Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Avoid product quality defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

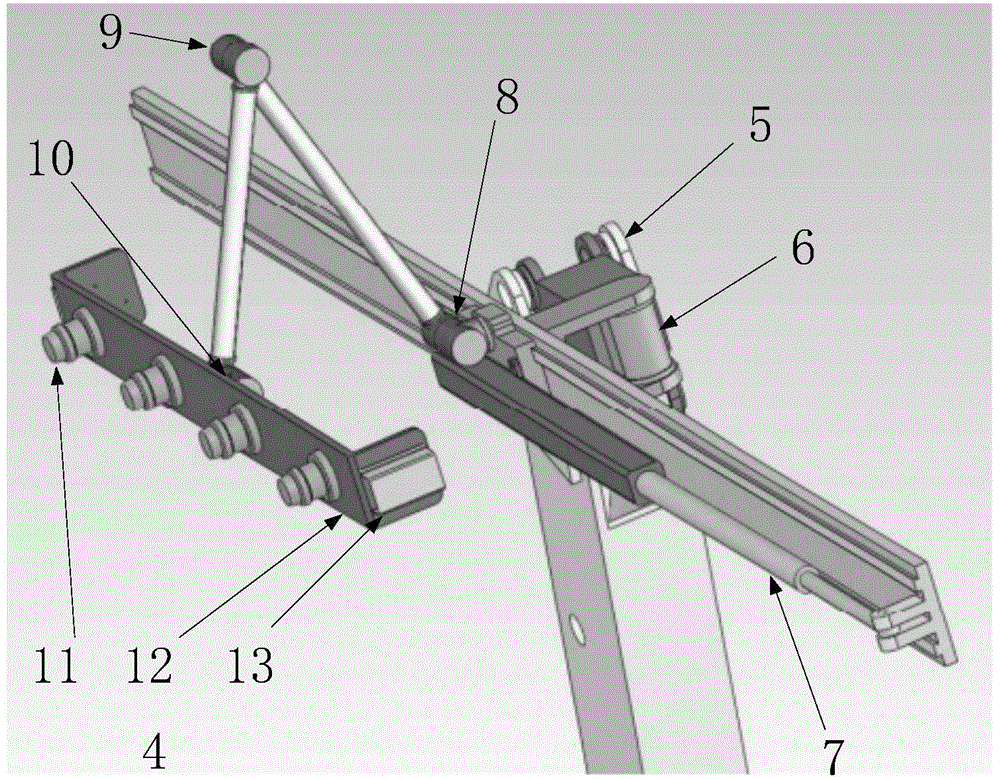

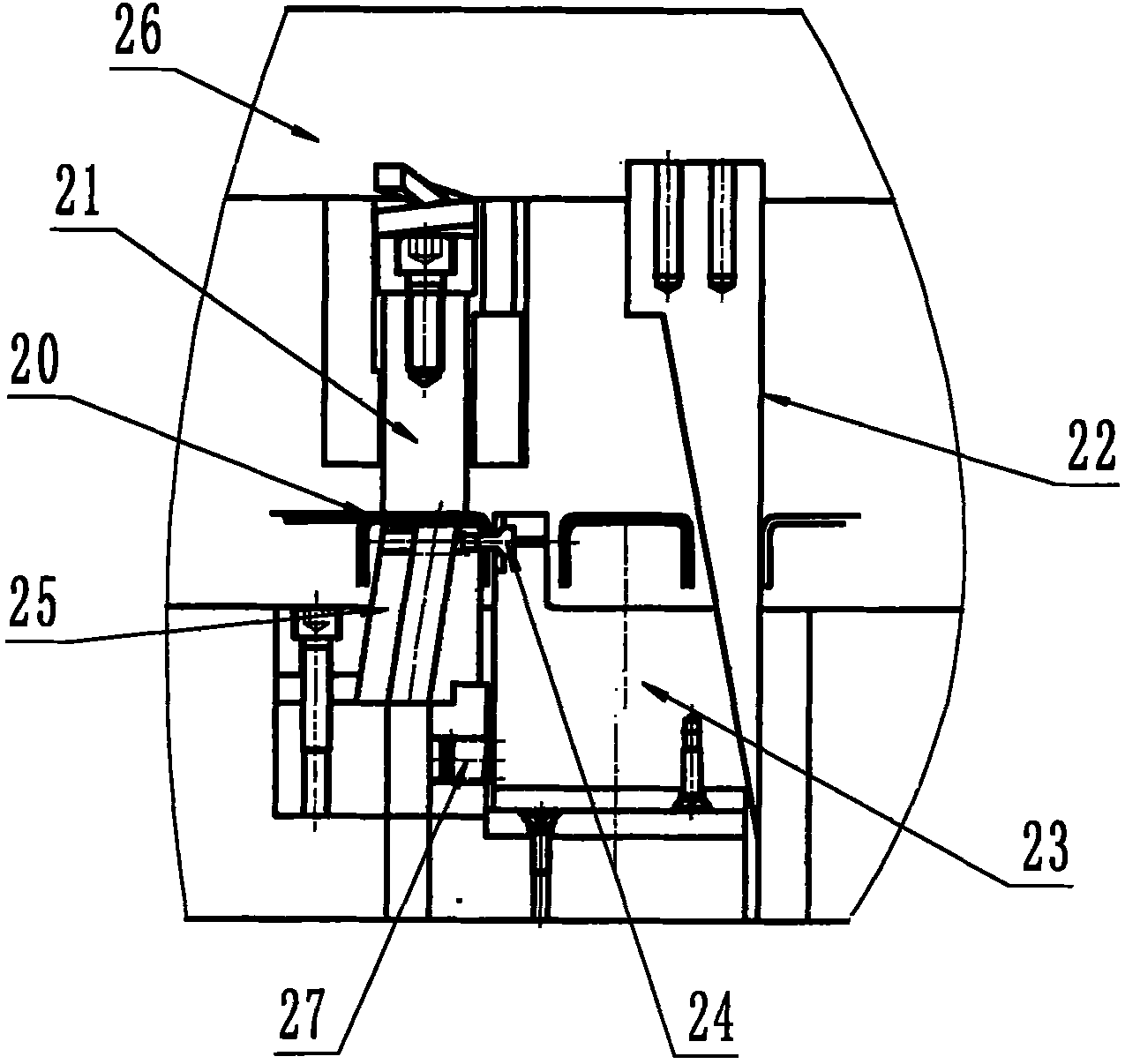

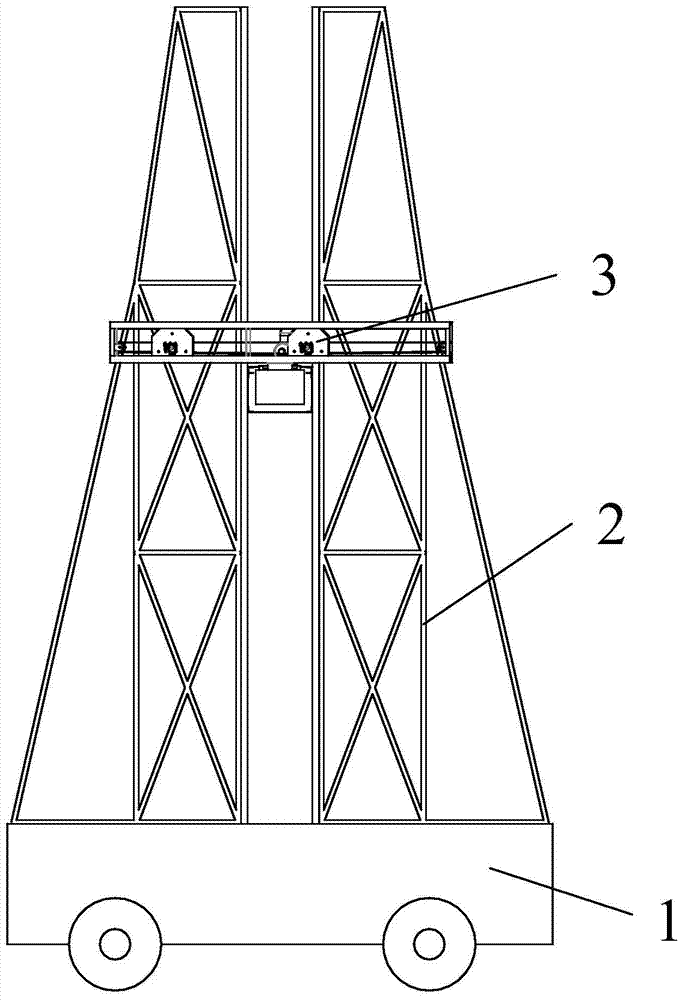

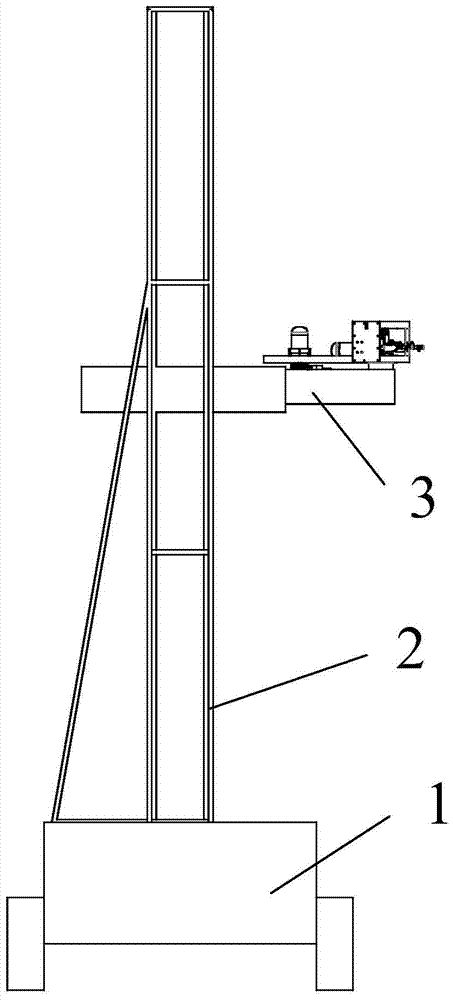

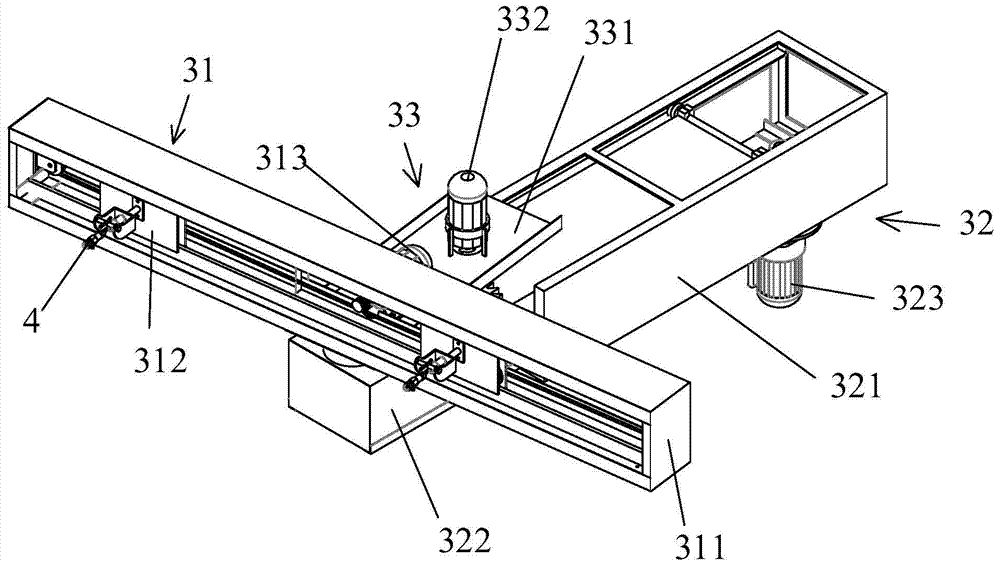

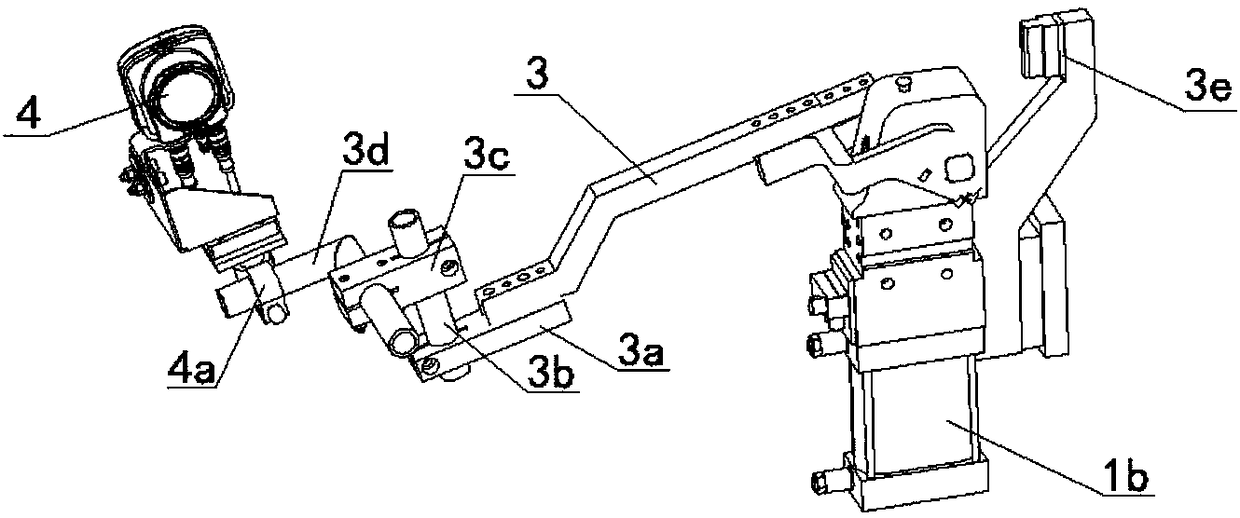

Automatic painting robot for shipbuilding coating

The invention discloses an automatic painting robot for shipbuilding coating. The automatic painting robot for shipbuilding coating comprises a painting movement mechanism, a PLC and a spray gun; the painting movement mechanism comprises a side-to-side movement mechanism, a front-to-back movement mechanism and a rotational movement mechanism; the side-to-side movement mechanism comprises a first shell, a sliding block and a first motor, the first motor drives the sliding block to move from side to side, the spray gun is fixedly arranged on the sliding block, and the first shell is provided with a distance measuring sensor; the front-to-back movement mechanism comprises a second shell, an inner shell and a second motor, and the inner shell moves back and forth in the second shell; the rotational movement mechanism comprises a support plate, a third motor and a fixed gear wheel, the side-to-side movement mechanism and the support plate are connected with the inner shell through a bearing, the third motor drives the side-to-side movement mechanism to rotate around the bearing, and the distance measuring sensor, the first motor, the second motor and the third motor are electrically connected with the PLC. According to the automatic painting robot for shipbuilding coating, the work efficiency is improved, the labor cost is reduced, the construction period is shortened, the evenness of a paint coating is good, and the quality of the paint coating is improved.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

