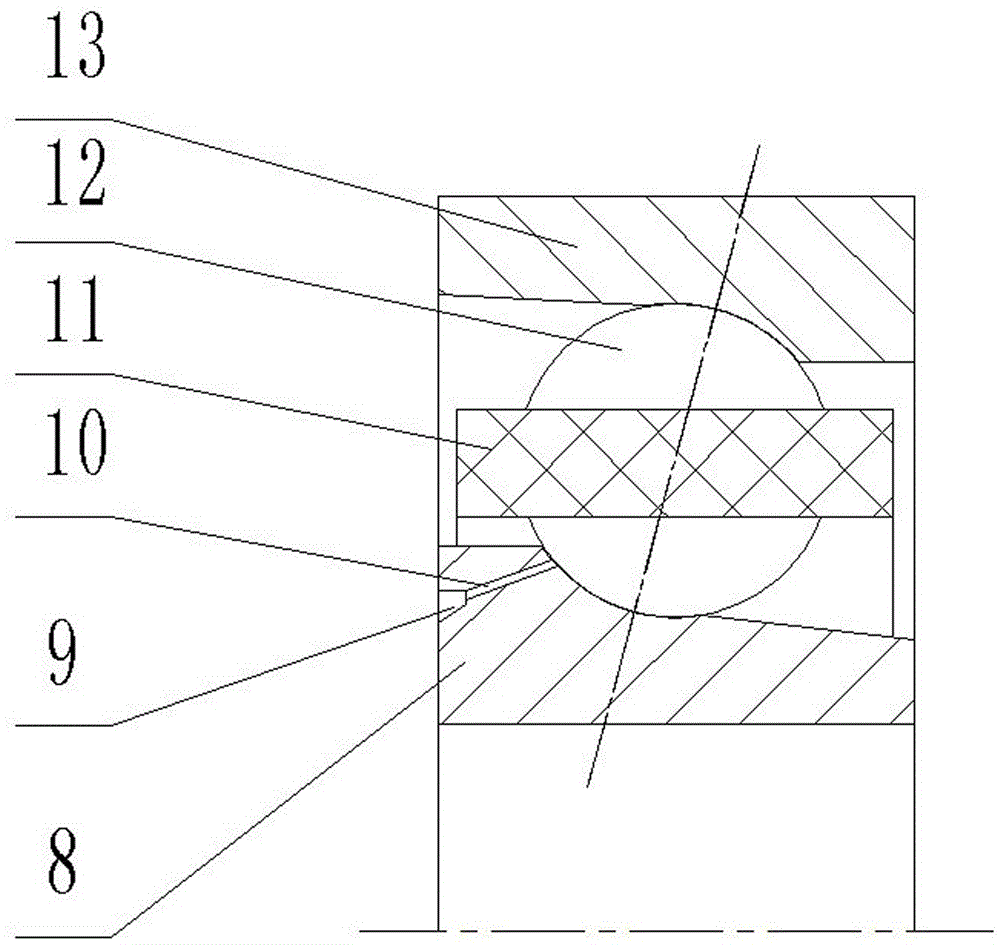

Insulation structure of friction specimen holder and apparatus body in current-carrying frictional wear experiment

ActiveCN101329234AThe overall thickness is thinLight in massMachine part testingInvestigating abrasion/wear resistanceElectricityWear testing

The invention relates to an insulation structure of a friction disc and an equipment body in a current-carrying friction wear testing machine. The friction disc is fixedly assembled at the external end of a transmission shaft; the transmission shaft is rotatablely assembled on the equipment body; a disconnecting surface is arranged on the transmission shaft of the exposed section at the internal side of the fixed assembly position with the friction disc; the disconnecting surface divides the transmission shaft into a left transmission shaft body section, a right transmission shaft body section and an end section; the left transmission shaft section and the right transmission shaft section have the same axis line and are fixed into a whole; electric insulated coating is coated on the disconnecting surface of at least one side. The insulated coating generally has thin thickness, light weight, large hardness, good rigidity and is not easy to deform when bearing the pressure; as the insulation type between the testing part and the machine body of a current-carrying testing machine, the insulation structure of the invention meets the insulation performance requirement at the high speed, improves the rotation precision and ensures the dynamic balance during the high-speed rotation process simultaneously, avoids the infidelity of the test results and correctly reflects the performance of the test objects.

Owner:HENAN UNIV OF SCI & TECH

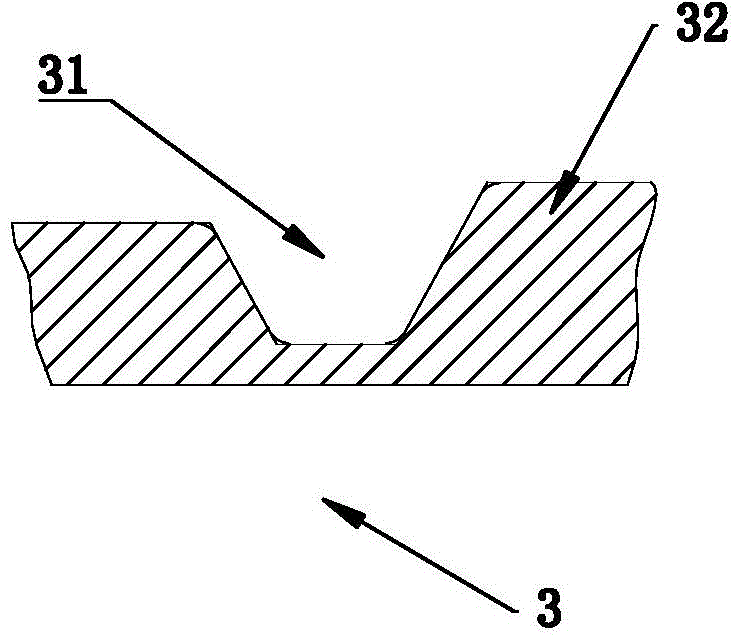

Multi-tool path layered and adjustable milling cutter

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

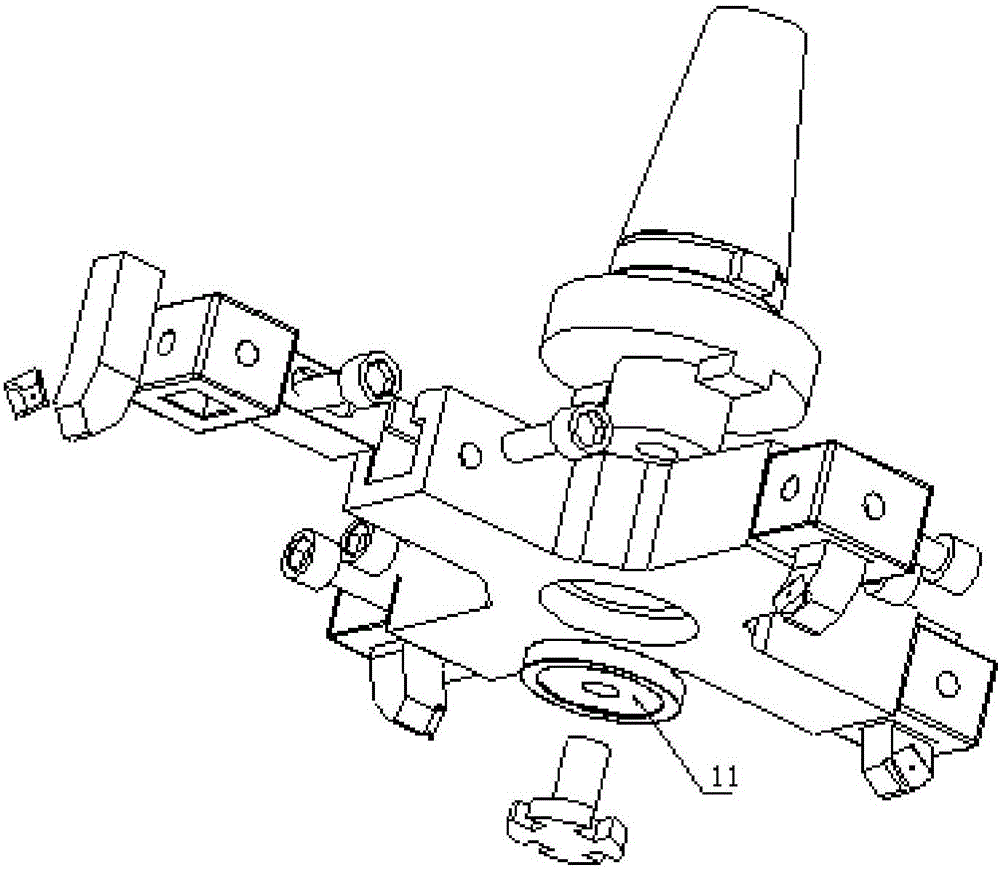

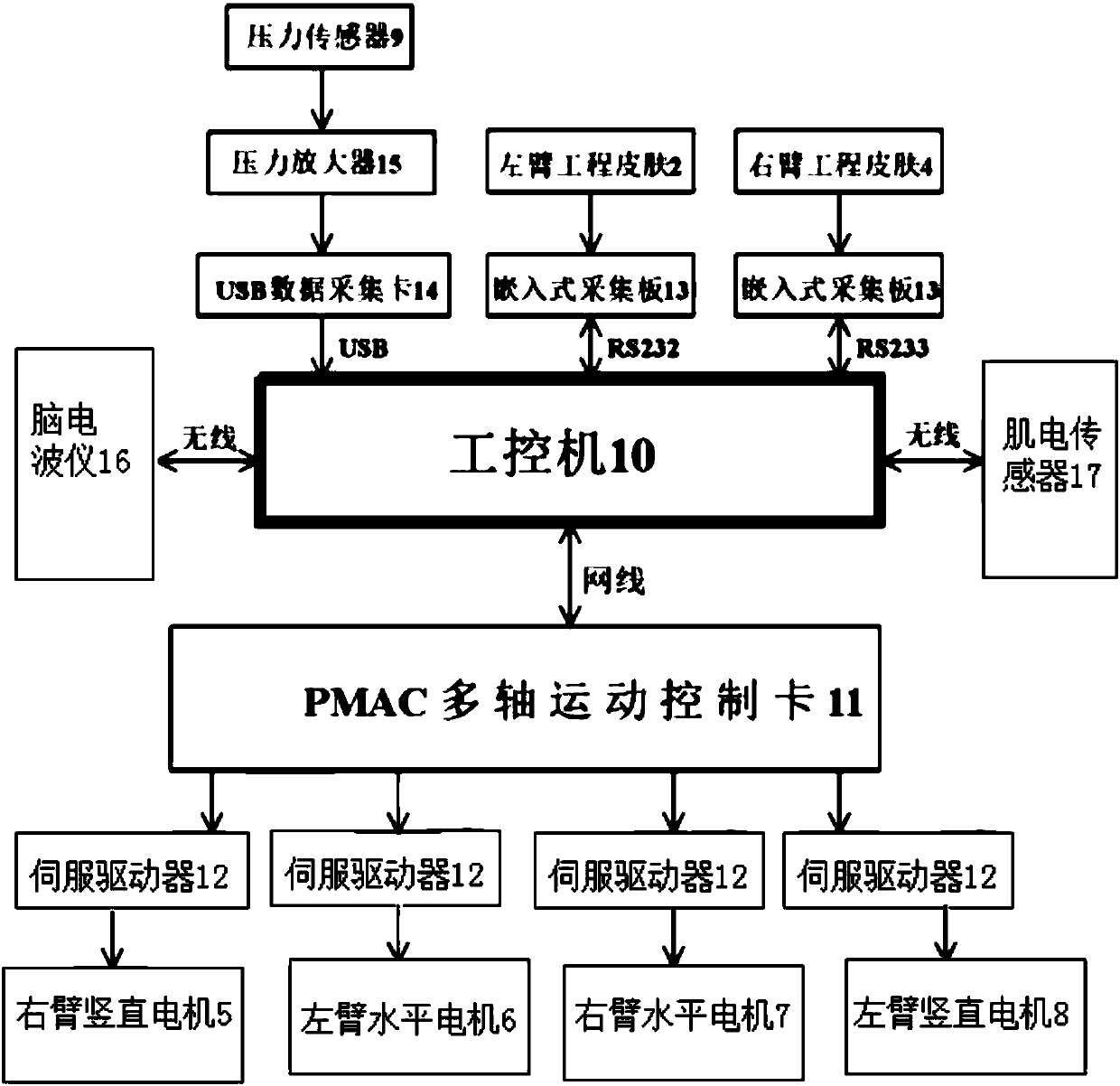

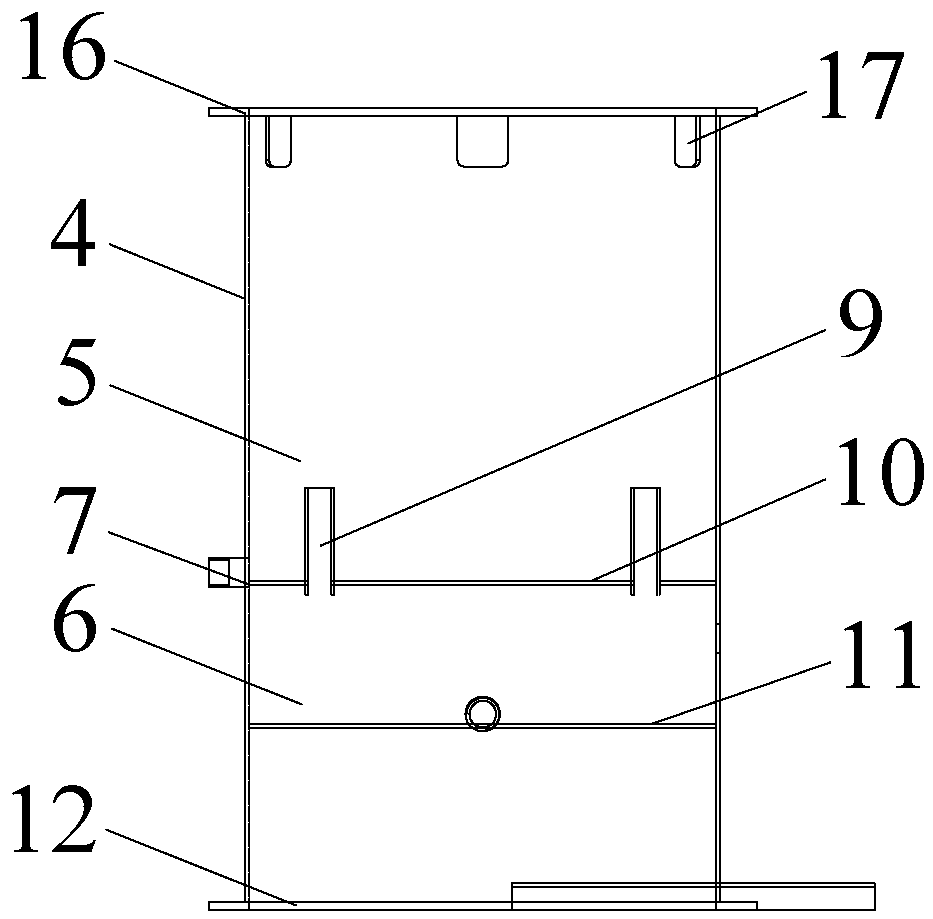

Double-arm moving and taking robot simulation experiment platform and testing method thereof

ActiveCN107825469AVerify reliabilityEnsure dynamic balanceManipulatorTotal factory controlHuman bodyVertical plane

The invention relates to a double-arm moving and taking robot simulation experiment platform and a testing method thereof. The platform comprises a tail end executing mechanism, a control system, a brain wave instrument and a myoelectricity sensor, and the tail end executing mechanism is composed of a left arm and a right arm, wherein the axis of the left arm is parallel to the axis of the right arm, the left arm and the right arm can do the plane movement in the vertical plane perpendicular to the axis, in other words, each arm has two freedom degrees in the vertical plane, and the two freedom degrees include the up-down horizontal movement and the left-right horizontal movement. The two-freedom-degree horizontal movement of the two arms in the vertical plane perpendicular to the axis isexecuted through corresponding motors. Left arm engineering skin and right arm engineering skin are attached to the left arm and the right arm correspondingly, and the front positions and the rear positions of the two arms are provided with pressure sensors used for detecting the pressure borne by the arms. The control system comprises an industrial personal computer and a PMAC. According to the method, under the situation that different human body model parameters are input, the double arms can meet the requirements of transversely-embraced human bodies for dynamic balance, the safety degree,the comfort degree and the like.

