Lead-acid battery grid casting device

A lead-acid battery and grid technology, which is applied in the field of grid casting devices, can solve the problems of high labor intensity of operators, easy deformation of grids, low production efficiency, etc., so as to overcome product quality defects, facilitate operation and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

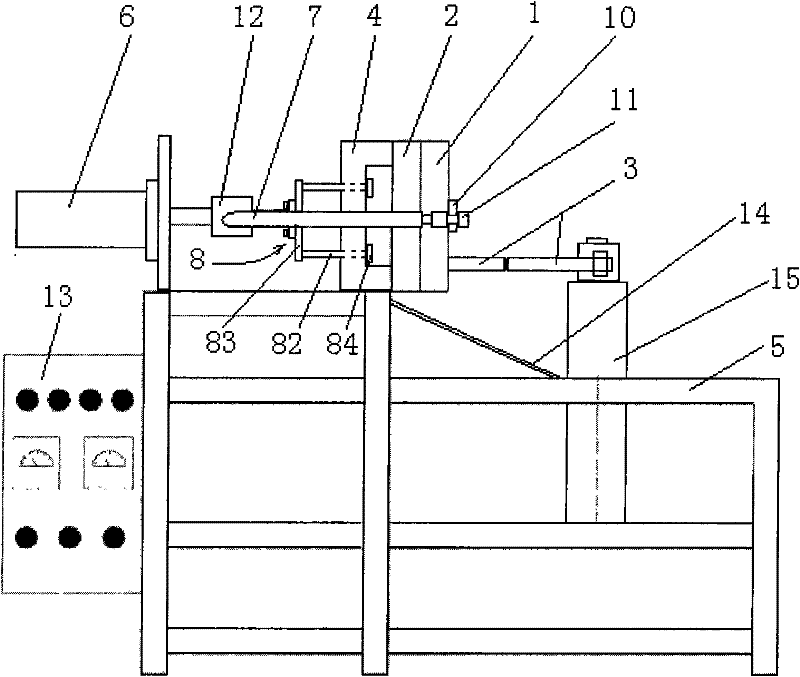

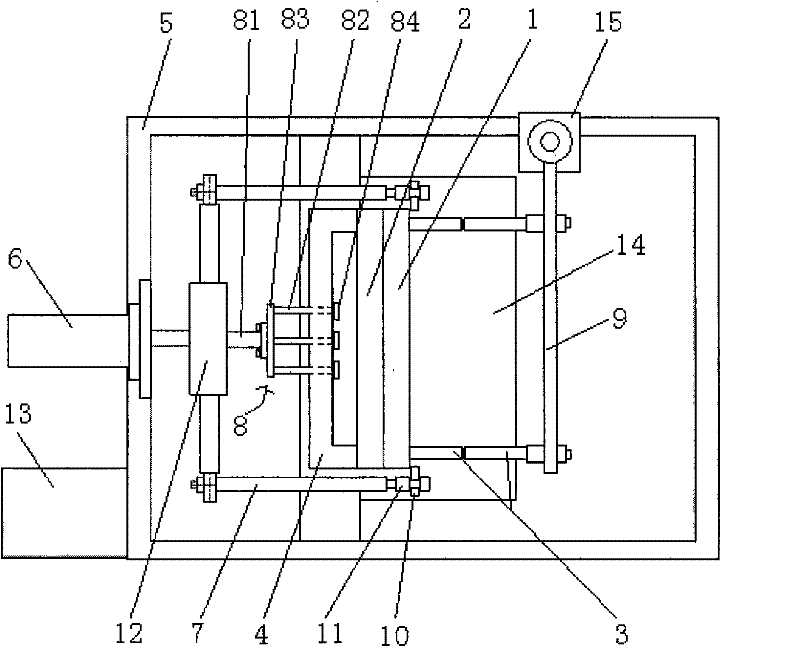

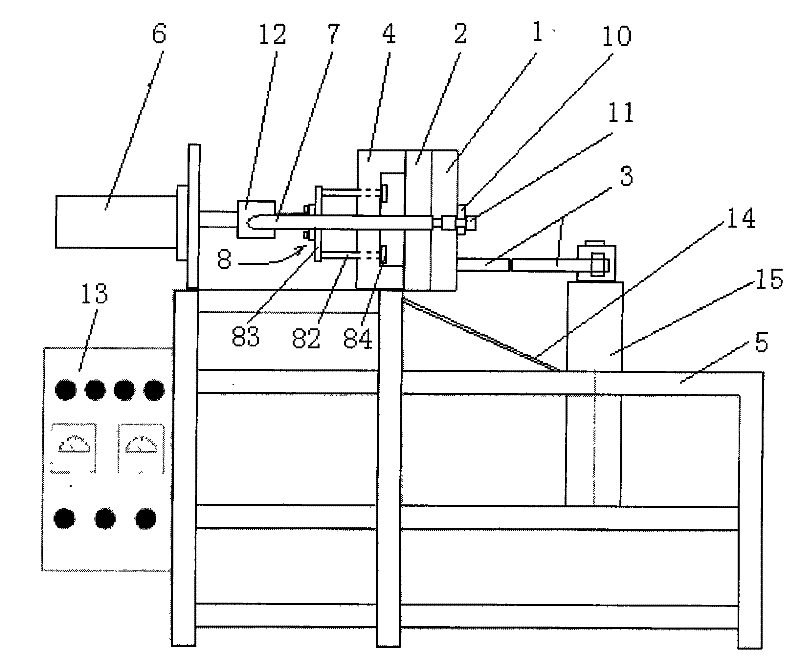

[0015] Such as figure 1 , 2 As shown, the present invention includes a movable mold 1, a fixed mold 2, an ejector rod (not shown) that is arranged in the fixed mold 2 and pushes out the grid in the mold cavity, and a movable mold that is fixedly connected to the fixed mold 2 1 guide rod 3 (the guide rod 3 is arranged symmetrically). A frame 5 and a power unit 6 are also included. The fixed mold frame 4 of the fixed mold 2 is fixedly connected to the frame 5, and the power unit 6 is fixedly connected to the frame 5 on this side of the fixed mold 2.

[0016] Described power unit 6 selects air cylinder, and its cylinder rod end is provided with connector 12, and the push-pull rod 7 of movable mold is symmetrically fixedly connected to the two ends of connector 12, and the other end of push-pull rod 7 is flexibly connected to the two ends of movable mold 1. side. Both sides of the movable mold 1 are provided with opening buckles 10 , and the push-pull rod 7 is pressed into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com