Ring die pelleter

A granulator and ring die technology, applied in presses, manufacturing tools, presses for material forming, etc., can solve problems such as uneven impact force, unequal gaps, and easy damage to main shaft bearings, and reduce cantilever loads. The effect of reducing power consumption and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

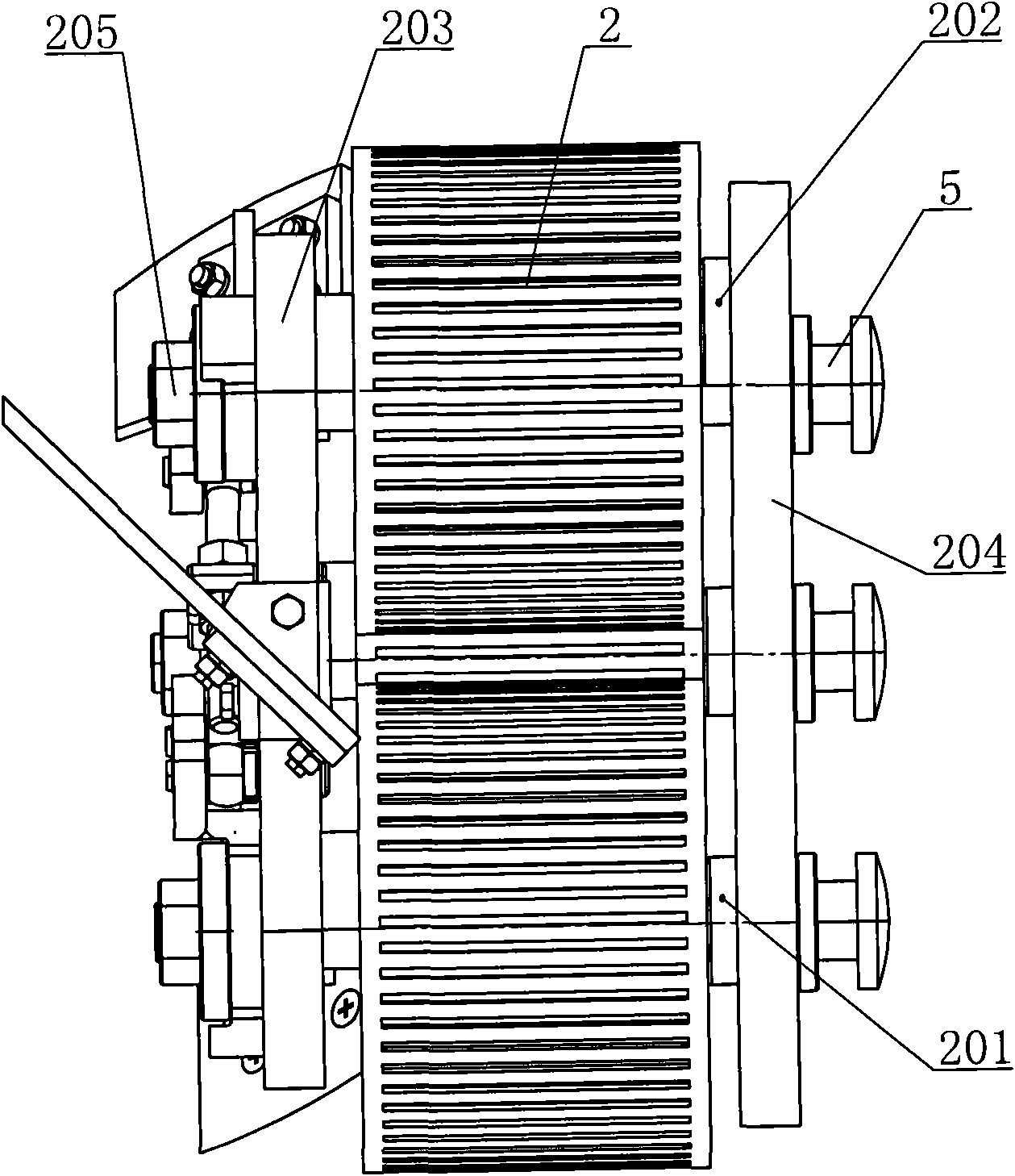

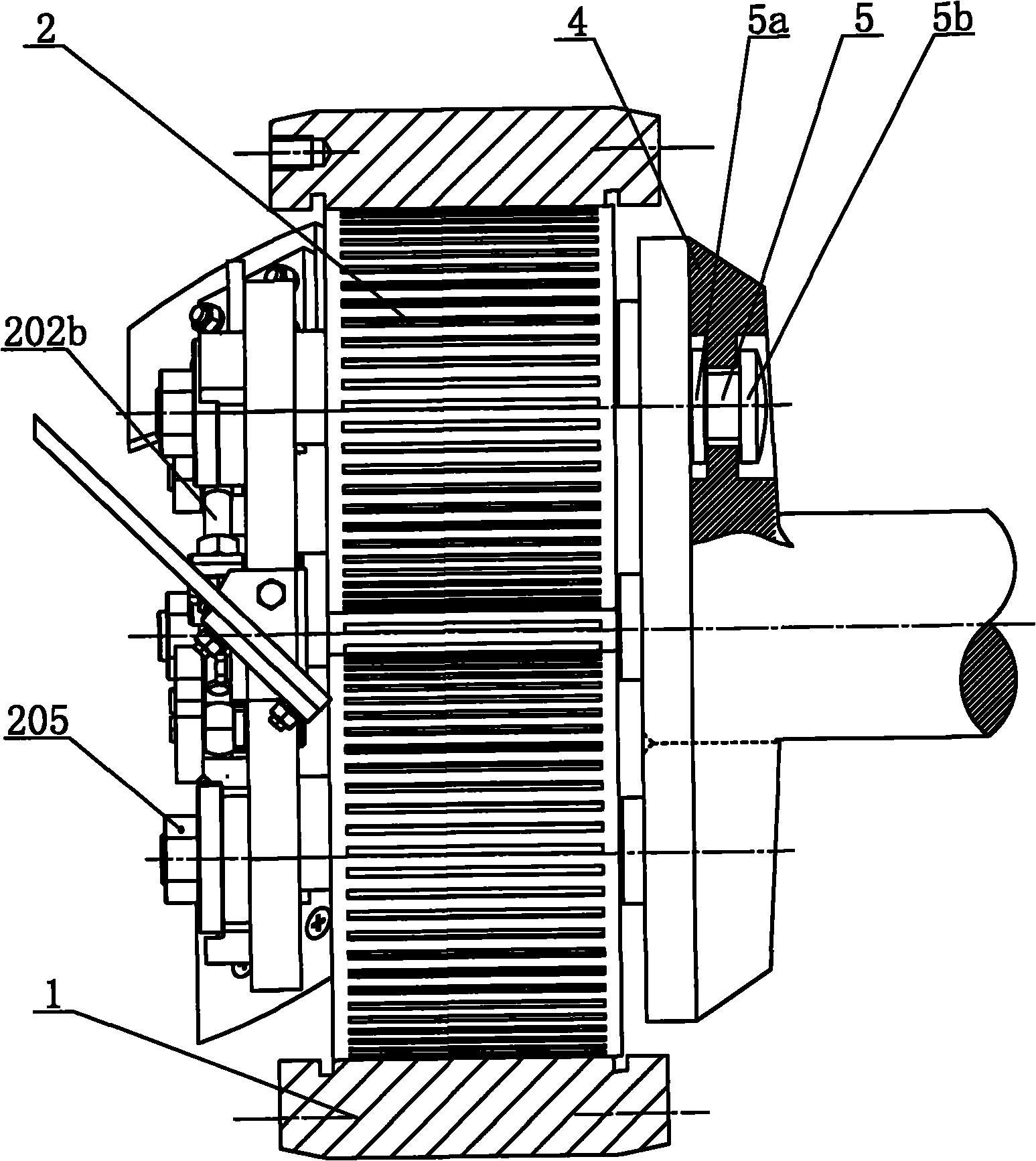

[0026] Such as figure 1 , figure 2 and Figure 6 As shown, the ring die granulator of the present invention includes a ring die 1, a pressing roller assembly 2 and a main shaft 3, the pressing roller assembly 2 is located in the ring die 1 as a whole, and the pressing roller assembly 2 includes two pressing roller support shafts 201, a Pressure roller eccentric shaft 202, front plate 203 and rear plate 204, three pressure rollers are distributed in a triangle, the two ends of pressure roller support shaft 201 and pressure roller eccentric shaft 202 are respectively supported on front plate 203 and rear plate 204, pressure roller lock The tightening nut 205 fixes the three pressure rollers from the outside of the front plate 203, one of the three pressure roller support shafts is the pressure roller eccentric shaft 202, and an eccentric shaft adjustment device connected with the pressure roller eccentric shaft 202 is provided on the outside of the front end of the front plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com