Owner:HEBEI UNIV OF TECH

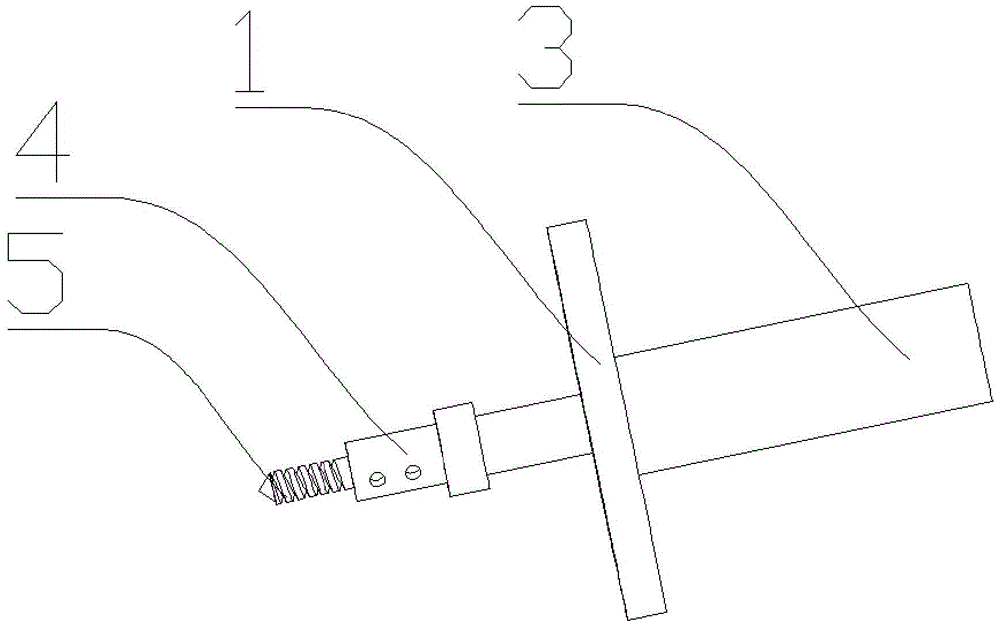

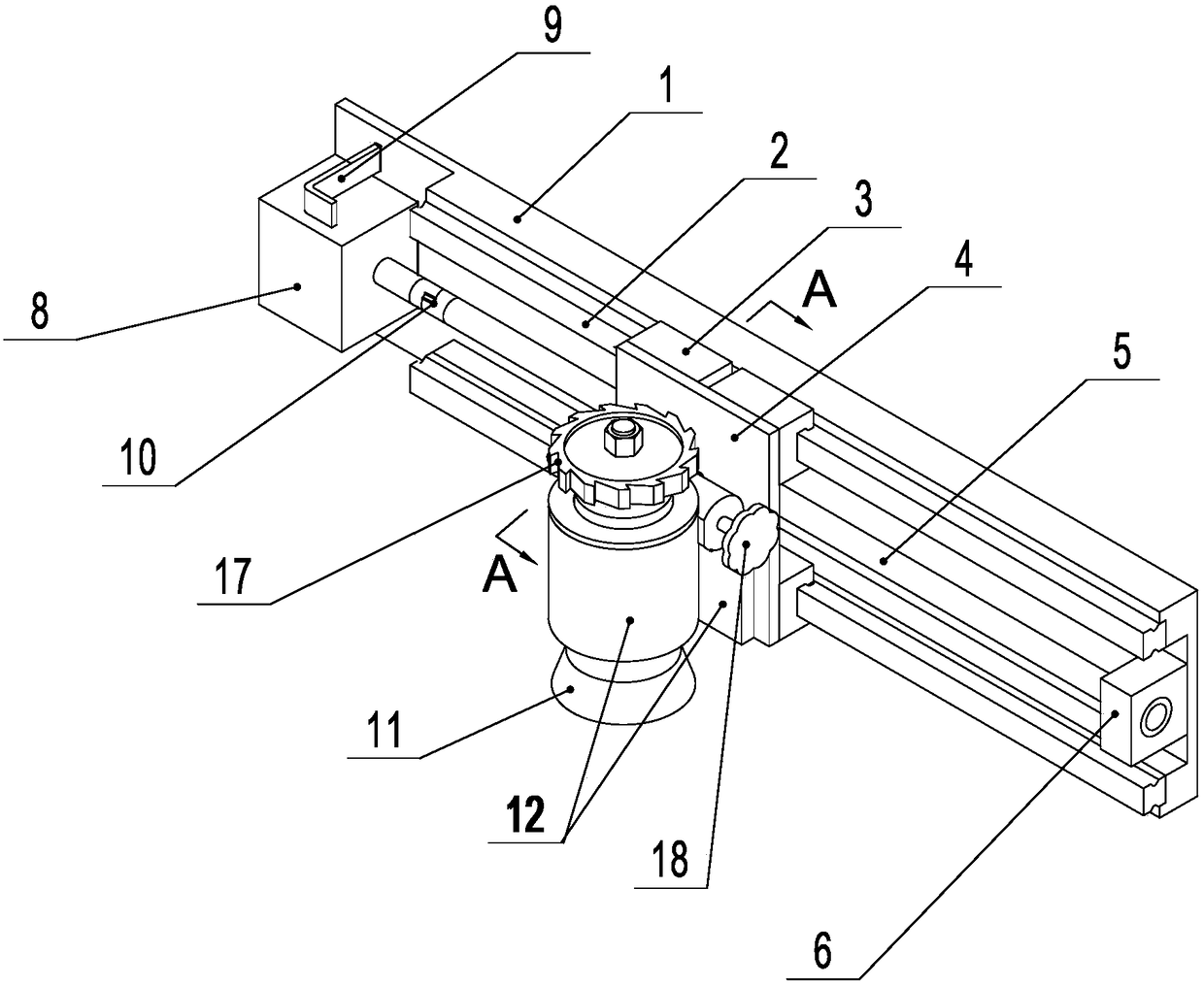

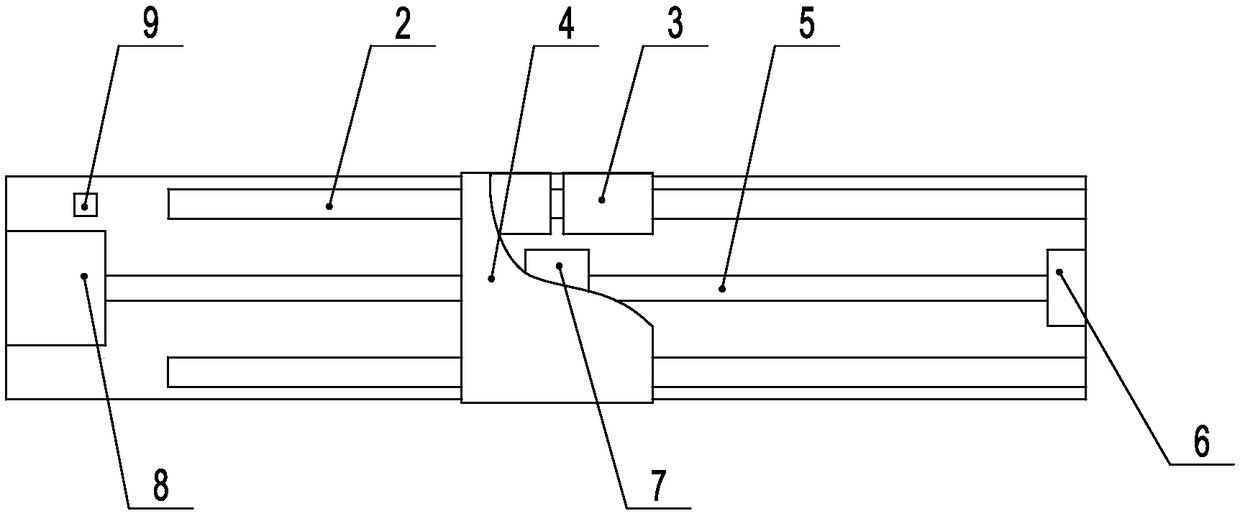

Silage harvester automatic knife sharpening device

The invention provides a silage harvester automatic knife sharpening device which is characterized by comprising a reciprocating motion mechanism and a knife sharpening feeding mechanism, wherein the reciprocating motion mechanism comprises a guide rail base, two guide rails horizontally installed on the guide rail base, paired sliding blocks installed on the two guide rails respectively, a sliding block plate for fixedly connecting the paired sliding blocks to form a whole body, a lead screw, a lead screw supporting seat, a screw nut, a motor and a pawl; the knife sharpening feeding mechanism comprises a knife sharpening shell, a knife grinder, a worm wheel, a worm gear, a shaft, a feeding sleeve and a ratchet and is connected with the sliding block plate of the reciprocating motion mechanism through the knife sharpening shell; before a knife is sharpened, the knife grinder is in contact with a moving blade of a rotary knife type cutter; and during knife sharpening, the screw nut drives the knife grinder to carry out reciprocating motion under the driving of the motor, and thus a cutting edge of the moving blade on a drum is sharpened again. According to the silage harvester automatic knife sharpening device, the structure design is simple and practical, the manufacturing difficulty and the cost are lowered, operation control is liable, and the working efficiency and the operation quality are improved.

Owner:SHANDONG UNIV OF TECH

Ring die pelleter

ActiveCN101828756AEven by forceReduce vibrationFeeding-stuffFood shapingCantileverMechanical engineering

The invention discloses a ring die pelleter belonging to the field of the feed machinery. A pressing roll assembly of the ring die pelleter is wholly arranged in a ring die; the pressing roll assembly comprises three pressing roll supporting shafts, a front plate and a rear plate; the three pressing roll supporting shafts are distributed in a triangle shape; two ends of each pressing roll supporting shaft are respectively supported on the front plate and the rear plate, and each pressing roll supporting shaft is locked by pressing roll locking nuts outside the front plate; one of the three pressing roll supporting shafts is a pressing roll eccentric shaft; connecting pins are evenly distributed on the rear end surface of the rear plate; the end of a main shaft, which is the same as that of the pressing roll assembly, is provided with connecting discs; the connecting discs are provided with pin slots which are respectively matched with the connecting pins; and the connecting pins are respectively clamped in the corresponding pin slots of the connecting discs. The main shaft of the ring die pelleter only supports a rotor assembly and restricts the pressing roll assembly from rotating along with the rotor assembly, and the rotor assembly only outputs power to the ring die, thus the load of the cantilever for the main shaft, the vibration and the damage of the bearing and other components are reduced, and less power is consumed.

Owner:扬州华美知识产权事务有限公司

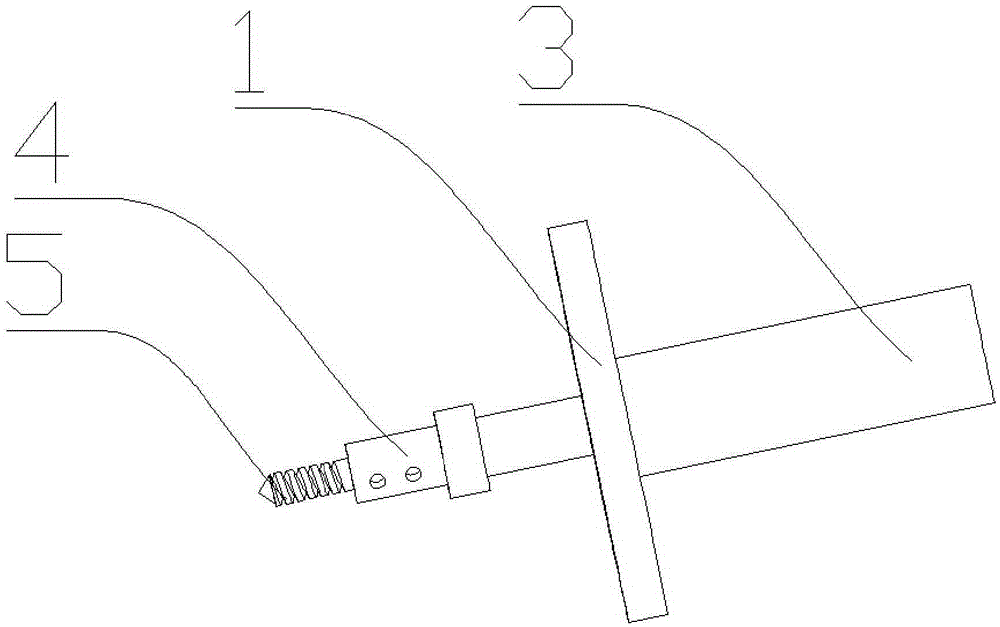

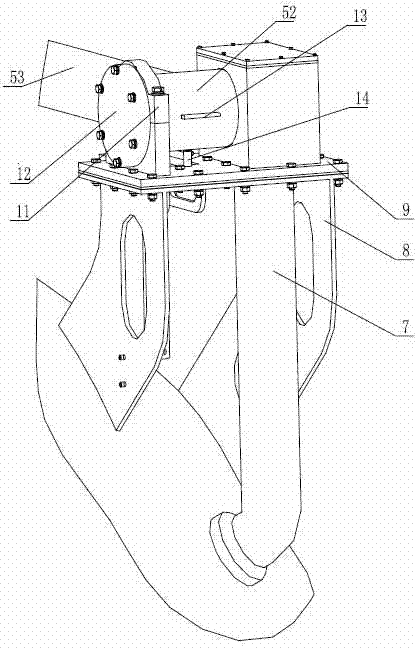

Wind driven generator end cover broken bolt dismounting device and dismounting method thereof

ActiveCN105345743AImprove maintenance efficiencyReduce maintenance costsMetal-working hand toolsWind forceEngineering

The invention discloses a wind driven generator end cover broken bolt dismounting device. A bearing is arranged in the center of a chassis; a rotating shaft rotates around the periphery of the chassis, and fits a bearing; a connecting end fitting a dismounting component is arranged at one end of the rotating shaft; the dismounting component comprises a drilling component for drilling a blind hole in a broken bolt, a tapping component for tapping the blind hole as a thread hole, and a screw rod component fitting the thread hole; the screw rod component comprises a screw rod; and the thread rotating direction of the screw rod is opposite to the thread rotating direction of the broken bolt. The dismounting device has the following beneficial effects: the broken bolt is drilled through the drilling component; then, the drilled hole is tapped; the screw rod component is connected with the tapped thread hole; and as the thread rotating direction of the screw rod is opposite to the thread rotating direction of the broken bolt, the broken bolt can be taken out through reversely rotating the rotating shaft, the operation is convenient and fast, the damage of a traditional thread and the dismounting of an outer end cover are not needed, the repair efficiency is greatly improved, and the repair cost is reduced.

