Positioning mechanism for the inner r-angle of the formed product nozzle

A technology of positioning and nozzle, which is applied in the field of positioning mechanism of the R angle inside the nozzle of the molded product, can solve the problems of high requirements and instability, and achieve the effect of low requirements, improved stability and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

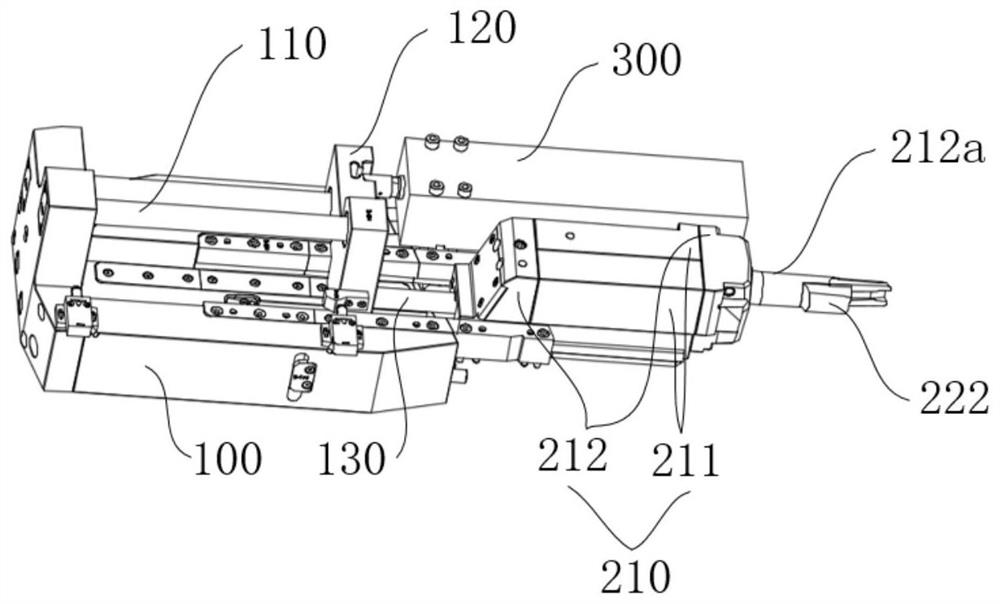

[0018] The invention proposes a positioning mechanism for forming an inner R angle of a nozzle of a product.

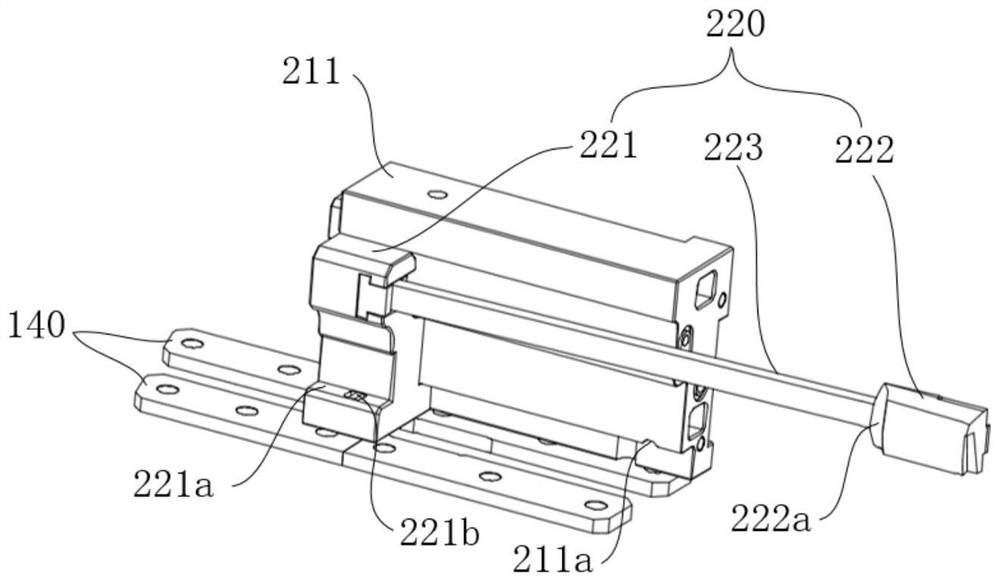

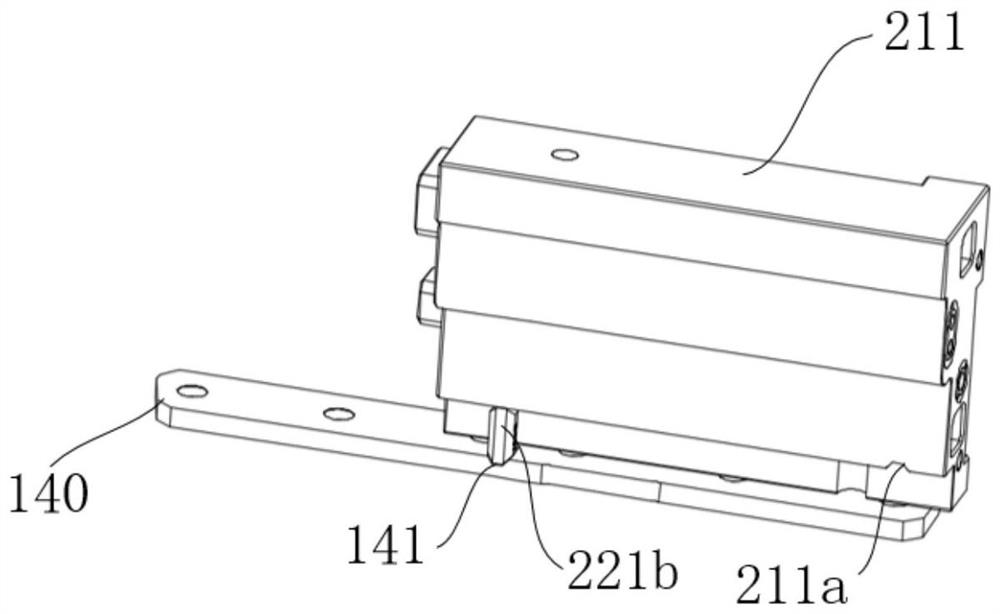

[0019] refer to Figure 1-5 , figure 1 It is a schematic diagram of the overall structure of an embodiment of the positioning mechanism used to form the inner R angle of the nozzle of the product according to the present invention, figure 2 It is an assembly structure diagram of the inclined ejector rod and the row block in one embodiment of the present invention, image 3 It is an assembly structure diagram between the lock pin, the row position bead and the fixed block in one embodiment of the present invention, Figure 4 It is a three-dimensional structure diagram of the product forming principle in an embodiment of the present invention, Figure 5 It is a cross-sectional structure diagram of the product forming principle in an embodiment of the present invention.

[0020] Such as Figure 1-2 As shown, in the embodiment of the present invention, the displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com