Conveying chain capable of automatically compensating and balancing tension

A technology of conveying chain and conveying device, applied in the direction of conveyor, conveyor object, conveyor control device, etc., can solve the problems of conveyor chain stop, conveyor chain relaxation, affecting the smooth conveying of conveyor chain, etc., to improve adaptability and reliability. Tone, avoid the effect of frequent movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Attached below Figure 1-3 Description of Embodiment 1 of the present application: a conveyor chain with automatic compensation and balanced tension, including a drive station 1, a conveyor chain, a sliding bracket, a telescopic guide rail, a sliding trolley 5, a trolley sliding rail 6, a counterweight tensioning assembly 7, Guide rail alarm limit switch 8, guide rail warning limit switch 9, guide rail position maintenance component. The driving station 1 provides the driving force to drive the conveying direction of the conveying chain. The conveying chain is arranged in the telescopic guide rail, and the sliding bracket is arranged on the conveying chain. The sliding support is used to carry the objects to be conveyed. The chain drives the sliding support and the objects to be conveyed on the sliding support to move towards the conveying direction.

[0026] It includes two sliding trolleys 5 and two trolley sliding rails 6, one sliding trolley 5 corresponds to one tr...

Embodiment 2

[0033] Embodiment 2: The difference between embodiment 2 and embodiment 1 is that the guide rail warning limit switch 9 and the guide rail position maintaining component are only arranged on the proximal side of the driving station 1 . Specifically in embodiment 2: the delivery device also includes a guide rail early warning limit switch 9 and a guide rail position maintenance assembly, the guide rail early warning limit switch 9 is located on the trolley slide rail 6 at the near end of the drive station 1, and is located at the guide rail alarm limit switch Before the switch 8; the guide rail position maintenance component is arranged on the outside of the sliding trolley 5 at the proximal end of the drive station 1, and is used to apply to the sliding trolley 5 or the U-shaped An inward force of the curved rail 2 makes the sliding trolley 5 or the U-shaped curved rail 2 no longer move outward until the object to be conveyed is transferred to the telescopic guide rail at the f...

Embodiment 3

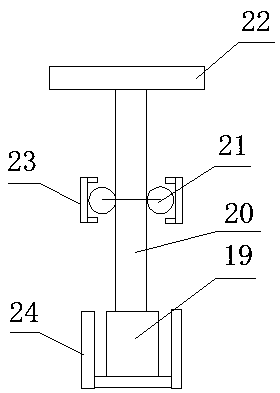

[0034] Embodiment 3: The difference between embodiment 3 and embodiment 1 is that the structure of the counterweight tensioning assembly 7 is different, specifically in embodiment 3: a guide rail bracket 14 is set under the telescopic guide rail, and the guide rail bracket 14 is used to support the telescopic guide rail and the trolley sliding rail 6; the U-shaped bottom of each U-shaped curved rail 2 is connected with a counterweight tensioning assembly 7, and the counterweight tensioning assembly 7 includes a counterweight 15, a counterweight bracket 18, Wire rope 16, pulley assembly 17, counterweight support 18 comprises vertical part and horizontal part, and the top of vertical part connects horizontal part; On the horizontal part of the heavy support 18, the fixed pulley at one end of the vertical part, the fixed pulley in the middle of the bottom surface of the end where the U-shaped curved rail 2 is located on the guide rail support 14, and the steel rope 16 one ends are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com