Owner:天赋新能源科技(南通)有限公司

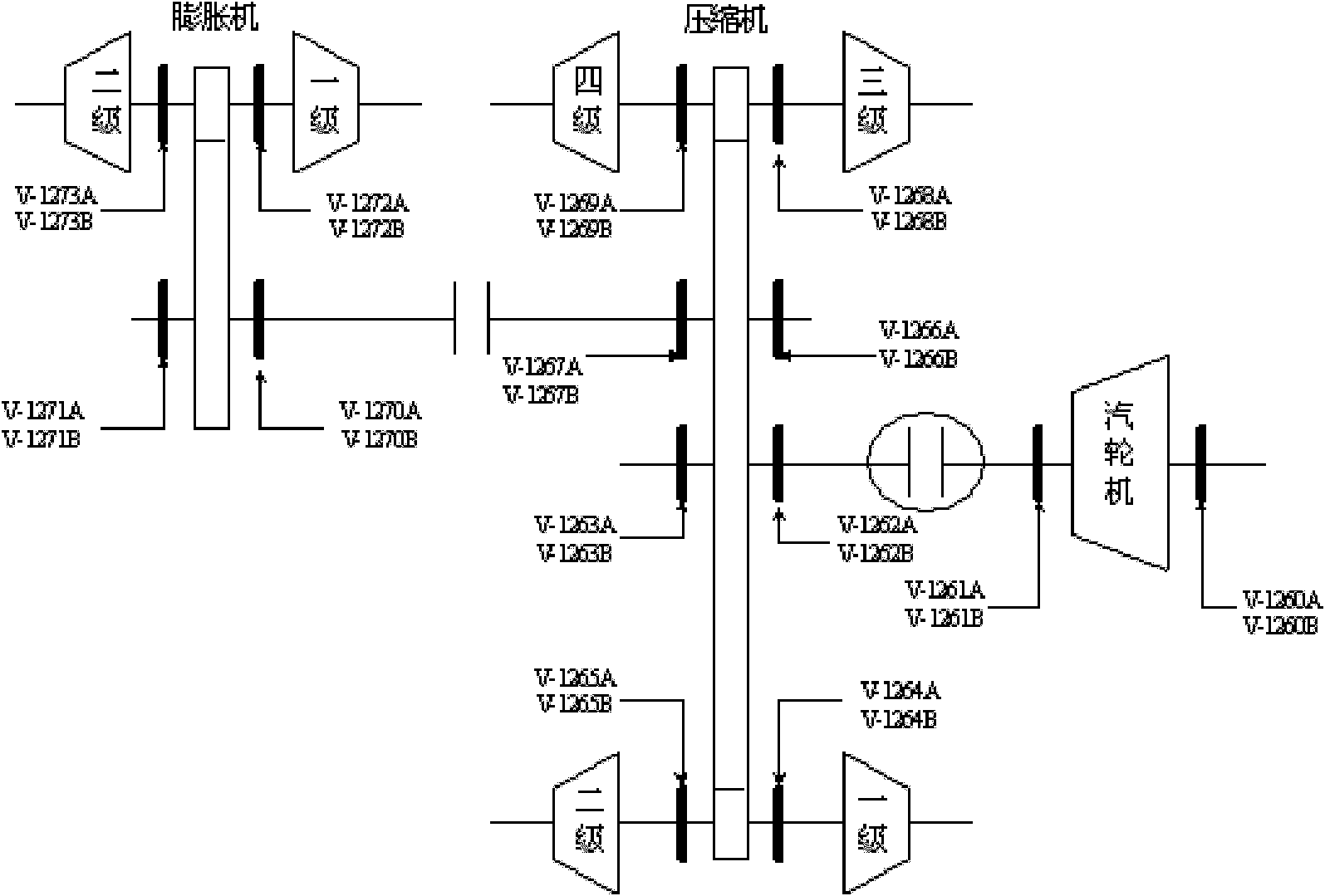

Mixing dynamic balance method for crossing outer rotor

InactiveCN101964565AEnsure dynamic balanceImprove balanceMechanical energy handlingLeast squaresEngineering

The invention discloses a mixing dynamic balance method for crossing an outer rotor, which comprises the steps: carrying out a dynamic balance work under the condition of covering by selecting a suitable balance surface crossing the outer rotor; utilizing a mixing dynamic balance method, i.e. a least-square influence coefficient balance method and a holographic dynamic balance technology, to calculate the balance adding weight, wherein the least-square influence coefficient balance method can enable the quadratic sum of the residual oscillation values of each measuring point to be minimum, and the holographic dynamic balance technology can combine a holographic spectrum principle and a flexible rotor dynamic balance technology; and fully utilizing the structure information and the vibration information of a set to enhance the precision and the efficiency of the dynamic balance on site. The mixing dynamic balance method for crossing the outer rotor can rapidly and effectively carry out the dynamic balance on the rotor and has the advantages of high speed and high accuracy.