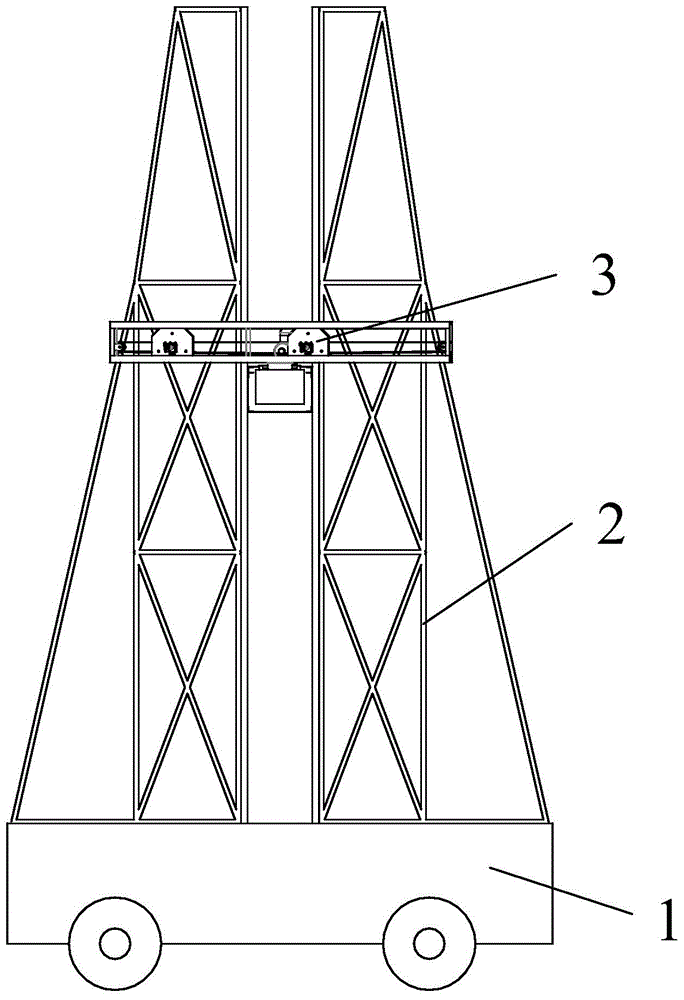

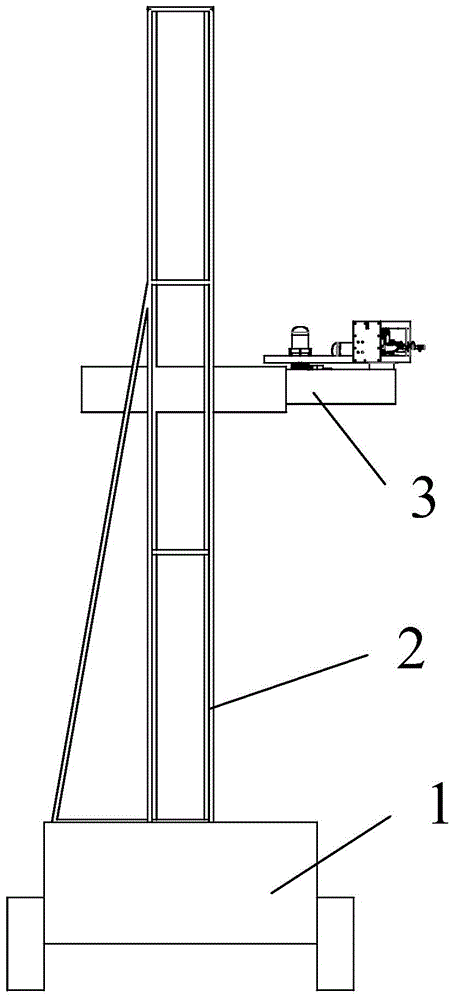

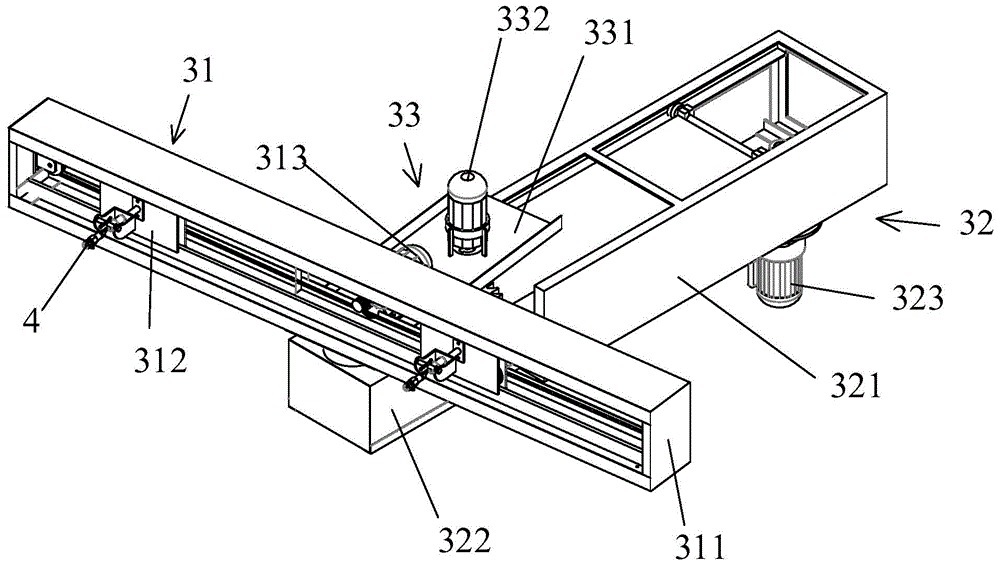

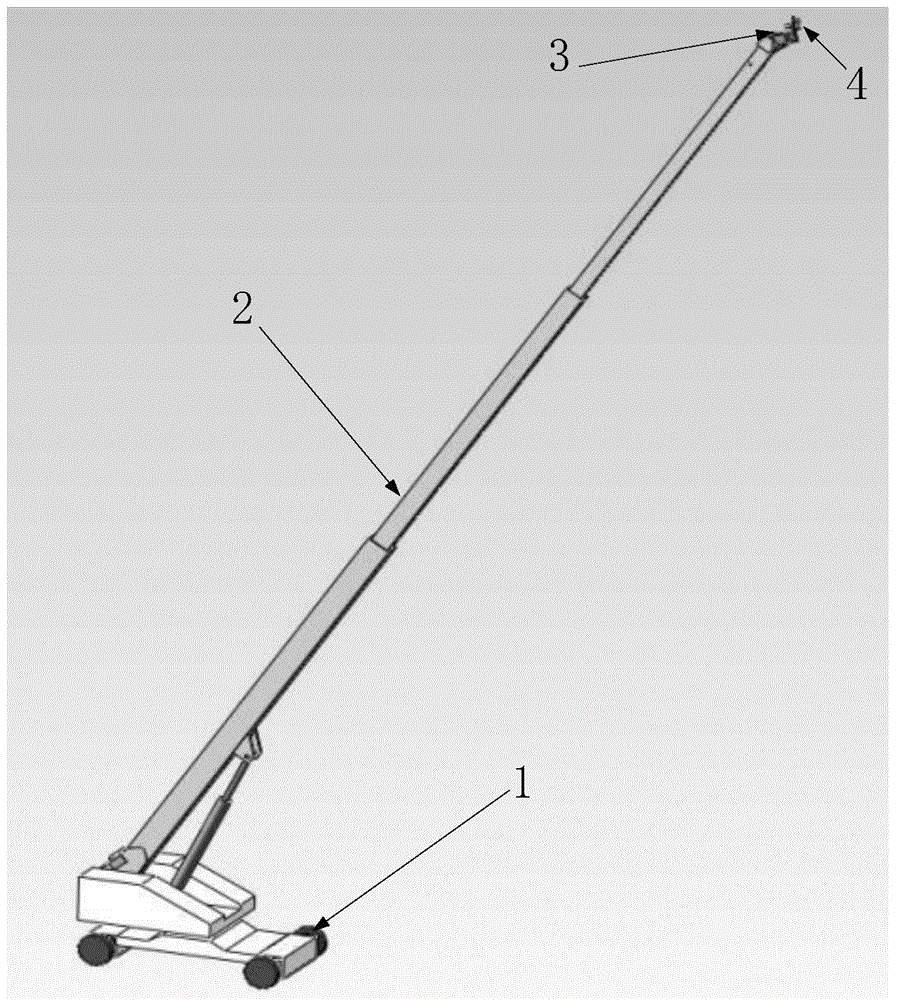

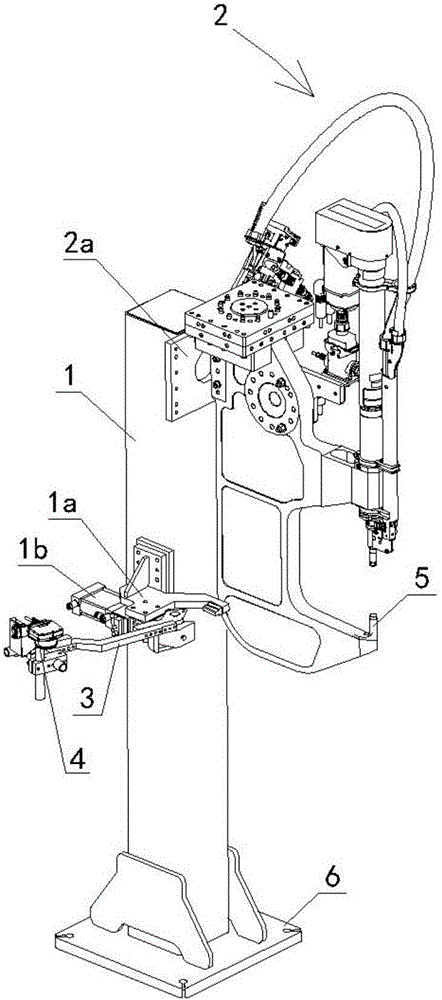

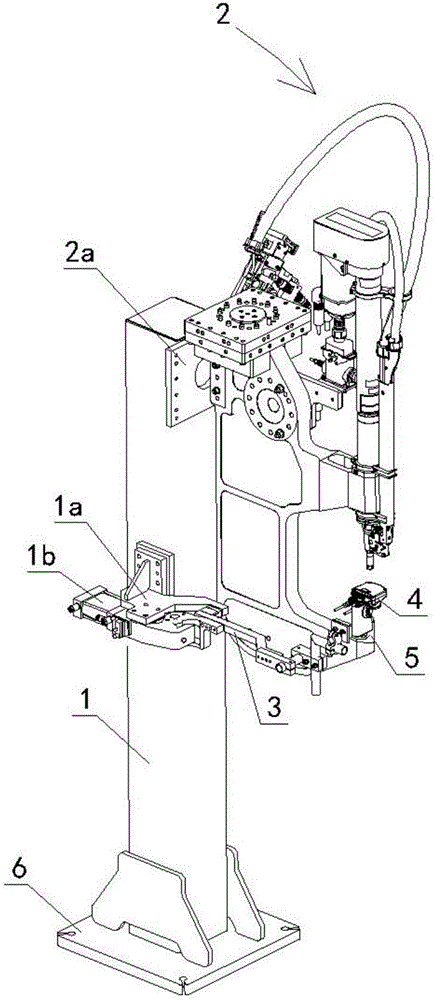

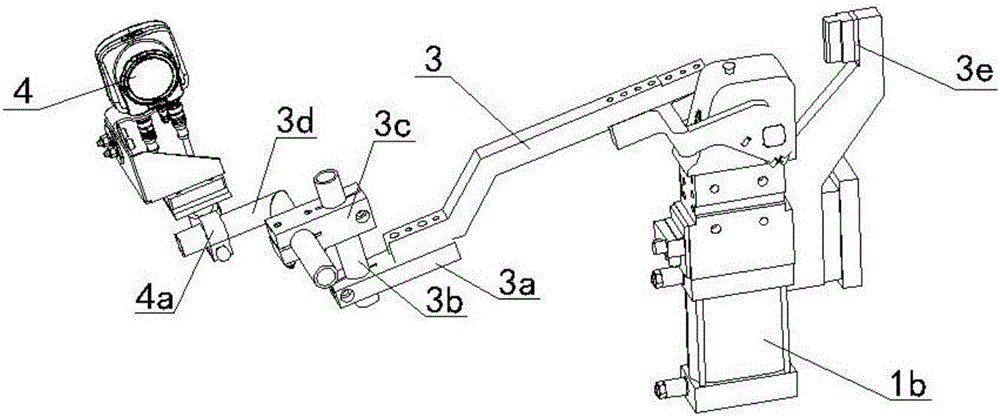

Spraying robot for surface of ship body

InactiveCN104624429AImprove spray uniformityHigh repeatabilitySpraying apparatusActuatorControl theory

The invention discloses a spraying robot for a surface of a ship body. The spraying robot comprises a chassis, a large arm, a small arm and a tail end actuator. The tail end actuator comprises a spraying gun installation base, at least one spraying gun and at least one laser displacement sensor for controlling the pose of the tail end actuator. The spraying robot for the surface of the ship body is used for avoiding influence of harmful gas in spraying and repeating the same operation action tirelessly, and is suitable for replacing manpower to carry out the operation in high pollution and intensity work like ship body spraying. The intelligent spraying robot for the ship body is adopted to complete the spraying work so that the pollution in the spraying process can be reduced, energy can be saved, and the working efficiency can be improved.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

