Novel servo ejection device for brick press

An ejector device and brick press technology, which is applied in the field of hydraulic control of brick presses, can solve problems such as high maintenance cost, ejection crawling stuck, and difficulty, and achieve high precision of ejection position and speed control, and ejection Smooth operation and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

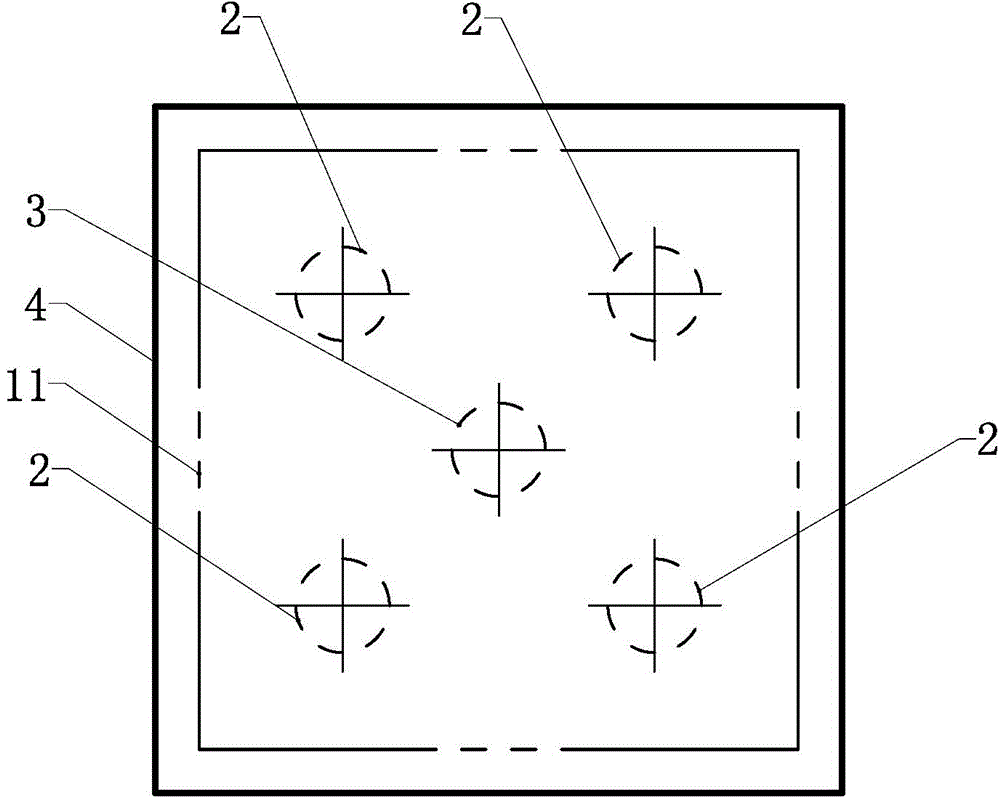

[0022] Such as Figure 3 to Figure 5 As shown, a novel servo ejection device for a brick press according to the present invention is installed on the table top of the base of the brick press, and is installed with the lower mold frame assembly 12, the lower mold core 13, the upper mold core 14, and the mold. The plate 15 and the upper punch 16 constitute the main working structure of the press-fitting machine.

