Novel mineral powder decomposition kettle

A kind of technology for decomposing kettle and mineral powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

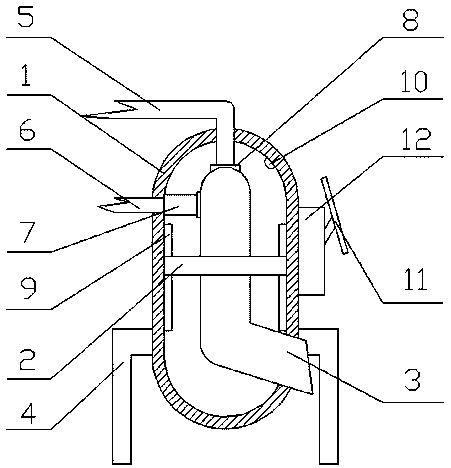

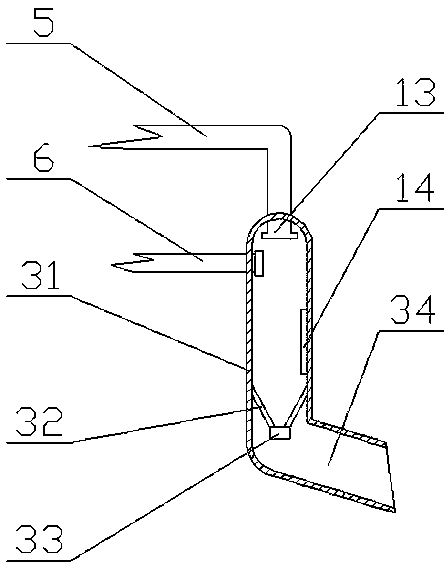

[0021] as attached figure 1 to attach image 3 shown

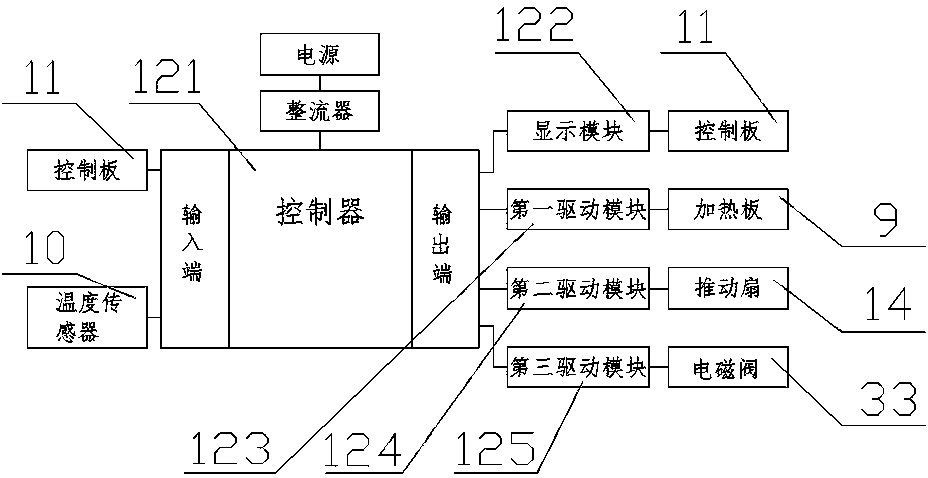

[0022] The present invention provides a novel mineral powder decomposition kettle, which includes a shell 1, a fixed plate 2, a decomposition chamber 3, a support leg 4, a carbon dioxide delivery pipe 5, a calcium carbonate delivery pipe 6, a heat protection pipe 7, a sealing ring 8, and a heating plate 9. Temperature sensor 10, control board 11, controller 12, one-way valve 13 and push fan 14, wherein the fixed plate 2 is installed inside the shell 1 by bolts, and the decomposition chamber 3 is installed inside the fixed plate 2 by bolts, Support legs 4 are welded below the housing 1; the carbon dioxide delivery pipe 5 is connected to the top of the decomposition chamber 3 through the hole at the top of the housing 1, and the calcium carbonate delivery pipe 6 is connected to one side of the decomposition chamber 3 through the hole on the side of the housing 1. side, the surface of the calcium carbonate delivery pipe 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com