Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Eliminate the demoulding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

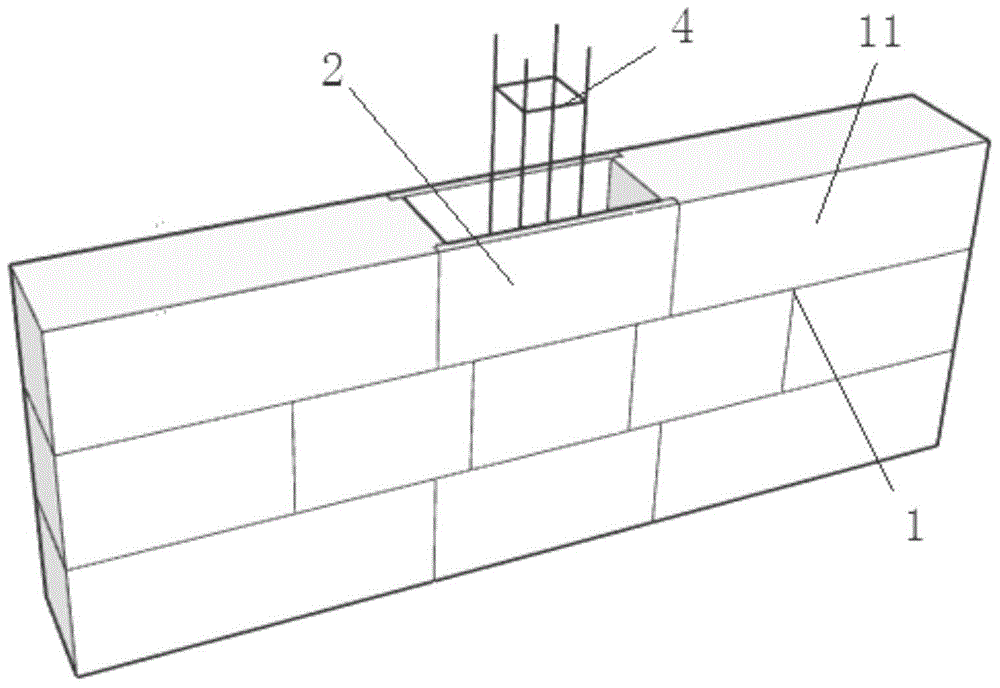

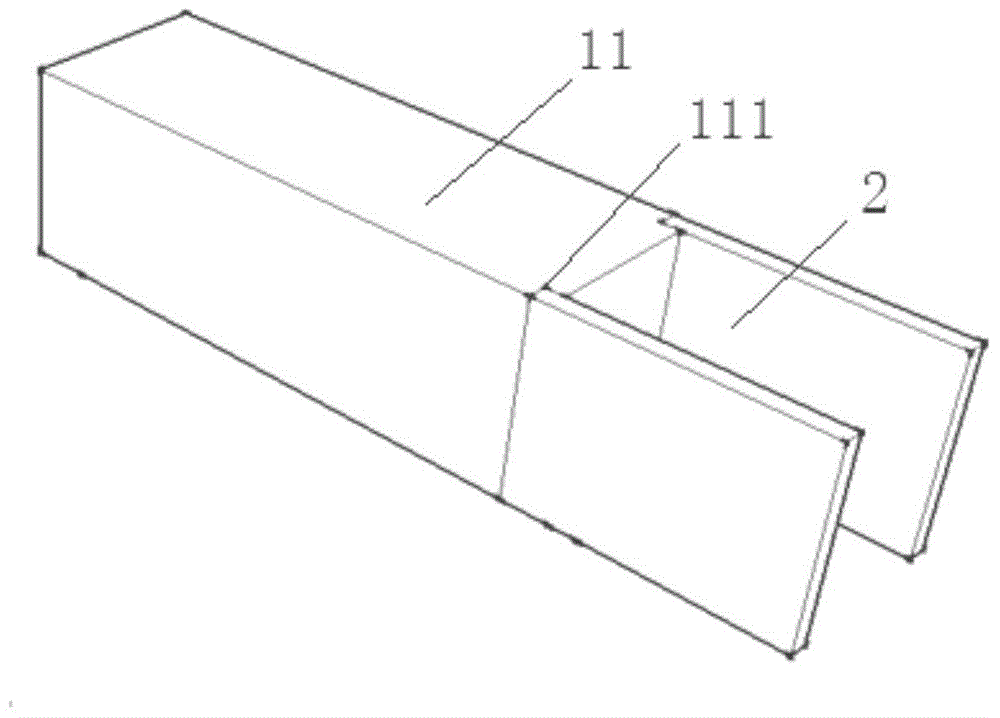

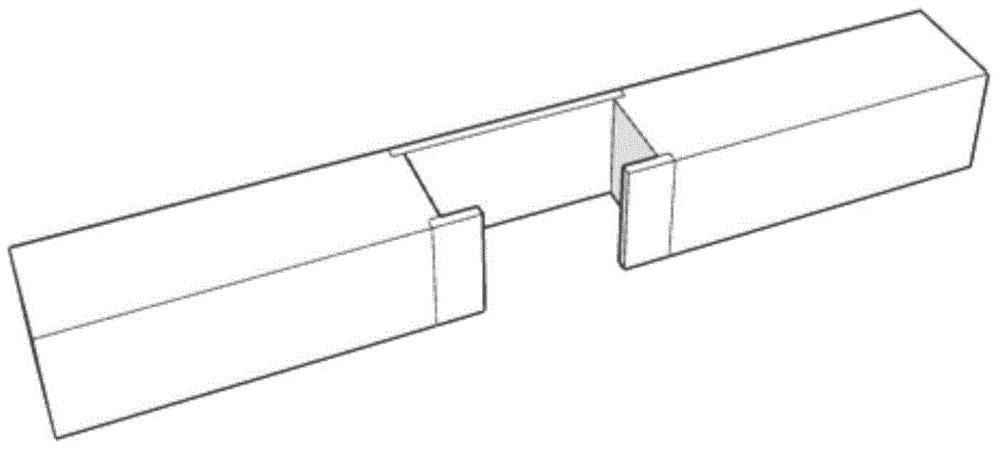

Formwork-free constructional column and construction method

InactiveCN105064543AEliminate the demoulding processGuaranteed StrengthWallsBuilding material handlingArchitectural engineering

