Line hanging mode for novel winding machine

A winding machine and a new type of technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of easy collision, high labor intensity of operators, easy head breakage, etc., and reduce labor intensity. , The effect of improving the hanging efficiency and shortening the hanging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

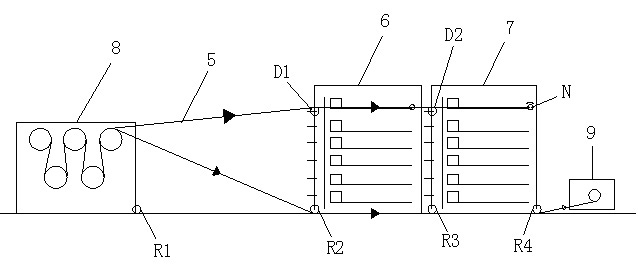

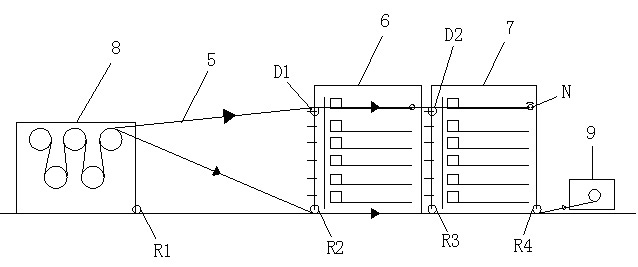

[0015] In this example, refer to figure 1 and figure 2 , the new winding machine hangs the line, and the equipment used includes A screen winding machine 6, B screen winding machine 7, five-roll drafting machine 8 and waste silk machine 9, A screen winding machine 6 and B screen winding machine The winding machines 7 are placed side by side, the five-roll drafting machine 8 is installed on the left side of the A-screen winding machine 6, and the waste silk machine 9 is installed on the right side of the B-screen winding machine 7, that is, the A-screen winding machine 6 and the B-screen The winding machine 7 is installed between the five-roll drafting machine 8 and the waste wire machine 9; a wire guide wheel is installed in the lower left corner of the A screen winding machine 6, and a wire guide wheel is respectively installed in the left and right lower corners of the B screen winding machine 7, Wire guide hooks D1 and D2 are installed on the A-screen winding machine 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com