Device for dismantling broken bolts of end cover of wind power generator

A technology for wind power generators and dismantling devices, which is applied in the manufacture of tools and hand-held tools, etc. It can solve the problems of heavy outer end cover, difficult maintenance, and easy deviation from the center, so as to improve the drilling and tapping effect and reduce maintenance Cost and improvement of maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

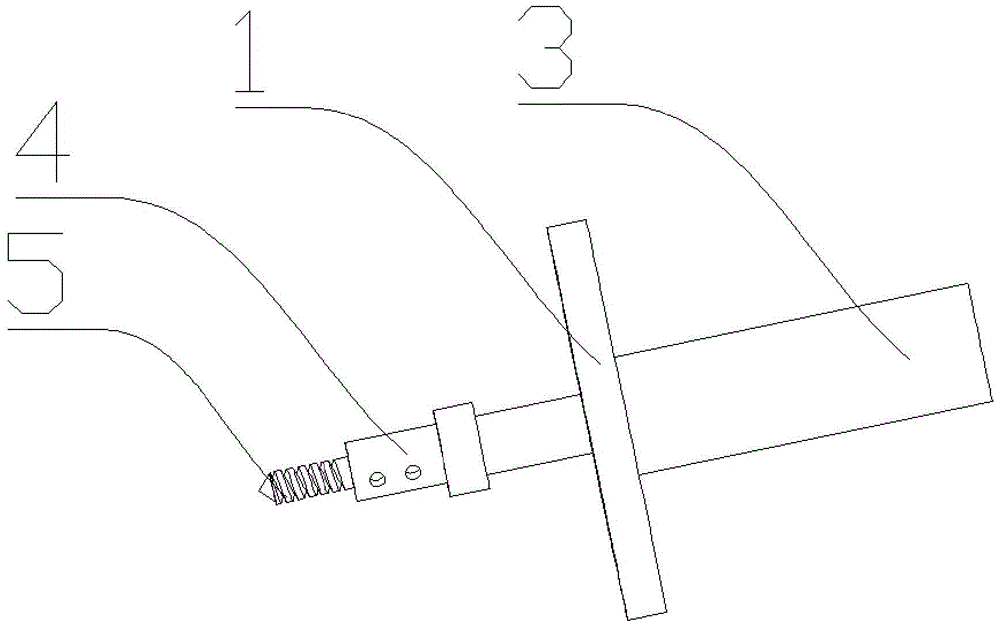

[0029] Below in conjunction with specific embodiment, the content of the present invention is described in further detail: a kind of wind power generator end cover broken bolt removal device, chassis 1 center is provided with a bearing 2; The bearing 2 is matched, and one end of the rotating shaft 3 is provided with a connection end matched with the disassembly assembly; the disassembly assembly includes a drilling assembly for drilling the first blind hole with the broken bolt, and a tapping assembly for tapping the first blind hole into a threaded hole And the screw assembly that cooperates with the threaded hole, the screw assembly includes a screw 8, the screw thread direction of the screw rod 8 is opposite to that of the broken bolt, the drilling assembly includes the drill bit 5 and the first rotating shaft 4, and the middle part of the first rotating shaft 4 is provided with a Step 41, one end is provided with a threaded hole, the other end is provided with a first fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com