Device for online wear detection of self-piercing riveting gun mold

A detection device and self-piercing riveting technology, which are used in measurement devices, material analysis by optical means, instruments, etc., can solve the problems that detection sensors cannot meet accuracy requirements, increased workload, product quality defects, etc., to avoid product quality. Defects, Avoidance of Human Errors, Discriminant Criteria Intuitive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

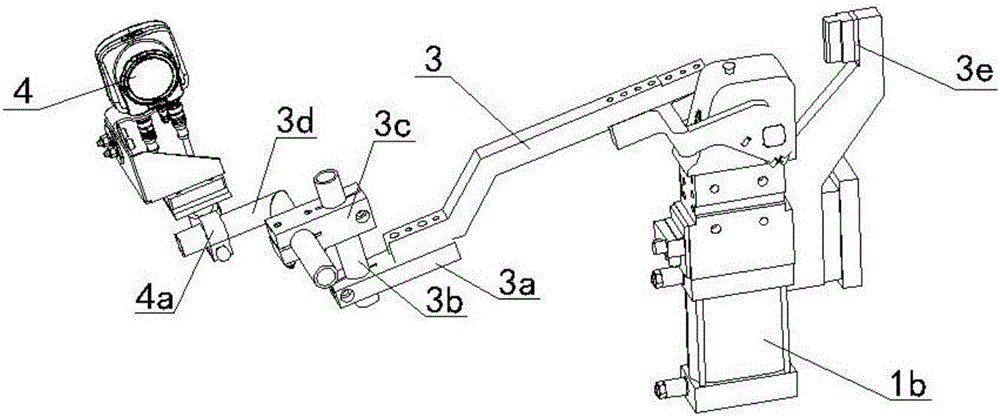

[0021] In this embodiment, the structural form of the self-piercing riveting gun mold wear on-line detection device is: an image acquisition platform is set for the riveting gun mold on the punching riveting production line, and an image acquisition device for obtaining mold images is installed on the image acquisition platform. The image acquisition signal of the image acquisition device is used as an output signal, and the computer is used to analyze the output signal, and then judge the degree of wear of the mold.

[0022] In order to improve the image quality, the image acquisition device in this embodiment adopts a CCD camera, and a microscope is arranged between the CCD camera and the mold to be photographed.

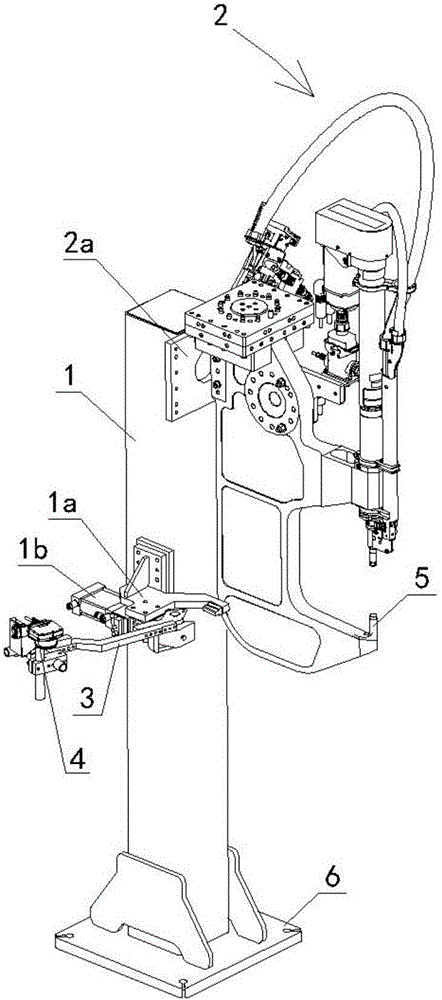

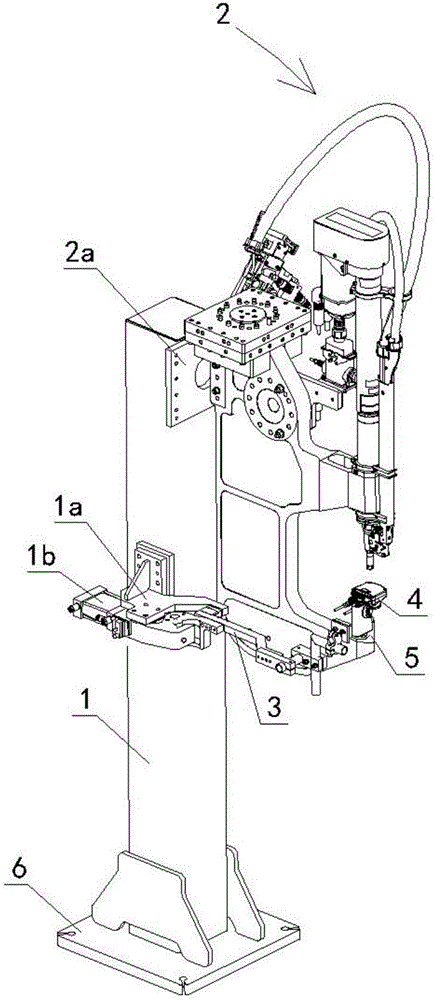

[0023] see Figure 1a and Figure 1b In this embodiment, a vertical support 1 is set, and the riveting gun 2 is fixedly installed on one side of the vertical support 1 by using the mounting plate 2a; on the other side of the vertical support 1, a turning mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com