Owner:GESHAN CONSTR GROUP +1

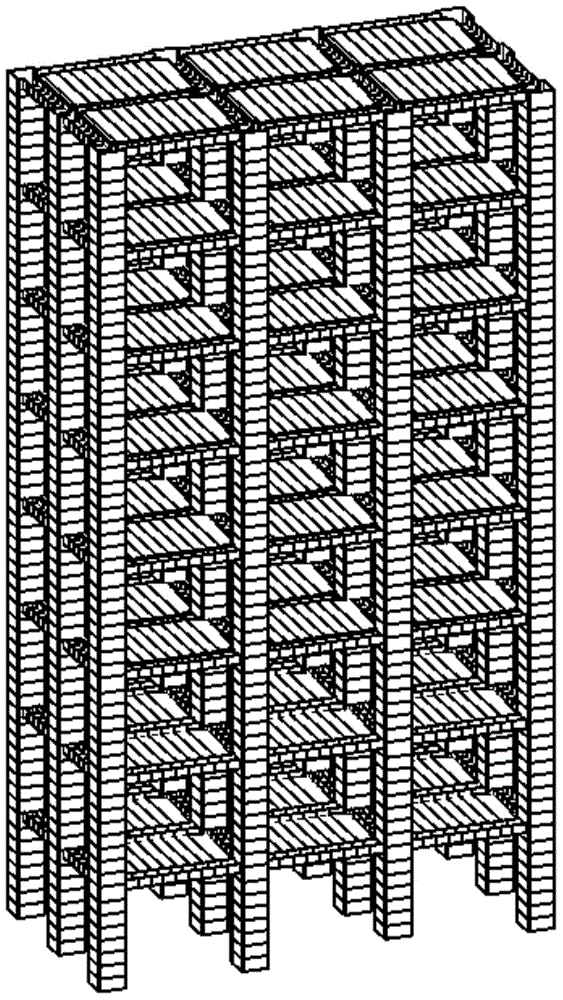

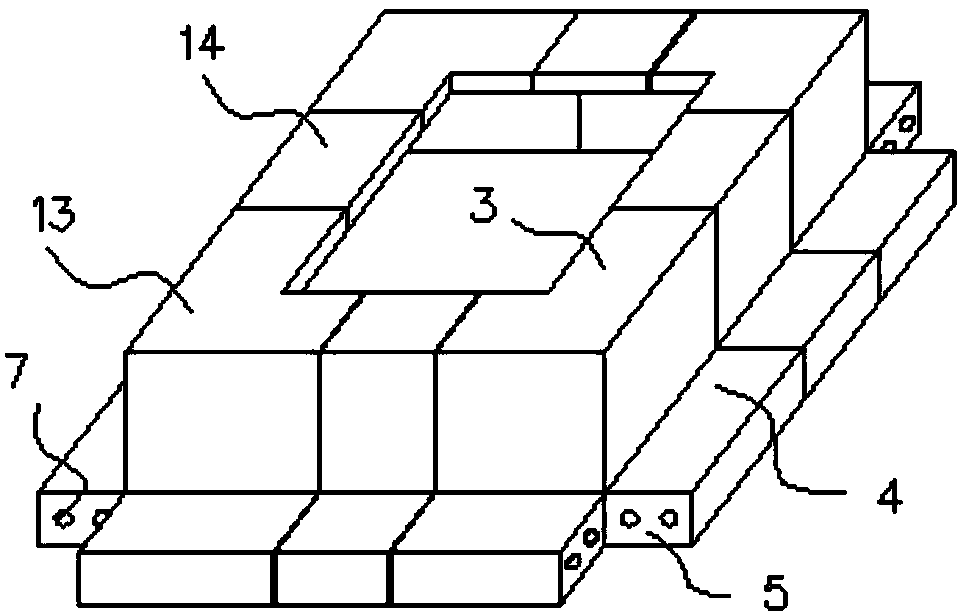

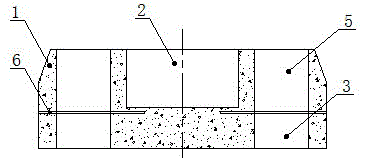

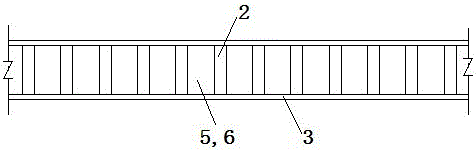

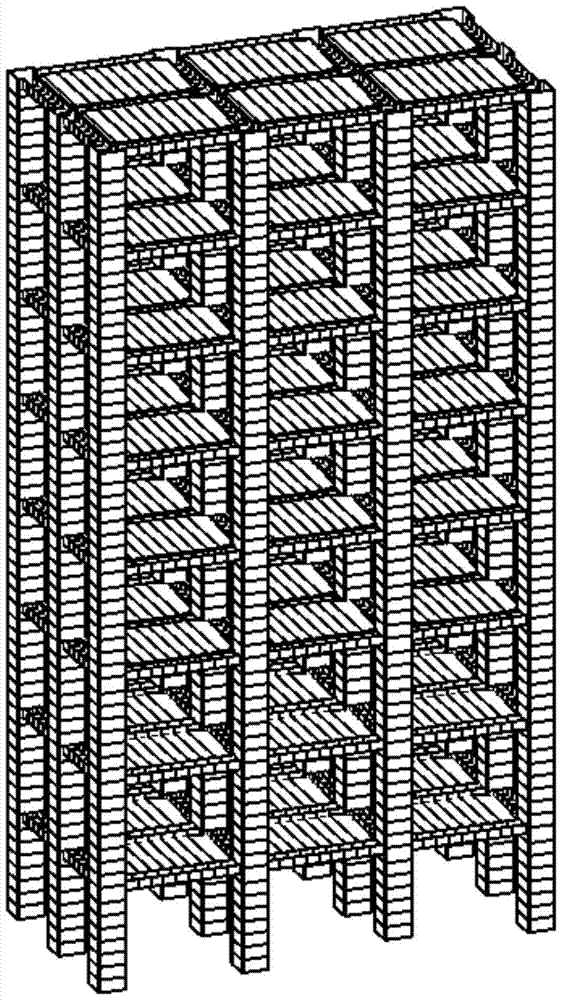

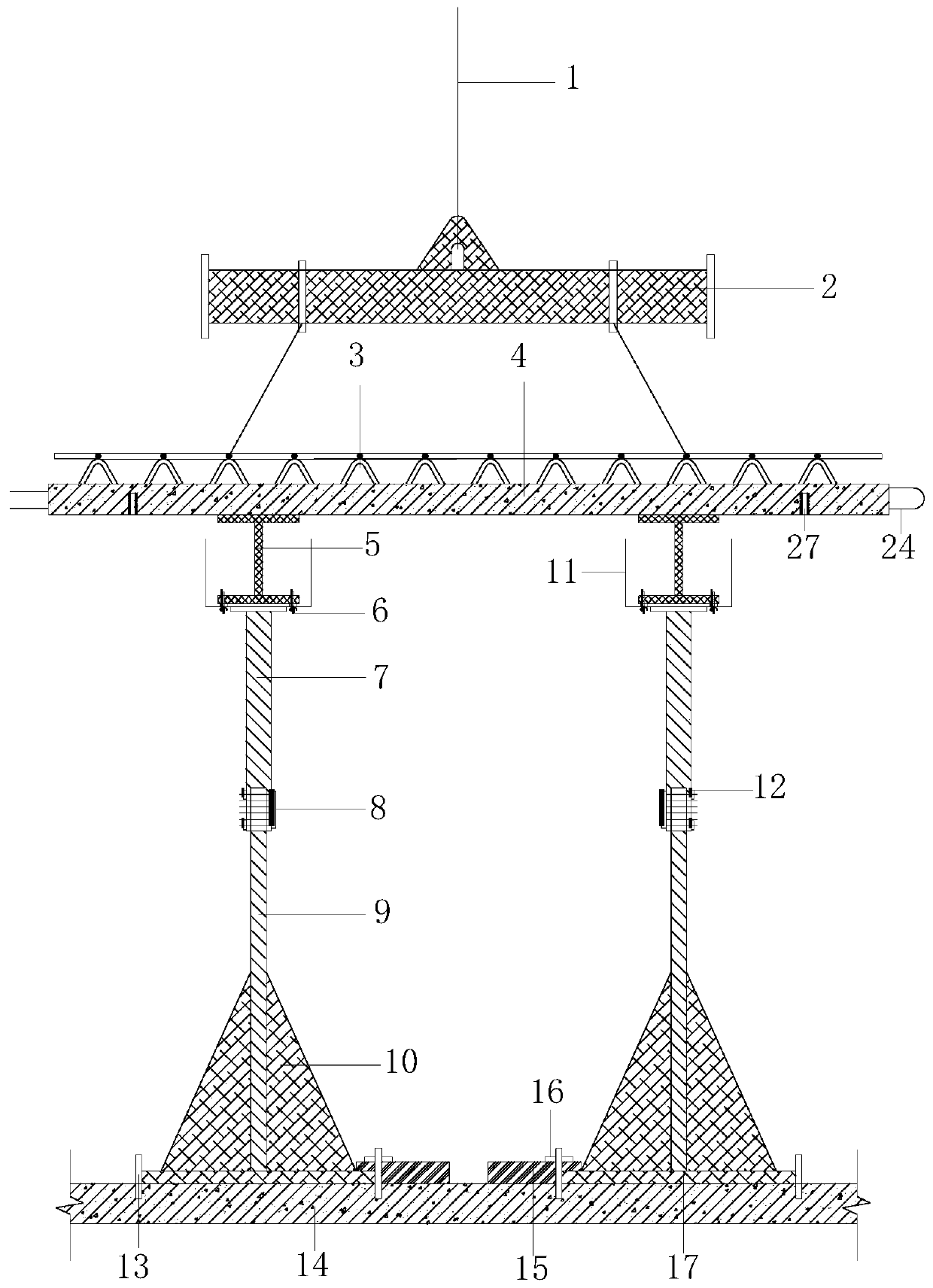

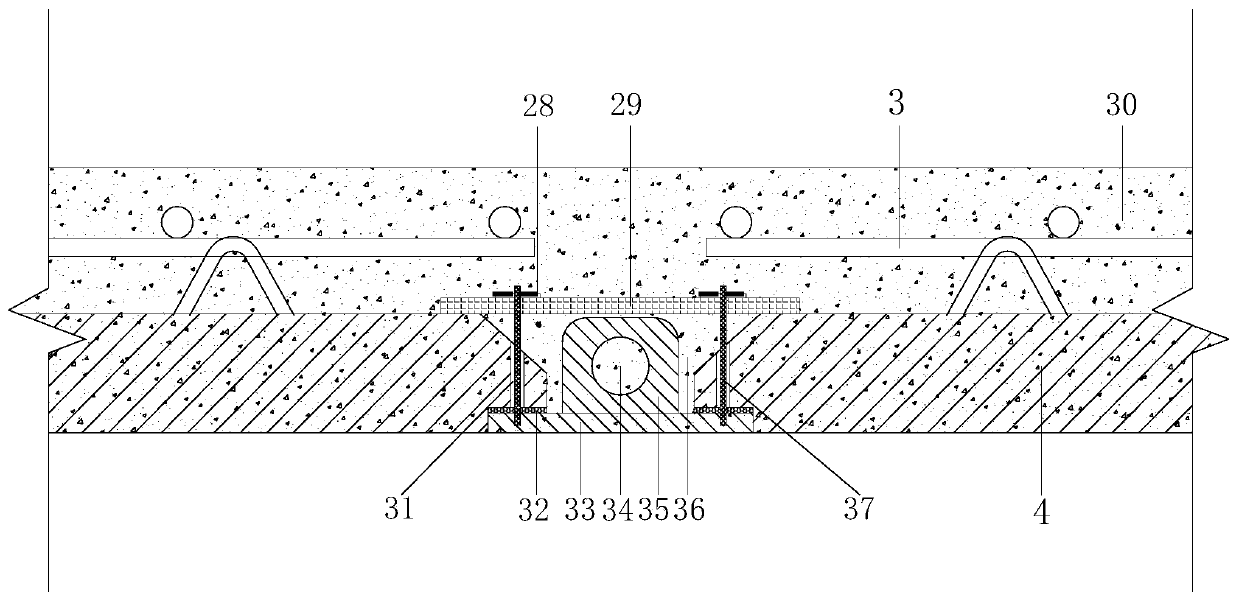

Integrated beam-slab-column formwork structural system and construction method

The invention relates to the technical field of constructional engineering, in particular to an integrated beam-slab-column formwork structural system and a construction method. The structural system is a frame structure formwork system composed of a non-dismantling column formwork, a beam formwork, a beam-column joint formwork and a slab formwork which are connected to each other; the column formwork, the beam-column joint formwork, the beam formwork and the slab formwork are respectively composed of corresponding formwork units by means of splicing; a non-dismantling formwork unit is made of a thin-wall shell structure and used as a formwork when pouring concrete, and also used as finishing material in the later stage, wherein one side of the non-dismantling formwork unit is processed into a rough surface and the other side is smooth; the splicing parts of the formwork units are built in by adopting a form of concave-convex groove and tongue; an outer side of the non-dismantling formwork is fastened by using a fastening hoop to resist the cast-in-situ concrete side pressure; the beam-column joint formwork makes the integrated beam-slab-column formwork structural system applicable to a preformed structural member, and also applicable to cast-in-situ; the preformed member is spliced or concrete is casted in situ to the preformed member to form one building unit of the frame structure, and a plurality of building units form a multilayer or a high-rise frame structure.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