Owner:XI AN JIAOTONG UNIV

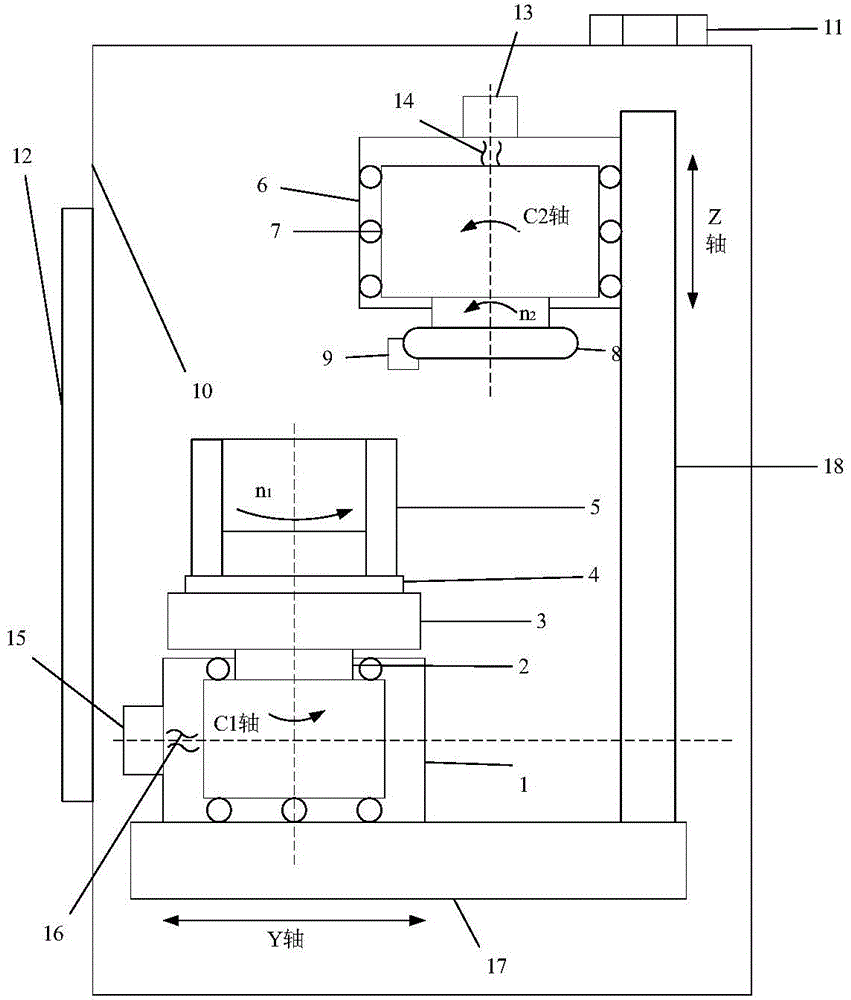

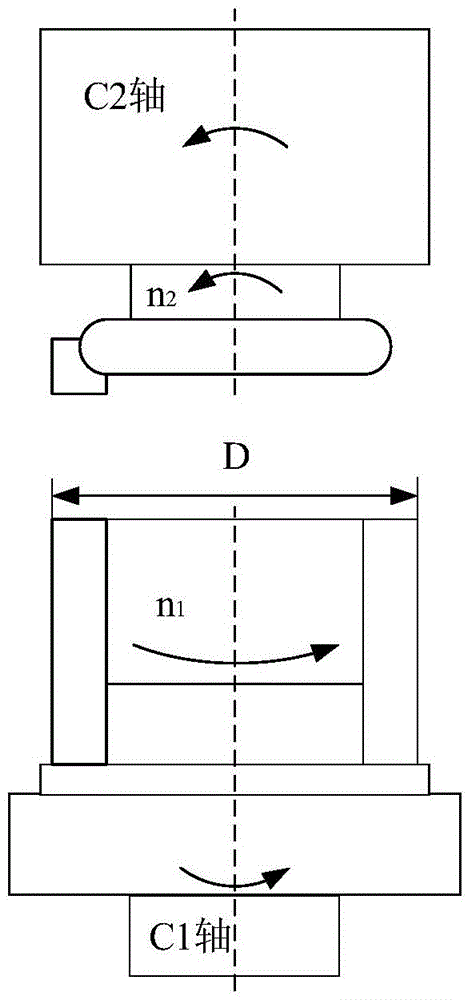

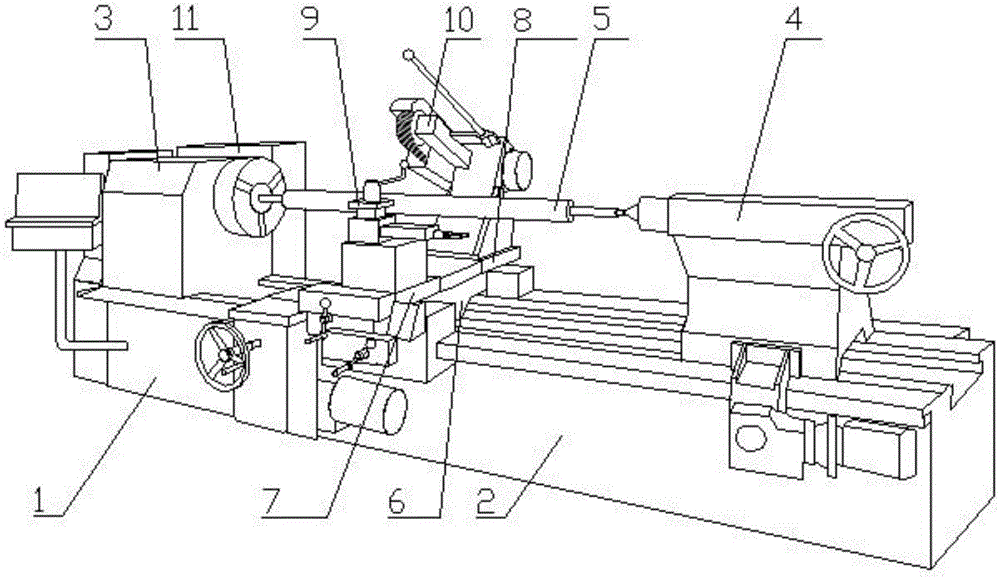

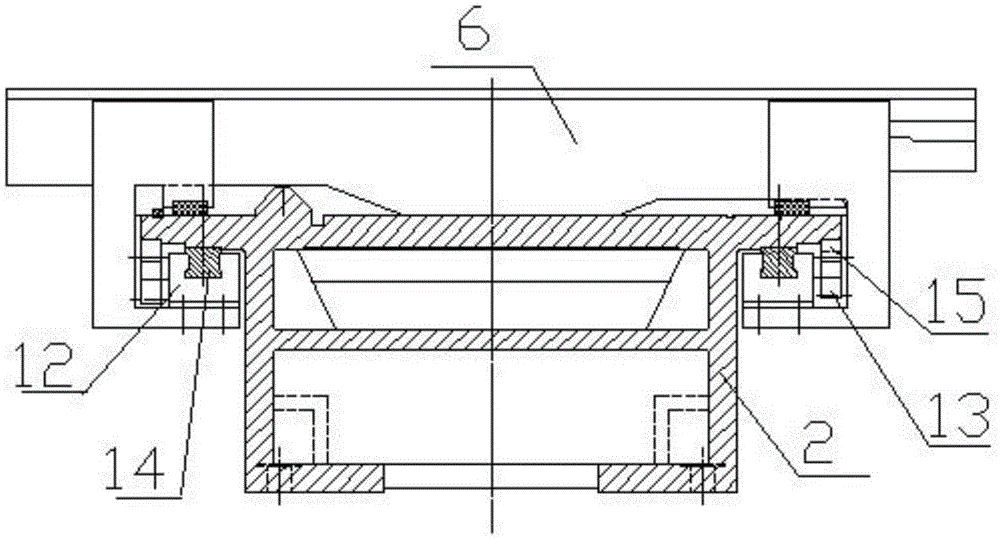

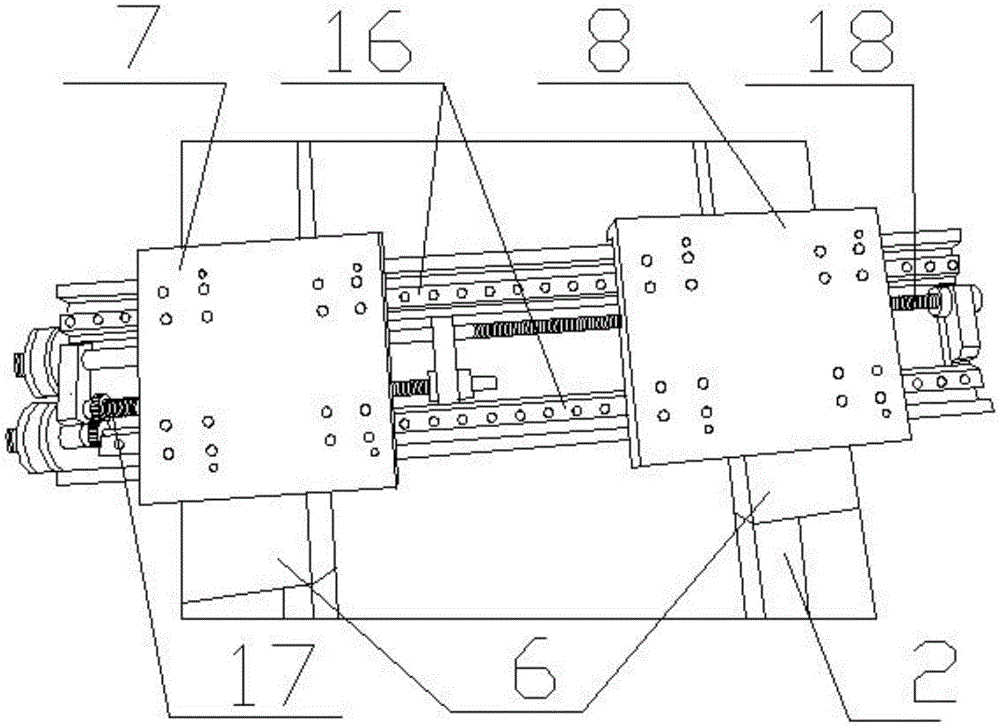

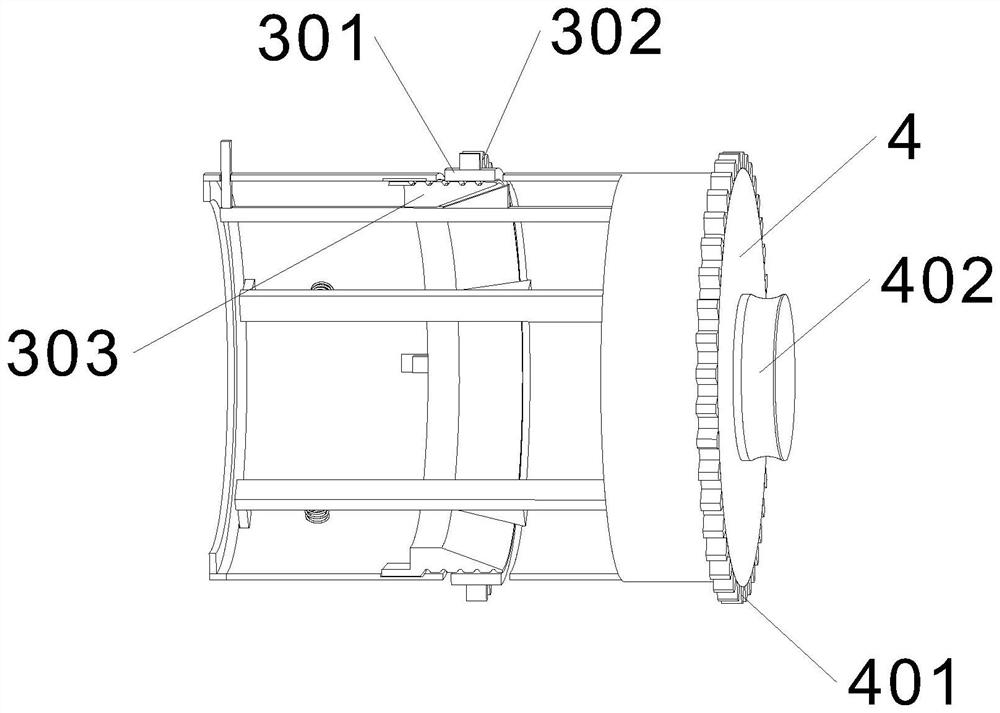

Vertical turn-milling composite machining experiment table

InactiveCN104128797AEnsure dynamic balanceRelative cutting speed increaseFeeding apparatusOther manufacturing equipments/toolsUltra high speedEngineering

The invention discloses a vertical turn-milling composite machining experiment table which comprises a base, a stand column, a workpiece motorized spindle movable working table, a workpiece motorized spindle, a workpiece rotating type working table, a Y-direction motor, a Z-direction motor, a Y-direction lead screw nut moving mechanism, a Z-direction lead screw nut moving mechanism, a tool motorized spindle movable working table, a tool motorized spindle and a cutting mechanism. During work, the rotating direction of the tool motorized spindle is opposite to the rotating direction of the workpiece motorized spindle. By means of the vertical turn-milling composite machining experiment table, ultra-high-speed milling, turning and boring can be achieved.

Owner:XI AN JIAOTONG UNIV

Sand mould structure pouring body of automobile power system crankshaft shell mold

PendingCN107309399AFacilitated coagulation sequenceSand surface quality optimizationFoundry mouldsFoundry coresCasting moldMechanical engineering

The invention provides a sand mould structure pouring body of an automobile power system crankshaft shell mold. The sand mould structure pouring body comprises sand mould bodies, casting mold cavities, dead heads, ingates, a cross gate, a sprue, a sprue cup and chilling blocks; the two casting mold cavities are symmetrically arranged on the sand mould bodies, one dead head is communicated to the upper portion of each casting mold cavity, the chilling blocks are placed at the overheating positions of the casting mold cavities, and the casting mold cavities are communicated with the ingates through bottom pouring type connection; and the ingates are communicated with the one cross gate, the cross gate is communicated with the sprue, and the sprue is connected with the sprue cup. According to the sand mould structure pouring body, the iron pattern sand coating technology is adopted for replacing wet molding sand technology for producing a crankshaft, and key product features such as product materials, sizes and dynamic balance are effectively guaranteed; and meanwhile, the product appearance is improved, the product quality is improved, the polishing treatment working amount is reduced, the waste rate is reduced, and the obvious economic benefit is obtained.

Owner:上海圣德曼铸造海安有限公司

Method for machining hot-mounted dam roller

ActiveCN107470854ASolve the problem that the balance accuracy is not highAvoid product quality defectsInterference fitNumerical control

The invention relates to a method for machining a hot-mounted dam roller. The method for machining the hot-mounted dam roller comprises the steps of machining of a roller cylinder, machining of spindle heads and assembling of the roller cylinder and the spindle heads; assembling of the roller cylinder and the spindle heads comprises the following steps that the spindle heads and the roller cylinder are in interference fit to obtain the dam roller; unbalance amount of the dam roller is detected, center offset amount and the offset direction of the dam roller are calculated, when the unbalance amount is larger than 10 g based on a balance amount, a double-four-jaw chunk clamping device on a lathe is adopted to conduct eccentric borrowing on the dam roller, outer circle turning is conducted to remove the unbalance amount; and finish turning is conducted on a second outer circle of the roller cylinder and eighth outer circles, ninth outer circles and tenth outer circles of the spindle heads by adopting a numerical control lathe turning. The method for machining the hot-mounted dam roller has the advantage of high balance precision.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

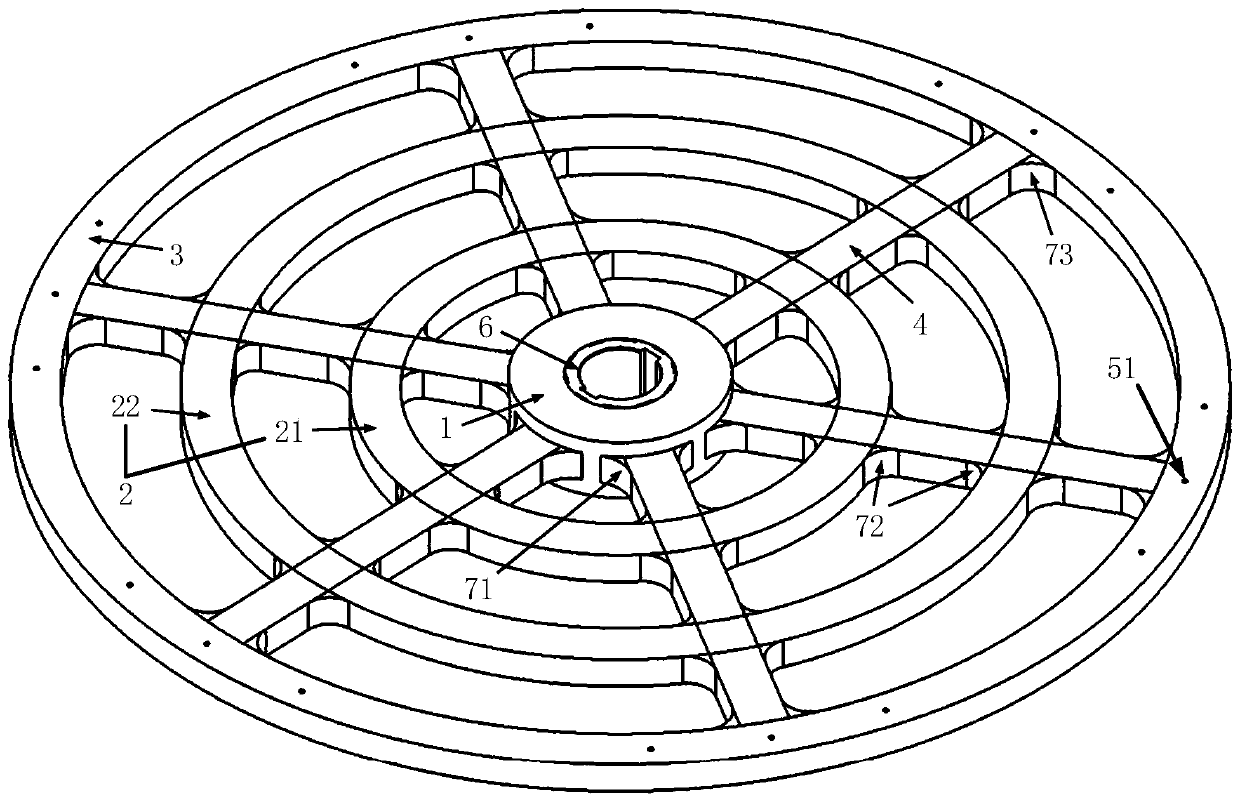

Foam-sandwich carbon fiber flywheel and manufacturing method thereof

ActiveCN111438962AMeeting Torsional Stiffness RequirementsIncreased torsional stiffnessFlywheelsBalloon aircraftsFiberSolid structure

The invention relates to the technical field of aerostat accessory equipment, and discloses a foam-sandwich carbon fiber flywheel and a manufacturing method thereof. The foam-sandwich carbon fiber flywheel comprises a flywheel inner ring, a flywheel middle ring and a flywheel outer ring which are coaxially arranged at intervals from inside to outside in sequence, and further comprises a pluralityof spokes which are arranged between the flywheel inner ring and the flywheel outer ring in the radial direction of the flywheel outer ring; the spokes are evenly distributed in the circumferential direction of the flywheel outer ring; the flywheel inner ring is of a carbon fiber composite material solid structure; and the flywheel middle ring, the flywheel outer ring and the spokes are of a carbon fiber composite material hollow structure, and the inside of the carbon fiber composite material hollow structure is filled with foam core materials. The flywheel further comprises a plurality of balancing weights connected with the flywheel outer ring, and the balancing weights are evenly distributed in the circumferential direction of the flywheel outer ring. The foam-sandwich carbon fiber flywheel has excellent mechanical property and realizes the design requirement that the weight of a flywheel body structure is reduced to the greatest extent; and the design of filling of foam core effectively improves the torsional rigidity of the flywheel in the process of rotation.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