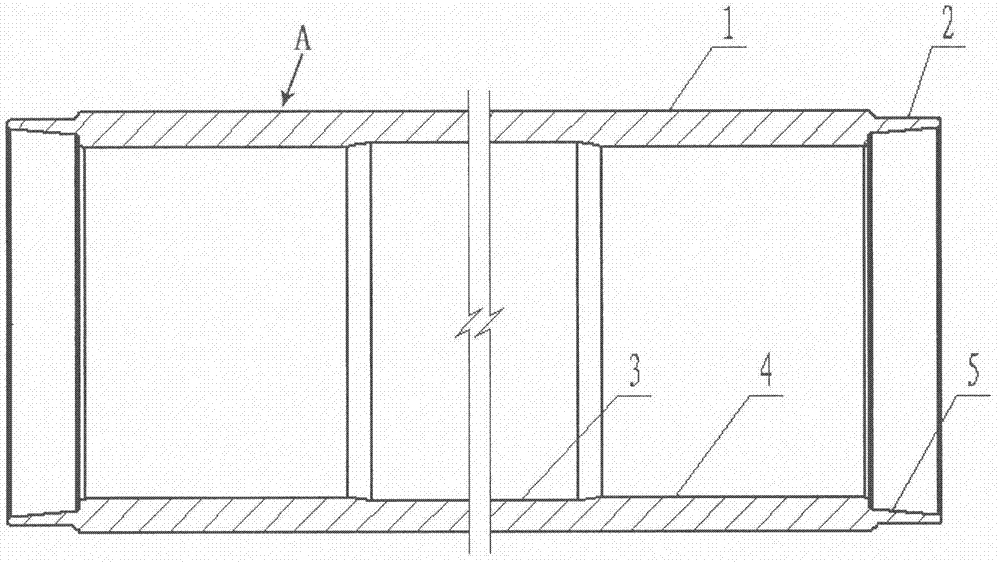

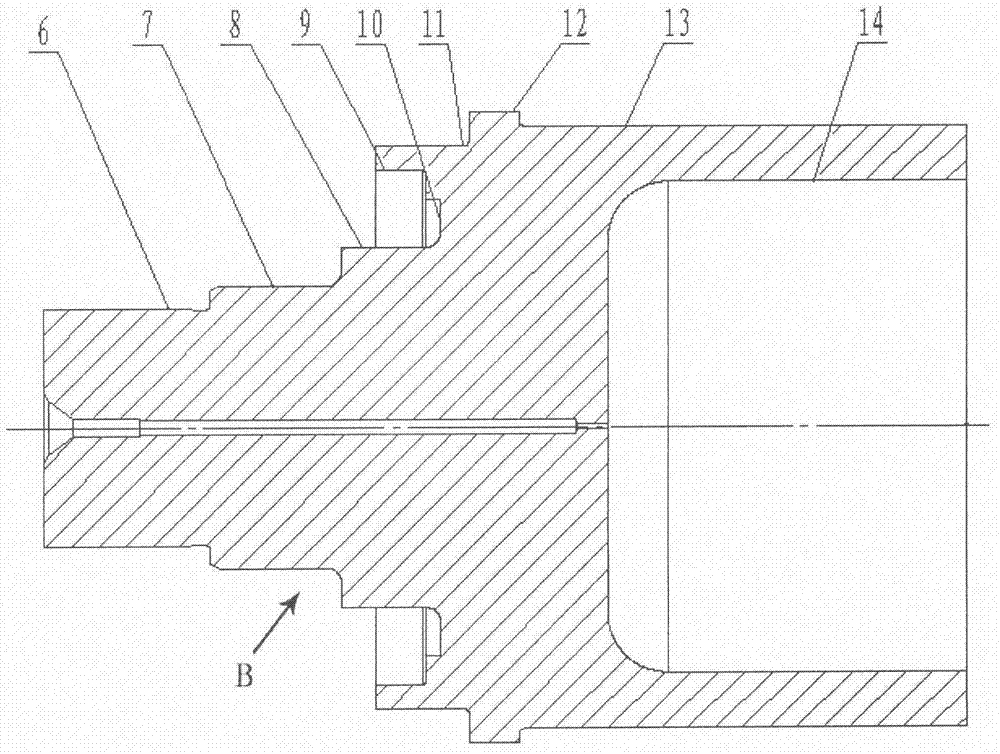

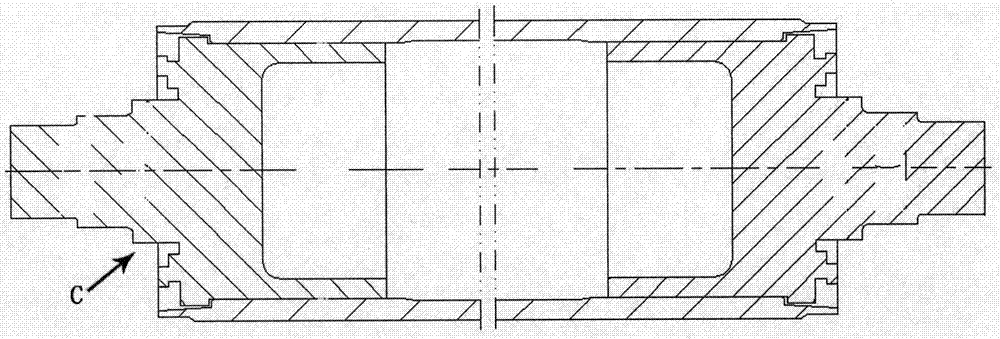

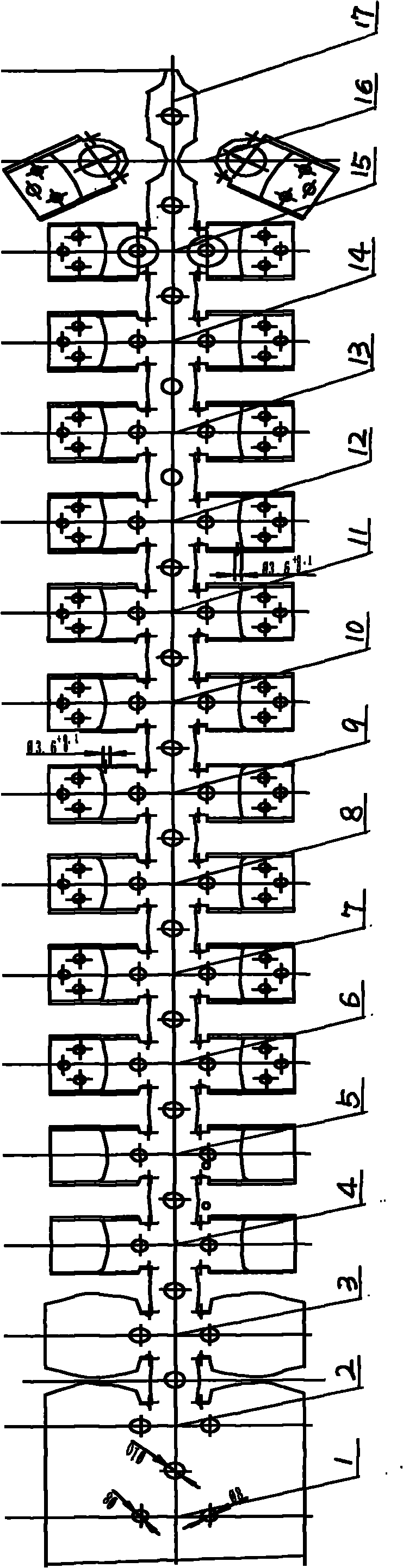

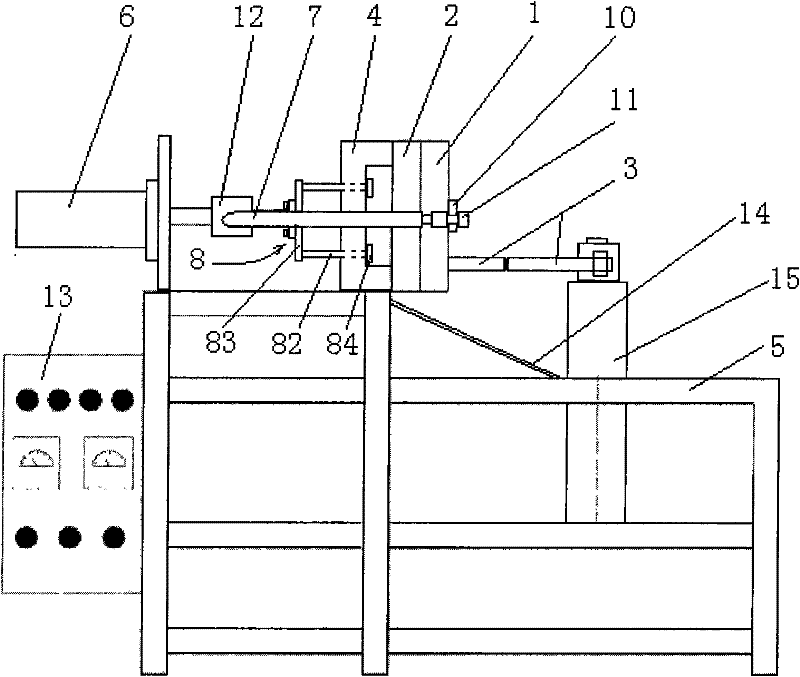

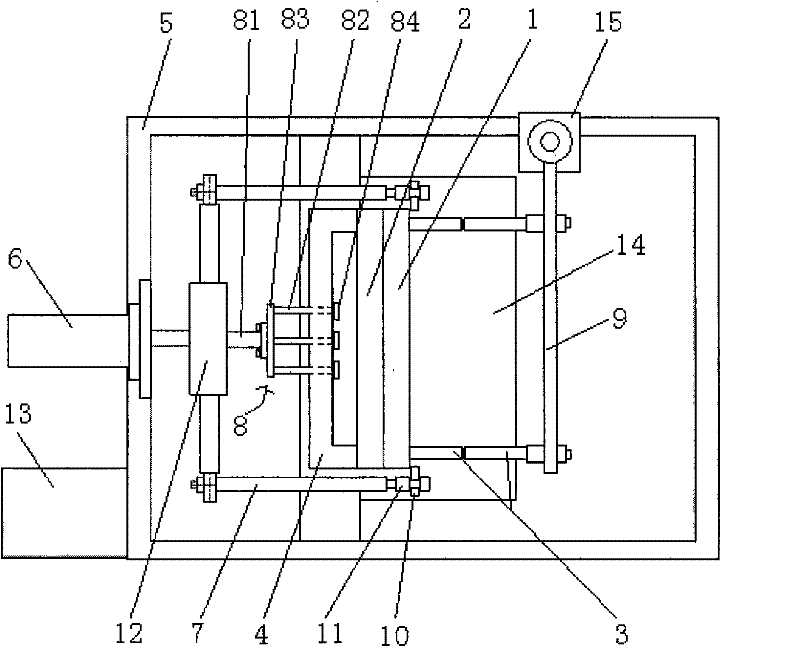

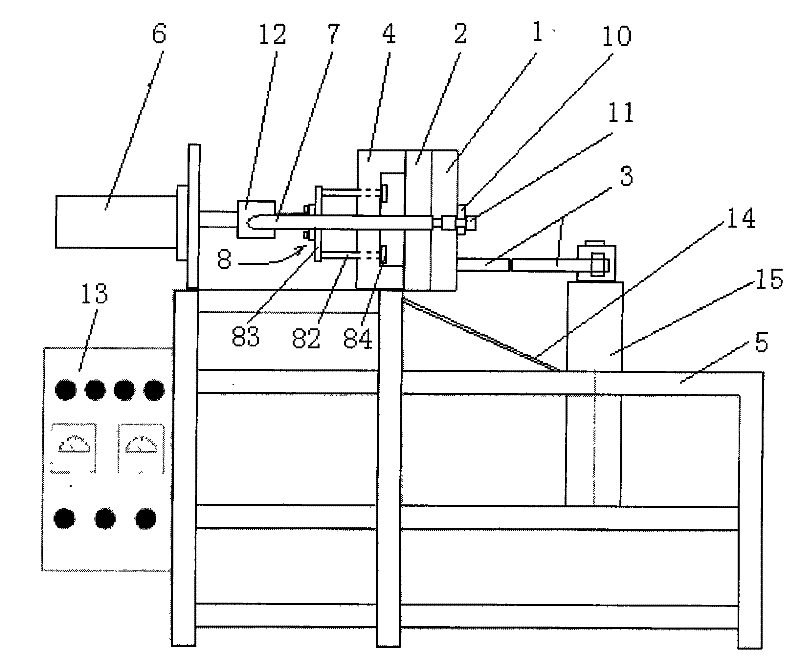

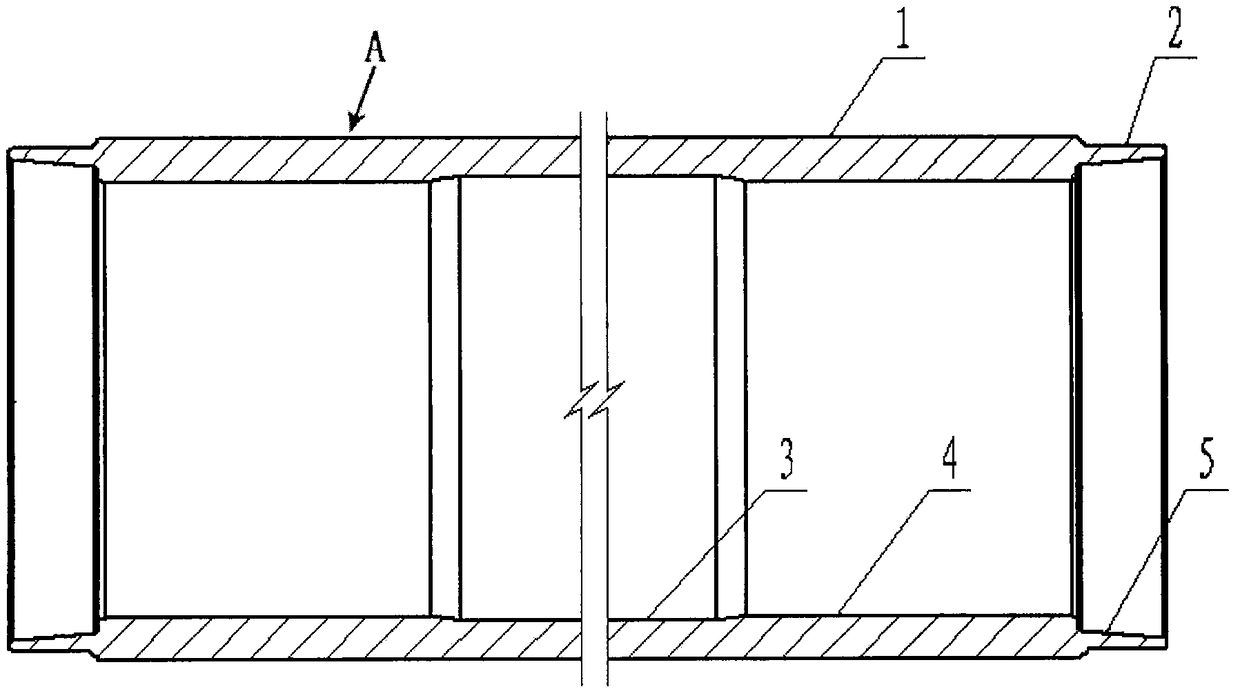

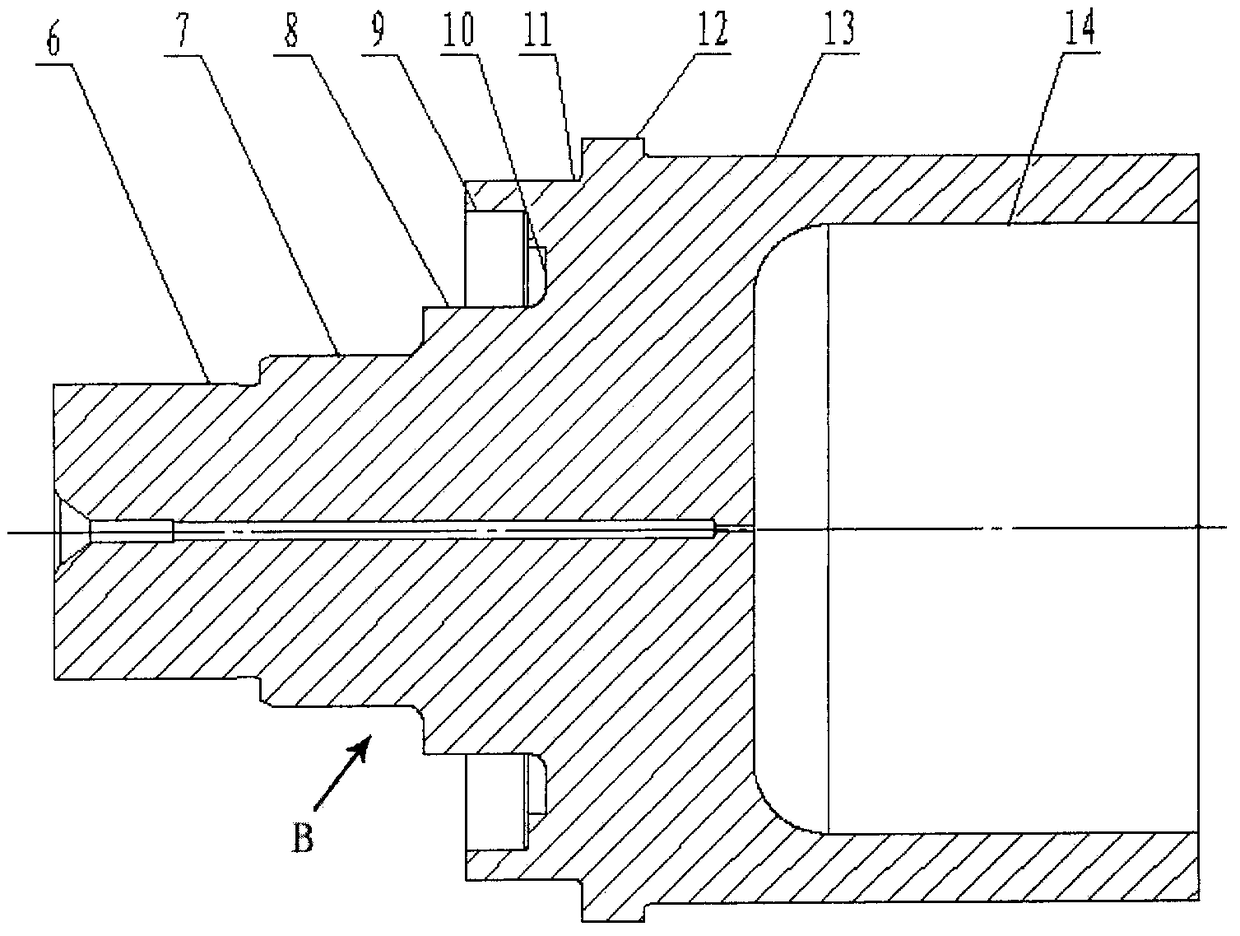

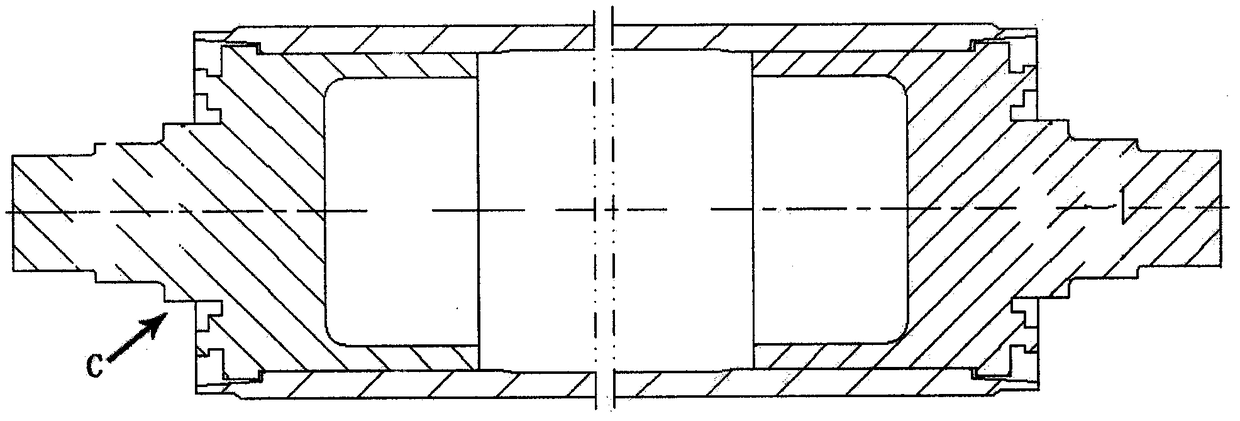

Method for machining hot-mounted dam roller

ActiveCN107470854ASolve the problem that the balance accuracy is not highAvoid product quality defectsInterference fitNumerical control

The invention relates to a method for machining a hot-mounted dam roller. The method for machining the hot-mounted dam roller comprises the steps of machining of a roller cylinder, machining of spindle heads and assembling of the roller cylinder and the spindle heads; assembling of the roller cylinder and the spindle heads comprises the following steps that the spindle heads and the roller cylinder are in interference fit to obtain the dam roller; unbalance amount of the dam roller is detected, center offset amount and the offset direction of the dam roller are calculated, when the unbalance amount is larger than 10 g based on a balance amount, a double-four-jaw chunk clamping device on a lathe is adopted to conduct eccentric borrowing on the dam roller, outer circle turning is conducted to remove the unbalance amount; and finish turning is conducted on a second outer circle of the roller cylinder and eighth outer circles, ninth outer circles and tenth outer circles of the spindle heads by adopting a numerical control lathe turning. The method for machining the hot-mounted dam roller has the advantage of high balance precision.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

One-step molding method of split foot with grounding hole

ActiveCN102101145AImprove stabilityAvoid product quality defectsMetal-working apparatusProduction scheduleSplit foot

The invention provides a one-step molding method of a split foot with a grounding hole, aiming to solve the problems that the production schedule of a foot molding procedure is faster than that of a procedure of punching a grounding hole of the foot, and the procedure of punching the grounding hole of the foot becomes a bottleneck procedure for restricting the promotion of the capacity. The invention has the essential that the production procedures of molding the foot and punching the grounding hole are realized on a set of dies at one time so as to achieve the purpose of generating different effects by the production schedule along different processing equipment. The invention overcomes the limits of manual production and has the advantages that the problem that the efficiency of punching the grounding hole of the foot is lower than the efficiency of molding is solved, and the efficiencies of the two procedures are made to consistent, so that the production efficiency of the foot is greatly improved.

Owner:沈阳中航机电三洋制冷设备有限公司

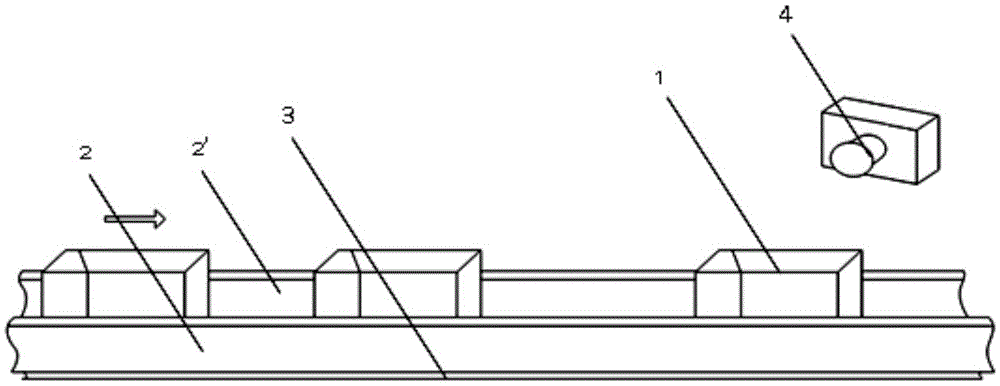

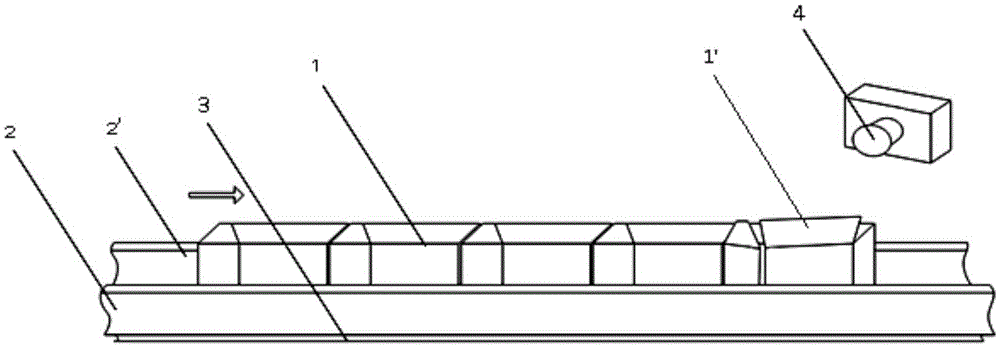

Device for online wear detection of self-piercing riveting gun mold

ActiveCN106323976AAvoid product quality defectsReduced detection processMaterial analysis by optical meansManufacturing lineImage acquisition

The invention discloses a device for online wear detection of a self-piercing riveting gun mold. The device is characterized in that an image acquisition platform is provided for a riveting gun mold on a piercing riveting production line; an image acquisition device for obtaining a mold image is mounted on the image acquisition platform; an image acquisition signal of the image acquisition device is used as an output signal; a computer is used for analyzing the output signal so as to judge the wear degree of a mold. The device provided by the invention can timely monitor the wear state of the mold in an online detection manner, avoids product quality defects, also avoids tediousness brought by disassembly process and the influence on the normal process section, effectively improves the production efficiency, and ensures the product quality.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