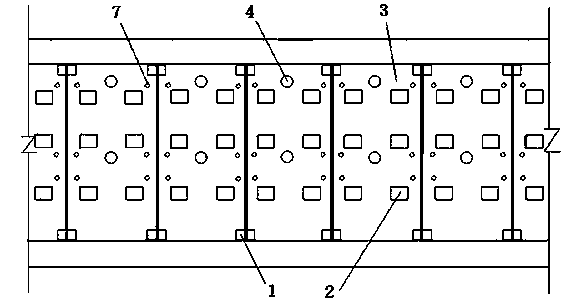

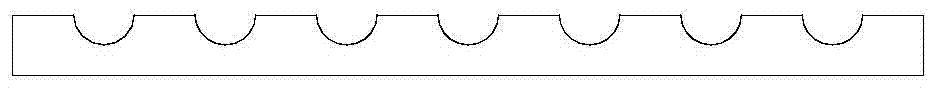

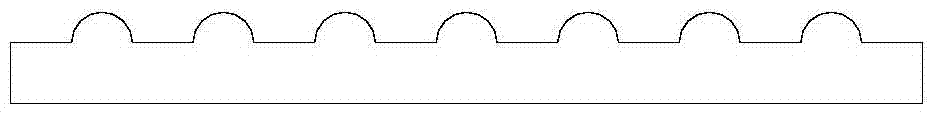

Cover die for construction of composite-section ribbed floor and construction method thereof

ActiveCN109680929ASolve mold problemsReduce production processForms/shuttering/falseworksReinforced concreteEngineering

The invention discloses a cover die for construction of a composite-section ribbed floor and a construction method thereof. The cover die comprises two cylinders or one cylinder and one box or two boxes, wherein each cylinder is of a cylindrical surrounding body structure of which the upper part and lower part are communicated; the cylinders comprise a cylinder I and / or a cylinder II; each box isof a cavity body structure of which one end is opened and the other end is sealed; the boxes comprise a box I and / or a box II; the cylinder I is sheathed above the exterior of the cylinder II, and / orthe box I is sheathed above the exterior of the cylinder II, and / or the box I is sheathed above the exterior of the box II; a lower flange die cavity of a cast-in-situ concrete rib is formed between the cylinder and / or the box; a web plate die cavity of a cast-in-situ concrete dense rib is formed between the adjacent cylinders and / or the boxes. One of the cover die is reserved in a reinforced concrete prefabricated rib cylinder or box, and the other one is a detachable and repeatedly used cylinder die, or is a prefabricated concrete cylinder reserved in the floor. The cover die is a construction die with the advantages that the production is simple; the construction is convenient; the construction period is short; the manufacturing cost is low; the good use effect is obtained.