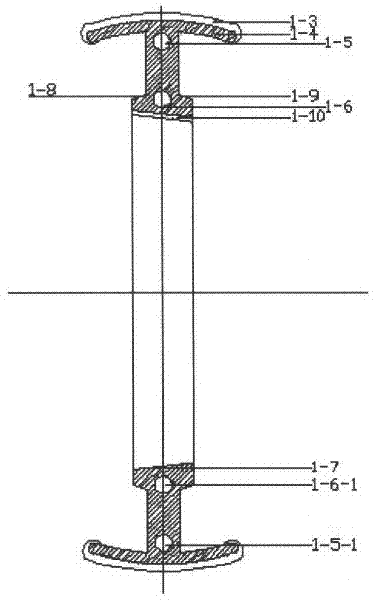

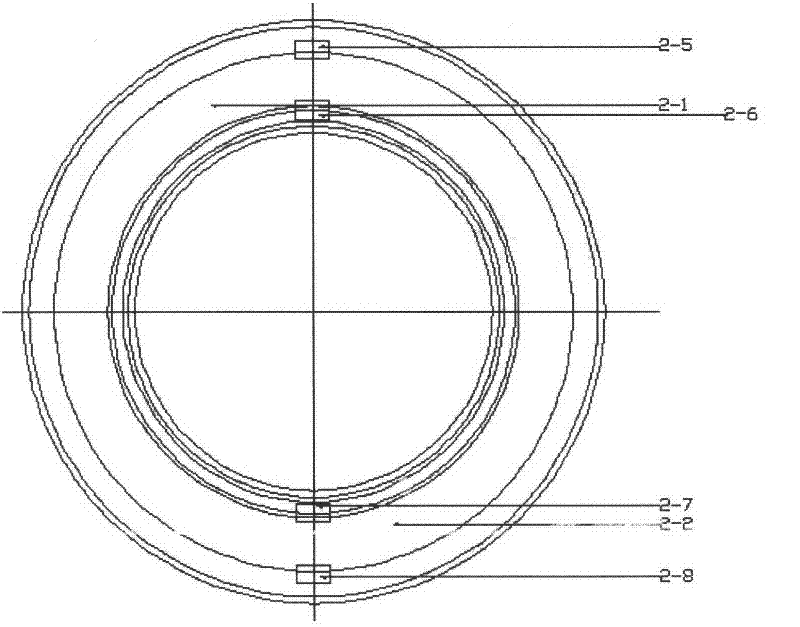

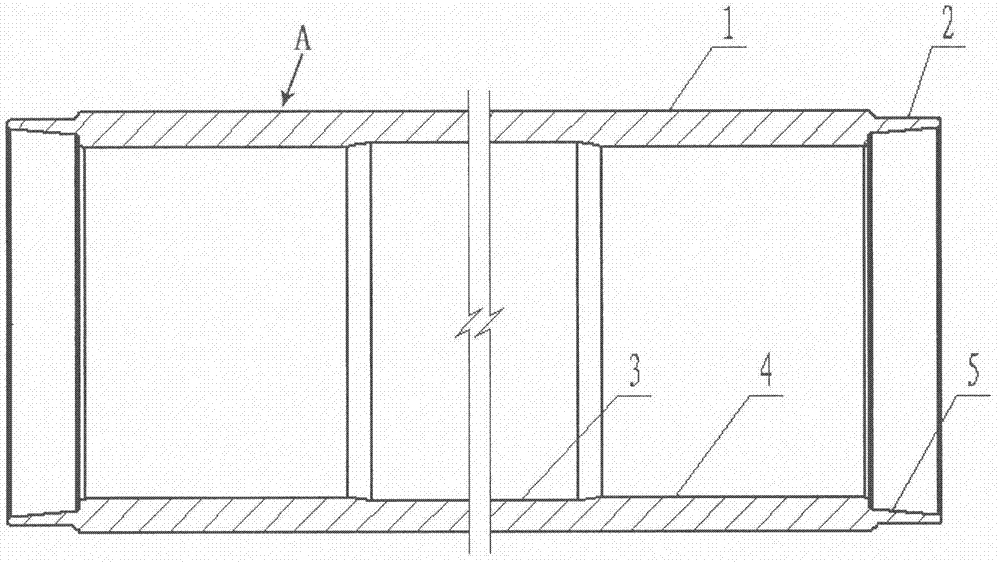

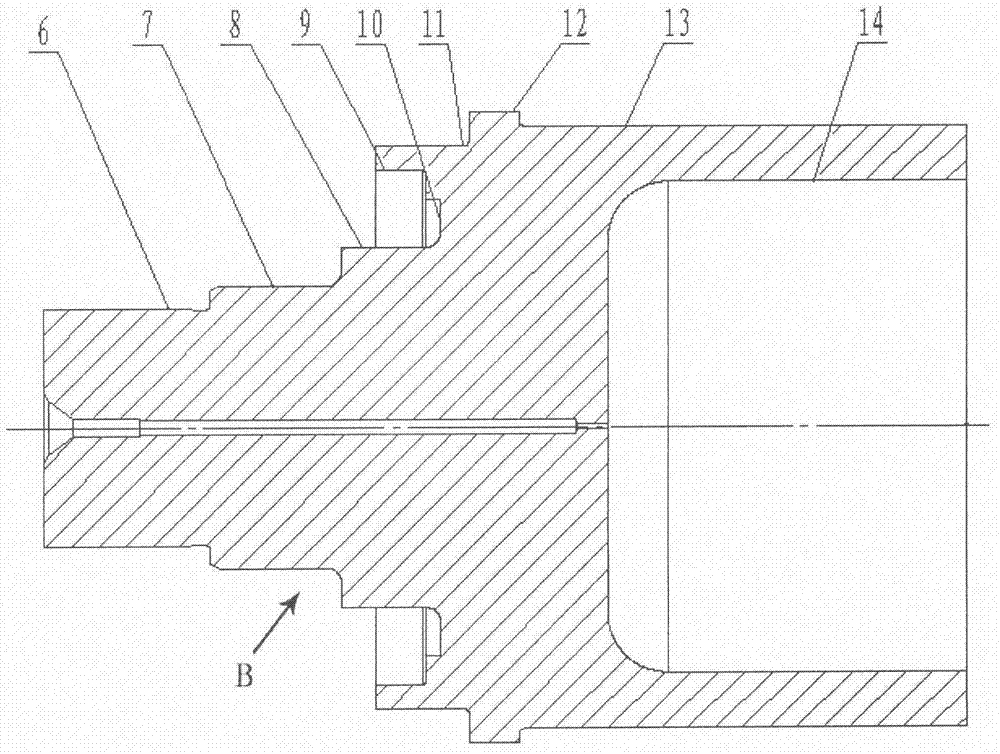

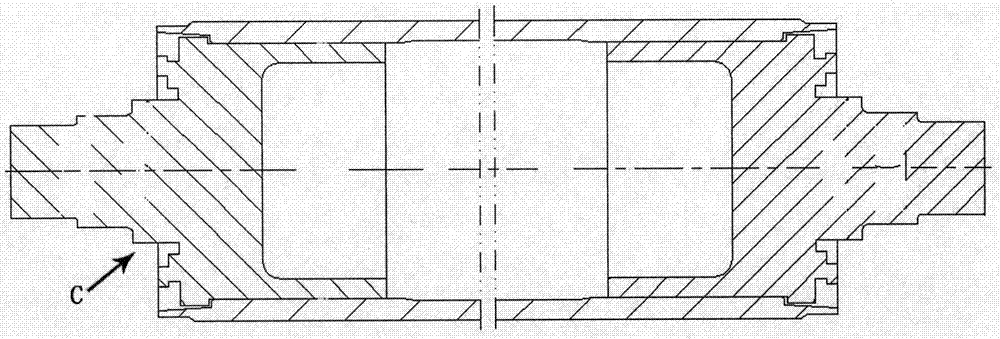

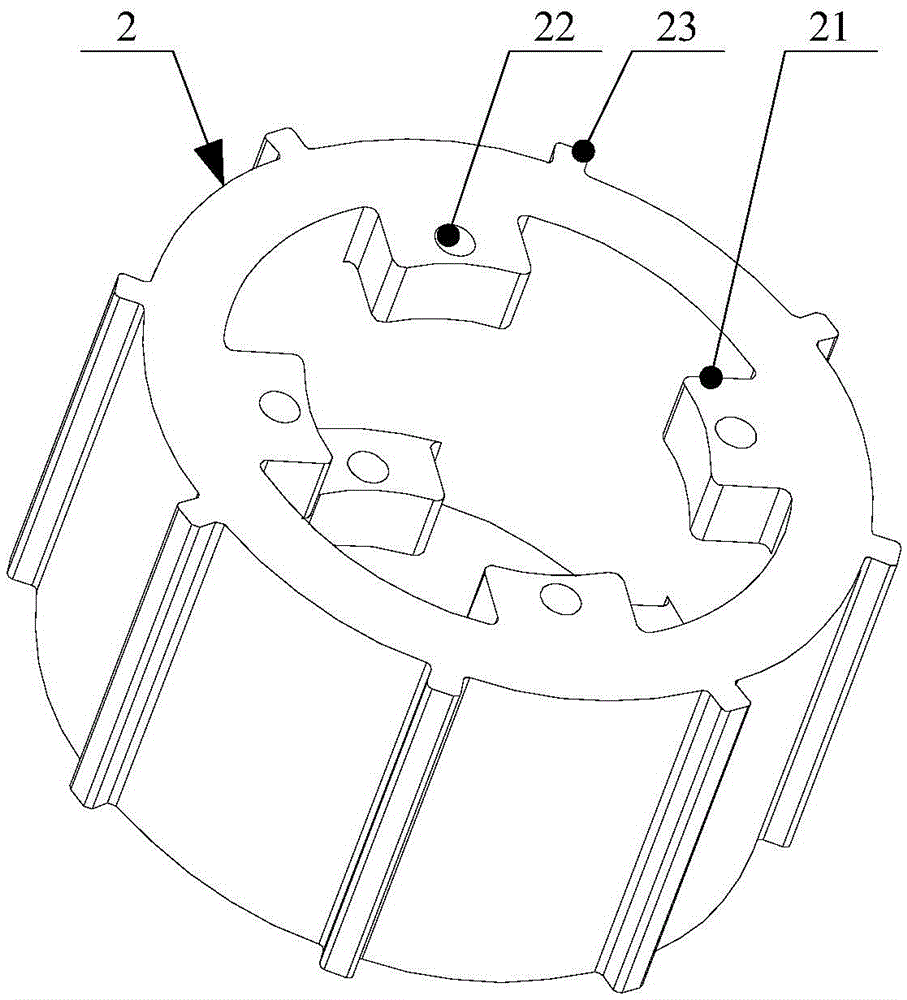

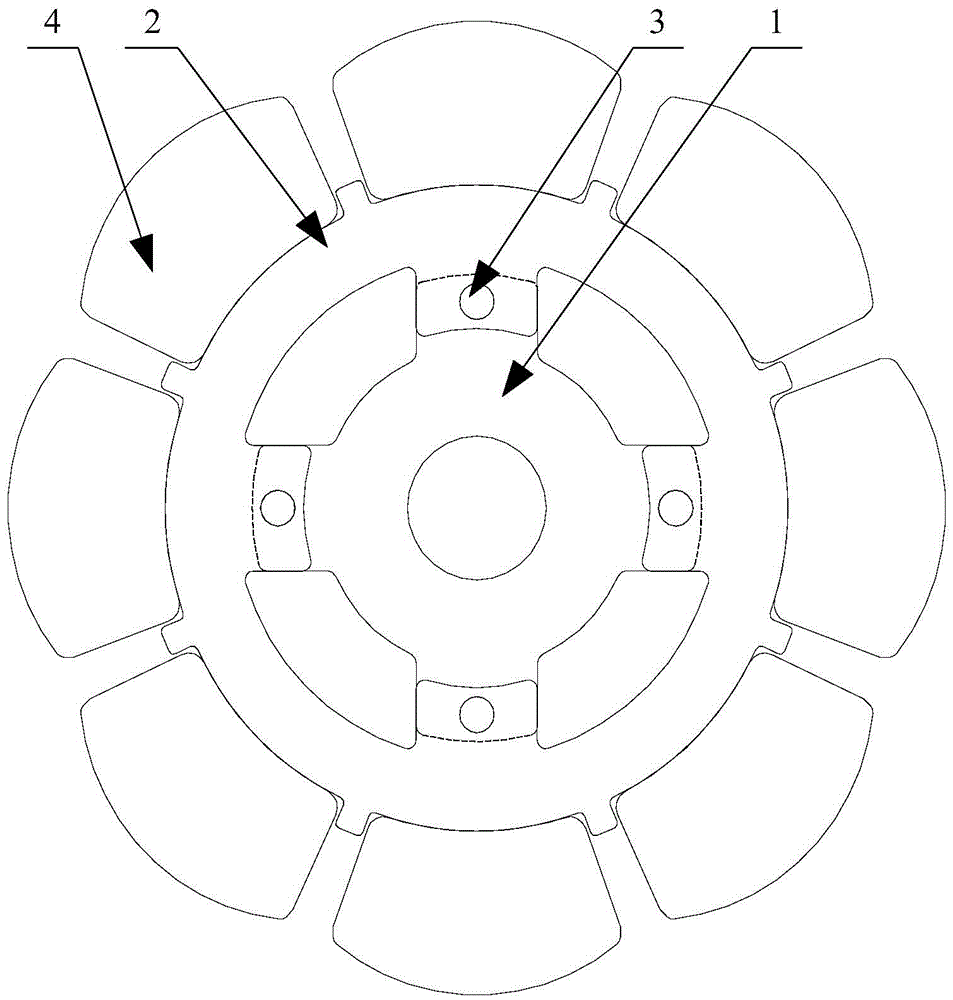

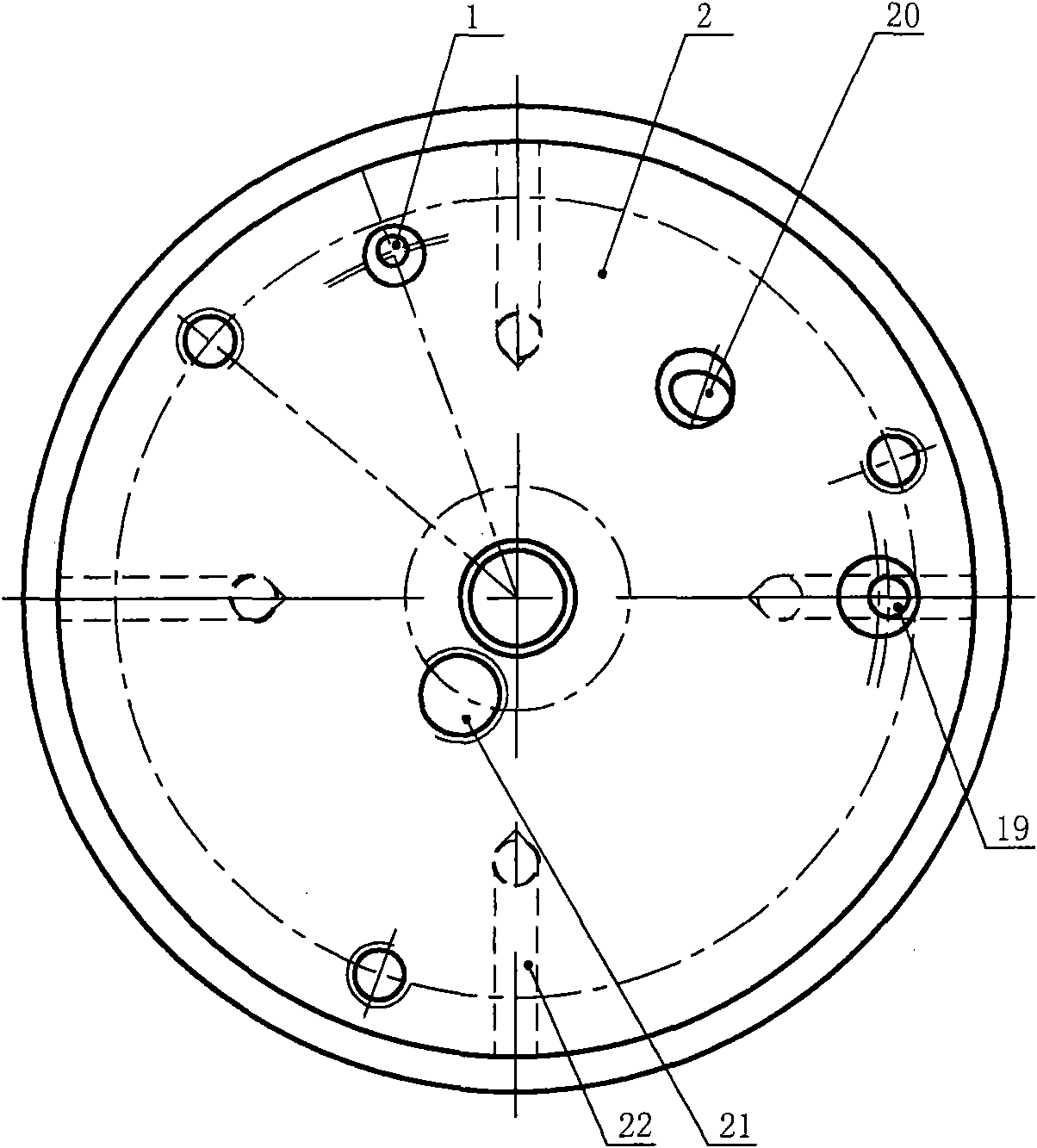

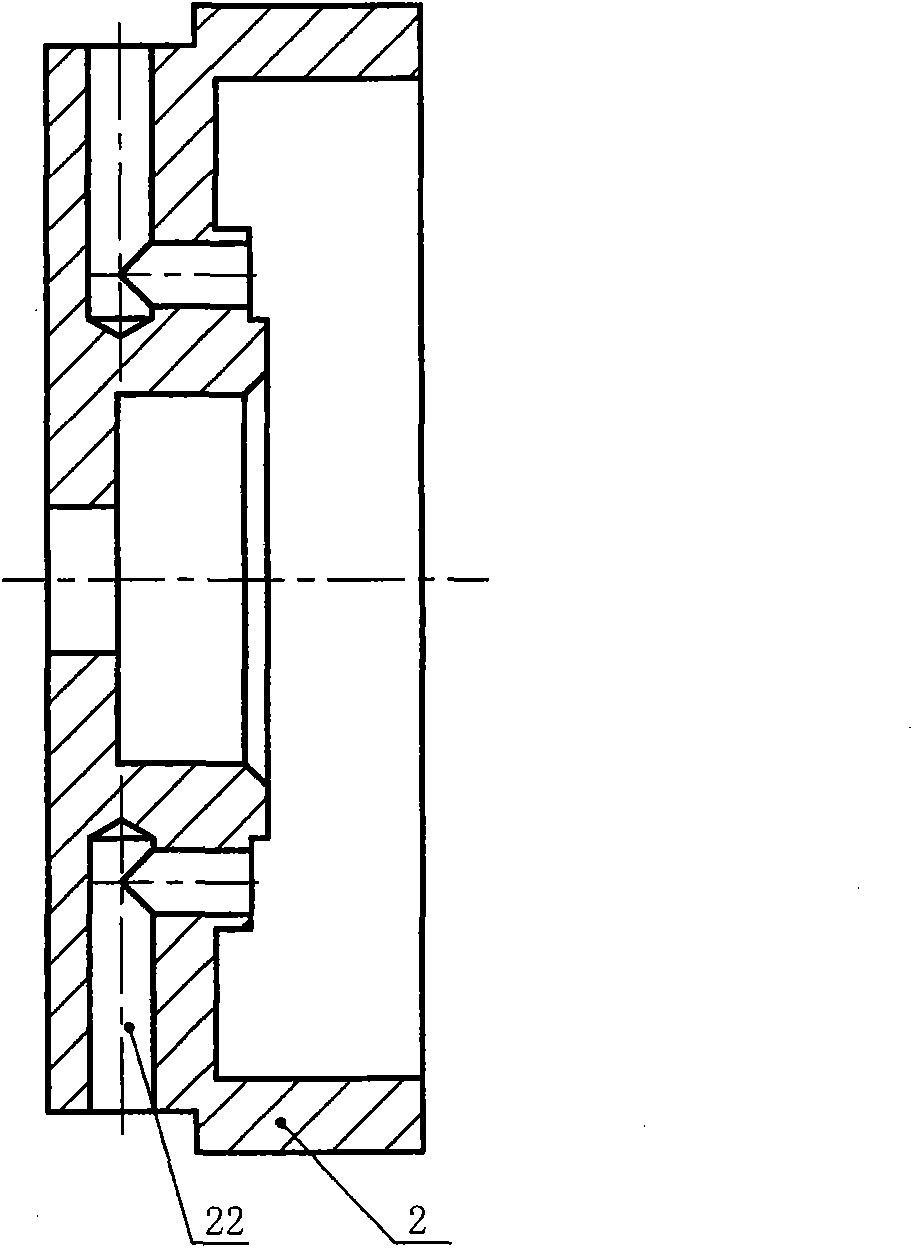

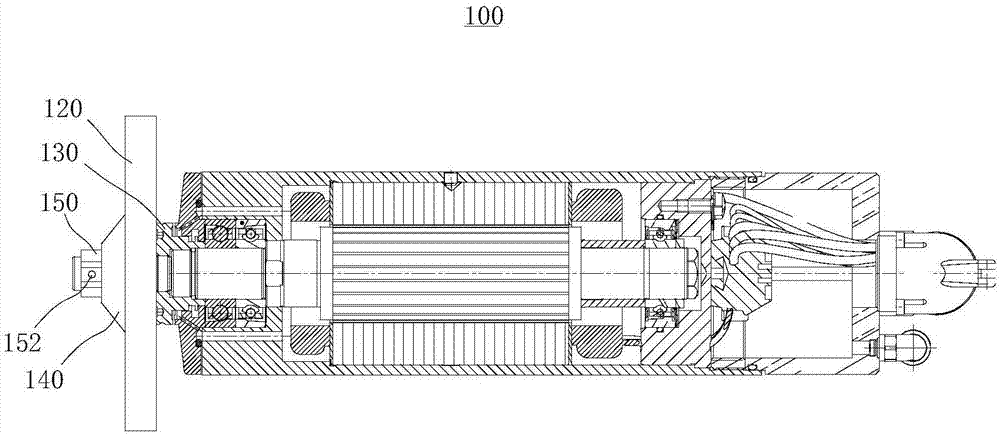

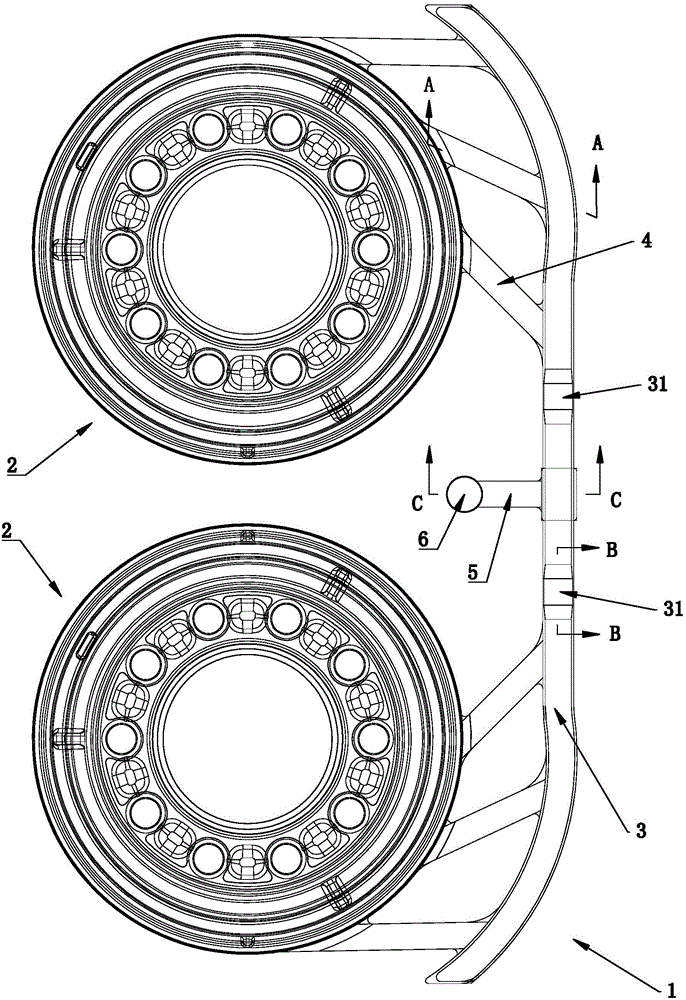

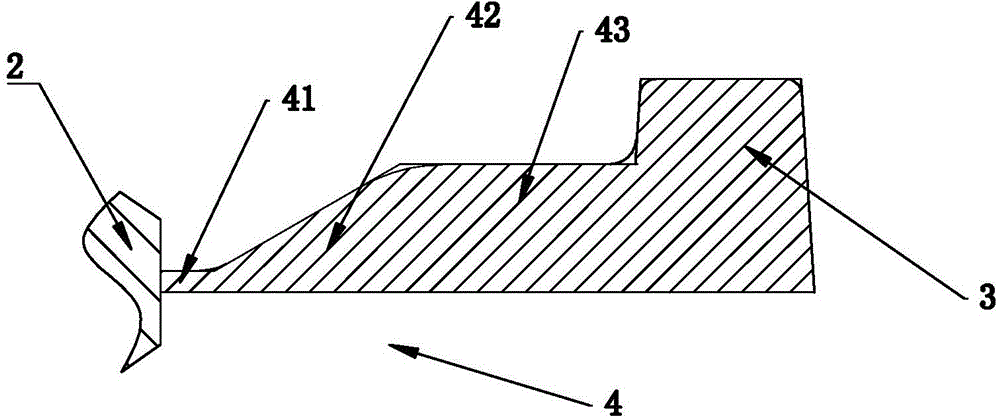

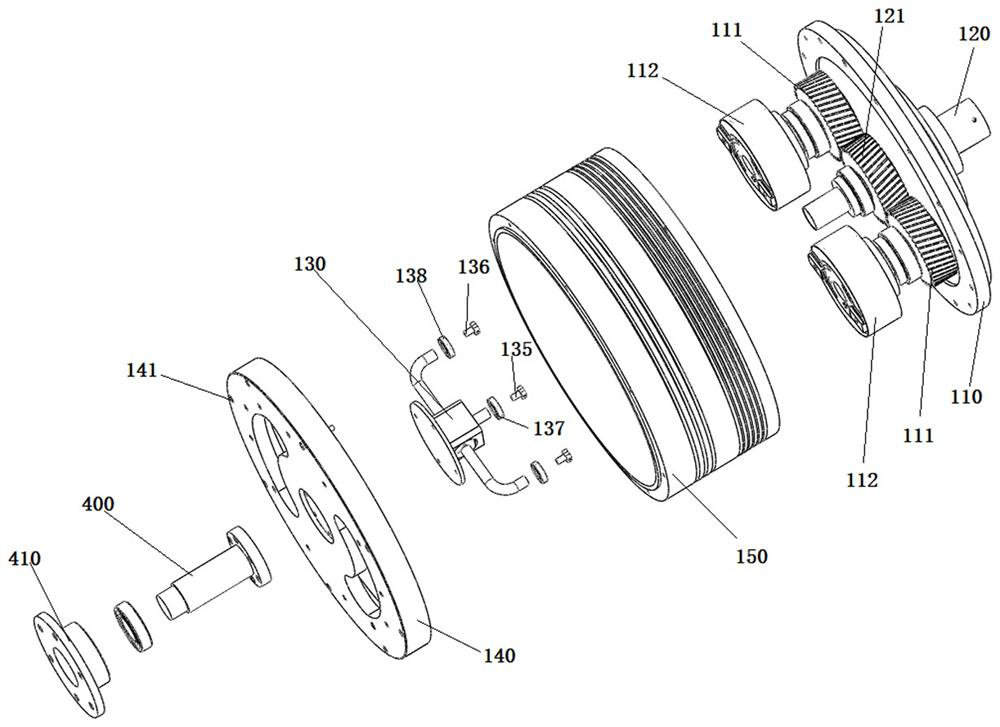

Motor, rotor and installation method of rotor

ActiveCN105576866AEnsure dynamic balanceGuaranteed operational reliabilityMagnetic circuit rotating partsManufacturing stator/rotor bodiesDynamic balanceEngineering

The invention discloses a motor, a rotor and an installation method of the rotor. The rotor comprises an inner rotor iron core (1) and an outer rotor iron core (2), wherein a plurality of inner rotor bosses (11) distributed uniformly are arranged on the outer wall of the inner rotor iron core (1), first positioning holes (12) are formed in the inner rotor bosses (11), outer rotor bosses (21) are arranged on the inner wall of the outer rotor iron core (2) and are in one-to-one correspondence to the inner rotor bosses (11), the outer rotor bosses (21) and the inner rotor bosses (11) are staggered in an axial direction, and second positioning holes (22) are formed in the outer rotor bosses (21) and arranged corresponding to the first positioning holes. With the rotor provided by the invention, the inner rotor bosses and the outer rotor bosses are prevented from being mismatched, the rotor dynamic balance performance is ensured, and the running reliability of the rotor is ensured.

Owner:GREE ELECTRIC APPLIANCES INC

Conveying chain capable of automatically compensating and balancing tension

PendingCN110255087AAvoid frequent movementsImprove adaptabilityConveyorsControl devices for conveyorsDynamic balanceEngineering

The invention belongs to the technical field of conveying devices, and particularly relates to a conveying chain capable of automatically compensating and balancing tension. The conveying chain comprises a driving station, a conveying chain, a sliding support, a telescopic guide rail, a sliding trolley, a trolley sliding rail, a counterweight tensioning