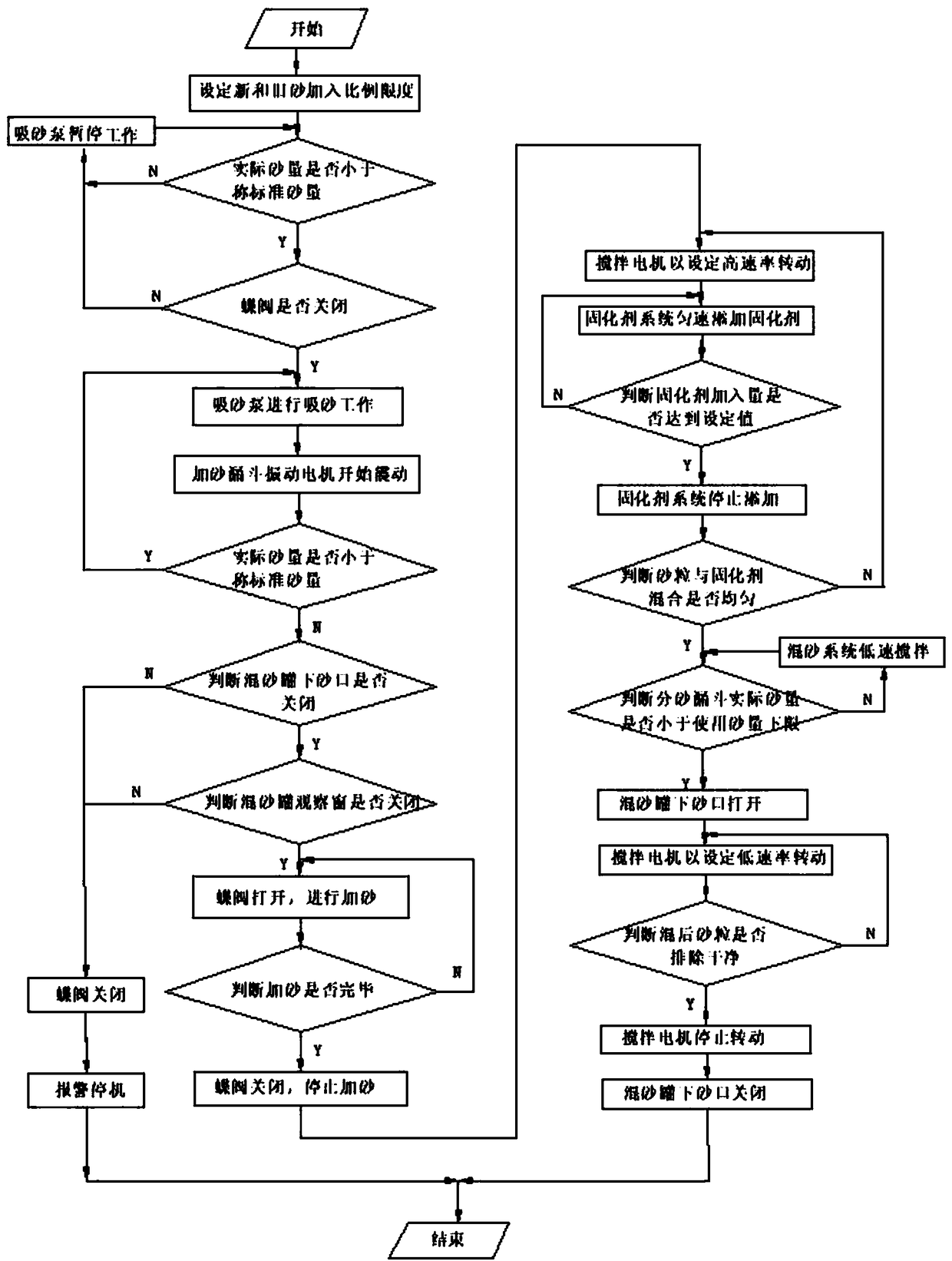

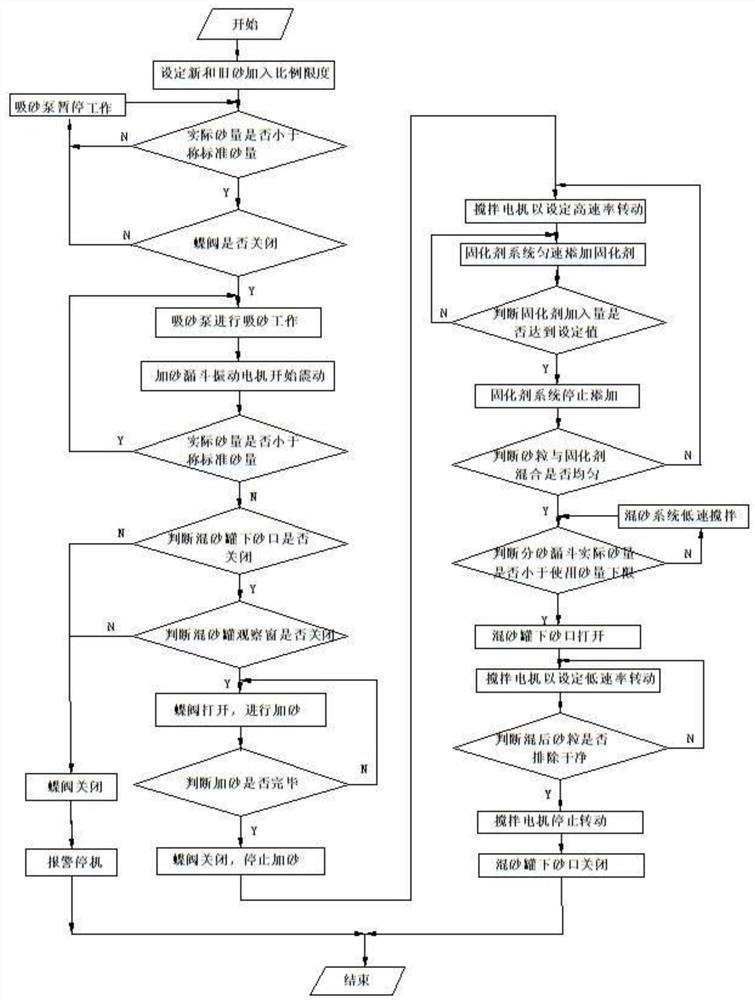

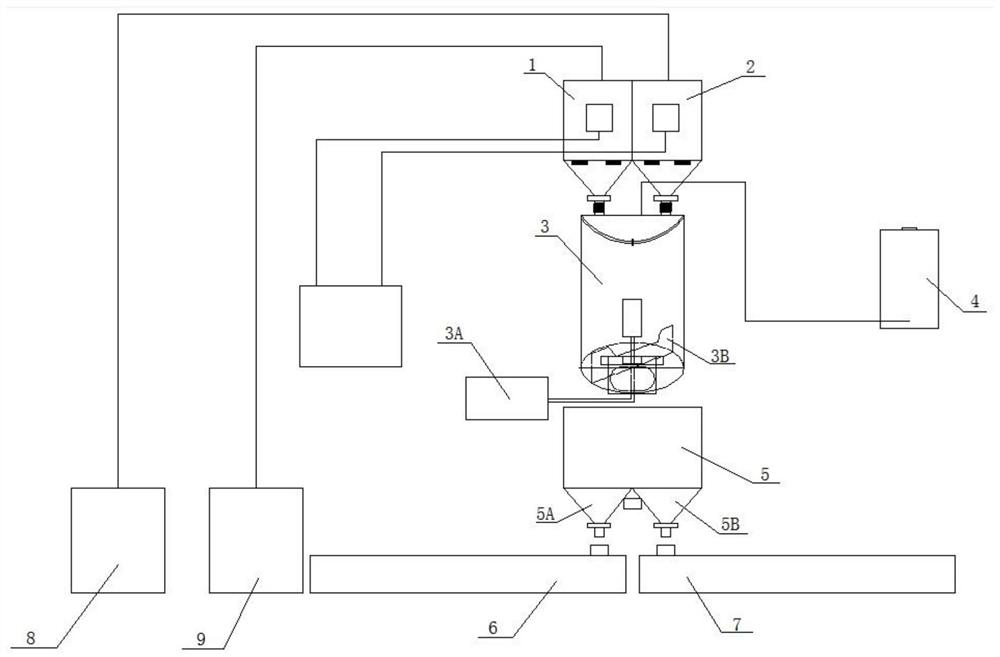

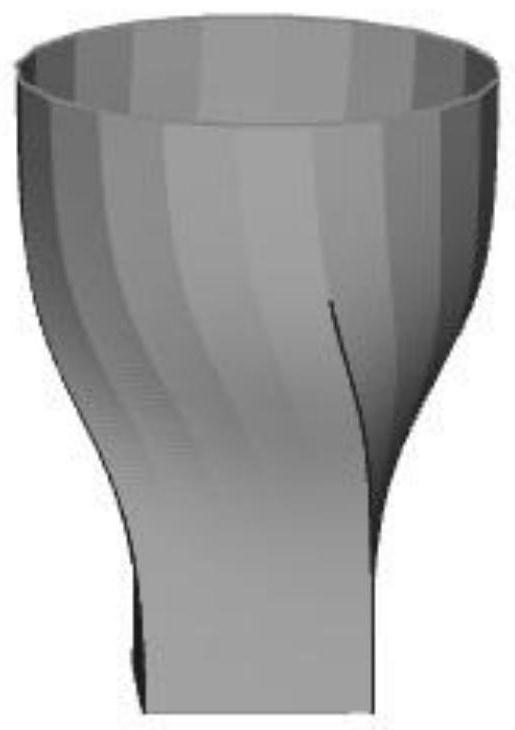

Preparation method of fine-sand-shaped raw material

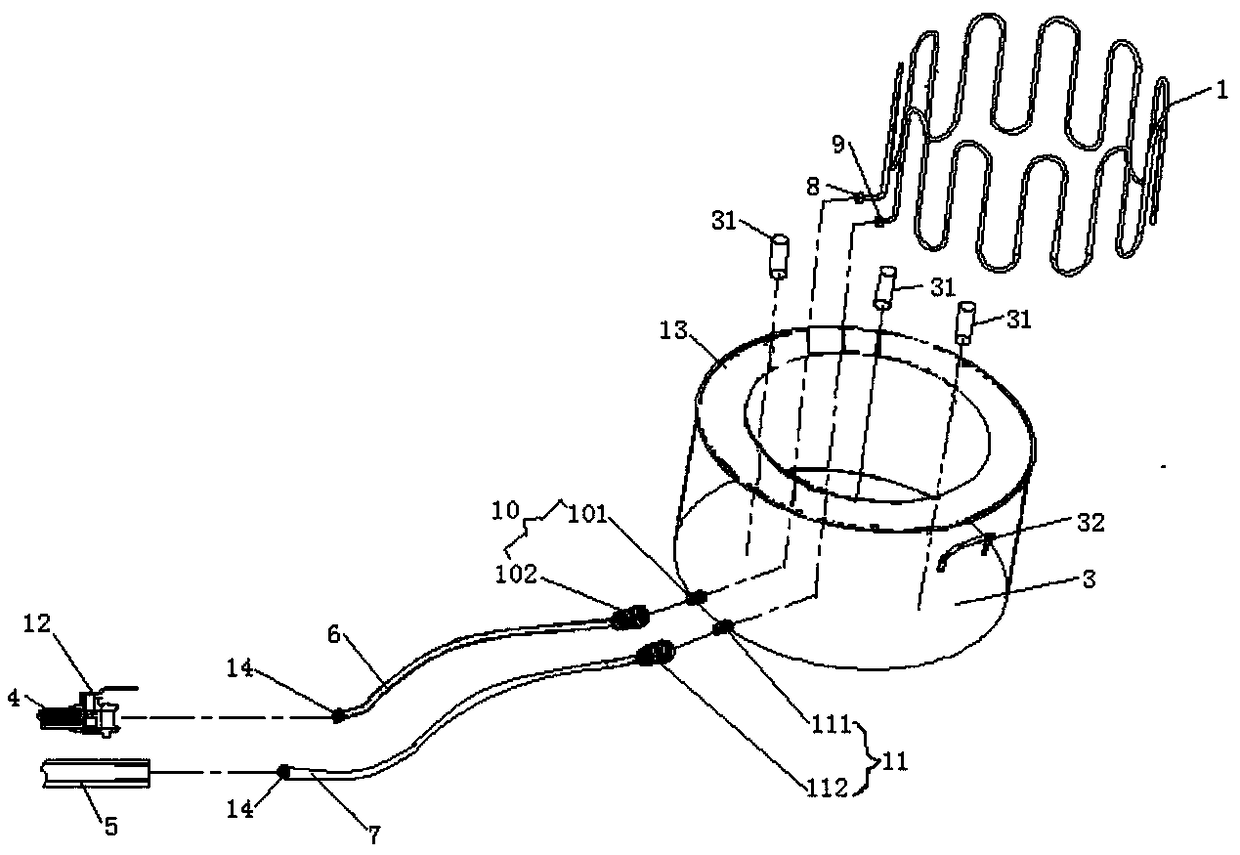

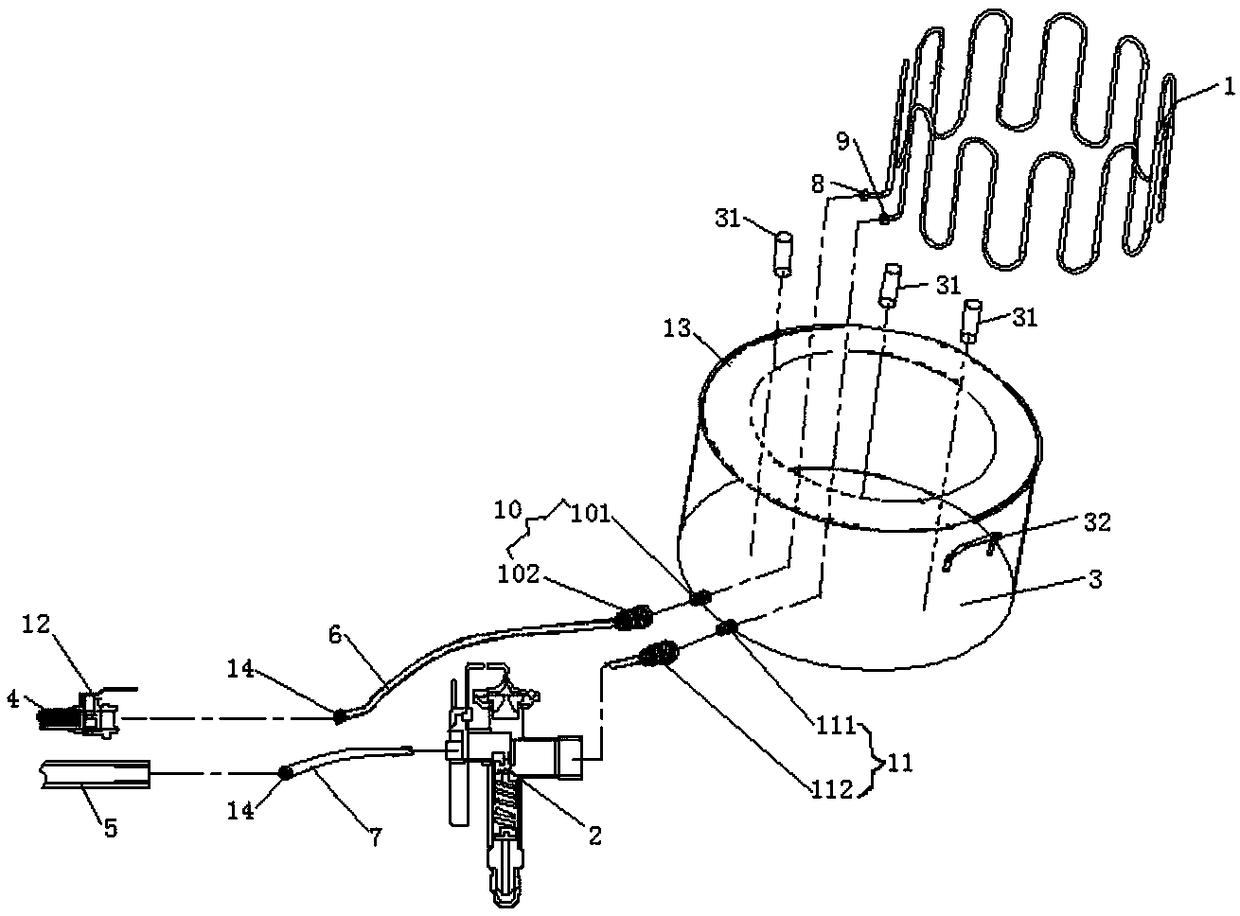

ActiveCN109046171AAchieve hybridHigh degree of automationAdditive manufacturing apparatusTransportation and packagingEngineeringButterfly valve

The invention provides a preparation method of a fine-sand-shaped raw material, and aims to overcome the defects of unstable preparation and mixing as well as poor uniformity in the fine-sand raw material for additive manufacturing equipment. According to the preparation method of the fine-sand-shaped raw material, a butterfly valve type switch component is arranged on a hardware component, and hardware actions are controlled through software in order to realize accurate control of the adding amount. In the preparation method of the fine-sand-shaped raw material, a reasonable stirring structure is provided, and the stirring time is controlled, so that the mixing uniformity is realized, thereby ensuring the accuracy of raw material preparation and the mixing uniformity, and guaranteeing theproduction of qualified products.

Owner:NINGXIA KOCEL MOLD

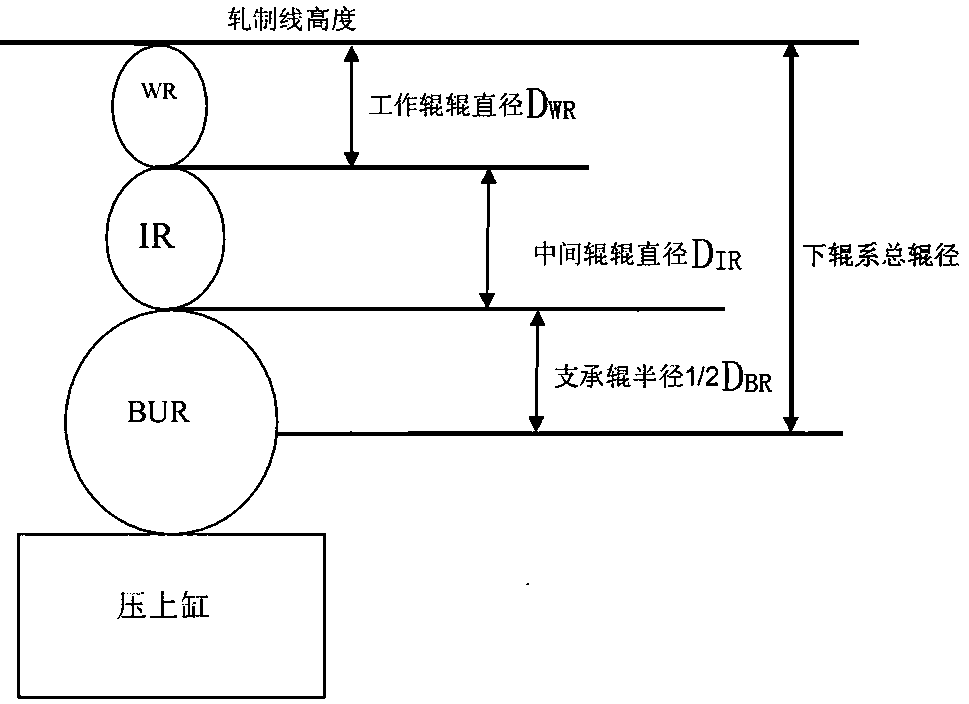

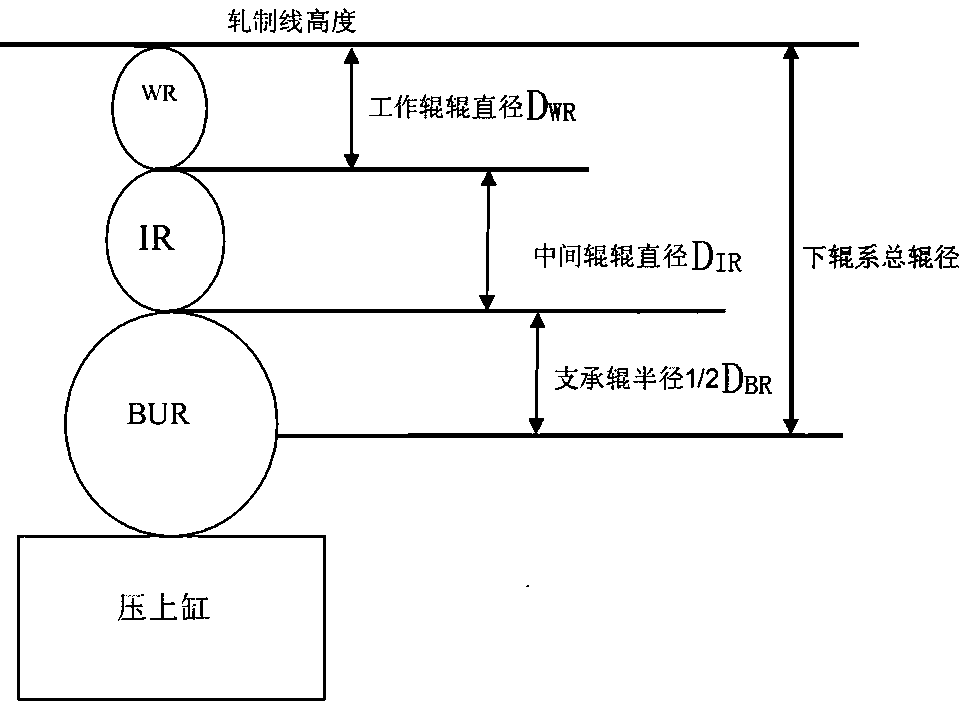

Control method for utilizing roller diameter difference to achieve automatic pressing zeroing of aluminum cold rolling mill

ActiveCN107583958AIncrease productivityImprove yieldRoll mill control devicesMetal rolling arrangementsAutomatic controlRolling mill

The invention relates to a control method for realizing automatic zero approach of an aluminum cold rolling mill by utilizing the difference in roll diameter. This method determines the roll gap setting value by determining the contact rolling force and pressing rolling force parameters of the roll system, and using the roll diameter difference: the roll gap set value is calculated by calculating the roll diameter difference of the new and old roll system before and after the roll change , and give two roll gap values in stages, that is, the initial roll gap value and the secondary roll gap value; then, based on the above calculation parameters, automatic pressing is performed. The method of the invention improves the production efficiency and yield of the rolling mill, and avoids the occurrence of product quality defects caused by pressing.

Owner:CHINALCO RUIMIN

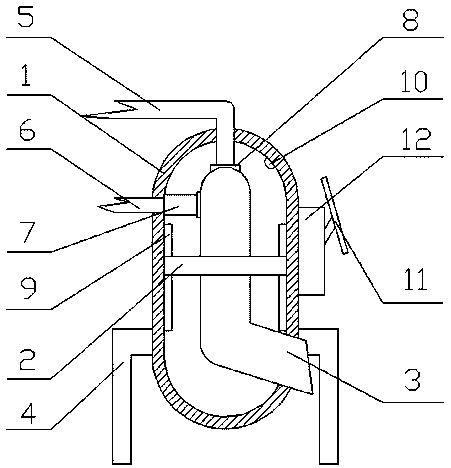

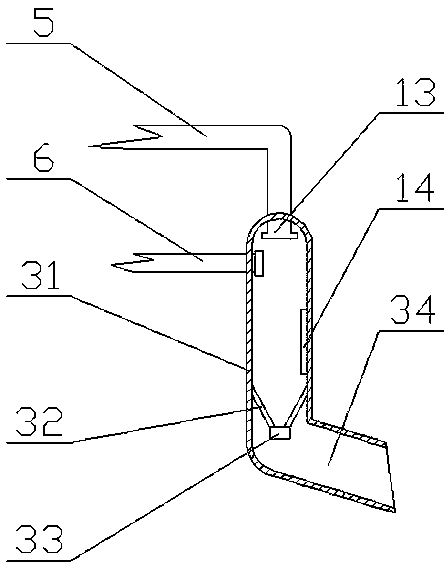

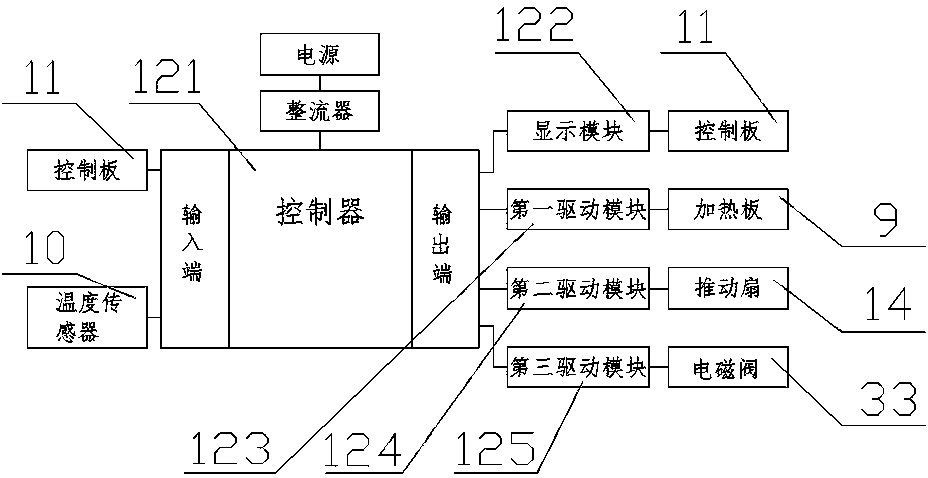

Novel mineral powder decomposition kettle

InactiveCN109183149ASimple responseAvoid product quality defectsPolycrystalline material growthFrom normal temperature solutionsDecompositionCarbon dioxide

The invention provides a novel mineral powder decomposition kettle. The decomposition kettle comprises a shell, a fixed plate, a decomposition chamber, supporting legs, a carbon dioxide conveying tube, a calcium carbonate conveying tube, a heatproof protection tube, a sealing ring, a heating plate, a temperature sensor, a control panel, a controller, a check valve and a push fan, wherein the fixedplate is mounted in the shell by bolts, the decomposition chamber is mounted in the fixed plate by bolts, and the supporting legs are welded to the lower part of the shell; and the carbon dioxide conveying tube is connected to the top of the decomposition chamber through a hole in the top of the shell, the calcium carbonate conveying tube is connected to one side of the decomposition chamber through a hole in one side of the shell, and the surface of the calcium carbonate conveying tube is bonded with the heatproof protection tube. The arrangement of the carbon dioxide conveying tube, the calcium carbonate conveying tube, the heating plate and the check valve makes the novel mineral powder decomposition kettle have the advantages of small size, small occupied space, simplicity in reaction, no clogging, high decomposition efficiency, realization of internal stirring at any time, and convenience in market promotion and application.