Owner:贵州皆盈科技开发有限公司

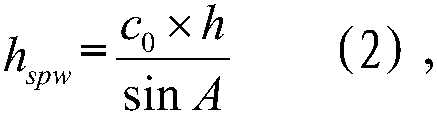

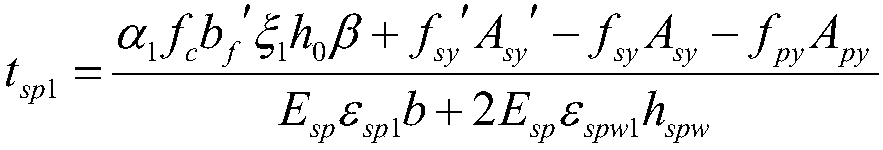

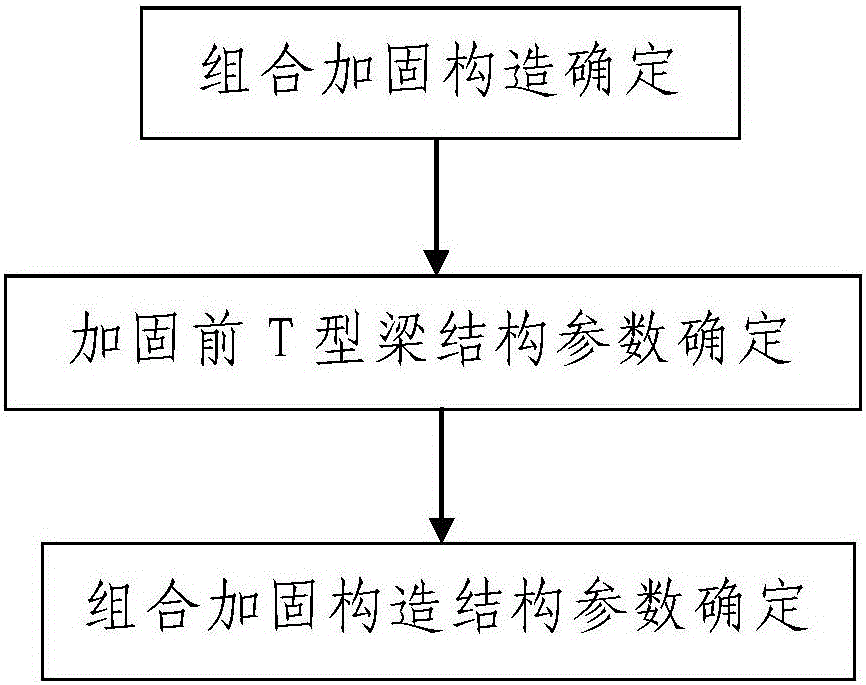

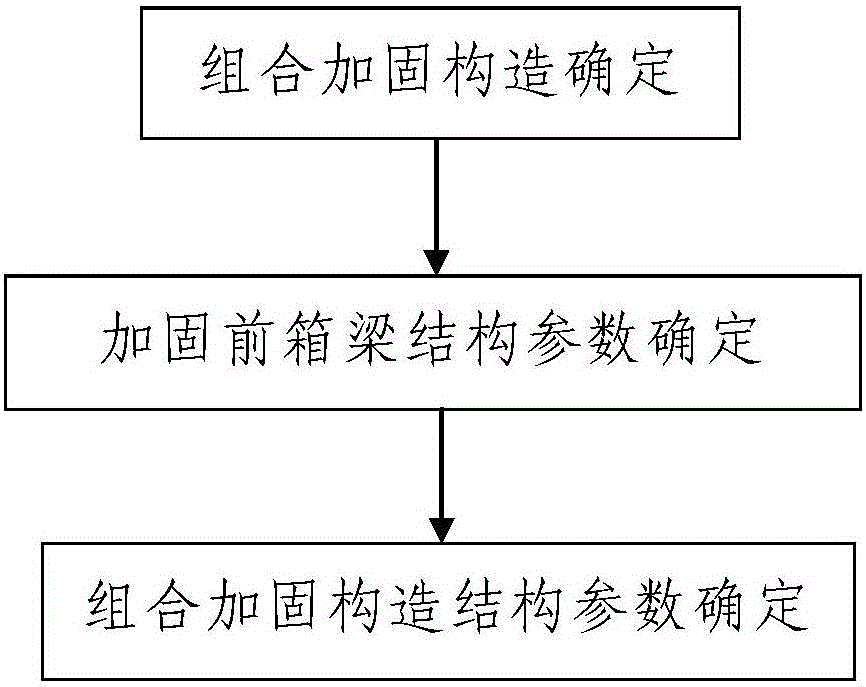

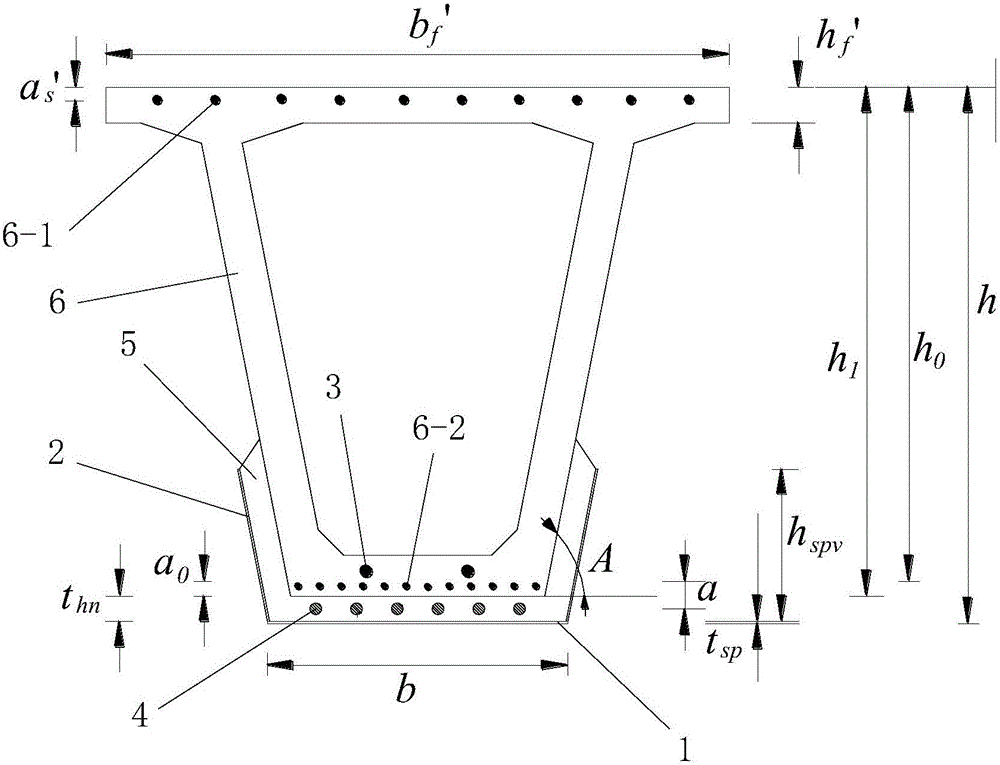

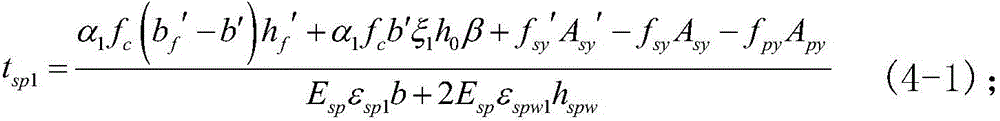

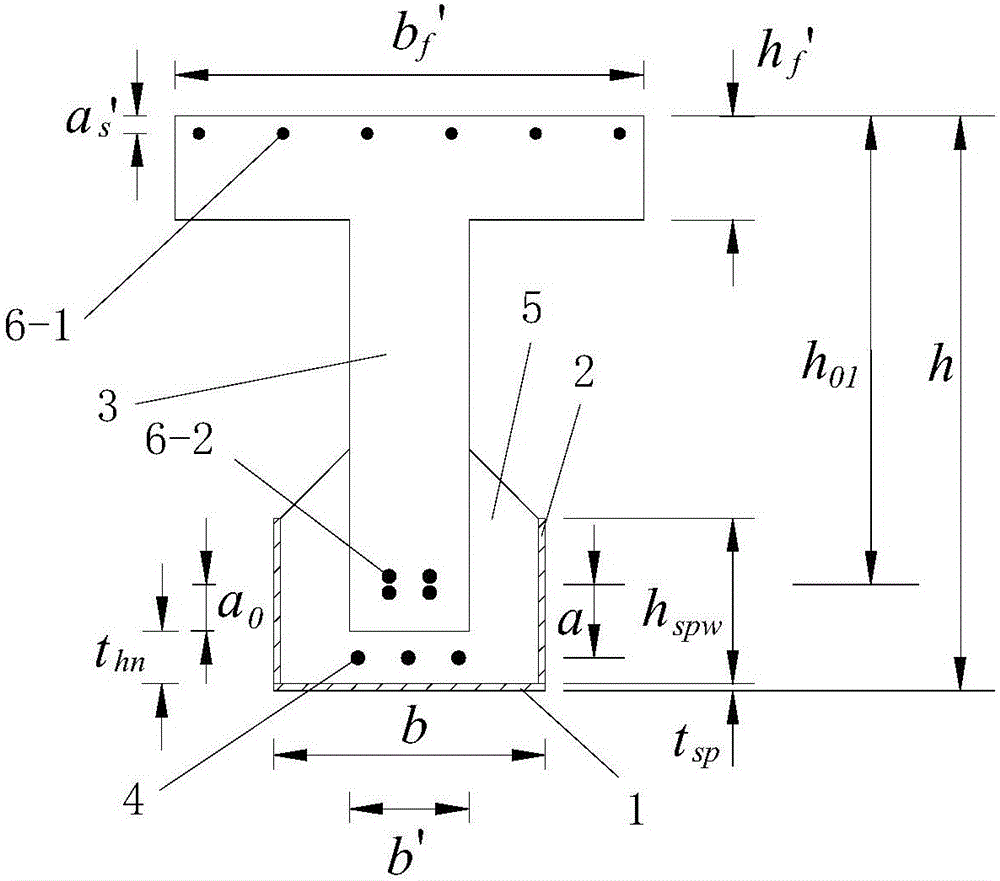

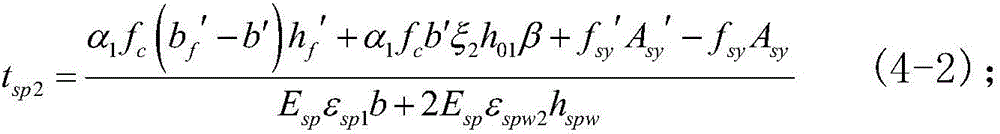

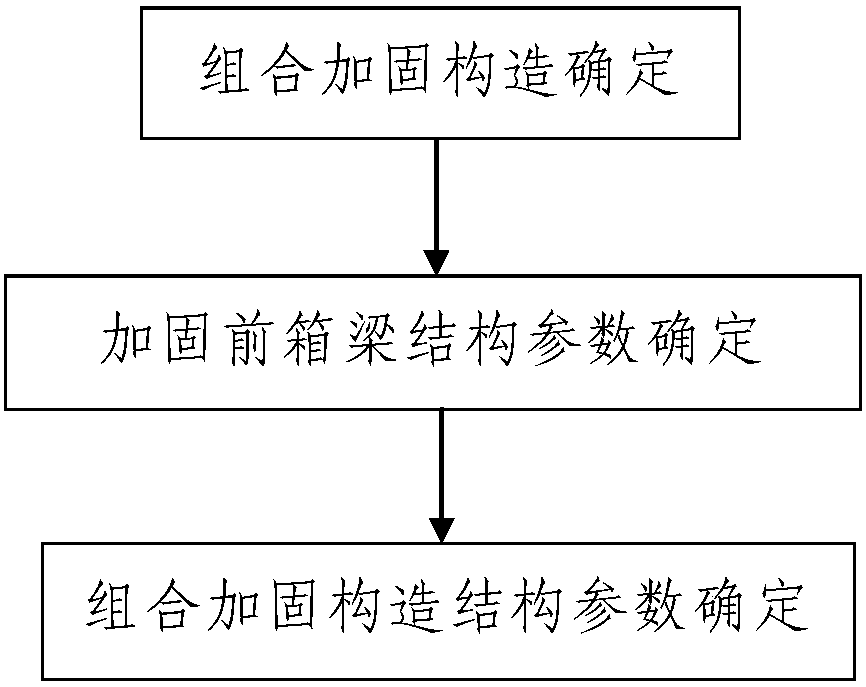

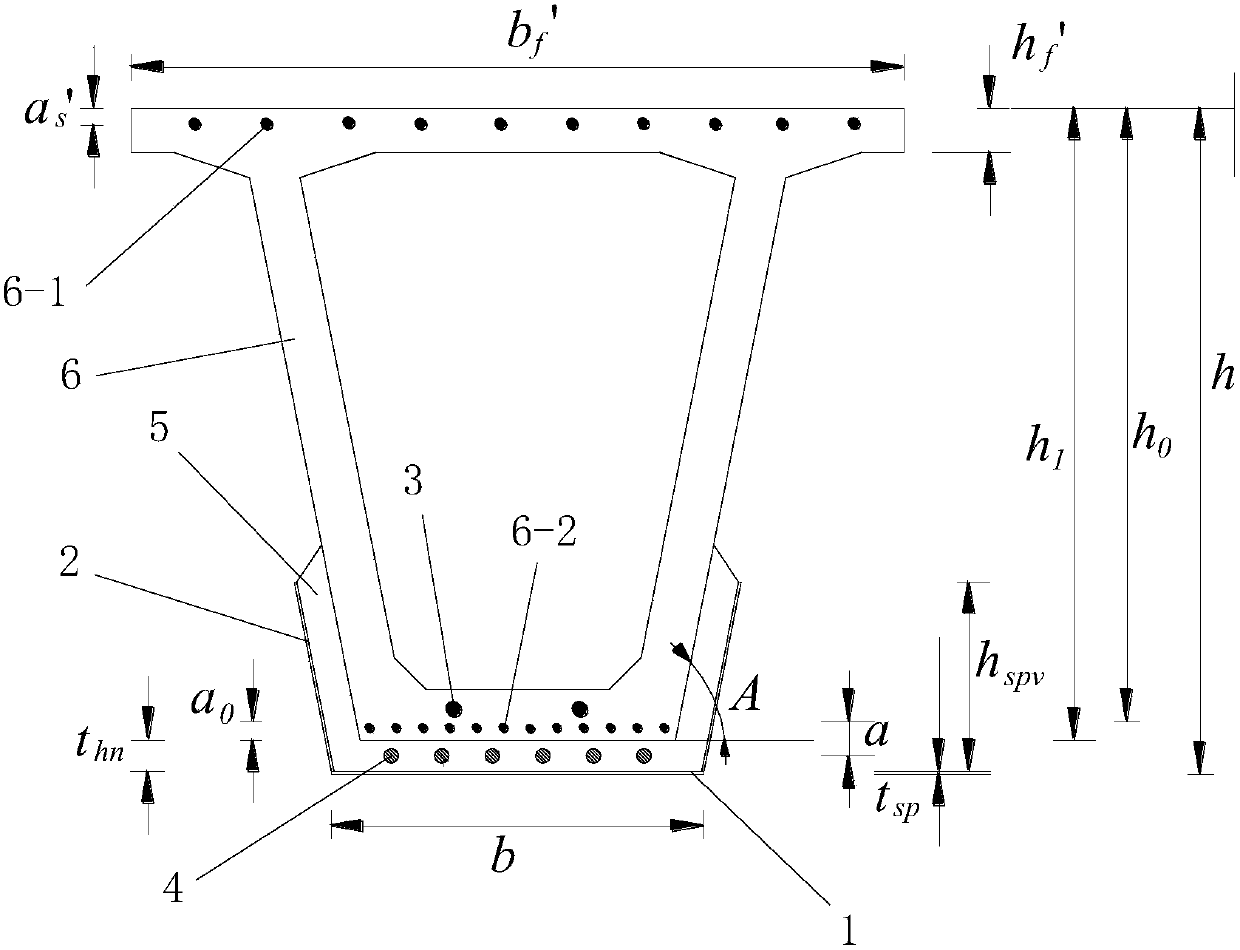

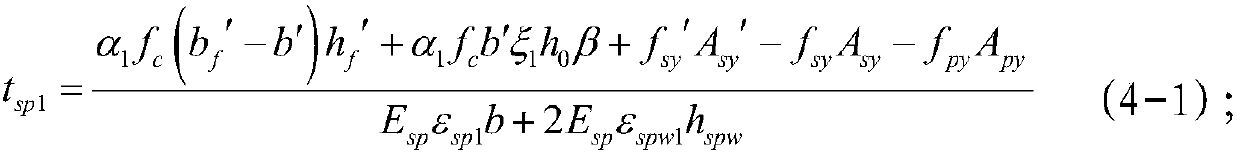

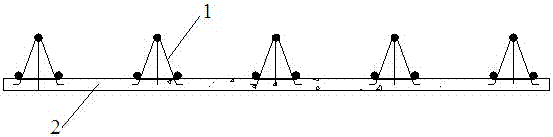

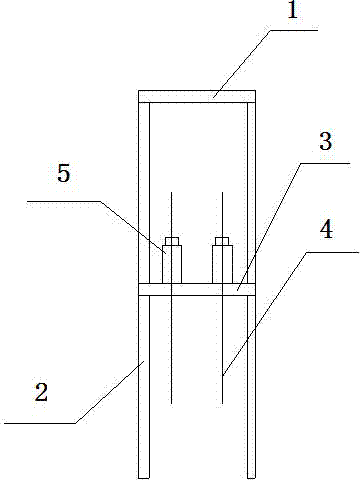

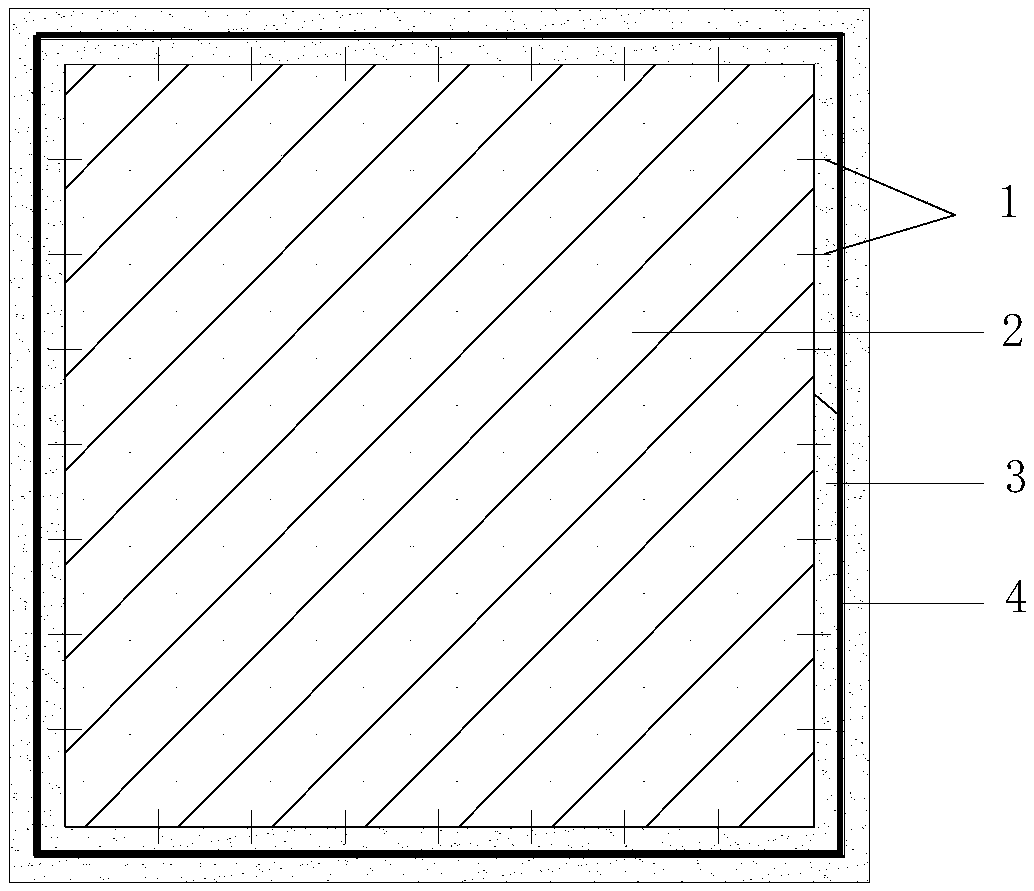

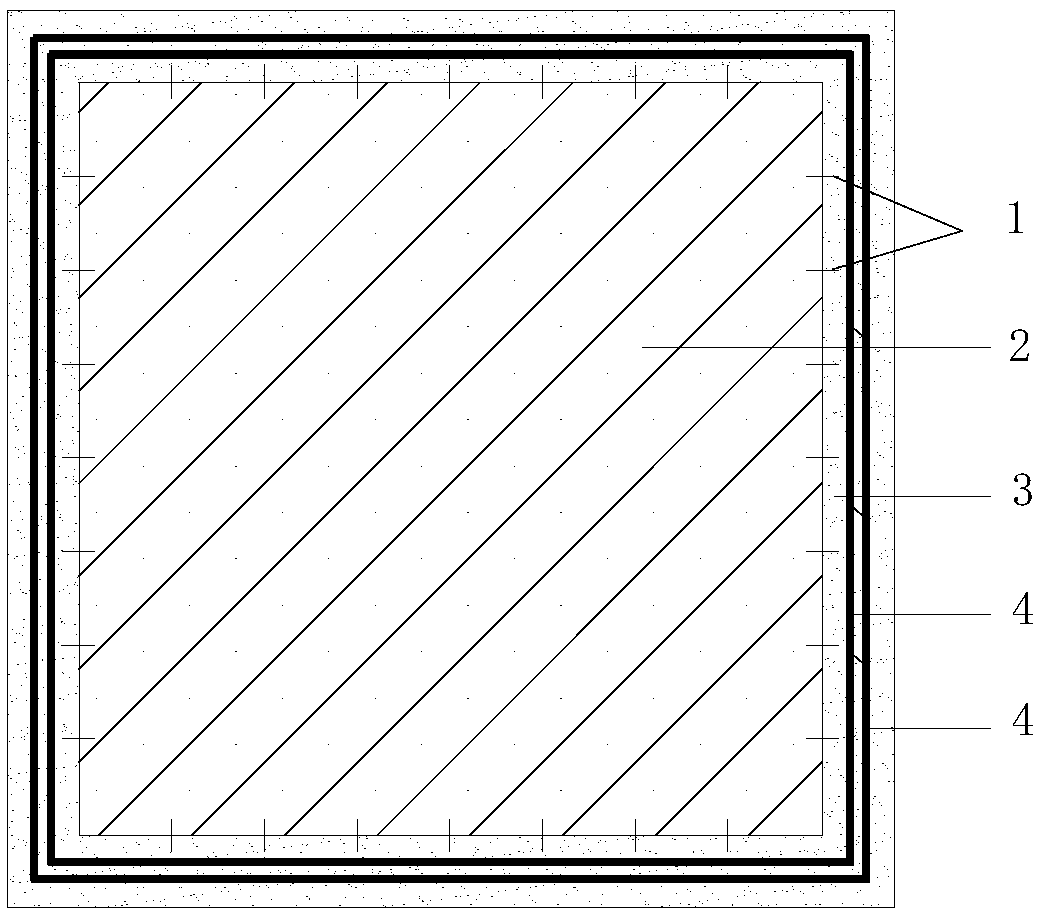

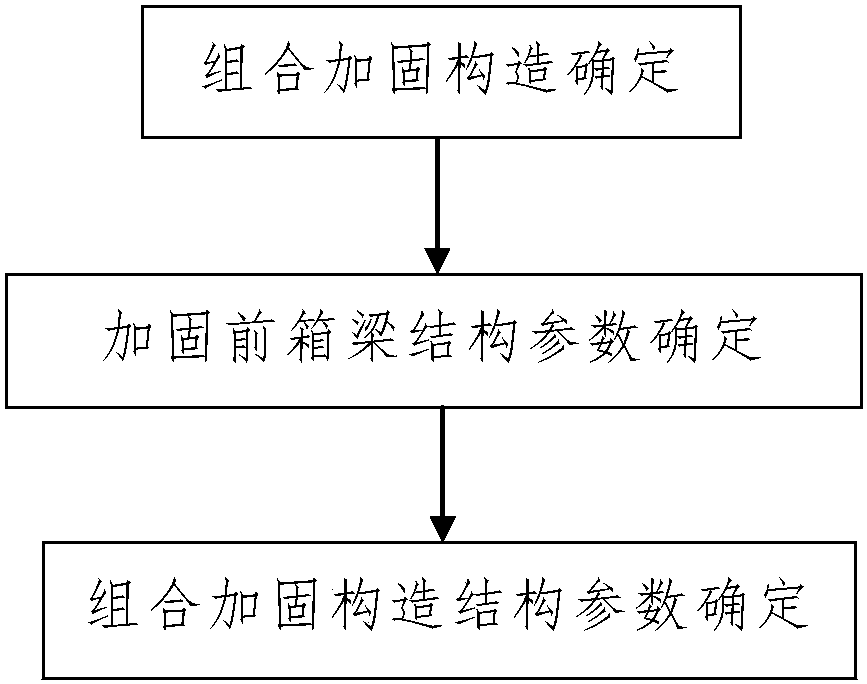

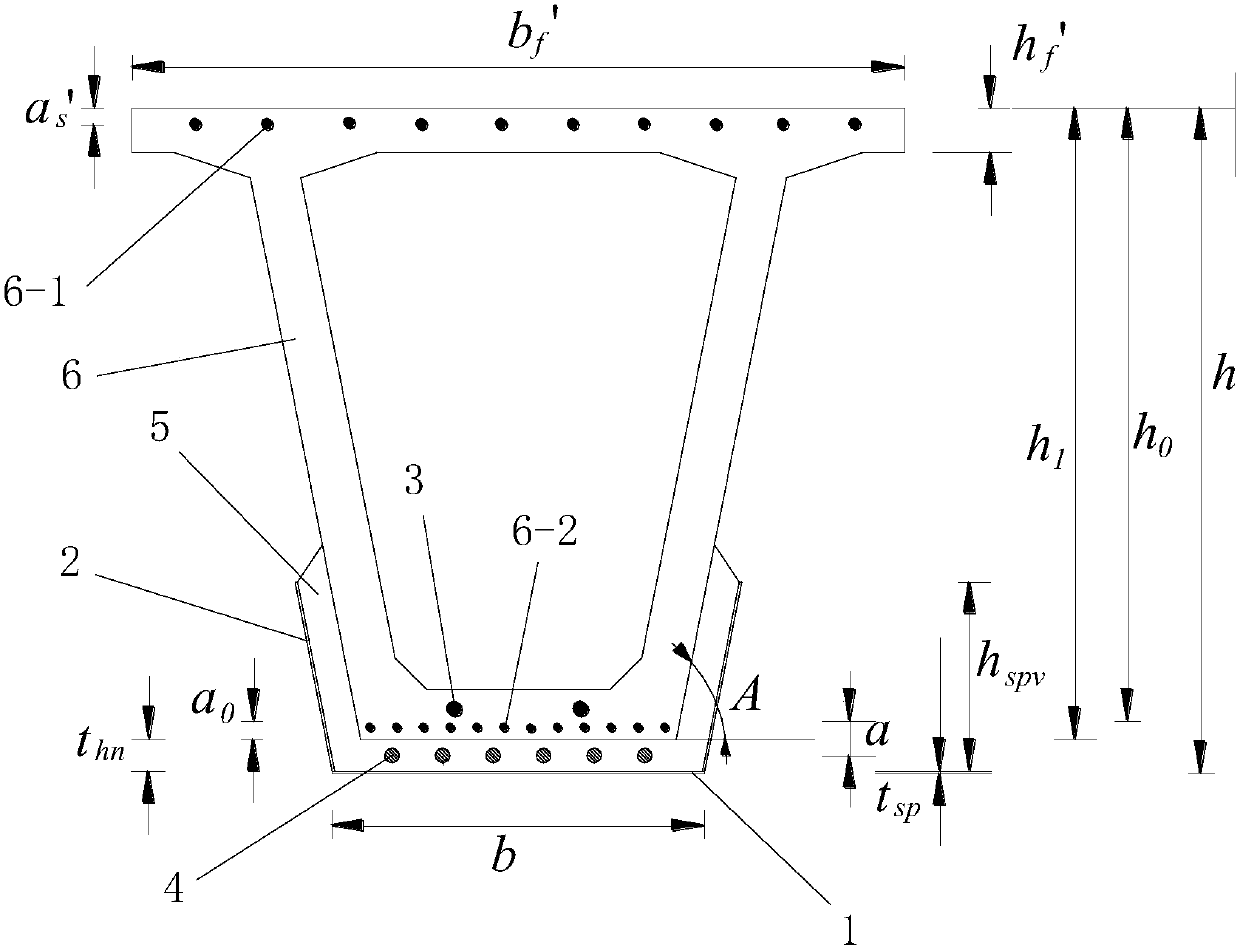

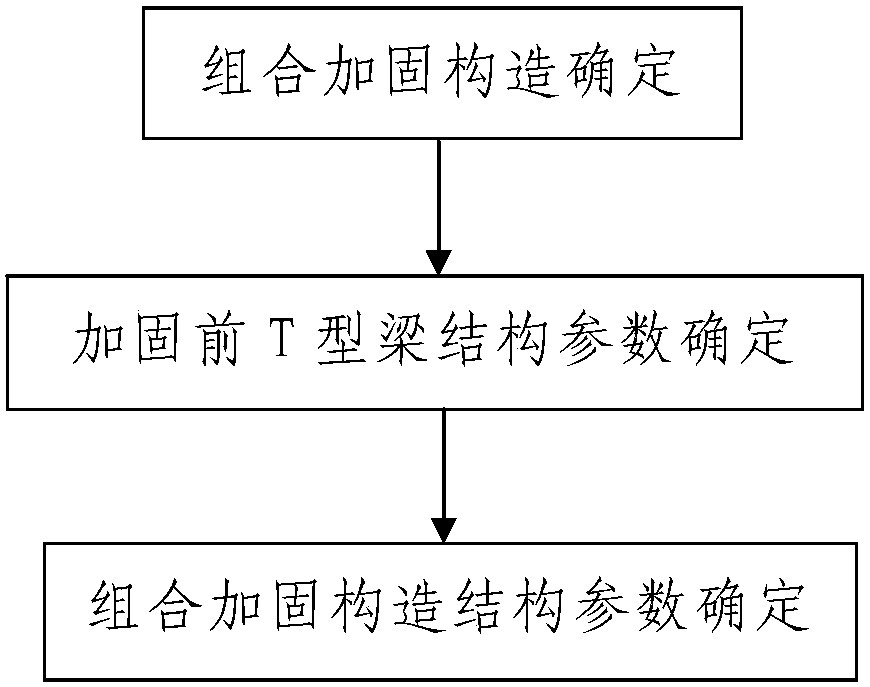

Design method for unbonded prestress and steel-concrete combined reinforcement of concrete box girder

ActiveCN106120574AThe method steps are simpleReasonable designBridge erection/assemblyBridge strengtheningSteel jacketPre stress

The invention discloses a design method for unbonded prestress and steel-concrete combined reinforcement of a concrete box girder. The design method comprises the following steps of I, determining a combined reinforcing structure: determining the unbonded prestress and steel plate-concrete combined structure of the box girder to be reinforced wherein the combined reinforcing structure comprises a steel jacket box formed by a base steel pate, two longitudinal side steel plates and two end part plugging steel plates, and a plurality of unbonded prestressed reinforcing bars are arranged in the steel jacket box; II, determining structural parameters for reinforcing the front box girder; and III, determining structural parameters of the combined reinforcing structure in the process comprising the following steps of initializing the parameters, calculating theoretical maximum thickness of the reinforcing steel plates, determining the thickness of the reinforcing steel plates and the thickness of concrete, and determining the height of the longitudinal side steel plates and the width of the base steel plate. The method disclosed by the invention is simple in steps, reasonable in design, convenient to realize, and good in using effect, the structural parameters of the combined reinforcing structure of a bridge can be simply, conveniently and quickly determined, and the designed combined reinforcing structure of the bridge is economical and practical and good in reinforcing effect.

