Forming Die for Plum Blossom Joint Rubber Needle

A forming mold and plum-blossom-shaped technology, which is applied in the field of plum-blossom-shaped row-type plastic needle molding molds, can solve the problems of complex plum-blossom head shape, large pressure loss, and small flow-length ratio, so as to avoid product quality defects and ejection The effect of smooth action and reliable ejection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

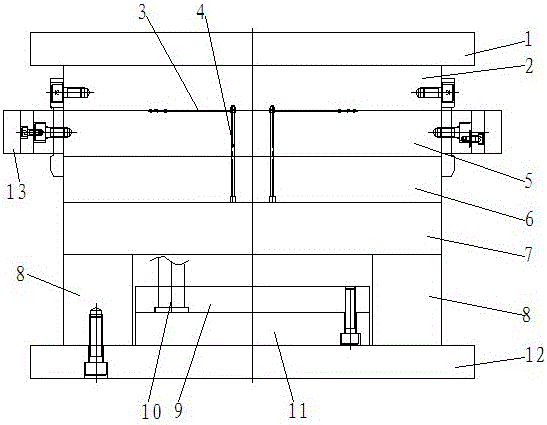

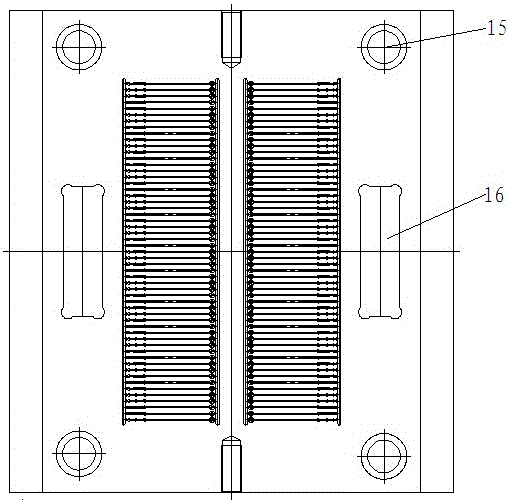

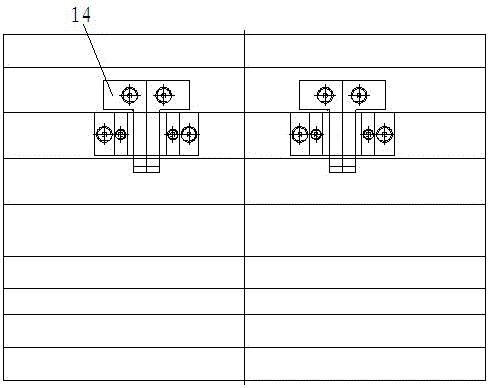

[0010] The specific embodiment of the present invention will be described with reference to the accompanying drawings. The technical solution adopted in the present invention is: the forming mold of plum blossom-shaped row-type rubber needles, including an upper fixing plate 1, a front mold 2, a rear mold 5, a supporting plate 6, a pushing plate 7, a mold foot 8 and a lower fixing plate 12. The front mold 2 is fixed on the upper fixing plate 1. When the front mold 2 and the rear mold 5 are closed, two molding cavities of the plum blossom-shaped rubber needles are formed. The pushing plate 7 and the rear mold 5 There is a support plate 6 between them, the pusher plate 7 is connected to the two mold feet 8, the lower fixed plate 12 is fixedly connected with the two mold feet 8 and the rear mold middle plate 11, and the upper ejector plate 9 is fixed to the rear mold middle plate by screws 11, the rear mold middle plate 11 and the upper ejector plate 9 are located between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com