Owner:昌邑市滨海盐化供销服务有限公司

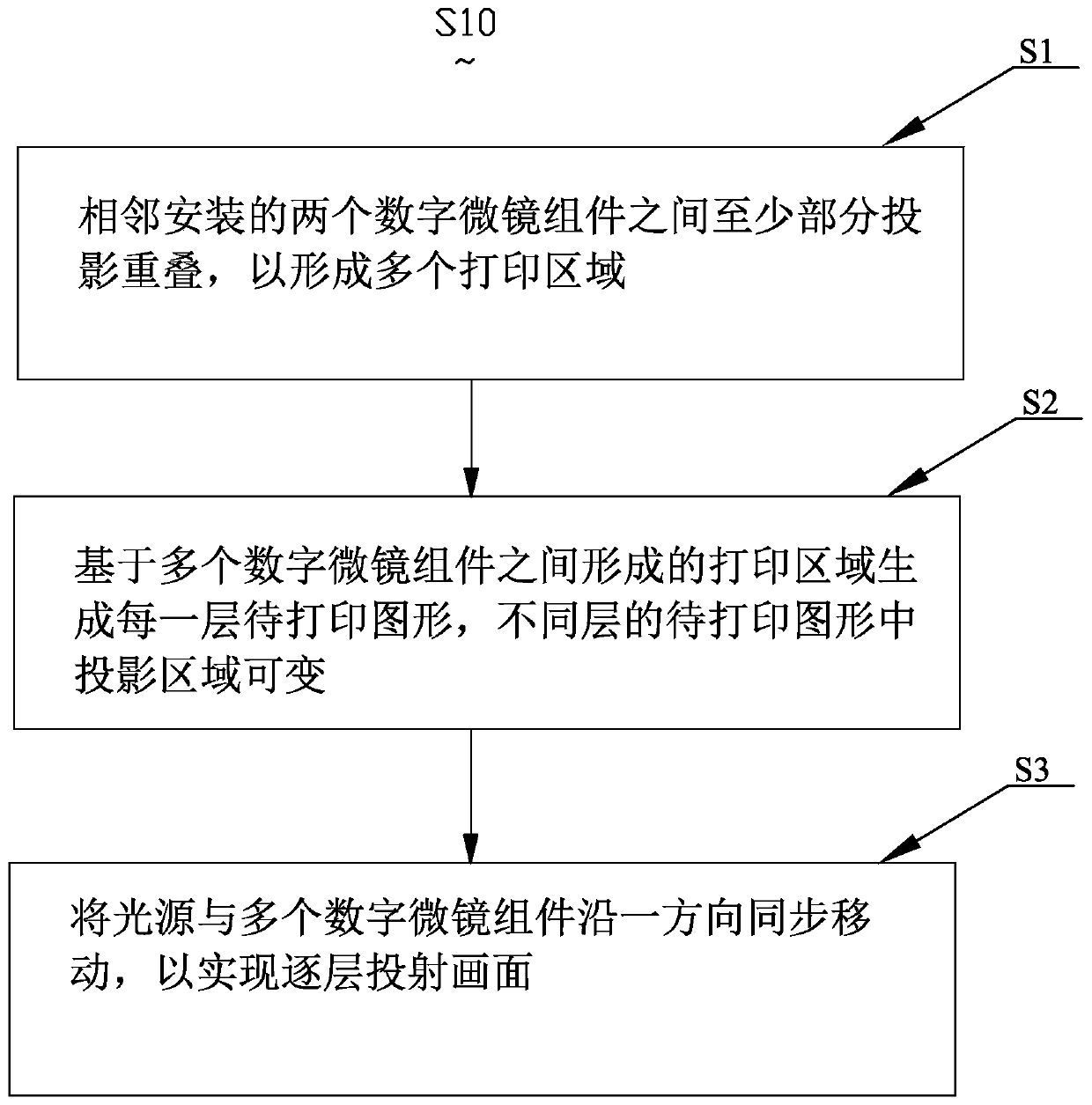

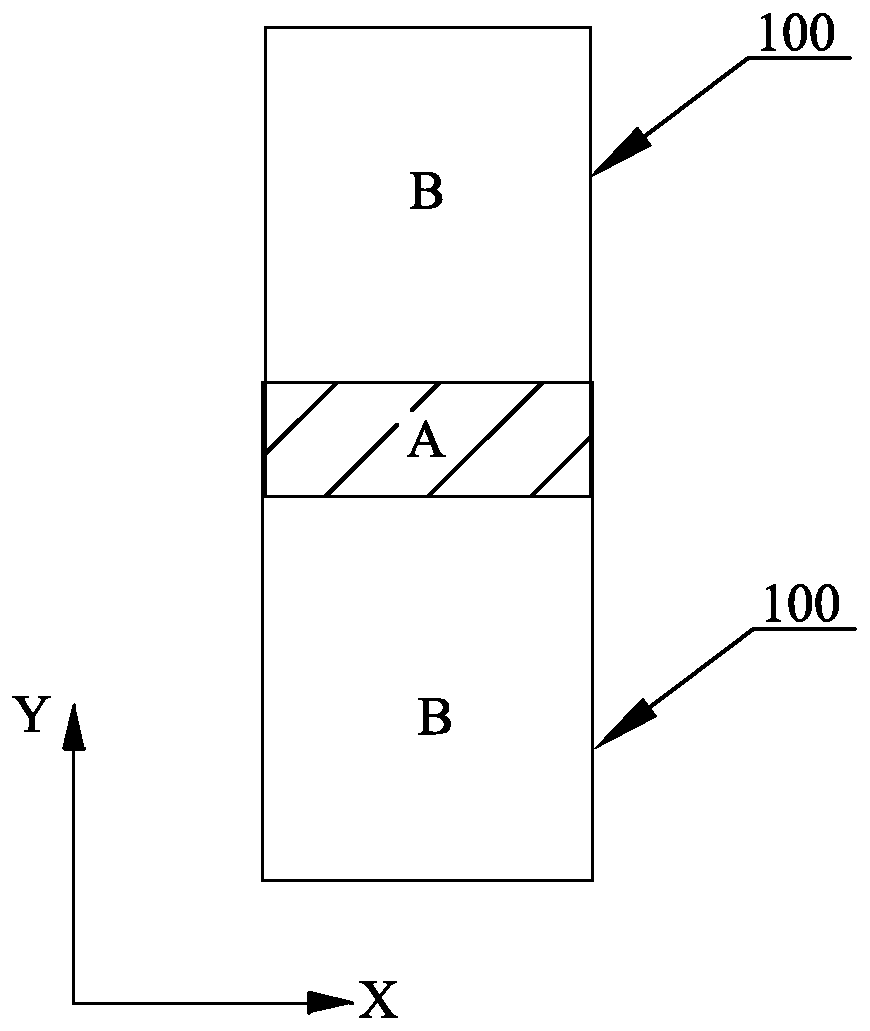

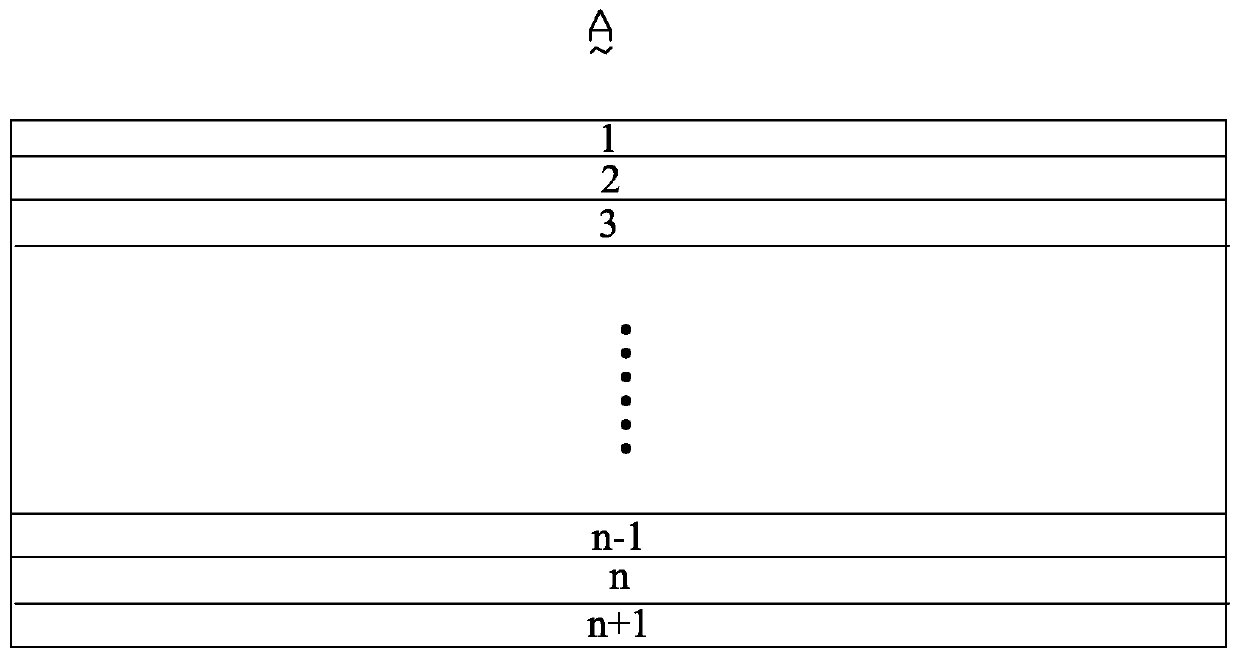

3D printing method and 3D printing equipment

PendingCN110625935ARealize splicingImprove mechanical propertiesAdditive manufacturing apparatus3D object support structuresStress concentrationGraphics

The invention relates to the technical field of 3D printing, in particular to a 3D printing method and 3D printing equipment. The 3D printing method comprises the steps that (1) at least partial projections overlap between two digital micromirror assemblies arranged adjacently to form a plurality of printing areas; (2) each layer of graph to be printed is generated on the basis of the printing areas formed among the plurality of digital micromirror assemblies, wherein projection areas in the graphs to be printed of different layers are variable; and (3) a light source and the plurality of digital micromirror assemblies are synchronously moved along one direction so as to realize layer-by-layer picture projection. By using the 3D printing method, the projection overlapping areas among the plurality of digital micromirror assemblies can be dispersed, so that stress concentration is avoided, and the mechanical property of a final product is improved.

Owner:李佳

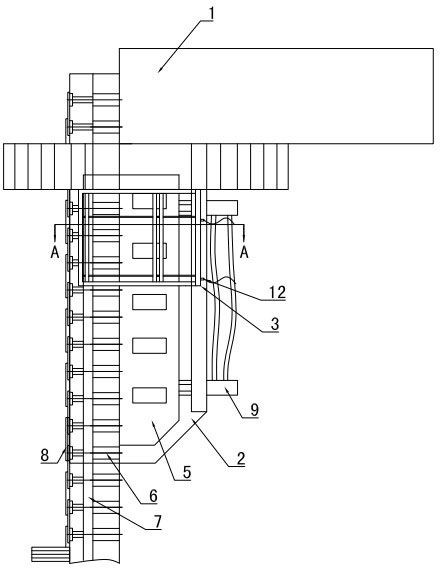

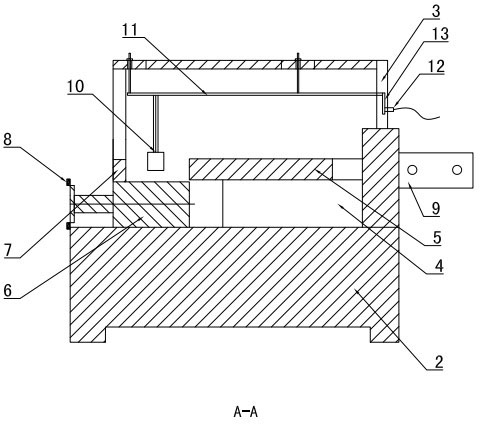

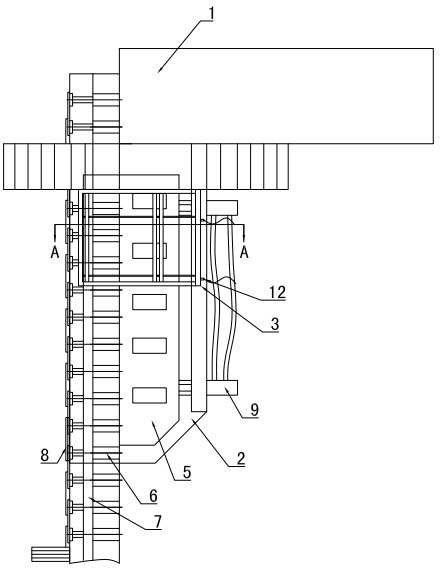

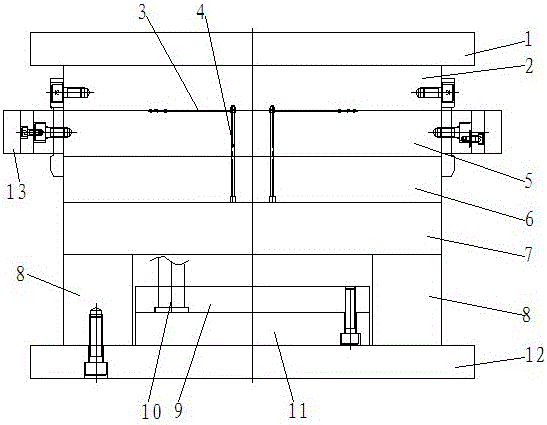

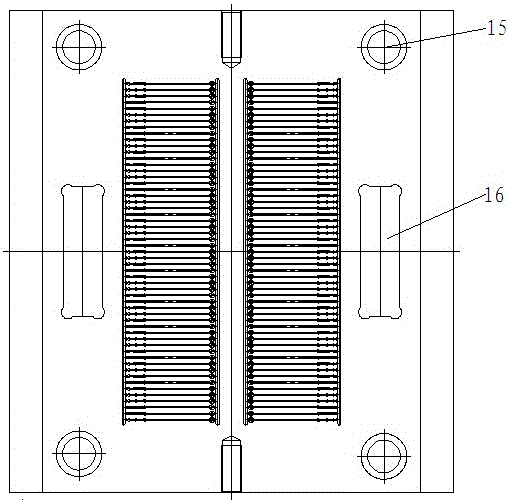

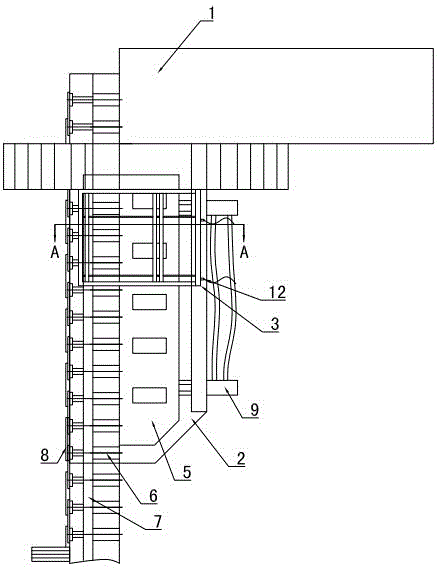

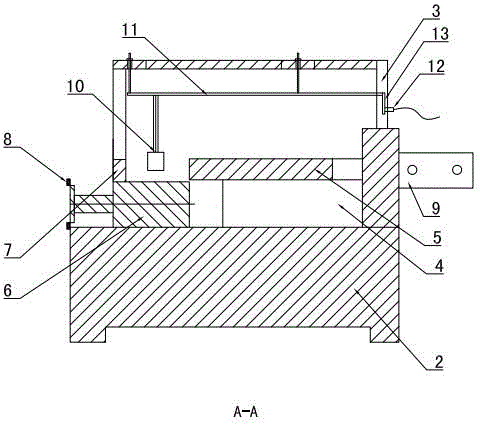

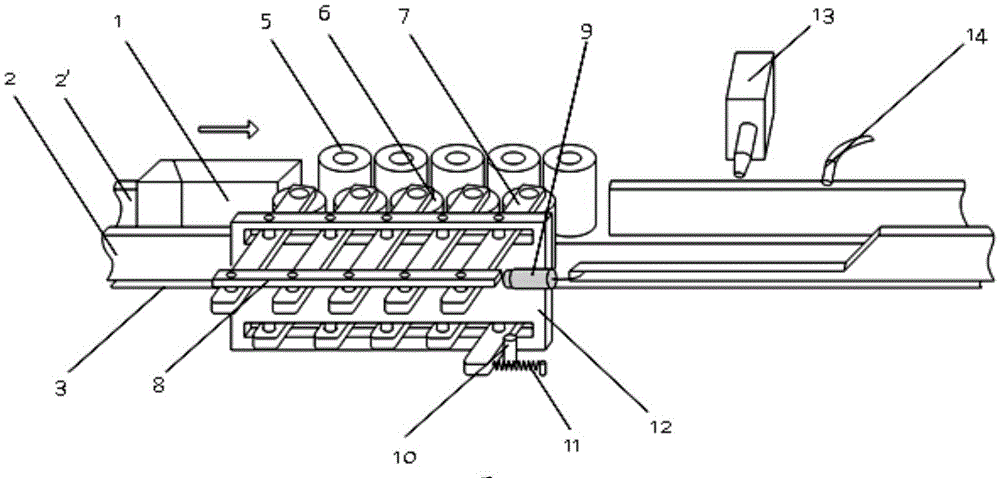

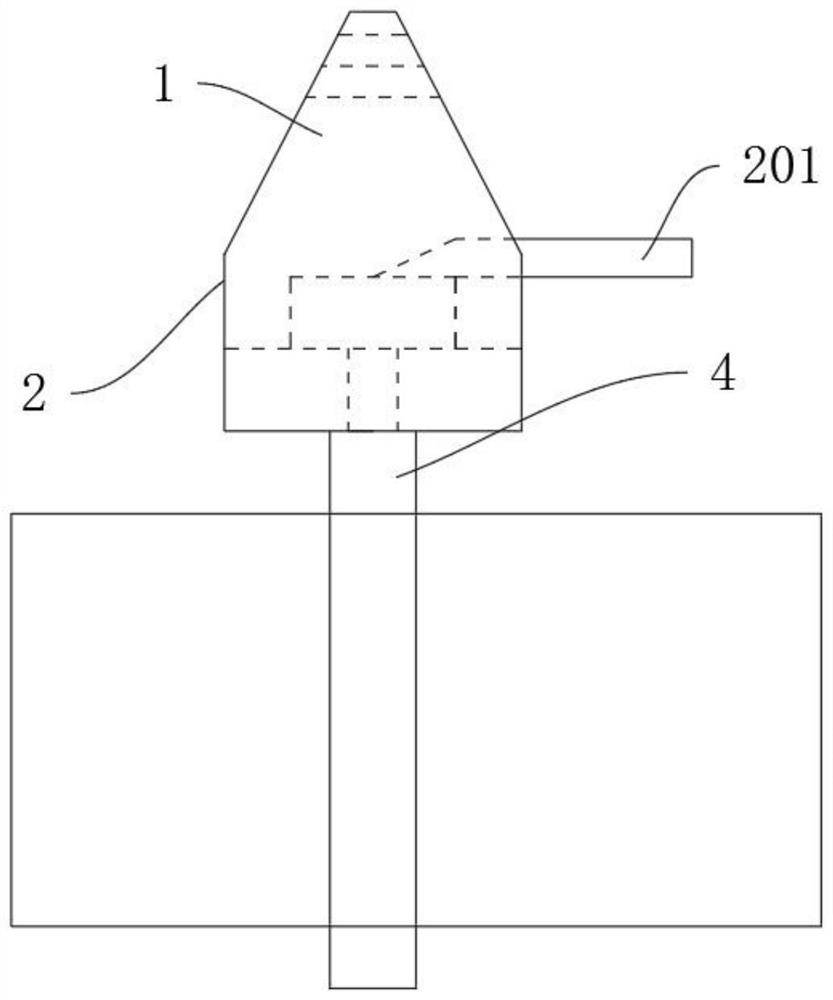

Automatic straightening device of reed

ActiveCN102632109ARealize automatic alignmentImprove work efficiencyMetal-working feeding devicesPositioning devicesControl systemBiochemical engineering

The invention relates to an automatic straightening device of a reed and belongs to the field of automobile part manufacture equipment. The automatic straightening device comprises a quenching furnace (1) and is characterized in that one side of the quenching furnace (1) is fixedly provided with a work table (2), the upper plane of the work table (2) is provided with a reed conveying device and a reed straightening device side by side, a support frame (3) is supported and fixed above the reed conveying device and the reed straightening device, and a control device is arranged on the support frame (3) and is connected with a motive power device (9) arranged at one side of a reed extrusion device. The automatic straightening device of the reed has the advantages that the automatic straightening of the reed can be realized, the work efficiency is improved, the labor and the materials are saved, the product quality is improved, meanwhile, a control system is simple, the machine halt caused by part damage can be effectively prevented, and in addition, the work is safer.