assembly, a guide rail warning limit switch, a guide rail early warning limit switch and a guide rail position maintaining assembly, through the arrangement of the telescopic guide rail and the counterweight tensioning assembly, the conveying chain can automatically adjust the telescopic, tensioning and balancing of the guide rail, and the conveying efficiency of the conveying chain is prevented from being influenced by loosening of the conveying chain; a guide rail early warning limit switch and a guide rail position maintaining assembly are additionally arranged, the guide rail position maintaining assembly provides a reverse compensation force for the telescopic guide rail within a certain time when the guide rail early warning limit switch is triggered, the imbalance of the moving amount of the sliding trolley is reduced, the sliding trolley at the near end or the far end of the driving station can be prevented from triggering the limit position signal to give an alarm in advance, the whole conveying chain can not be shut down, so that the dynamic balance of tensioning stations at two positions can be guaranteed, and the tightness change of the chain can be completely counteracted.

Owner:CITIC DICASTAL

Fixing device for loop laying tube of loop laying head

InactiveCN105964726AGuaranteed weightGuaranteed to maintain the same weightEngineeringStructural engineering

The invention relates to a fixing device for a loop laying tube of a loop laying machine. The fixing device is characterized by comprising a loop laying head body, the loop laying tube, tube clamps and a fixing assembly, wherein the loop laying tube is arranged at the loop laying head body according to Archimedes spiral; the tube clamps are arranged on the loop laying tube and the loop laying head body; the fixing assembly is used for fixing the tube clamps and the loop laying head body and comprises fixing pins and bolts, the fixing pins are arranged in pin holes of the tube clamps and the loop laying head body, and the bolts are arranged in the fixing pins. The fixing device can prevent bump between the tube clamps of the loop laying head and a protection cover, protects the tube clamps of the loop laying head from wearing, guarantees stable dynamic balance of the loop laying head and reduces vibration of the loop laying head greatly.

