Hook-free side plate hanger for suspension chain

A spreader and side plate technology, applied in the field of carriage processing equipment, can solve problems affecting product quality, low production efficiency, and affecting appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

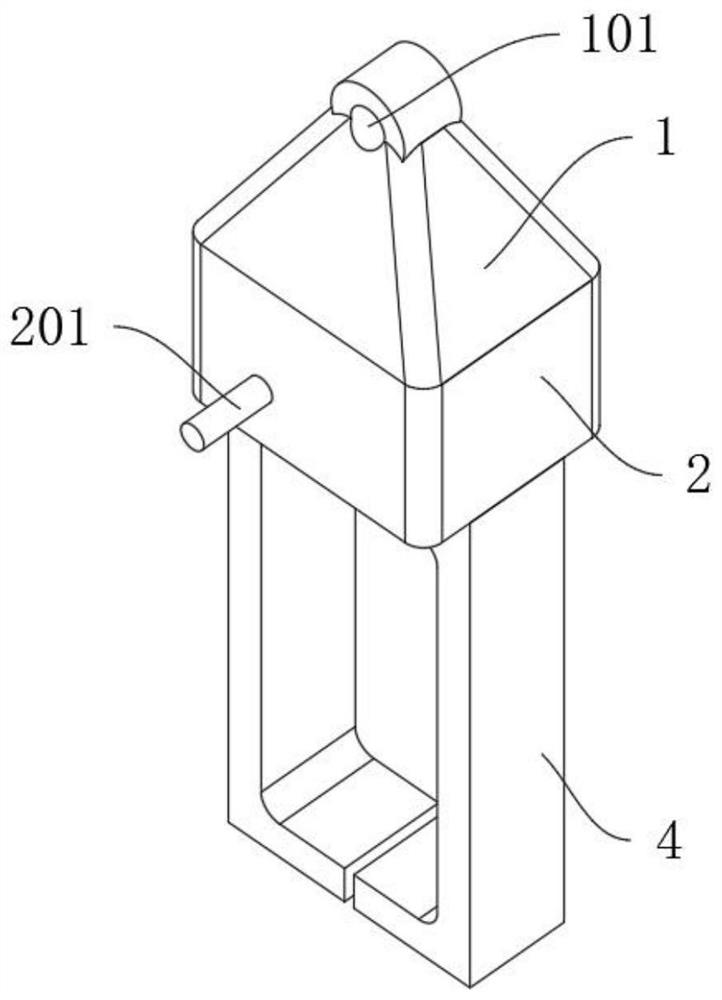

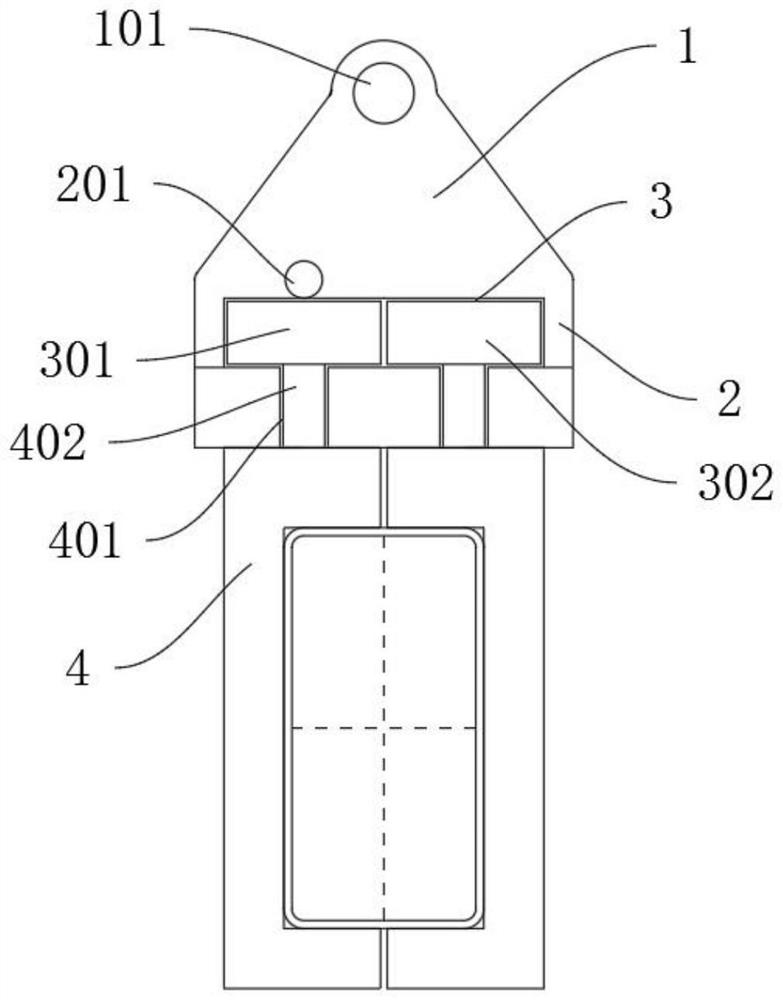

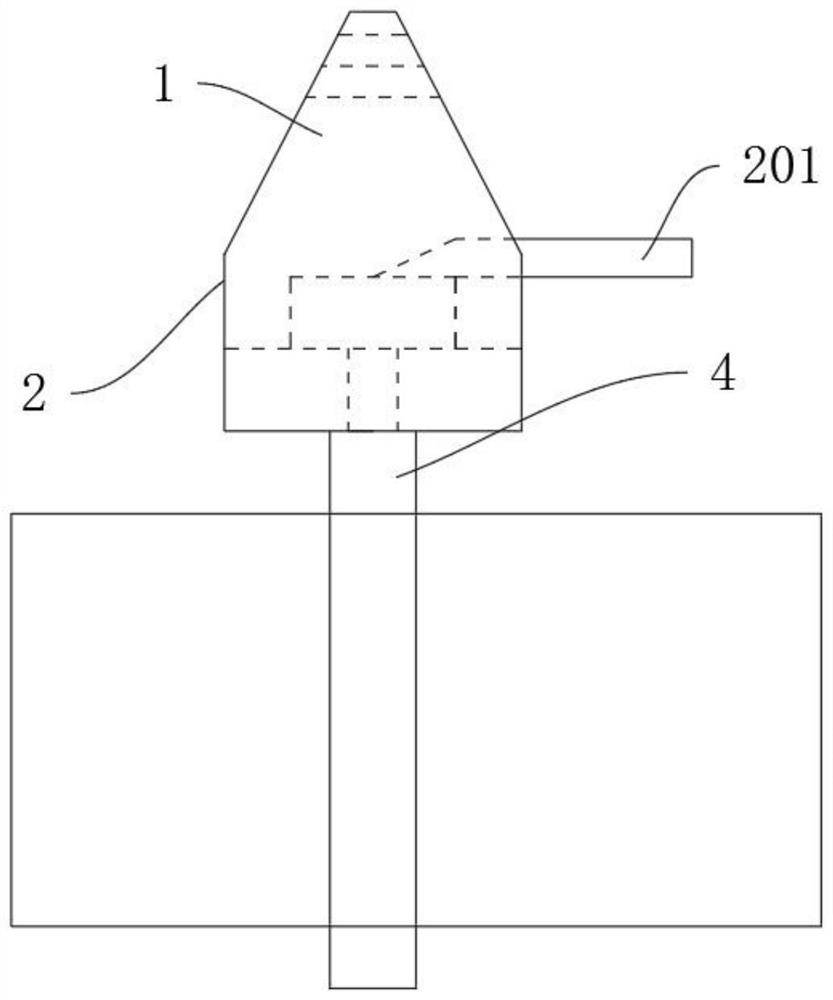

[0025] as attached figure 1 to attach Figure 4 Shown:

[0026] The invention provides a catenary hook-free side plate hanger, which comprises a main body 1, a base 2, an inner groove 3 and a splint 4, the main body 1 is a tapered structure, and the top of the main body 1 is an arc-shaped structure; The side is provided with a slot, and the base 2 is arranged at the bottom of the main body 1; the inner groove 3 is arranged inside the base 2, and the top of the left rotating plate 301 inside the inner groove 3 is equipped with a rotating rod 201 through a structural member; the splint 4 is a C-shaped structure, and the vertical groove 401 on the top of the splint 4 is set at the bottom of the base 2, and the vertical shaft 402 on the top of the splint 4 is respectively installed on the bottom of the left rotating plate 301 and the right rotating plate 302, and the hanging hole 101 can be directly It is connected with the crane spreader to facilitate the transportation of diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com