Owner:山东海华汽车部件制造有限公司

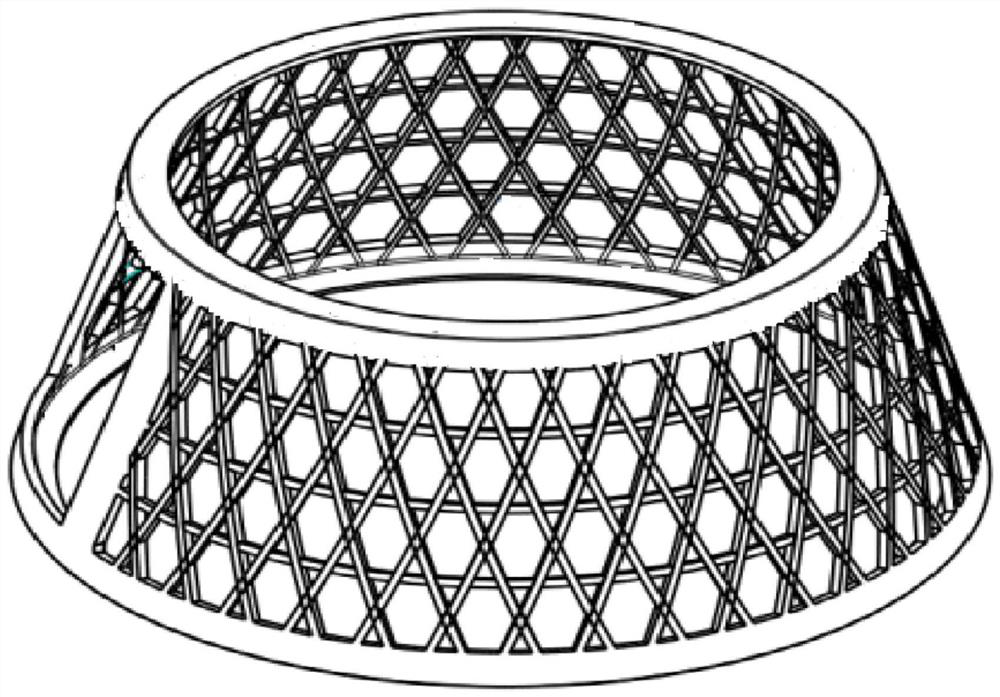

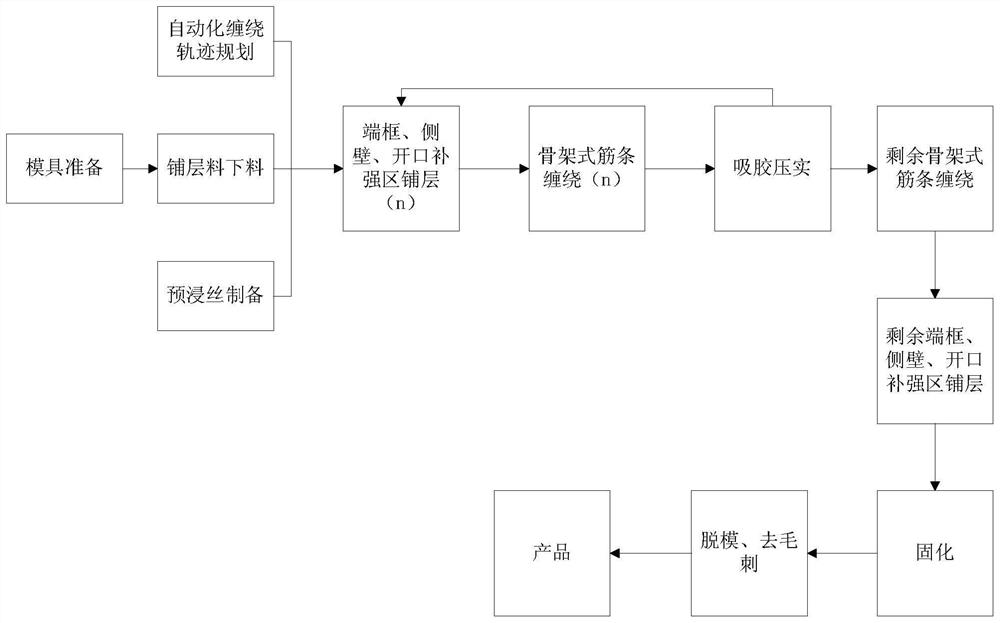

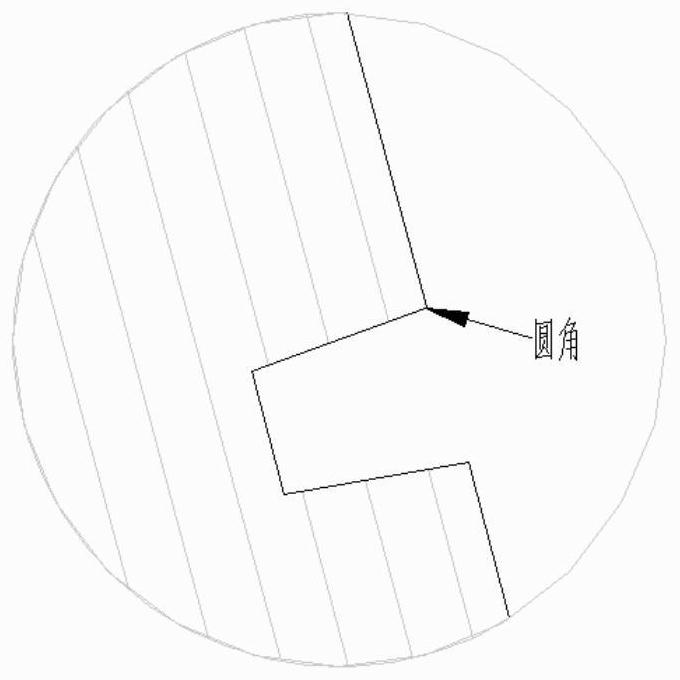

Preparation method of ultra-light multi-feature skin-free skeleton type composite material shell

ActiveCN113844078AUniform effective connectionGuaranteed stiffnessWeight reductionDomestic articlesNumerical controlStructural engineering

The invention relates to a preparation method of an ultra-light multi-feature skin-free skeleton type composite material shell. The preparation method comprises the following steps of automatically winding linear trajectory planning by arranging an end socket guiding and positioning device capable of freely moving, achieving accurate groove entering numerical control automatic winding of 'non-geodesic line 'equidistant spiral ribs and annular rib hot melting prepreg filaments and alternate proceeding of framework ribs and multi-feature structure laying are. Aiming at a multi-feature skin-free skeleton type structure, uniform and effective connection of side wall flanges, end frames and skeleton ribs is realized through balanced interactive coupling layering structure design, accurate calculation of a skeleton rib hot-melt prepreg filament winding cycle number, balanced interactive coupling rib winding-end frame-opening reinforcing area layering structure, rib scattering and the like, and the overall rigidity and stability of the product are ensured. By optimizing the design of a framework rib R-angle mold, a pre-compaction control technology and a reasonable curing process, the problems of poor rib size precision, rib defects and product quality defects caused by the problem of multi-feature structure curing pressurization interference due to edge overflow of a skin-free framework rib are solved, high-quality and high-dimensional-precision integrated forming of the ultra-light multi-feature skin-free framework composite material shell is achieved, the weight is reduced by 30% or above compared with a traditional skin structure, and the requirement for light weight of spaceflight models is met.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

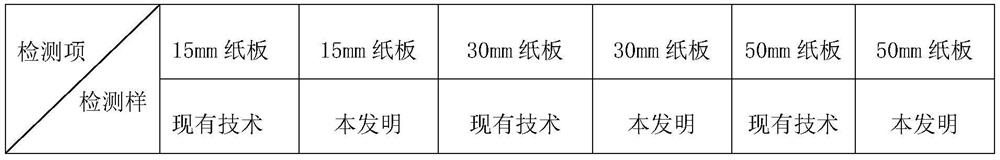

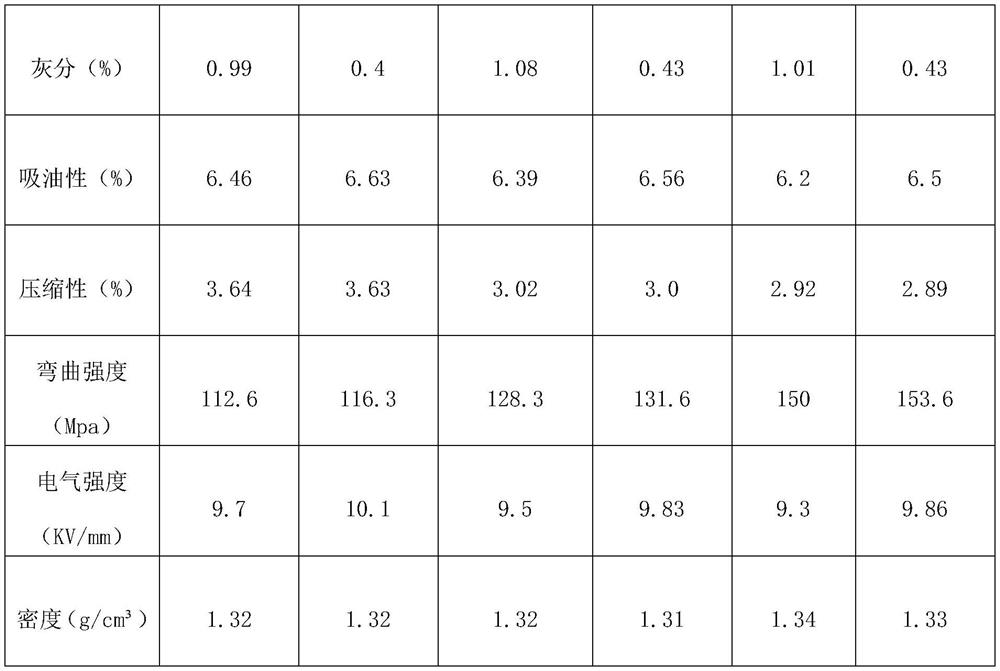

Preparation method of insulating paper board

ActiveCN113183536AResolve the breakUniform rolling operationMechanical working/deformationAdhesivePaperboard

The invention discloses a preparation method of an insulating paper cylinder. The method comprises the following steps of: selecting the thicknesses and the quantity of veneers according to the thickness of a final product, carrying out humidifying, stacking, standing and mold loading, carrying out cold pressing and hot pressing on a wet paper board on a mold, and finally carrying out cutting and forming. According to the preparation method, the defects caused by an adhesive can be effectively removed in the preparation of the insulating paper board with the thickness of 10-50mm, and the overall quality and the production efficiency of the insulating paper board are improved.

Owner:WEIFANG HUISHENG INSULATION TECH

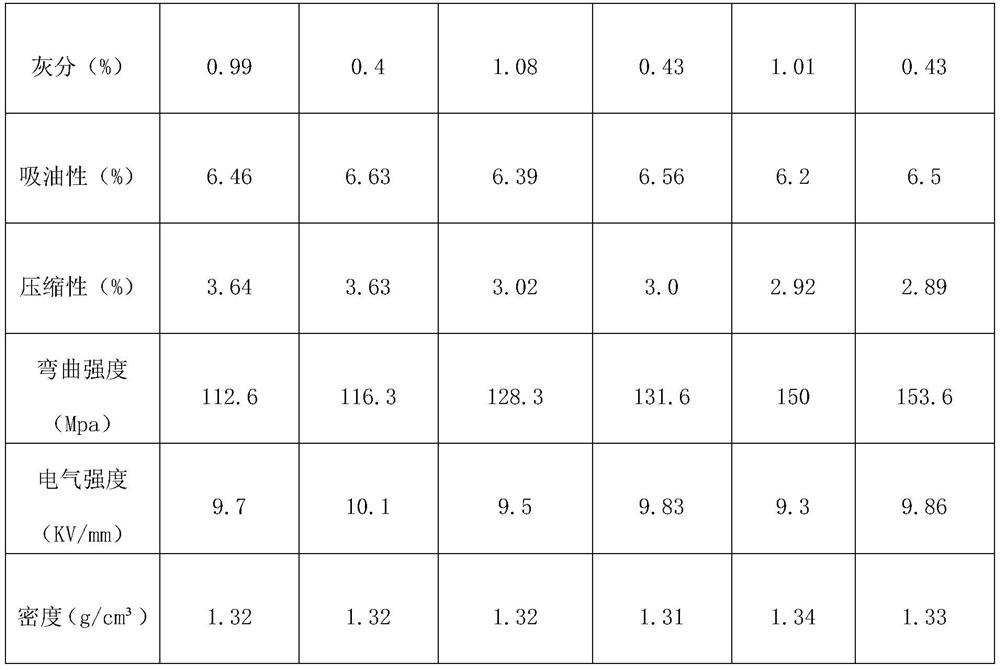

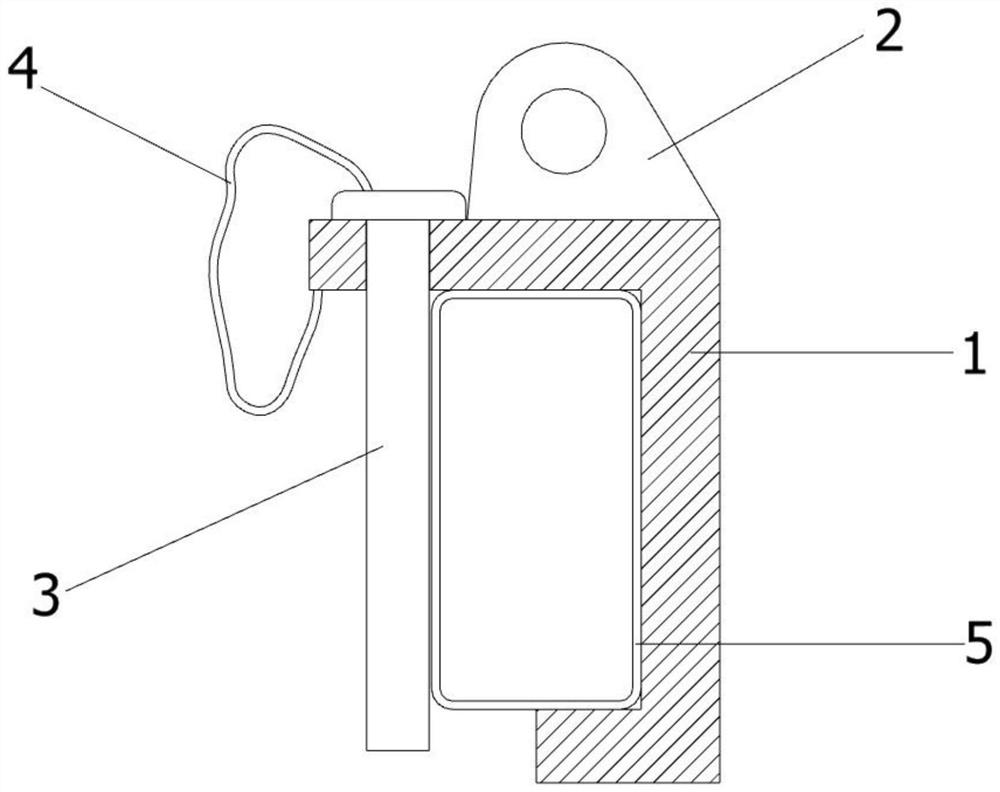

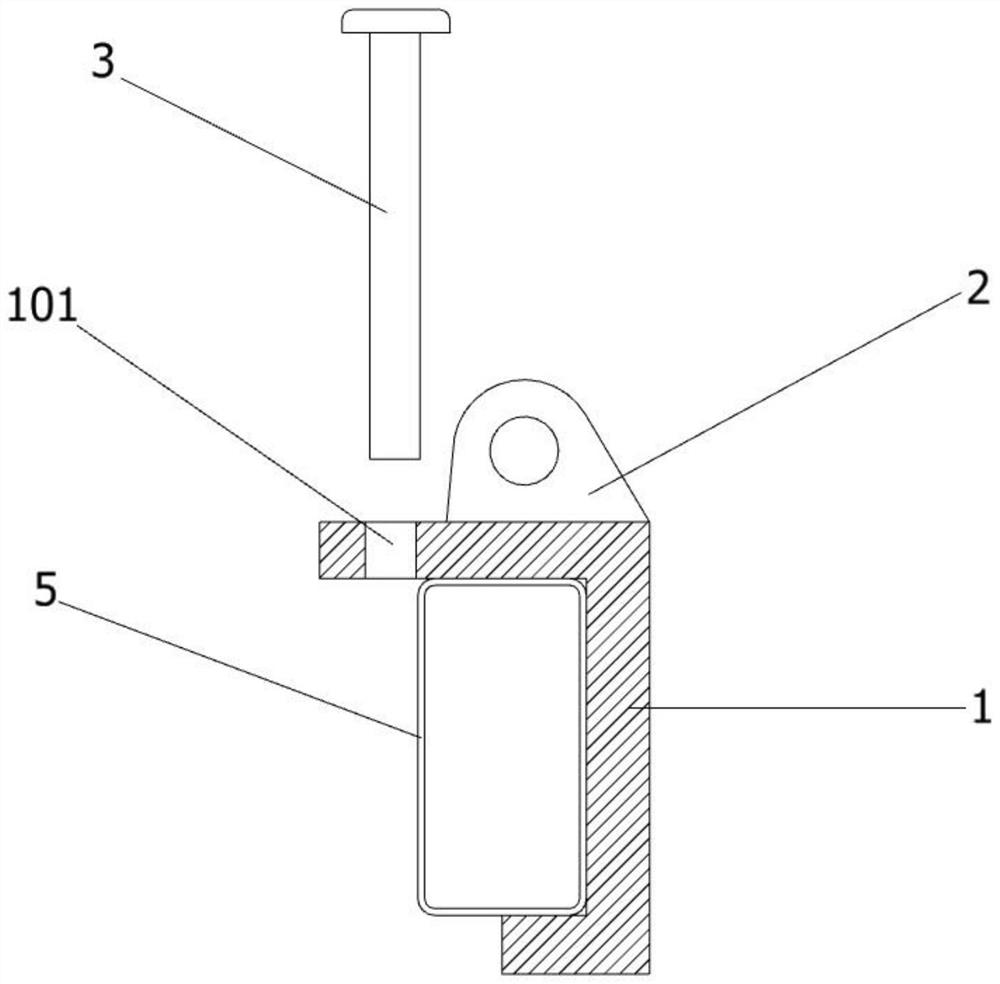

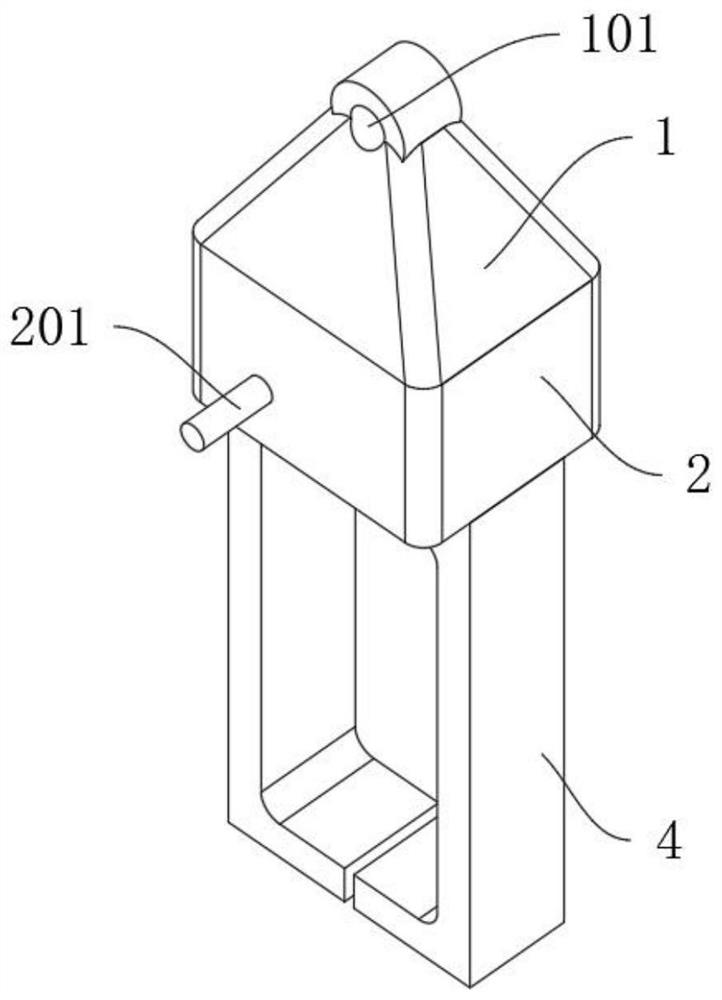

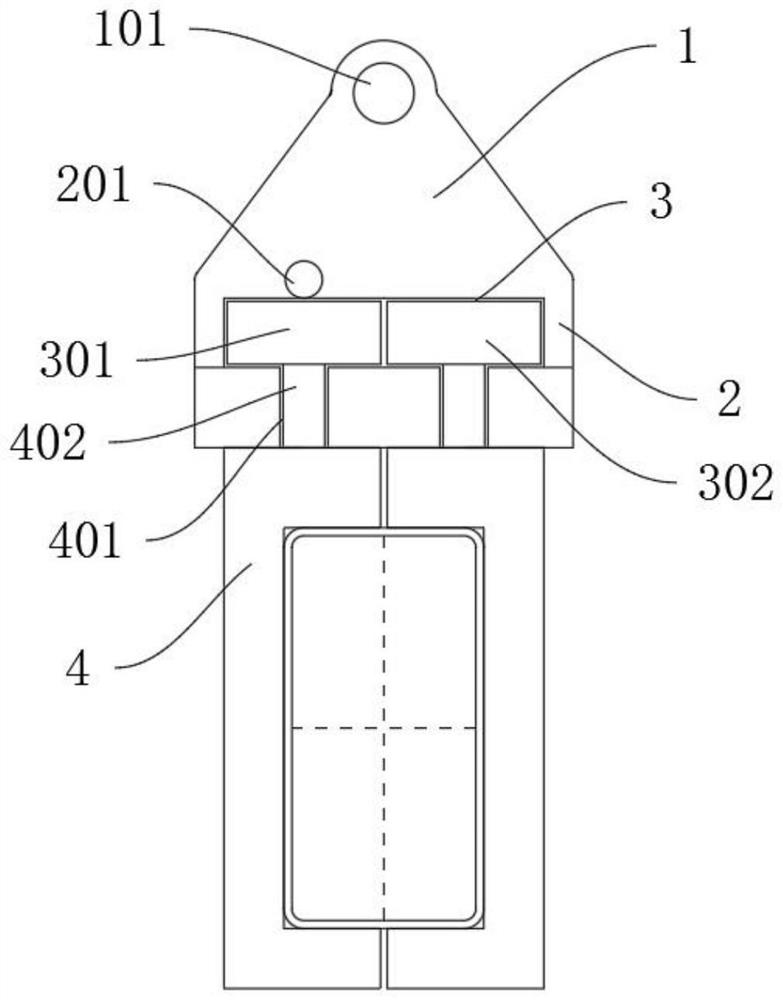

Van vehicle side plate lifting appliance

The invention provides a van vehicle side plate lifting appliance, belongs to the technical field of side plate lifting appliances, and aims at solving the problems that in the existing van vehicle side plate crane transport process, according to a crane transport manner, a van vehicle square and rectangular pipe is punched or welded with a special hanging piece, the product production efficiencyis greatly reduced through the punching and hanging piece welding modes, and product quality is affected. The van vehicle side plate lifting appliance comprises a fastener main body, a hanging lug isarranged at the top of the fastener main body, and a plug pin is inserted into the left side of the fastener main body. By means of the van vehicle side plate lifting appliance, workpieces composed ofall van vehicle square and rectangular pipes and corrugated plates can be hung, and the van vehicle side plate lifting appliance is safe, reliable and convenient to fix and detach; and product quality defects and unnecessary cutting repair welding operation caused by original punching and hanging piece welding modes are effectively avoided. The hanging efficiency of a carriage sub-assembly amongall procedures is improved, and the appearance quality of products is improved.