Owner:XIAN HIGHWAY INST

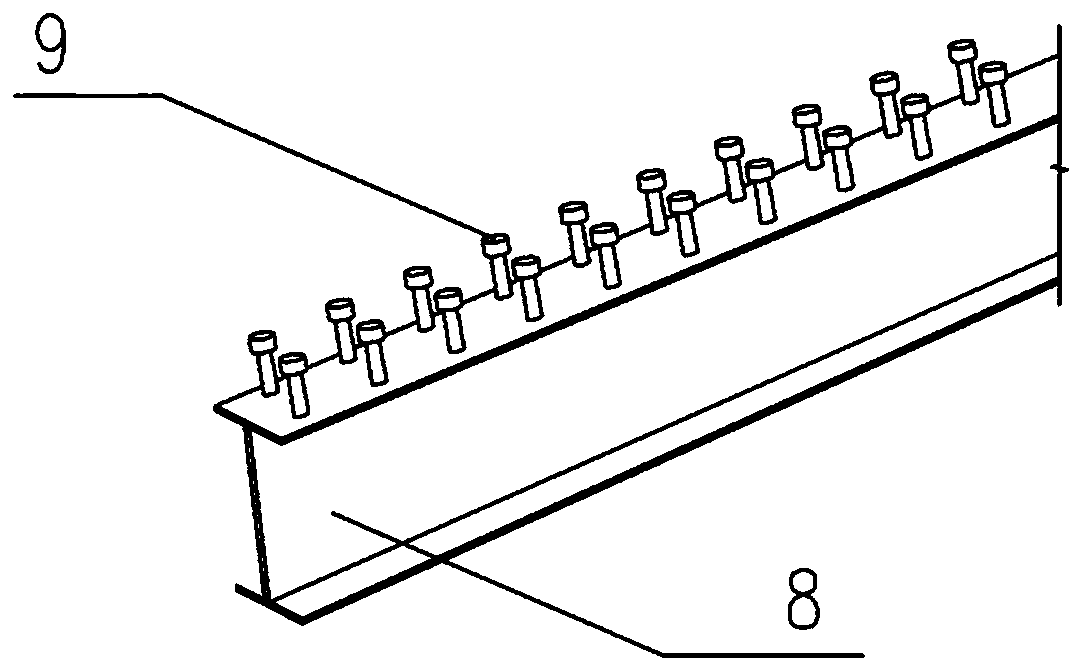

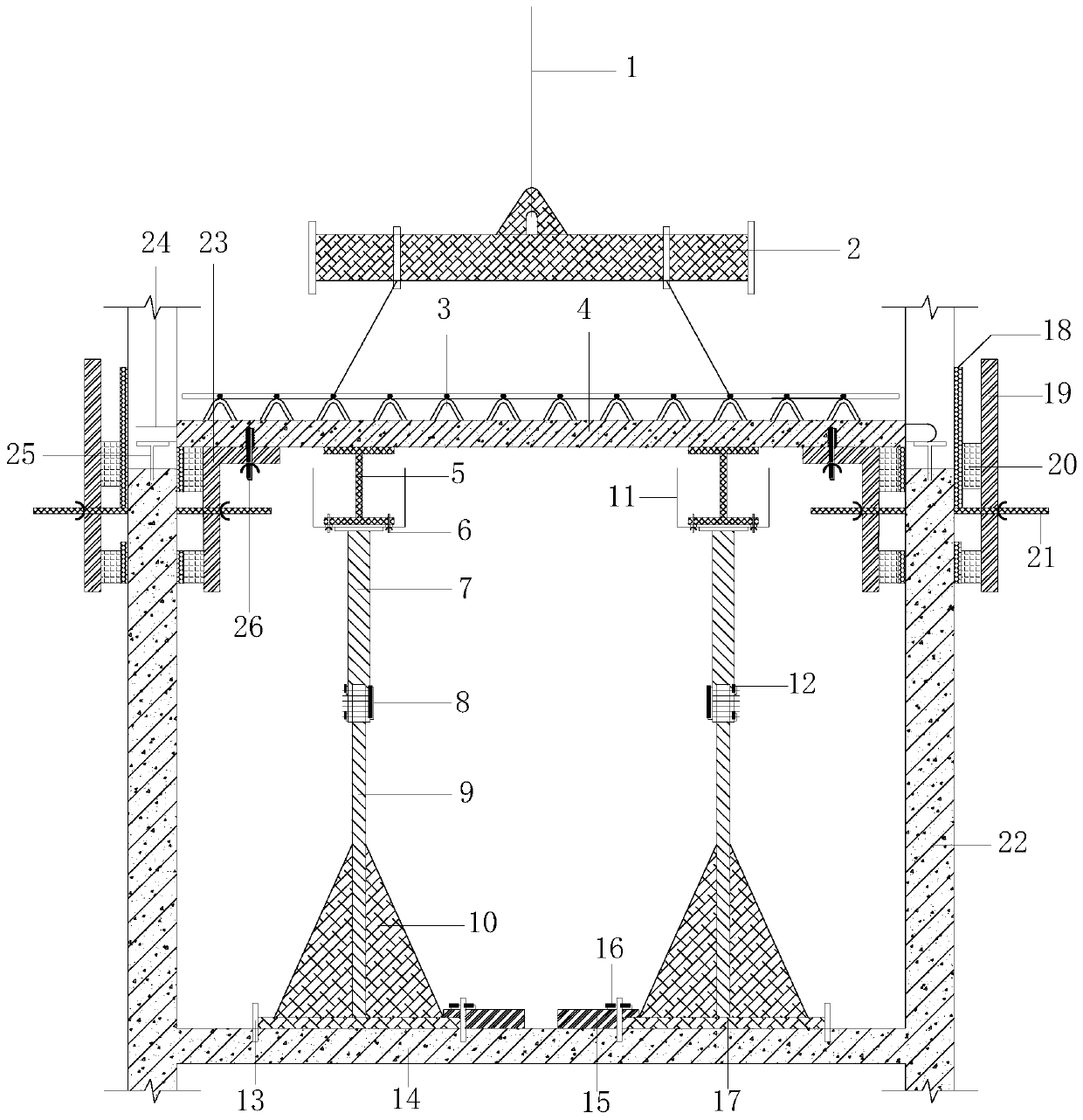

Seamless connection system for assembled steel structure beam-column member and floor bearing plate and construction method

InactiveCN111305440AFirmly connectedSolve the problems of long-span applicationsFloorsBuilding material handlingSteel columnsRebar

The invention relates to a seamless connection system for an assembled steel structure beam-column member and a floor bearing plate and a construction method. The seamless connection system comprisesa prefabricated steel bar truss deck, a steel I-beam, an upper chord connecting reinforcement, a lower chord connecting reinforcement, additional reinforcements, a column-side connection profile steelpart and a profile steel column, wherein the steel I-beam is fixed to a lower part of the steel bar truss deck; the upper and lower chord connecting reinforcements are arranged on an upper part and alower part of the steel bar truss deck respectively; the additional reinforcements are arranged on the top and at the bottom of the steel bar truss deck respectively; the column-side connection profile steel part is connected with the steel bar truss deck; the profile steel column is welded together with the column-side connection profile steel part; the steel bar truss deck comprises a bottom die steel plate and a plurality of spatial steel bar trusses which are fixed to the bottom die steel plate at intervals; the spatial steel bar trusses comprise upper chord reinforcements, lower chord reinforcements and web member reinforcements; one upper chord reinforcement and two lower chord reinforcements are fixed by a plurality of web member reinforcements; the web member reinforcements are arranged along the widths of the spatial steel bar trusses at intervals; and the lower chord reinforcements extending along the longitudinal directions of the spatial steel bar trusses are arranged below two sides of the upper chord reinforcements respectively.

