Cleaning device for high-speed rotary atomizer

A technology of high-speed rotation and cleaning device, applied in the direction of spray device, etc., can solve the problems of shortening the service life of equipment, excessive vibration value of equipment, clogging of buffer distribution area, etc., to shorten the maintenance time, prolong the service life, and ensure the effect of dynamic balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

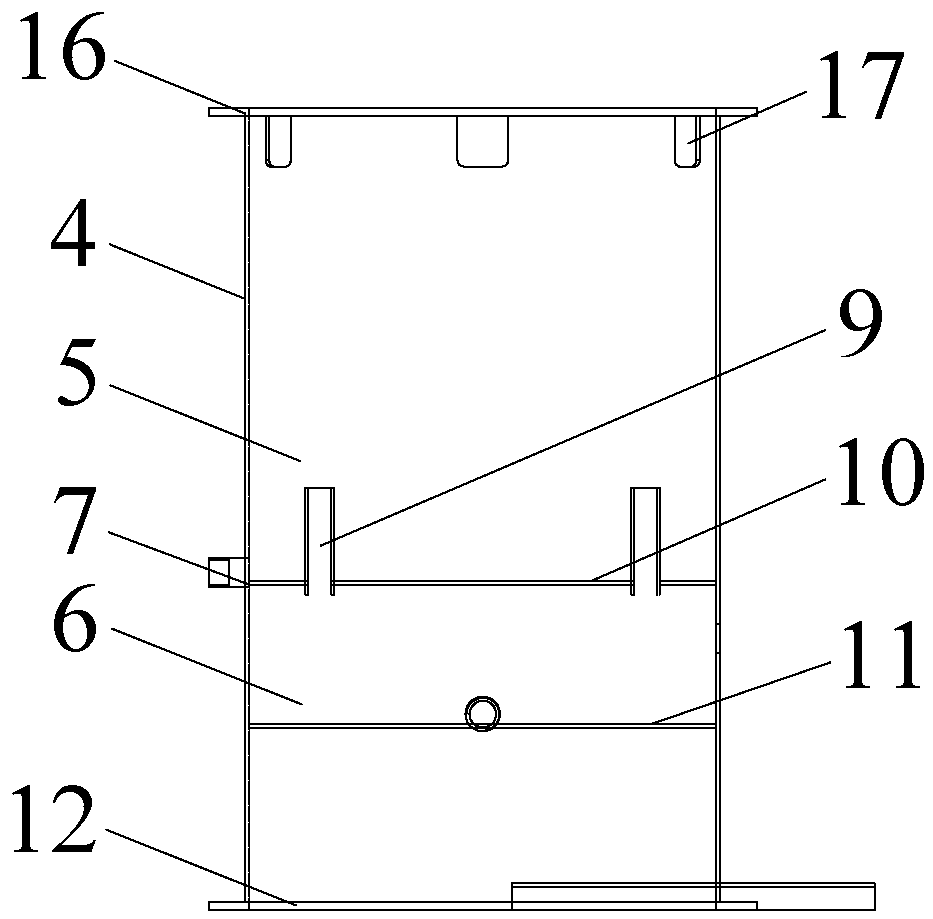

[0015] like Figure 1~Figure 4 As shown, the present invention includes an atomizer 1, and the atomizer 1 includes a connected lime slurry channel 2, an atomizing disc 3, and it also includes a cylinder 4 and a circulation pump 18 located outside the cylinder 4, and the cylinder 4 The interior is divided into a soaking area 5 and a storage area 6 by partitions, and the cylinder 4 at the bottom of each area is provided with a sewage outlet 7, and each sewage outlet 7 is connected to a sewage tap 8, and the atomizer 1 is installed in the cylinder 4, and place the atomizing disc 3 in the soaking area 5, the storage area 6 is connected to the circulation pump 18 and communicates with the lime slurry channel 2, and the water hole 9 with a height higher than the atomizing disc 3 is arranged on the partition plate, A cleaning solution is added to the storage area 6, and the cleaning solution is a citric acid solution with a concentration of 30% to 50%.

[0016] The dividing plate co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com