Owner:DONGFENG SPECIAL PURPOSE VEHICLE

Automatic painting robot for shipbuilding painting

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

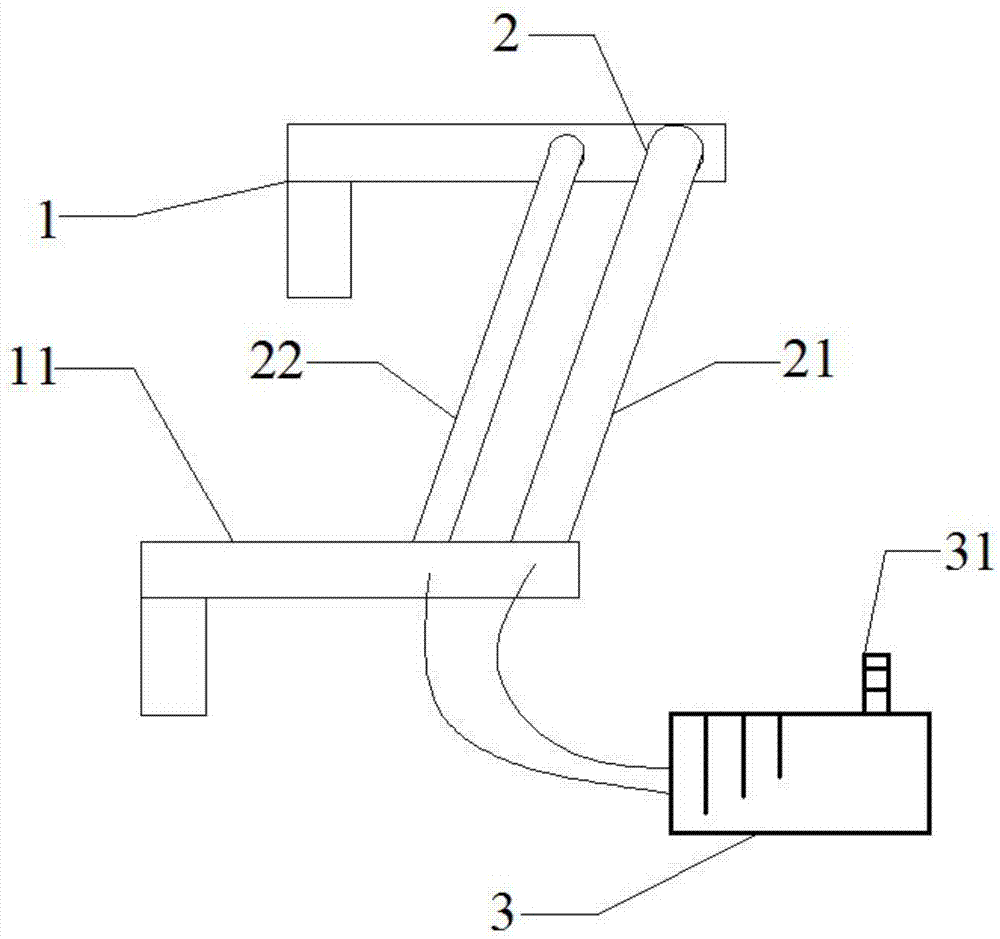

A gravure water-based ink cooling device

ActiveCN106739474BReduce the temperatureGood printabilityPrinting press partsWater basedWater discharge

The invention discloses a water-based ink cooling device for gravure printing, which comprises a cooling water tower, a main water inlet pipe, a main water outlet pipe, a high-pressure resistant water inlet cooling pipe, a high-pressure resistant water outlet cooling pipe, a cooling water bucket and a cooling copper pipe; The copper pipe is fixedly arranged on the inner side wall of the cooling bucket through the water inlet joint and the water outlet joint, and the high pressure resistant water inlet cooling pipe and the high pressure resistant water outlet cooling pipe are connected with the water inlet joint and the water outlet respectively. The water outlet is connected by a joint, the main water inlet pipe and the main water outlet pipe are respectively connected to the cooling water tower, the high pressure resistant water inlet cooling pipe is connected to the main water inlet pipe, the high pressure resistant water outlet cooling pipe is connected to the Main outlet connection. The device can effectively reduce the temperature of the gravure water-based ink, and control it within the temperature range required by the process, reduce the influence of the temperature of the gravure water-based ink on the pH value and viscosity of the ink, and make the printing suitability of the ink more stable. Solve product quality defects caused by ink temperature rise.

Owner:CHANGDE JINPENG PRINTING

A gravure printing water-based ink constant temperature control device

ActiveCN106739435BReduce the temperatureGood printabilityRotary intaglio printing pressTemperature controlWater based

The invention discloses a gravure water-based ink constant temperature control device, which comprises a cooling water tower, a main water inlet pipe, a main water outlet pipe, a high pressure resistant water inlet cooling pipe, a high pressure resistant water outlet cooling pipe, a cooling water bucket, a cooling copper pipe and an adjustable thermal expansion valve; the cooling copper pipe is fixedly arranged on the inner side wall of the cooling bucket through the water inlet joint and the water outlet joint, and the high pressure resistant water inlet cooling pipe and the high pressure resistant water outlet cooling pipe respectively The water inlet joint is connected with the water outlet joint, the main water inlet pipe and the main water outlet pipe are respectively connected with the cooling water tower, the high pressure resistant water inlet cooling pipe is connected with the main water inlet pipe, and the water resistant The high-pressure water outlet cooling pipe is connected to the main water outlet pipe, and the adjustable thermal expansion valve is arranged in the middle of the high-pressure resistant water outlet cooling pipe. The device can effectively reduce the temperature of the gravure water-based ink, and control it within the temperature range required by the process, so that the printability of the gravure water-based ink is more stable.

Owner:CHANGDE JINPENG PRINTING

Forming Die for Plum Blossom Joint Rubber Needle

Owner:广州市鑫富塑胶有限公司

Exposed steel wire detection device of tire forming machine

InactiveCN104713908AAvoid product quality defectsSave resourcesMaterial analysis by electric/magnetic meansEngineeringMechanical engineering

The invention belongs to the technical field of exposed conductor detection and particularly relates to an exposed steel wire detection device of a tire forming machine. The exposed steel wire detection device comprises a bracket, pressure rollers and a controller, wherein the bracket is provided with a suspension beam; the pressure rollers include a first pressure roller and a second pressure roller; the first pressure roller and the second pressure roller are same in length; the outer diameter of the first pressure roller is greater than that of the second pressure roller; the ends of both the first pressure roller and the second pressure roller are insulated; the first pressure roller and the second pressure roller are mounted in parallel on the suspension beam; the controller is connected with one end of each pressure roller through a lead wire. The exposed steel wire detection device can be used for automatically detecting a steel wire exposed from a belted layer of a tire, thereby avoiding product quality defects and saving resources; an alarm device is arranged, so that when the exposed steel wire is detected, an alarm can be given in time to notify working personnel.

Owner:QINGDAO SENTURY TIRE CO LTD

A kind of preparation method of insulating cardboard

ActiveCN113183536BResolve the breakUniform rolling operationMechanical working/deformationPolymer scienceAdhesive

Owner:WEIFANG HUISHENG INSULATION TECH

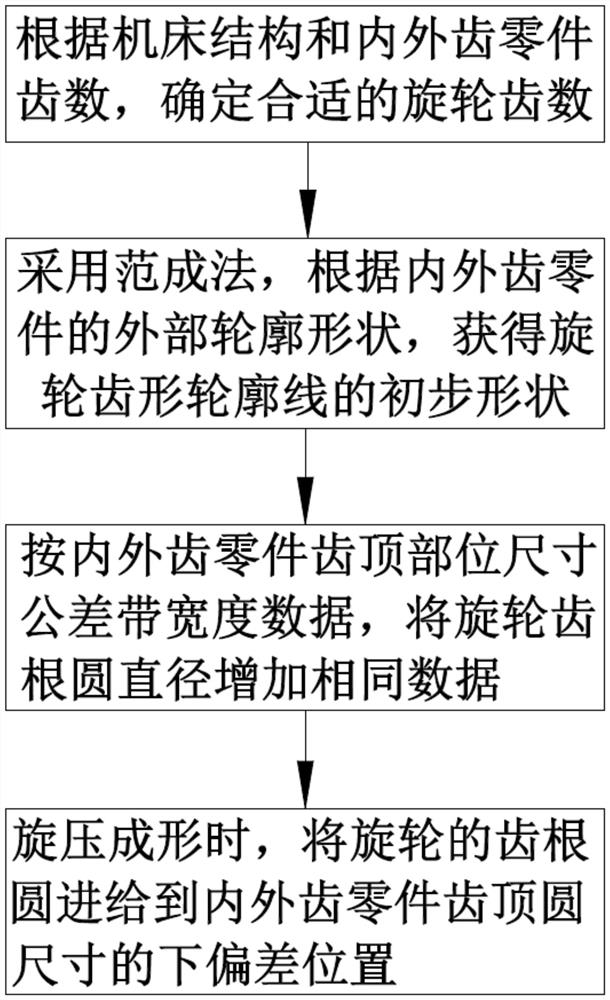

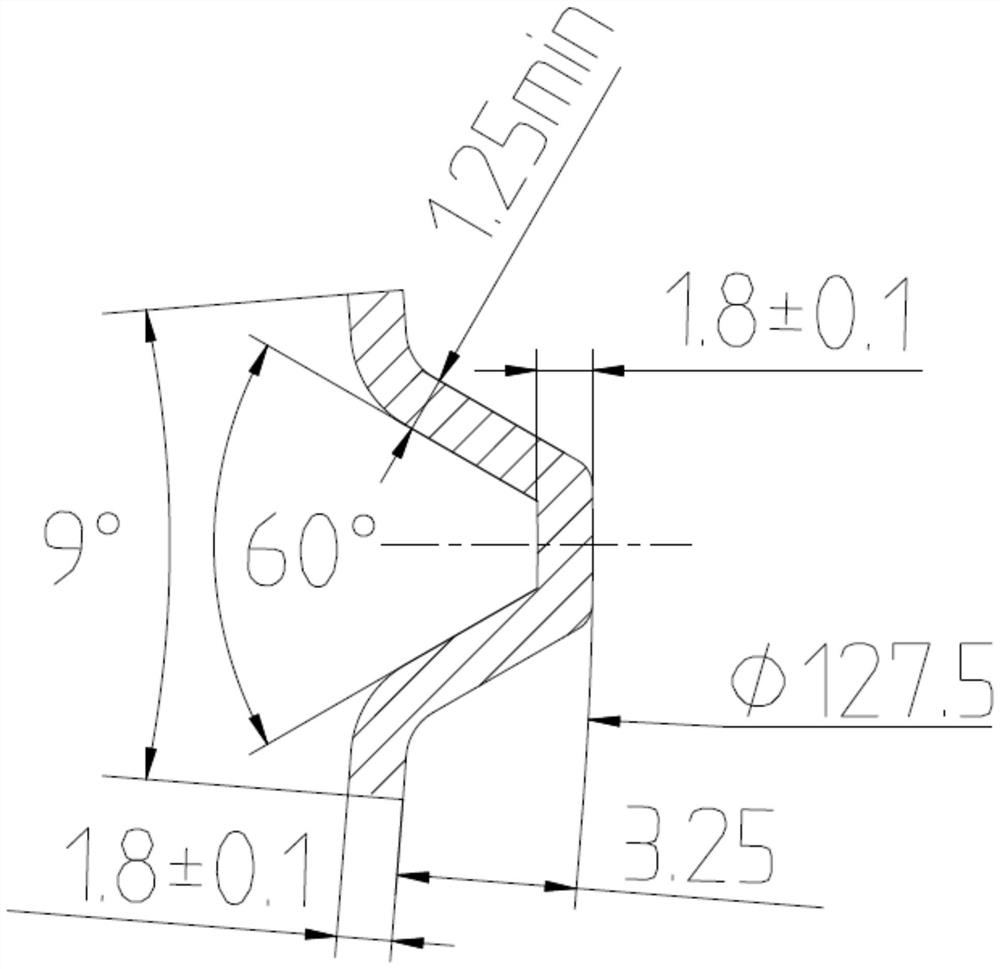

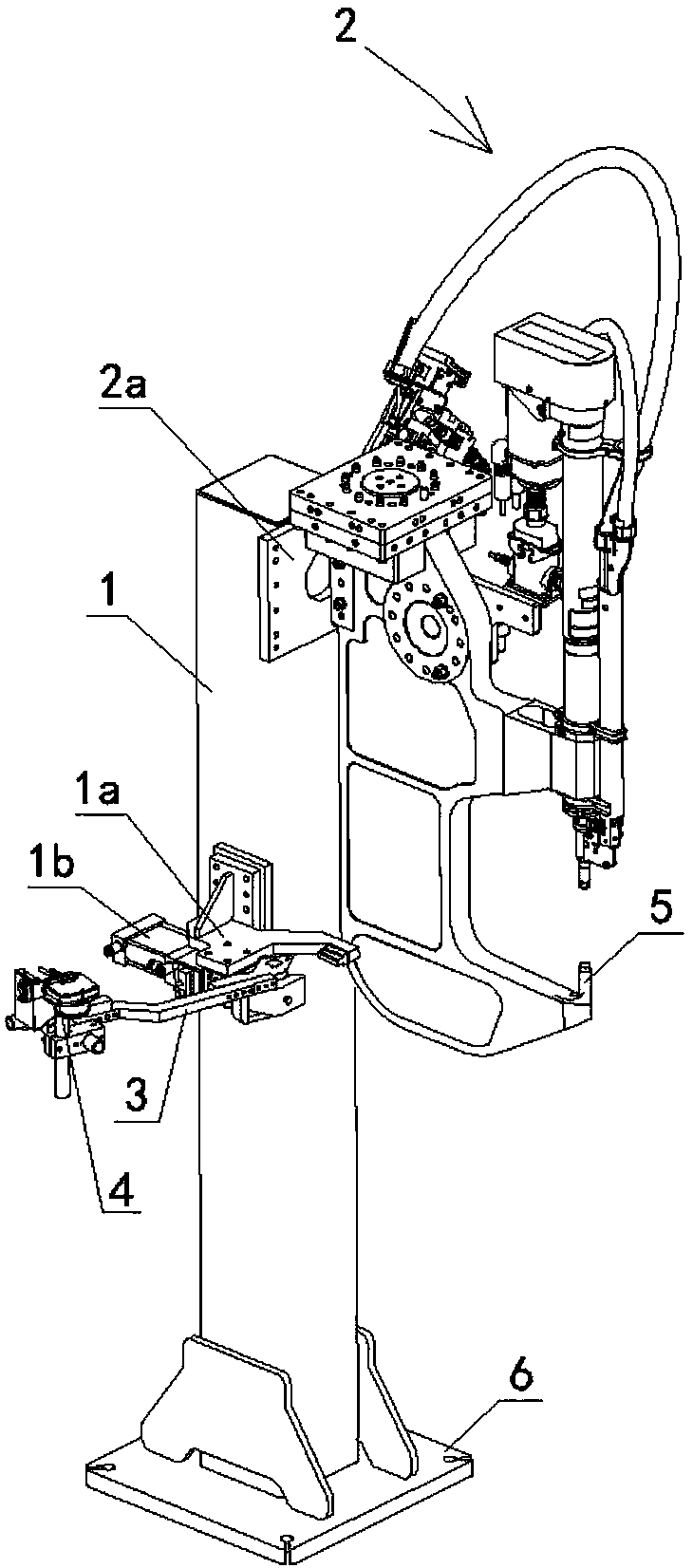

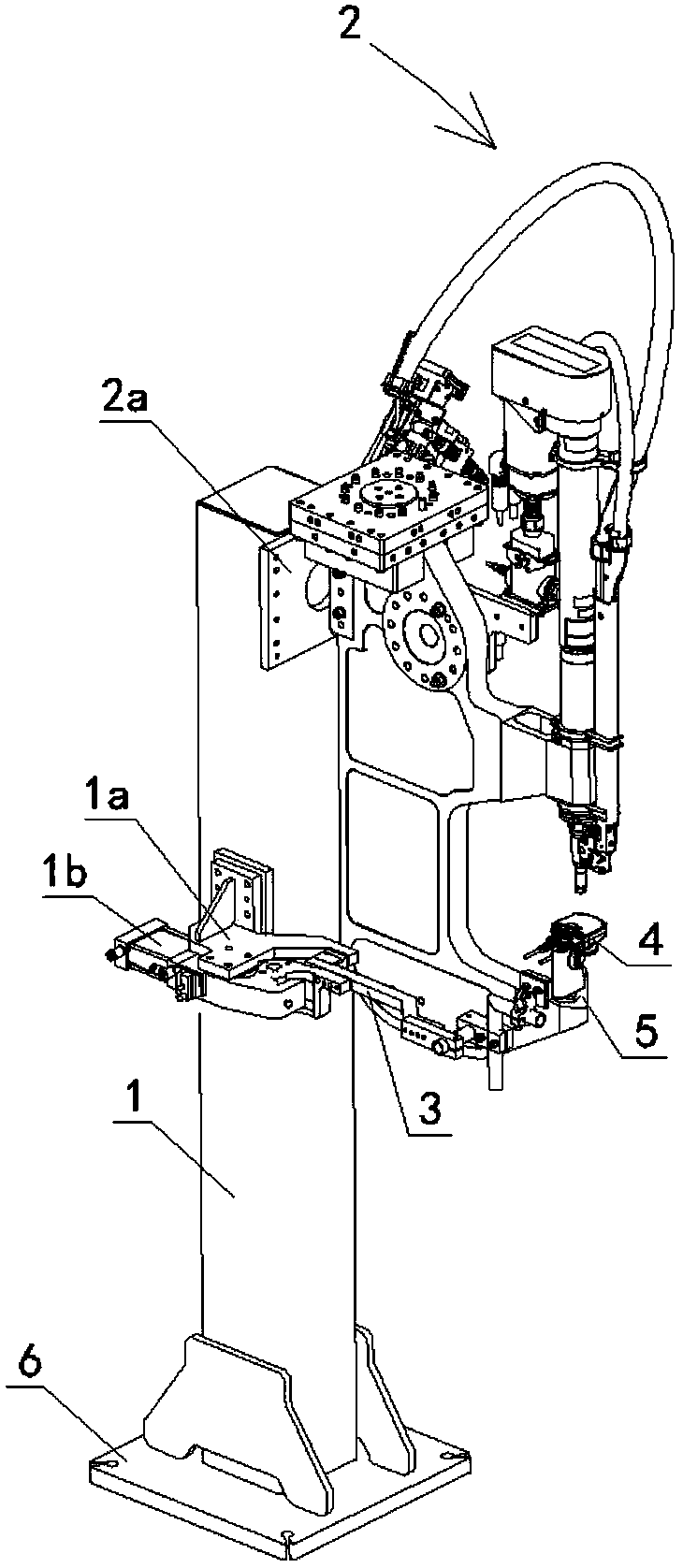

Design method for tooth profile contour line of spinning wheel during spinning forming of internal and external tooth part

PendingCN114192646AHigh precisionAvoid product quality defectsGear wheelsContact frictionHomogeneous deformation

The invention discloses a method for designing a tooth profile contour line of a spinning roller during spinning forming of an internal and external tooth part, which comprises the following steps of: firstly, determining a tooth number ratio between a core mold and the spinning roller and the tooth number of the spinning roller, and then obtaining a primary shape of the tooth profile contour line of the spinning roller by adopting a generation method according to an external contour shape of the internal and external tooth part; and according to the contact and friction conditions between each deformed part of the blank and the core mold or the spinning roller in the spinning forming process and the generated non-uniform deformation, the initial shape of the tooth profile of the spinning roller is adjusted by combining the wall thickness requirement of the internal and external tooth part, so that the tooth profile line of the spinning roller is obtained. The defects in the prior art are overcome.

