Automatic straightening device of reed

A straightening device and reed straightening technology, applied in the directions of feeding device, positioning device, storage device, etc., can solve the problems of difficult control of product quality by manual operation, reduction of product qualification rate, unqualified reed quality, etc. Achieve the effect of avoiding product quality defects, improving product quality and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

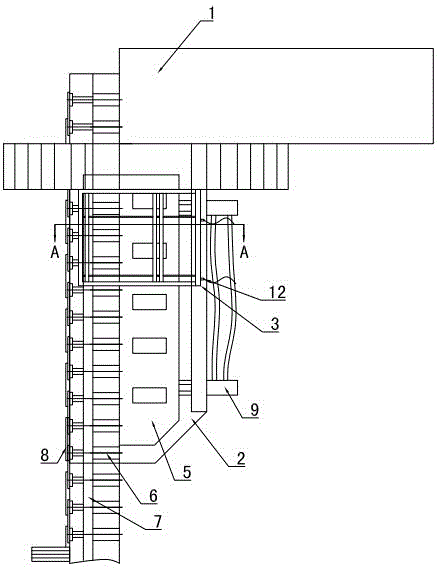

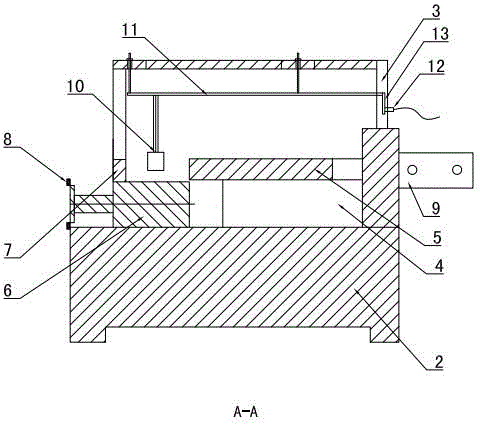

[0021] Refer to attached Figure 1~2 : The reed automatic straightening device includes a quenching furnace 1 and a workbench 2 on one side of the quenching furnace 1. The reed conveying device and the reed straightening device are installed side by side on the upper plane of the workbench 2, and a support frame 3 is supported and fixed above the reed conveying device and the reed straightening device, and a control device is installed on the support frame 3. The power unit 9 on one side of the sheet extrusion device is connected. The power unit 9 is a hydraulic oil cylinder, and identical two sets are arranged side by side, and two sets of hydraulic oil cylinders work simultaneously.

[0022] The reed straightening device includes a support block 4 and a straightening block 5, the support block 4 is fixed on the upper plane of the workbench 2, and the straightening block 5 is slidably arranged above the support block 4, which is an iron block with a smooth surface on one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com