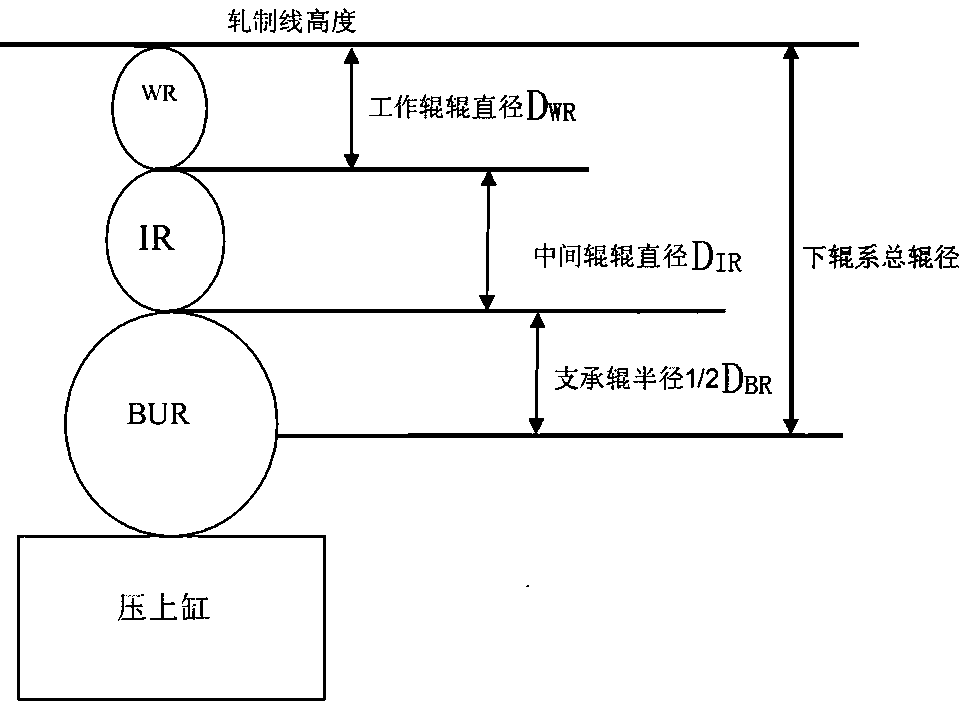

A Control Method for Realizing Automatic Zeroing of Aluminum Cold Rolling Mill Using Roll Diameter Difference

A control method and roll diameter difference technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as unsatisfactory requirements, low production efficiency, and low efficiency, so as to avoid product quality defects and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0057] The first step: meet the pressing conditions;

[0058] Step 2: Give certain parameters such as bending roll and tilting roll value, roll gap position, rolling force, etc., and start the pressing system after the actual value of bending roll meets the requirements;

[0059] Step 3: After the pressing system is started, open the rolling oil system;

[0060] Step 4: After the rolling oil is turned on, set the roll gap value for the second time in APC mode: G ref =G 二次 , continue to press the upper cylinder at a low speed until T Act =T 接触 (of which: G ref : given roll gap value, T Act : Actual rolling force, T 接触 : Roll contact rolling force);

[0061] Step 5: Start the main motor, and set the rolling force T ref =T 压靠 , here take 800 tons ((of which: T ref : Given rolling force, T 压靠 : the roller system presses against the rolling force);

[0062] Step 6: After satisfying the zero-clearing condition of the roller system pressure contact, clear the related valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com