Owner:JIANGSU YONGGANG GROUP CO LTD

A rubber grinding machine for rubber rollers

ActiveCN103331614BExtended use timeExtend the life cycleTurning toolsOther manufacturing equipments/toolsSand blastingEngineering

The invention discloses a special automobile rubber grinding machine for a rubber covered roller. The special automobile rubber grinding machine comprises a lathe head and a lathe bed which are sequentially connected, wherein the lathe head is provided with a headstock, the lathe bed is provided with a tailstock, and a workpiece is fixed between the headstock and the tailstock; the lathe bed below the workpiece is provided with a large planker, a sliding block and a gear are arranged on the large planker, the lathe bed is provided with a linear guide rail and a rack, the sliding block is matched with the linear guide rail, and the gear is matched with the rack; the large planker is provided with a premedial planker and a postmedial planker which can move on the large planker, the premedial planker is provided with a knife rest, and the postmedial planker is provided with a belt sanding machine. According to the special automobile rubber grinding machine, the firmness between a bonding agent and a central spindle can be guaranteed, a traditional sand blasting technology can be replaced, and the surface is not needed to be washed by any solvent, so that the balance of the central spindle can not be damaged, the production efficiency can be improved, the cost is reduced and the labor force is saved, and the key is that the bonding between the rubber and the central spindle can be reliably guaranteed. According to the special automobile rubber grinding machine, the consumable materials can be saved and the environment pollution can be reduced.

Owner:JINAN POWER RUBBER ROLLER EQUIP

High-speed air floatation turbine device

InactiveCN101564715AAvoid irregular vibrationImprove stabilityLiquid spraying plantsTurbineHigh velocity

The invention relates to a high-speed air floatation turbine device, mainly comprising a turbine disk, an end cap of the turbine disk, a hollow shaft, an air flotation bush, a bearing front cap and a bearing rear cap; among the components, the hollow shaft rear is provided with a shaft shoulder; the clearance of the shaft shoulder is embedded between the end cap of the turbine disk and the air floatation bush in a matching way; the front circumference of the end cap of the turbine disk is provided with an axial air floatation supporting air inlet that communicates an intake chamber of floating air to the back end surface of the shaft shoulder of the hollow shaft, and the rear circumference of the air flotation bush is provided with an axial air floatation supporting air inlet that communicates the intake chamber of floating air to the front end surface of the shaft shoulder of the hollow shaft. The device is the highly innovative high-speed air floatation turbine device, and has the advantages of compact structure, scientific and reasonable design, high reliability and long service life; and by providing radial and axial stable support for the hollow shaft by floating air, the device is effectively ensured to operate smoothly at high speed.

Owner:TIANJING UNIV OF TECH & EDUCATION

Vertical fine crushing machine for straw

ActiveCN107750679AEnsure dynamic balanceIncrease the areaCuttersAgricultural engineeringFermentation

The invention relates to a vertical fine crushing machine for straw, and belongs to the technical field of agricultural machinery. The vertical fine crushing machine includes a frame, a vertical barrel fixed on the frame, and a vertically-disposed crushing main shaft. The upper and lower ends of the barrel are separately sealed with an upper cover plate and a lower sieve plate. The side wall of the barrel is provided with a plurality of discharge holes which can be used for installing a screen mesh. The upper cover plate is provided with a feed inlet and a plurality of air-supplying holes forconnecting the inside and the outside of the barrel. The crushing main shaft is arranged in the barrel and the top end of the crushing main shaft protrudes out of the upper cover plate. An axial flowfan is fixed on the upper part of the crushing main shaft, and a plurality of fan blade type hammer bracket plates are arranged at the lower part of the crushing main shaft at intervals. The back of each fan-blade-type hammer bracket plate is fixedly provided with fan blades along the radial direction of the crushing main shaft. U-shaped fixed blades are fixed on the outer sidewall of the barrel,and the teeth of each U-shaped fixed blade extend into the inner sidewall of the barrel. The vertical fine crushing machine for straw can crush high-moisture short straw into straw fines of 20 mm or below to meet requirement of straw biogas fermentation process.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI +1

Automobile oil pipe joint machining device and machining method thereof

ActiveCN114367849AGuaranteed stabilityUniform force distributionPositioning apparatusMetal-working holdersGear wheelElectric machinery

The invention relates to an automobile oil pipe joint machining technology, in particular to an automobile oil pipe joint machining device and a machining method thereof, and aims to solve the problems that clamping is unstable during automatic clamping of an automobile oil pipe joint, vibration noise is too large in the using process of a motor, and transmission efficiency is low. A workpiece is clamped through the clamping plates, the clamping contact area is wide, the workpiece is prevented from shaking left and right with a clamping point as a fulcrum, the stability of the workpiece in the machining process is guaranteed, the machining precision is improved, the motor is of a fixedly-installed structure, the stability of the motor is guaranteed, vibration and noise are effectively reduced, and the machining precision is improved. The transmission efficiency is improved, when the transmission gear switches the meshing state, through sliding of the transmission gear on the main driving shaft and compression of the reset spring, rapid adjustment can be achieved when the transmission gear is overlapped with the locking gear or the driving gear, smooth connection of the transmission gear is guaranteed, and switching between gear connection states is rapid and stable.

Owner:安徽祥源汽车配件制造有限公司

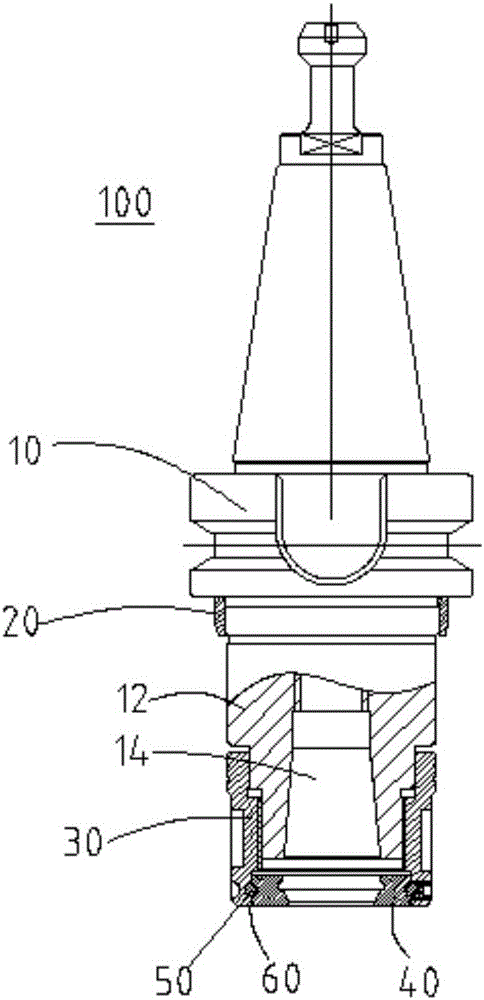

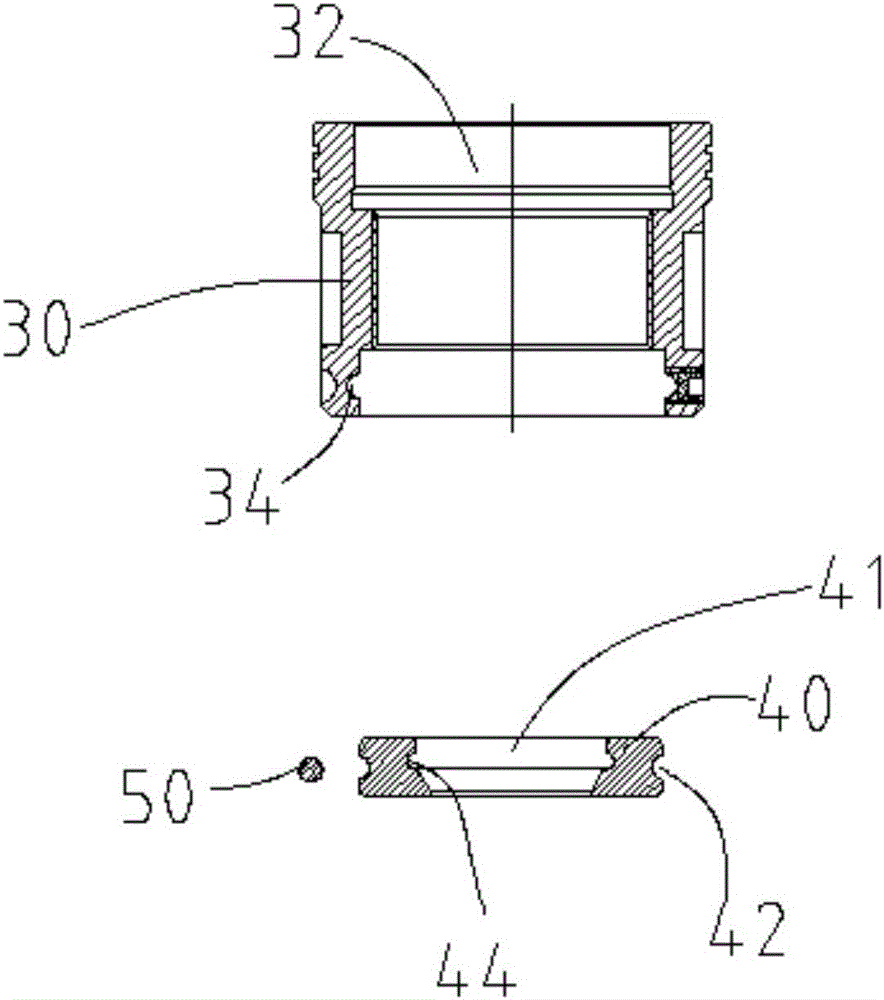

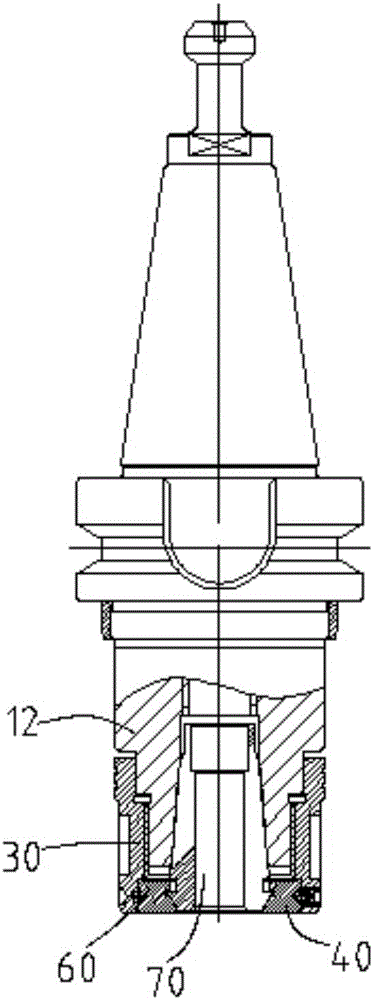

High-precision elastic barrel clamp fixing device

InactiveCN105773261AAvoid kinetic frictionGuaranteed assembly accuracyFeeding apparatusPositioning apparatusEngineeringMechanical engineering

The invention discloses a high-precision elastic barrel clamp fixing device. The high-precision elastic barrel clamp fixing device comprises a first fixing piece, a locking piece fixed to the first fixing piece, a clamping piece and a plurality of rolling pieces. The clamping piece and the locking piece are matched and form a roller path. The multiple rolling pieces are contained in the roller path and make contact with the locking piece and the clamping piece. According to the high-precision elastic barrel clamp fixing device, through cooperation of the rolling pieces, the clamping piece and the locking piece, kinetic friction between the first fixing piece and a clamped elastic barrel clamp is avoided, the assembling precision is guaranteed, and the service life is prolonged.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

Device for dismantling broken bolts of end cover of wind power generator

ActiveCN105345743BFree from destructionImprove maintenance efficiencyMetal-working hand toolsEngineeringTurbine

The invention discloses a wind driven generator end cover broken bolt dismounting device. A bearing is arranged in the center of a chassis; a rotating shaft rotates around the periphery of the chassis, and fits a bearing; a connecting end fitting a dismounting component is arranged at one end of the rotating shaft; the dismounting component comprises a drilling component for drilling a blind hole in a broken bolt, a tapping component for tapping the blind hole as a thread hole, and a screw rod component fitting the thread hole; the screw rod component comprises a screw rod; and the thread rotating direction of the screw rod is opposite to the thread rotating direction of the broken bolt. The dismounting device has the following beneficial effects: the broken bolt is drilled through the drilling component; then, the drilled hole is tapped; the screw rod component is connected with the tapped thread hole; and as the thread rotating direction of the screw rod is opposite to the thread rotating direction of the broken bolt, the broken bolt can be taken out through reversely rotating the rotating shaft, the operation is convenient and fast, the damage of a traditional thread and the dismounting of an outer end cover are not needed, the repair efficiency is greatly improved, and the repair cost is reduced.

Owner:天赋新能源科技(南通)有限公司

Ceramic ferrule processing device and ceramic ferrule production equipment

PendingCN107030538APrecise positioningImprove verticalityGrinding wheel securing apparatusRevolution surface grinding machinesCircular discComposite material

The invention provides a ceramic ferrule processing device and ceramic ferrule production equipment, and belongs to the field of ceramic ferrule production equipment. The ceramic ferrule processing device comprises a motor, a circular-disc-shaped cutter, a first positioning plate and a fastening piece, wherein the first positioning plate positions the cutter on the output shaft of the motor; the fastening piece fixes the cutter; the cutter is driven by the motor to grind the outer circle of the ceramic ferrule. The ceramic ferrule processing device and the ceramic ferrule production equipment have the benefits that when in use, the first positioning plate reliably positions the circular-disc-shaped cutter, so that the perpendicularity of the cutter relative to the output shaft is greatly improved; when the cutter performs high speed rotation, the dynamic balance of the cutter is ensured; the ceramic ferrule production equipment adopts the ceramic ferrule processing device, and therefore the ceramic ferrule processing device and the ceramic ferrule production equipment are quite suitable for processing the outer circle of the ceramic ferrule.

Owner:苏州速科德电机科技有限公司

Static pressure line double-brake-drum rotary casting device

ActiveCN104690232AImprove qualityAvoid rising sandFoundry mouldsFoundry coresDynamic balanceTangential force

The invention discloses a static pressure line double-brake-drum rotary casting device which comprises a mold body arranged in a sand box. The mold body comprises two brake drum forming molds, wherein a first cross gate forming mold is arranged on the same side of the two brake drum forming molds, and a plurality of ingate forming molds tangent with the brake drum forming molds are arranged on the first cross gate forming mold. A second cross gate forming mold is arranged under the first cross gate forming mold, and a fiber filter screen is arranged between the second cross gate forming mold and the first cross gate forming mold. Two flow choking grooves are formed in the first cross gate forming mold, and a skim bob forming mold is formed between the two flow choking grooves. When molten iron is cast, tangential force is produced and pushes the molten iron to rotate constantly, a sand cut phenomenon is avoided, and mixing uniformity of the molten iron is ensured. The molten iron is cooled and solidifies while casting is completed, the hardness difference of products is reduced, dynamic balance is ensured, the problem of large working allowance difference is solved, and technological yield, rate of finished products and the quality of castings are improved.