Owner:BAOSHAN IRON & STEEL CO LTD

Self-piercing riveting gun mold wear on-line detection device

ActiveCN106323976BAvoid product quality defectsReduced detection processMaterial analysis by optical meansRivet gunComputer science

The invention discloses a device for online wear detection of a self-piercing riveting gun mold. The device is characterized in that an image acquisition platform is provided for a riveting gun mold on a piercing riveting production line; an image acquisition device for obtaining a mold image is mounted on the image acquisition platform; an image acquisition signal of the image acquisition device is used as an output signal; a computer is used for analyzing the output signal so as to judge the wear degree of a mold. The device provided by the invention can timely monitor the wear state of the mold in an online detection manner, avoids product quality defects, also avoids tediousness brought by disassembly process and the influence on the normal process section, effectively improves the production efficiency, and ensures the product quality.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

A Control Method for Realizing Automatic Zeroing of Aluminum Cold Rolling Mill Using Roll Diameter Difference

ActiveCN107583958BIncrease productivityImprove yieldRoll mill control devicesMetal rolling arrangementsRolling millAluminium

The invention relates to a control method for utilizing a roller diameter difference to achieve automatic pressing zeroing of an aluminum cold rolling mill. The method comprises the steps of determining given roller gap values by determining the parameters of contact rolling force and squeezin rolling force of roller systems and utilizing the roller diameter difference, wherein the given roller gap values are calculated by calculating the roller diameter difference of the new and old roller systems before roller replacement, and the two roller gap values including the initial roller gap valueand the secondary roller gap value are given by stages; conducting automatic pressing on the basis of the calculation parameters. By means of the method, the production efficiency and finished productratio of the rolling mill are increased, and the occurrence of product quality defects caused by pressing is avoided.

Owner:CHINALCO RUIMIN

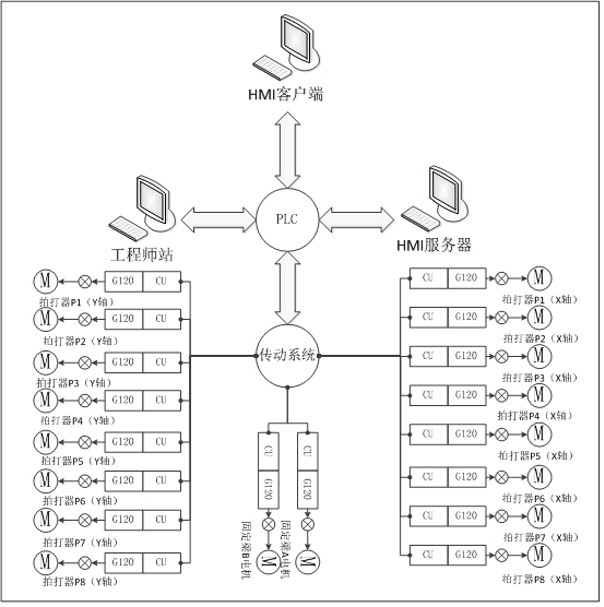

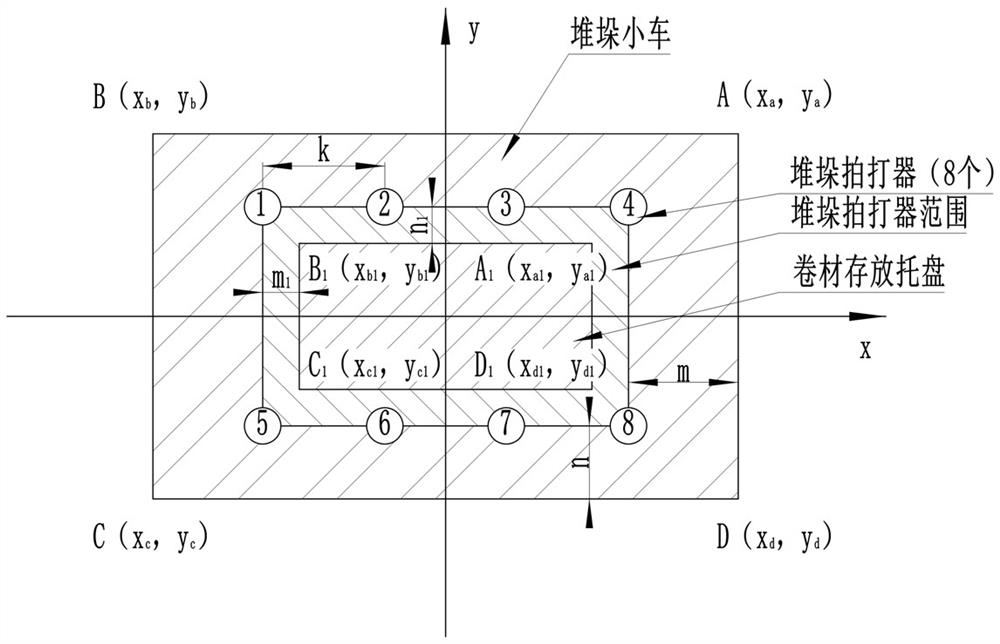

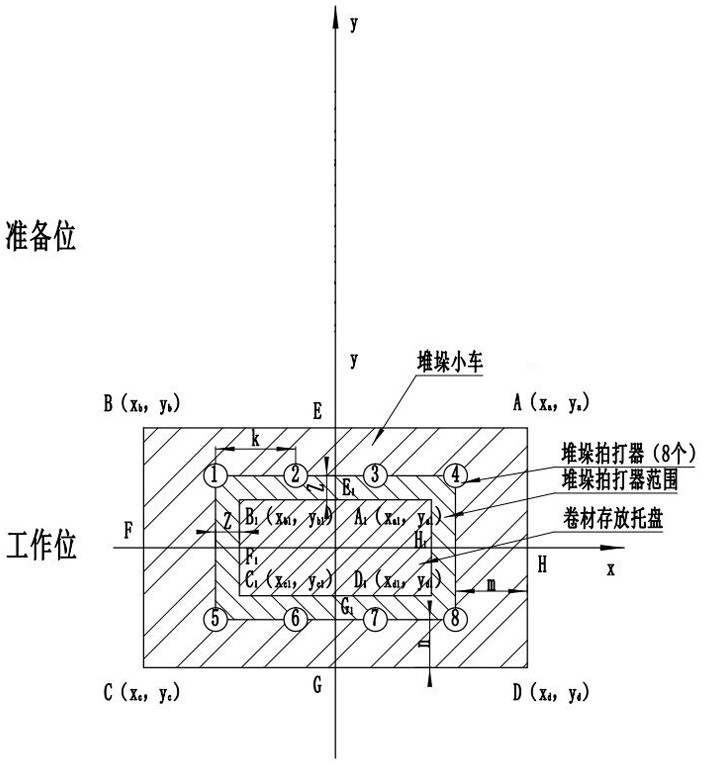

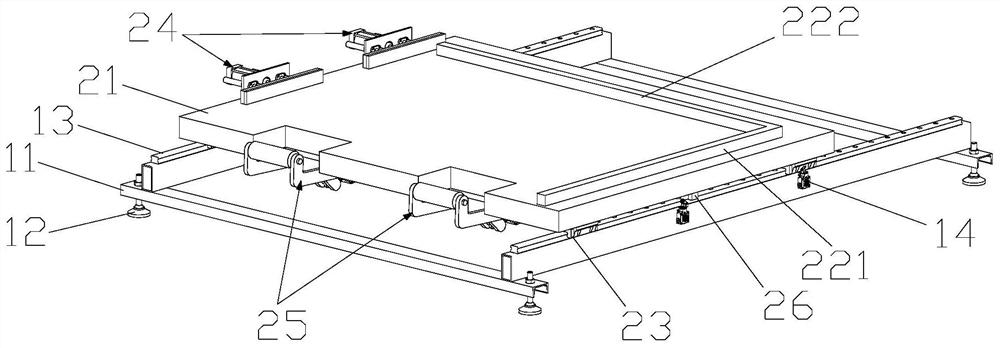

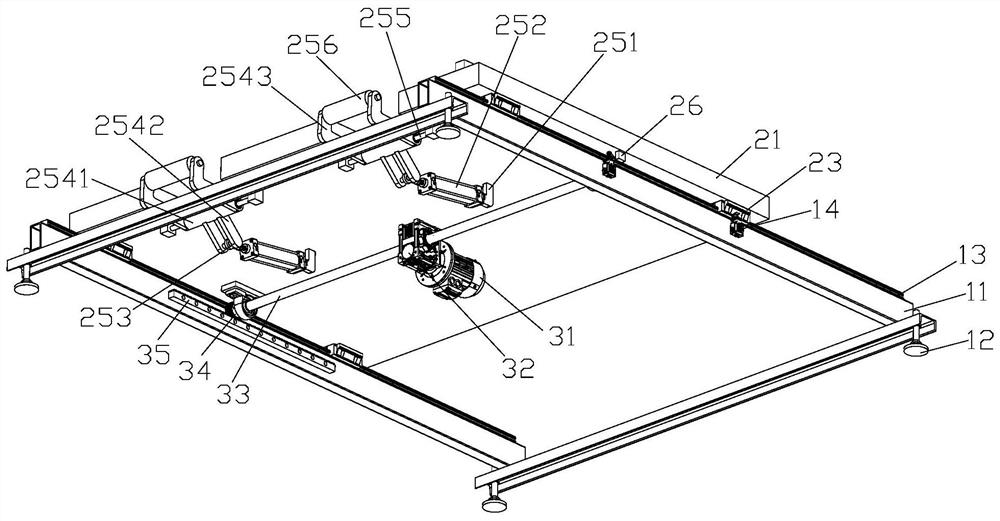

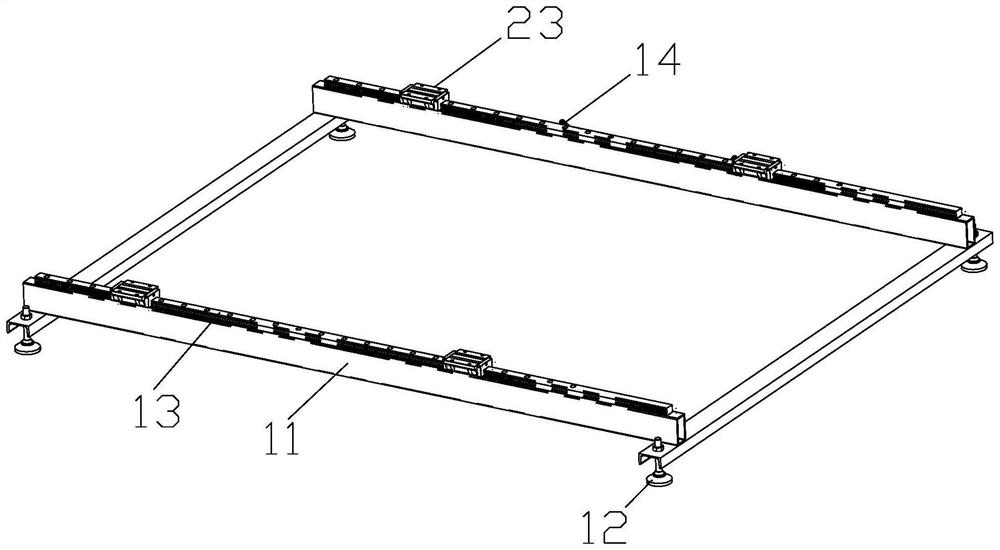

Automatic panel stacking adjusting device and control method

PendingCN112010088ARealize automatic adjustment functionRealize acquisitionPile receiversArticle deliveryLaser rangingElectric machinery

The invention provides an automatic panel stacking adjusting device and a control method. The automatic panel stacking adjusting device is characterized by comprising a stacking trolley, a panel storage tray, two groups of beaters and at least four laser range finders; the panel storage tray is placed on a platform of the top of the stacking trolley, and the edge of the panel storage tray is parallel to a working datum line; the at least four laser range finders are correspondingly arranged on the periphery of the stacking trolley and are aligned with the panel storage tray; the two groups ofbeaters are correspondingly mounted through fixing beams; the fixing beams are parallel to the working datum line and have a moving degree of freedom perpendicular to the working datum line; the beaters have the degree of freedom of translation on the fixing beams; each fixing beam and each beater are correspondingly driven by a motor and are connected with an encoder; and the motor, the laser range finders, the encoder and the beaters are correspondingly connected with a controller. The production efficiency of a shearing line is improved, and the time for manually adjusting the positions ofthe panel storage tray and the beaters is shortened.

Owner:CHINALCO RUIMIN

Batching method of fine sand raw material

ActiveCN109046171BAchieve hybridHigh degree of automationAdditive manufacturing apparatusRotary stirring mixersProcess engineeringButterfly valve

The invention overcomes the disadvantages of unstable configuration and mixing of fine sand-like raw materials in additive manufacturing equipment and poor uniformity, and provides a batching method of fine sand-like raw materials. The batching method of the fine sand-like raw material is achieved by setting a butterfly valve switch component on the hardware component and controlling the hardware action through software, thereby realizing accurate control of the amount added; the batching method of the fine sand-like raw material is achieved by setting a reasonable stirring structure And the control of mixing time realizes the uniformity of mixing, thus ensuring the accuracy of raw material configuration and uniformity of mixing, and then providing guarantee for the production of qualified products.

Owner:NINGXIA KOCEL MOLD

Automatic straightening device of reed

ActiveCN102632109BRealize automatic alignmentImprove work efficiencyMetal-working feeding devicesPositioning devicesControl systemBiochemical engineering

Owner:山东海华汽车部件制造有限公司

Device and method for detecting and removing deformed cigarette packs, and cigarette pack conveying equipment

ActiveCN103921970BPrevent inflowAvoid damagePackaging cigarettePackaging cigarsReal-time computingPacket detection

The invention relates to a deformed cigarette packet detecting and removing device and method and a cigarette packet conveying device. The deformed cigarette packet detecting and removing device comprises a deformed cigarette packet detection mechanism and a deformed cigarette packet removing mechanism, wherein the deformed cigarette packet detection mechanism is arranged on a cigarette packet conveying passageway and detects arrival of deformed cigarette packets through exterior outline extrusion force of the deformed cigarette packets, and the deformed cigarette packet removing mechanism is arranged on the downstream portion of the conveying passageway of the deformed cigarette packet detection mechanism and removes the deformed cigarette packets from the conveying passageway. According to the deformed cigarette packet detecting and removing device and method and the cigarette packet conveying device, the situation that the thicknesses of the cigarette packets are increased after deformation is taken into consideration, whether the deformed cigarette packets arrive or not can be detected by detecting the exterior outline extrusion force of the deformed cigarette packets through the system, and therefore the deformed cigarette packets can be removed out of the conveying passageway on the downstream portion of the conveying passageway after arrival of the deformed cigarette packets is detected, the deformed cigarette packets are prevented from flowing into the next procedure, damage which is caused by the deformed cigarette packets to downstream devices is avoided, and product quality defects caused when the deformed cigarette packets flow into finished products are avoided.

Owner:LONGYAN CIGARETTE FACTORY

Transfer platform of carrier

ActiveCN112591196AGuaranteed positioning accuracyLimit movement distancePackagingRobot handReciprocating motion

The invention relates to a transfer platform of a carrier. The transfer platform comprises a base, a transfer mechanism and a carrying mechanism, wherein the carrying mechanism is movably installed onlinear guide rails fixedly arranged on the two sides of the base through sliding blocks fixedly arranged on the two sides of the bottom surface, the transfer mechanism is fixedly arranged on the bottom surface of the carrying mechanism, and the transfer mechanism provides driving force for the the carrying mechanism to carry out reciprocating motion along the linear guide rails. According to thetransfer platform of the carrier, the carrier on the carrying mechanism can be accurately positioned, the position accuracy of the carrier in the packaging process can be improved further due to the positioning accuracy of the transfer mechanism, and the it is avoided that a ceramic plate is damaged due to poor positioning. In addition, the problems of site limitation and insufficient moving rangein the mechanical arm packaging process can be solved.

Owner:JIANGXI WONDERFUL CERAMICS CO LTD +2

Lead-acid battery grid casting device

The invention discloses a lead-acid battery grid casting device, which comprises a movable mold, a fixed mold, an ejector rod arranged in the fixed mold to push out the grid in the mold cavity, and a movable mold guide rod fixedly connected to the fixed mold. It includes a frame and a power device, the fixed mold frame of the fixed mold is fixedly connected to the frame, the end of the push-pull rod connected with the power device is connected to both sides of the movable mold, and the push rod connected with the power device is located on the fixed mold The back side corresponds to the ejector rod set by the fixed mold. The invention utilizes the existing guide post and guide sleeve type grid mold for the cast plate machine, and does not need to make a purely manual grid mold with positioning pins, which has the advantages of saving cost and time. The invention uses the air cylinder to automatically open and close the grid mold and push out the grid at the same time, which not only improves the production efficiency, but also overcomes the product quality defect caused by manual tearing of the grid.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU +3

Processing method of heat-loaded dam roller

ActiveCN107470854BSolve the problem that the balance accuracy is not highAvoid product quality defectsNumerical controlInterference fit

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

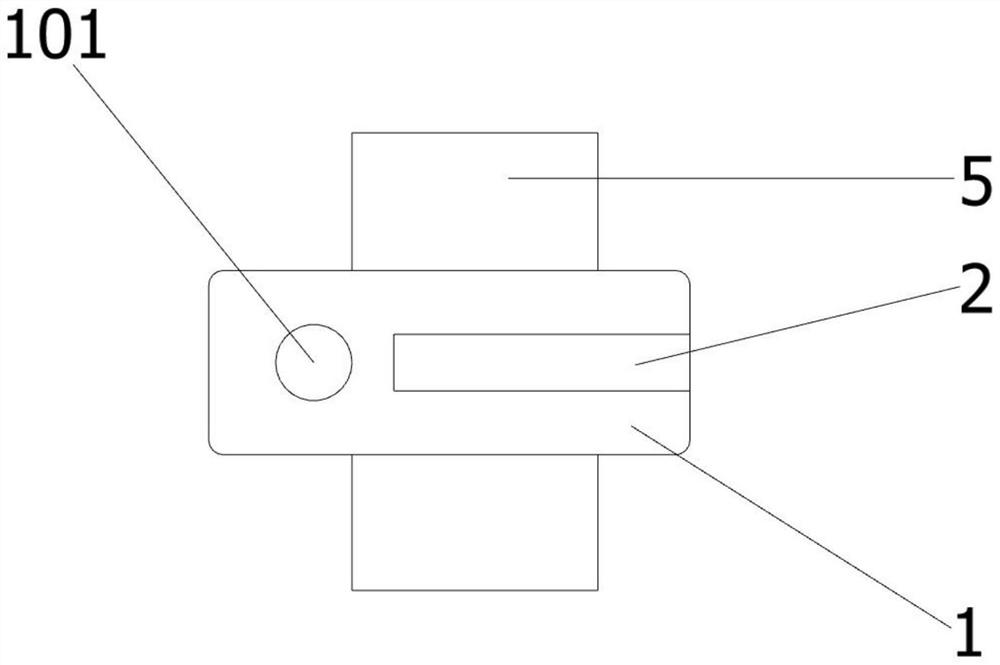

Hook-free side plate hanger for suspension chain

InactiveCN112279081AImprove hanging efficiencyAvoid product quality defectsLoad-engaging elementsStaged repairStructural engineering

The invention discloses a provides a hook-free side plate hanger for a suspension chain, which relates to the technical field of car processing equipment, and solves the problem that product quality is affected as appearance is affected by punching in a square tube and even later-stage repair welding and hole plugging is needed while an existing hanger is in use. The hook-free side plate hanger comprises a main body, a pedestal, an inner slot and a clamping plate, wherein the pedestal is arranged on the bottom of the main body; the top of a left rotary plate inside the inner slot is equipped with a rotary rod through a component; the clamping plates are of C-shaped structures, and vertical slots in the tops of the clamping plates are formed in the bottom of the pedestal; and vertical shafts on the tops of the clamping plates are separately mounted on the bottom of a left rotary plate and the bottom of a right rotary plate. Materials such as the square tube are transported by the clamping plates, so that transportation on the square tube by a punching or welding way is reduced; during hanging, the two C-shaped clamping plates move relatively to fit to a rectangular tube, so that a surrounded shape is formed for clamping the rectangular tube, and thus, product quality defects and unnecessary cutting repair-welding operation caused by the original punching way and the original suspended part welding way can be avoided.

Owner:DONGFENG SPECIAL PURPOSE VEHICLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com