Vertical fine crushing machine for straw

A fine pulverizer, vertical technology, used in agricultural machinery and implements, cutting equipment, applications, etc., can solve problems such as failure of pulverizing operation, reducing gas production efficiency, blocking equipment, etc., to increase the area of airflow passages, and the effect is good Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

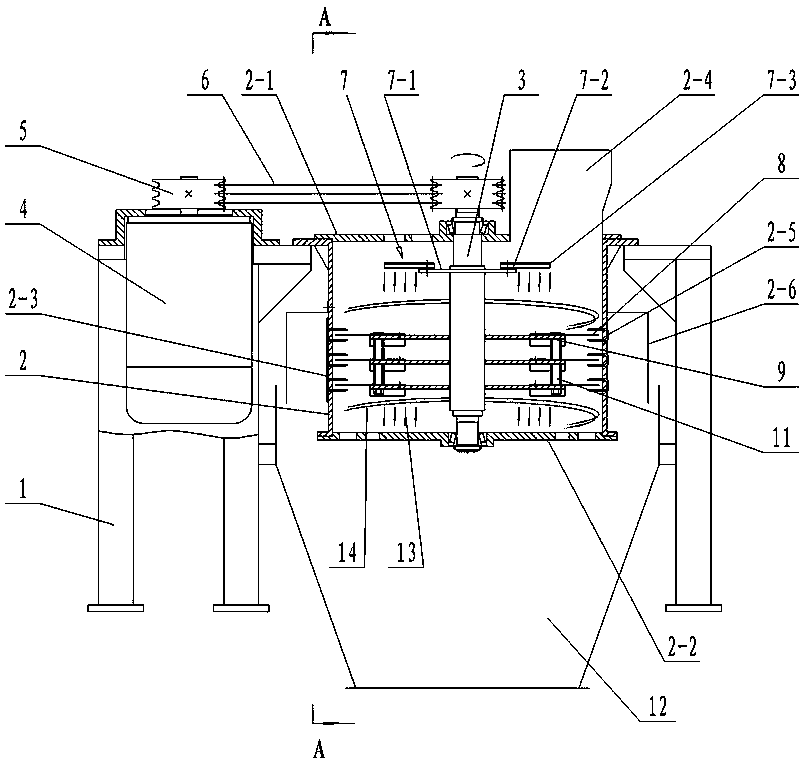

[0030] The vertical straw fine pulverizer of the present embodiment, as figure 1 and figure 2 As shown, it includes a frame 1, a vertical barrel 2 fixed on the frame 1 and a vertically arranged crushing main shaft 3.

[0031] A vertical motor 4 is fixedly connected on the frame 1, and the output shaft of the vertical motor 4 and the top of the crushing main shaft 3 are provided with a V-belt pulley 5 and a conveyor belt 6 connected between the two V-belt pulleys.

[0032] A circle of annular casing 2-6 is fixed on the outer wall of machine barrel 2 . A discharge cone 12 fixed on the frame 1 is provided below the annular casing 2-6. By adjusting the mutual position between the annular casing 2-6 and the discharge cone 12 up and down. Since the moisture content of the wet straw is about 60%, the dust produced by crushing has a large specificity and a large settling velocity, and the straw dust shrouded in the annular casing 2-6 and the discharge cone 12 will be accompanied b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com