Owner:山东康迈机械有限公司

Automatic sharpening device for silage harvester

The invention provides an automatic knife sharpening device for a silage harvester, which is characterized in that it includes a reciprocating mechanism and a knife sharpening feeding mechanism; wherein the reciprocating mechanism includes a guide rail base, two guide rails horizontally installed on the guide rail base, A pair of sliders installed on the two guide rails, a slider plate that fixes the pair of sliders together, a lead screw, a lead screw support, a lead screw nut, a motor and a pawl; the sharpening mechanism includes a grinding Knife housing, knife grinding wheel, worm wheel, worm, shaft, feed sleeve, ratchet wheel; knife grinding feeding mechanism is connected with the slider plate of the reciprocating mechanism through the knife grinding housing. Before grinding the knife, adjust the grinding wheel to be in contact with the moving knife of the hob-type chopper. When grinding the knife, the grinding wheel is driven by the motor to reciprocate by the screw nut, thereby resetting the cutting edge of the moving knife on the drum. sharpen. The structural design is simple and practical, reduces manufacturing difficulty and cost, is easy to operate and control, and improves work efficiency and work quality.

Owner:SHANDONG UNIV OF TECH

Fold-back ventilating device of collective escaping chamber

ActiveCN103921911AFloating state effectReduce the probability of pouring into the cabinLife-savingCylinder blockAir blower

The invention discloses a fold-back ventilating device of a collective escaping chamber. The fold-back ventilating device comprises an air inlet system and an air outlet system which are connected with an escaping chamber body and have a same structure, wherein the air inlet system comprises a connecting pipe; one end of the connecting pipe stretches into the chamber, and the other end of the connecting pipe is communicated with a closed conversion cavity outside the chamber; a screw plug is arranged at the end of the connecting pipe in the chamber; the conversion cavity is communicated with a horizontal ventilating duct; the ventilating duct and the conversion cavity are connected in a sealed and rotatable mode, and a radial ventilating hole is formed in the other end of the ventilating duct; a waterproof cover sleeves the end of the ventilating duct and covers the radial ventilating hole; a piston rod of a vertical cylinder is hinged with the ventilating duct; a cylinder body is hinged with a lower mounting seat; the lower mounting seat is fixedly arranged on the escaping chamber body; the conversion cavity is fixedly arranged on the lower mounting seat; when the escaping chamber floats to the water surface and needs ventilation, the screw plug in the air inlet system and the air outlet system is removed, and the connecting pipe in the chamber of the air outlet system and an air outlet pipe of an air blower in the chamber are connected with each other. Ventilation inside and outside the chamber can be realized under the condition that a chamber cover is not opened, and the operation is stable and reliable.

Owner:中国船舶重工集团公司第七〇二研究所

Angular contact ball bearing

The invention provides an angular contact ball bearing in order to reduce noise generated when the angular contact ball bearing operates. The angular contact ball bearing comprises an inner ring, an outer ring and oil injection holes formed in the inner ring or the outer ring; inlets of the oil injection holes are located in the end surface of the inner ring or the outer ring; outlets of the oil injection holes are located in the concave surface, corresponding to a rolling body, of the inner ring or the outer ring; and the outlets of the oil injection holes fall behind the inlets in the rotation direction of the inner ring or the outer ring where the oil injection holes are formed. The outlets of the oil injection holes fall behind the inlets in the rotation direction of the inner ring or the outer ring, lubricating oil in the oil injection holes can be thrown towards a rolling ball of the bearing by a backward throwing force generated when the inner ring or the outer ring rotates, so that the lubricating oil automatically enters the rolling ball of the bearing to realize lubrication; and compared with the existing high-speed jet oil injection way, the angular contact ball bearing has the advantages that the speed of the lubricating oil is reduced, and no relatively high noise can be generated after airflow collision caused when the bearing rotates.

Owner:LUOYANG BEARING RES INST CO LTD

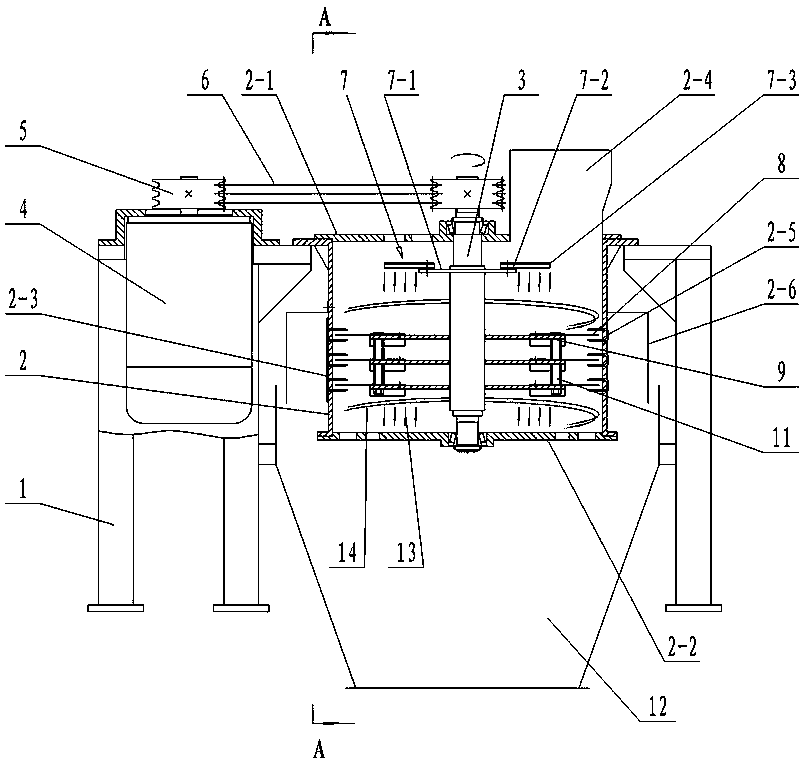

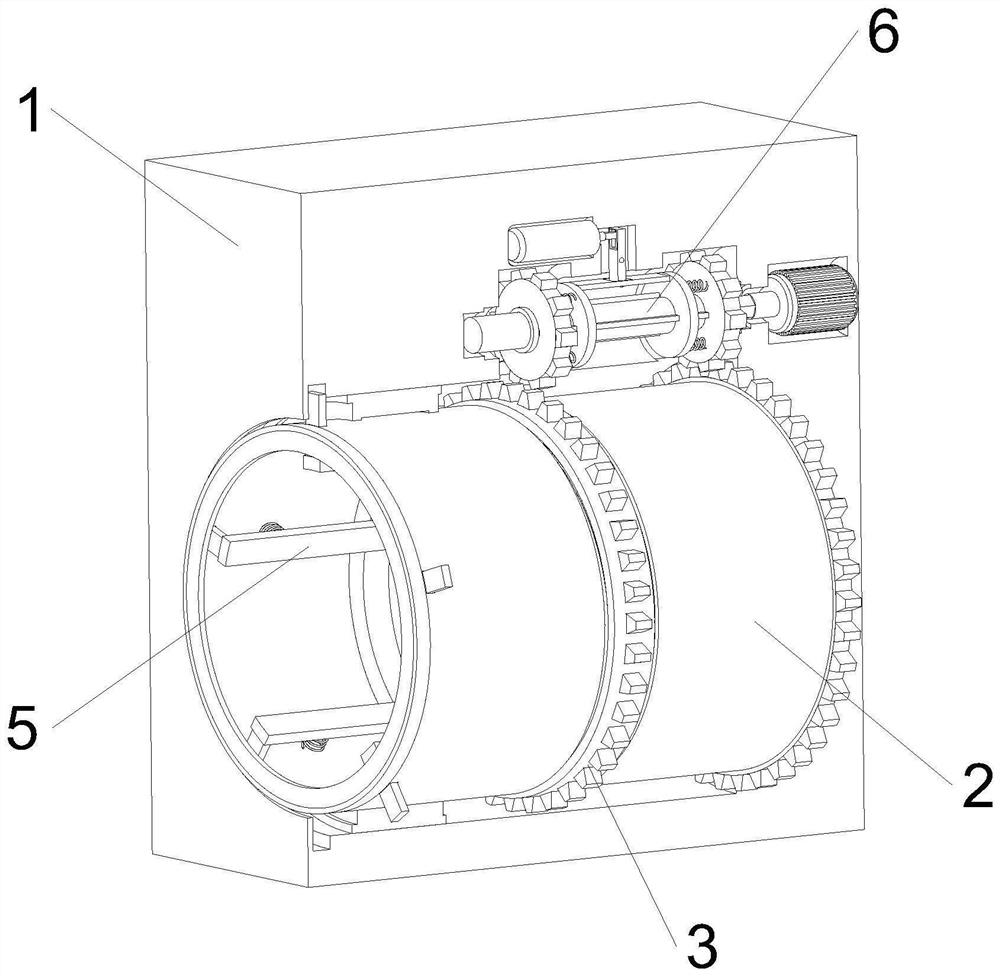

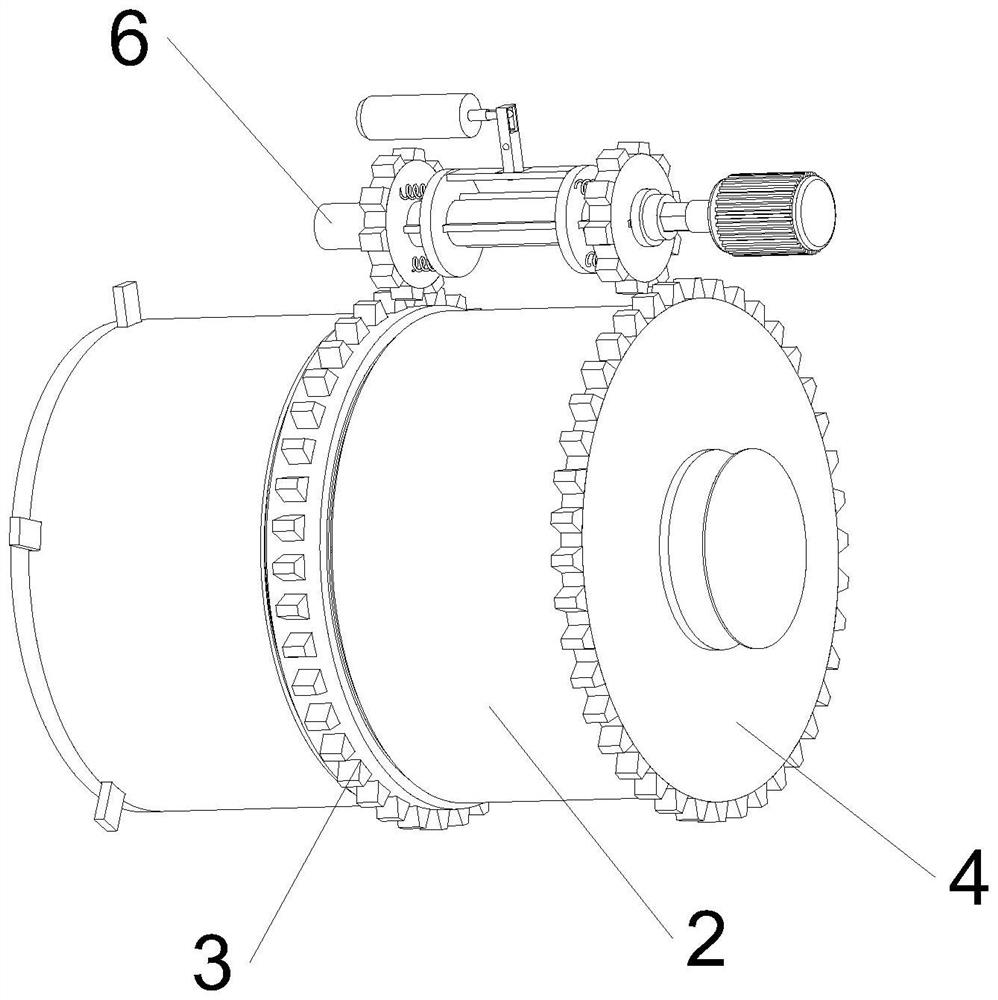

High-efficiency and high-speed analysis type counter-current chromatograph

ActiveCN111948312AEnsure dynamic balanceLarge column capacityComponent separationOil and greaseStructural engineering

The invention discloses a high-efficiency and high-speed analysis type counter-current chromatograph. A metal unwinding frame and a dynamic balance adjusting plate are arranged on an existing chromatograph; the metal unwinding frame comprises a metal base, a metal straight pipe, a center shaft oil plug, two symmetrically-arranged metal bent pipes and two separation column oil plugs, one end of each metal bent pipe is fixedly connected with the metal base, one end of each separation column oil plug is connected with a center hole of the corresponding separation column in an expanding mode, andthe other end of each separation column oil plug is arranged in the other end of the corresponding metal bent pipe. One end of the metal straight pipe is fixedly connected with the metal base, one endof the central shaft oil plug is in expansion connection with one end of the central shaft, the other end of the central shaft oil plug is arranged in the other end of the metal straight pipe, the metal straight pipe is communicated with the two metal bent pipes, and lining hoses filled with grease are arranged in the metal straight pipe and the two metal bent pipes; and the metal base is connected with the planet carrier through a dynamic balance adjusting plate. The chromatograph can realize counter-current chromatography separation at an ultra-high rotating speed, and has the characteristics of small size and high reliability.

Owner:SICHUAN UNIV

Cleaning device for high-speed rotary atomizer

The invention provides a cleaning device for a high-speed rotary atomizer. The cleaning device can efficiently clean away lime slurry adhering to an atomizing disc, the maintenance time is shortened,dynamic balance of the atomizing disc can also be guaranteed, and the service life of the equipment is prolonged; the cleaning device comprises the atomizer, the atomizer comprises a lime slurry channel and the atomizing disc which are communicated with each other, the atomizer further comprises a cylinder and a circulating pump arranged outside the cylinder, the interior of the cylinder is divided into a soaking area and a storing area by a clapboard, a sewage draining opening is formed in the position, at the bottom of each area, of the cylinder, the atomizer is installed on the cylinder, the atomizing disc is arranged in the soaking area, the storing area is communicated with the lime slurry channel after being connected with the circulating pump, the clapboard is provided with a waterpassing hole which is higher than the atomizing disc, and cleaning liquid is added into the storing area.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com