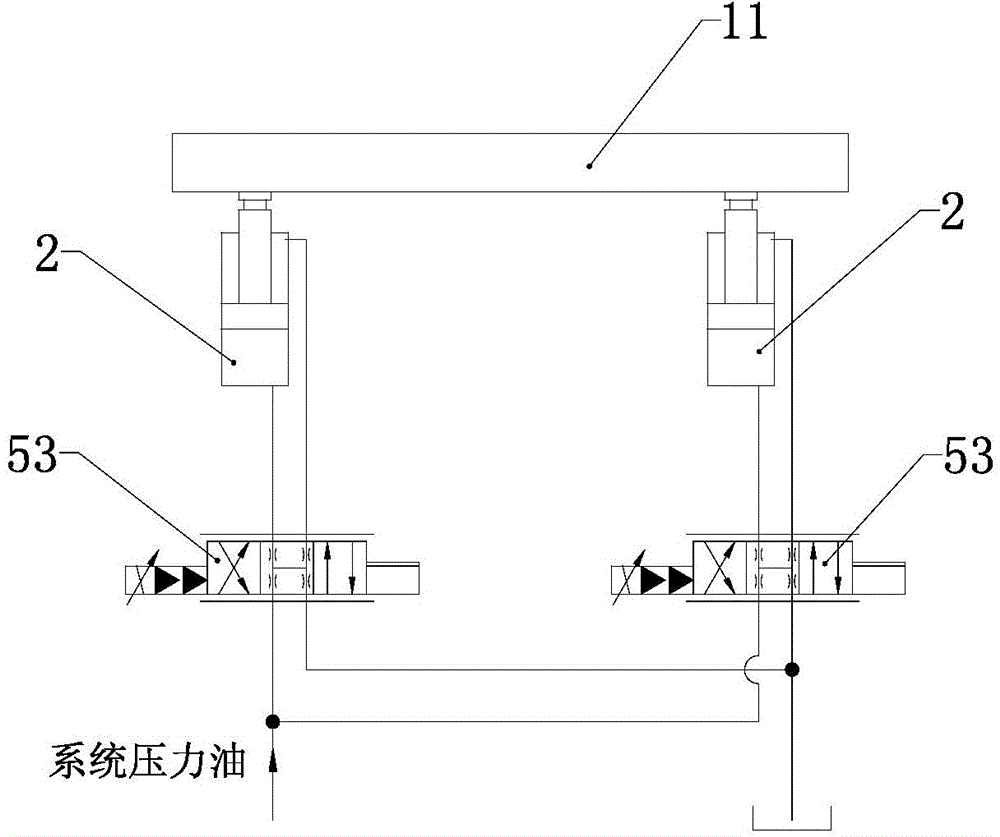

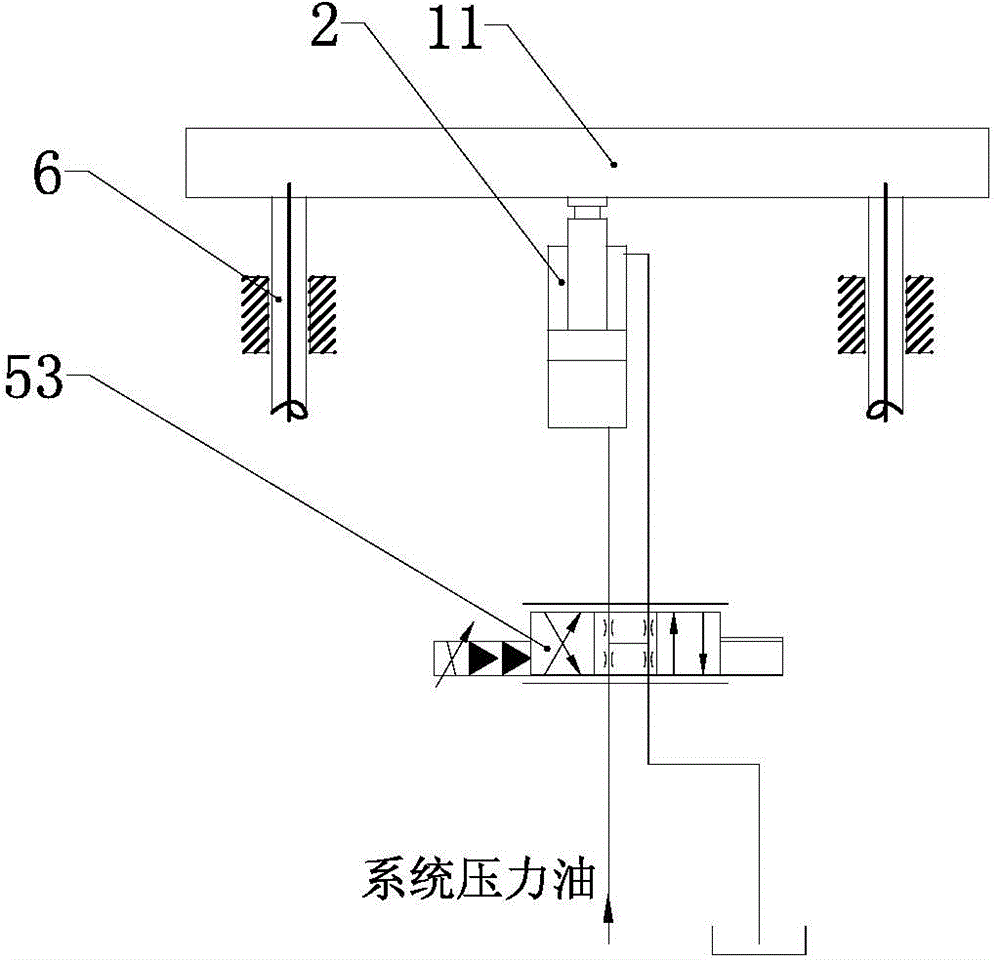

[0023] A new type of servo ejector for a brick press according to the present invention is mainly composed of an ejector main board 4, an ejector plate 11, four ejector cylinders 2, a clamping cylinder 3 and a hydraulic control assembly: the ejector main board 4 is installed On the table top of the press base. The cylinder part of the clamping cylinder 3 is embedded in the center of the ejector main plate 4, and the end side of the piston rod 31 is rigidly connected with the lower end surface of the ejector plate through the clamping plate 32. The cylinder body parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com