Owner:永富建工集团有限公司 +1

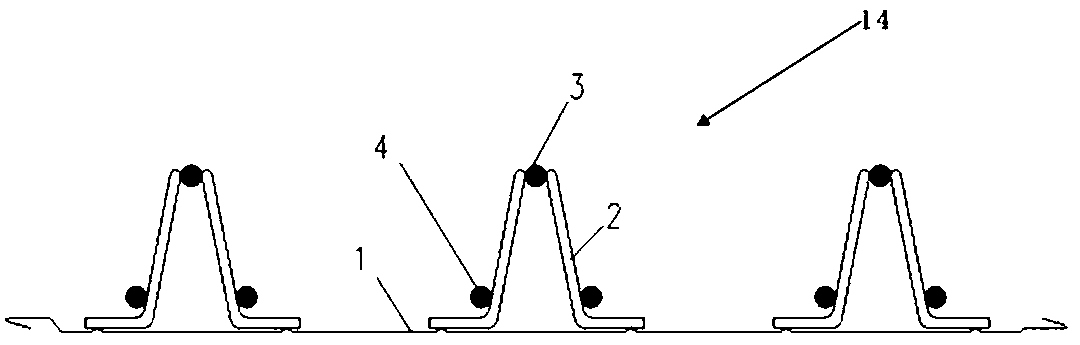

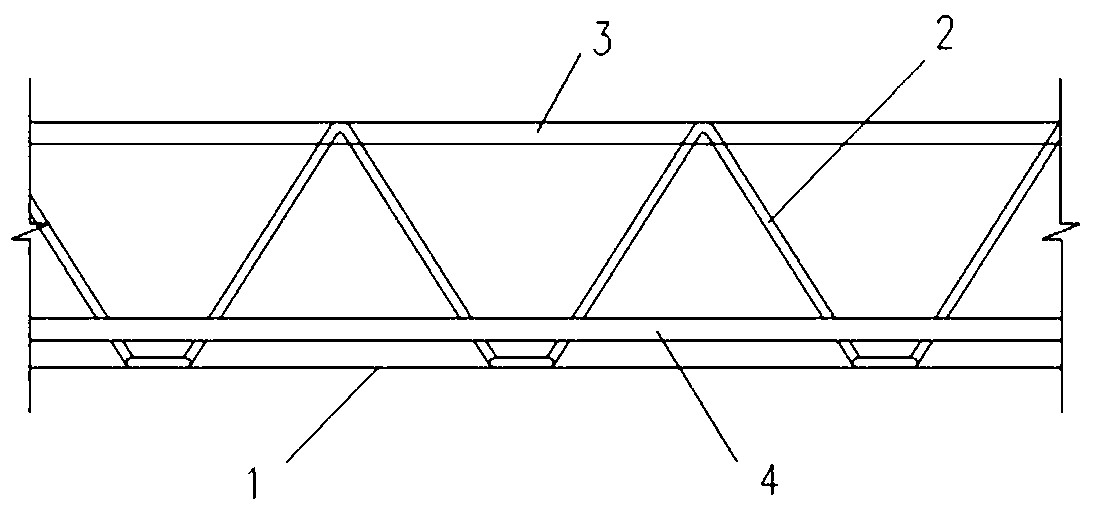

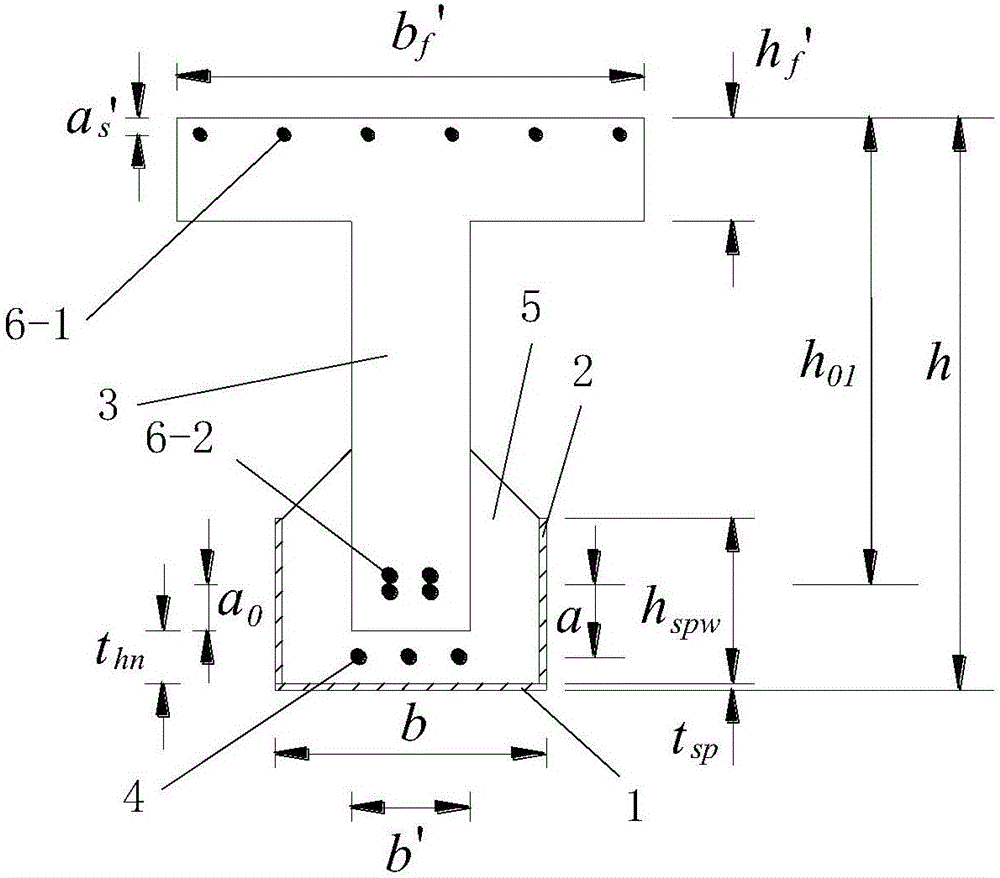

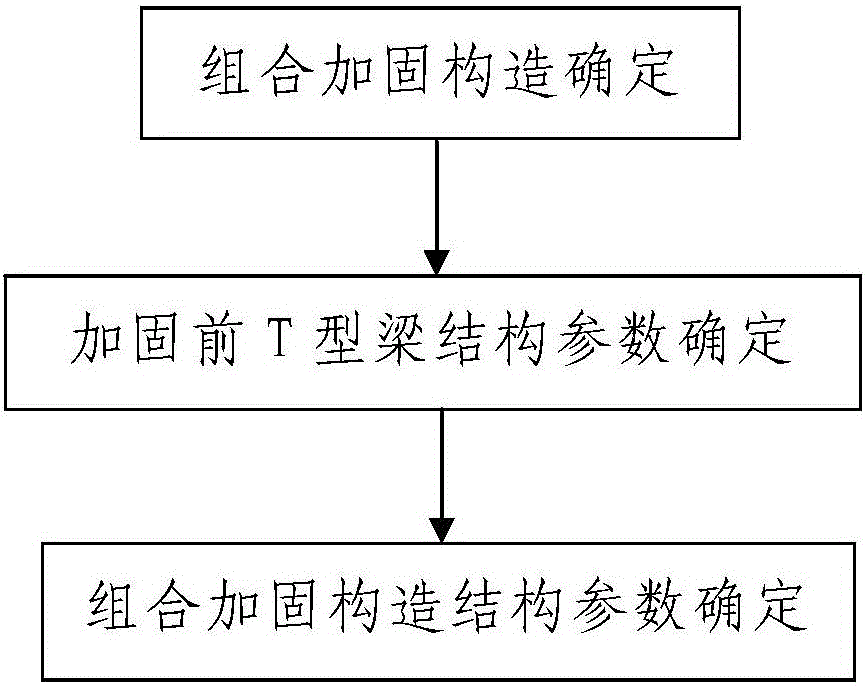

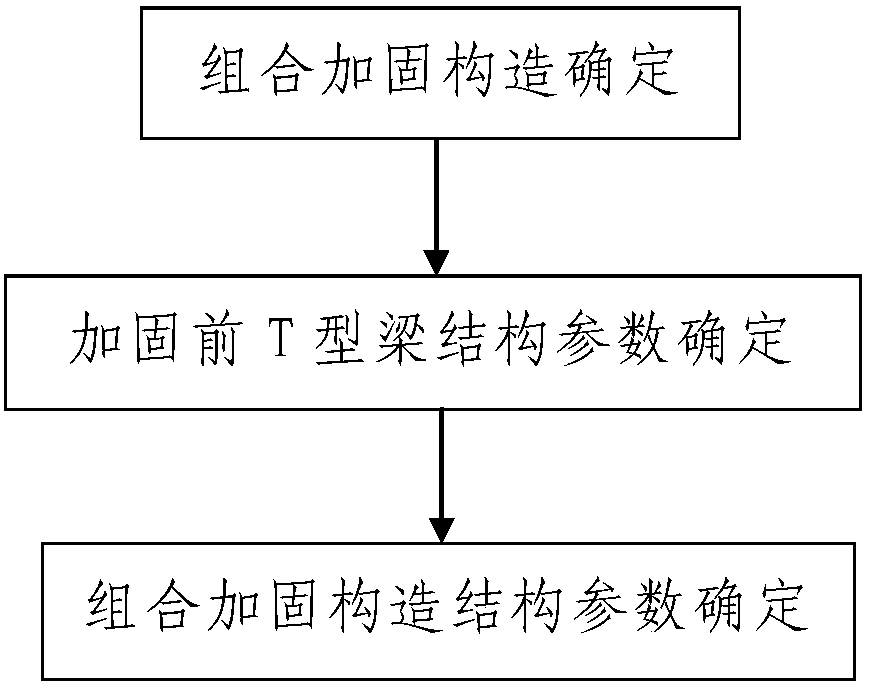

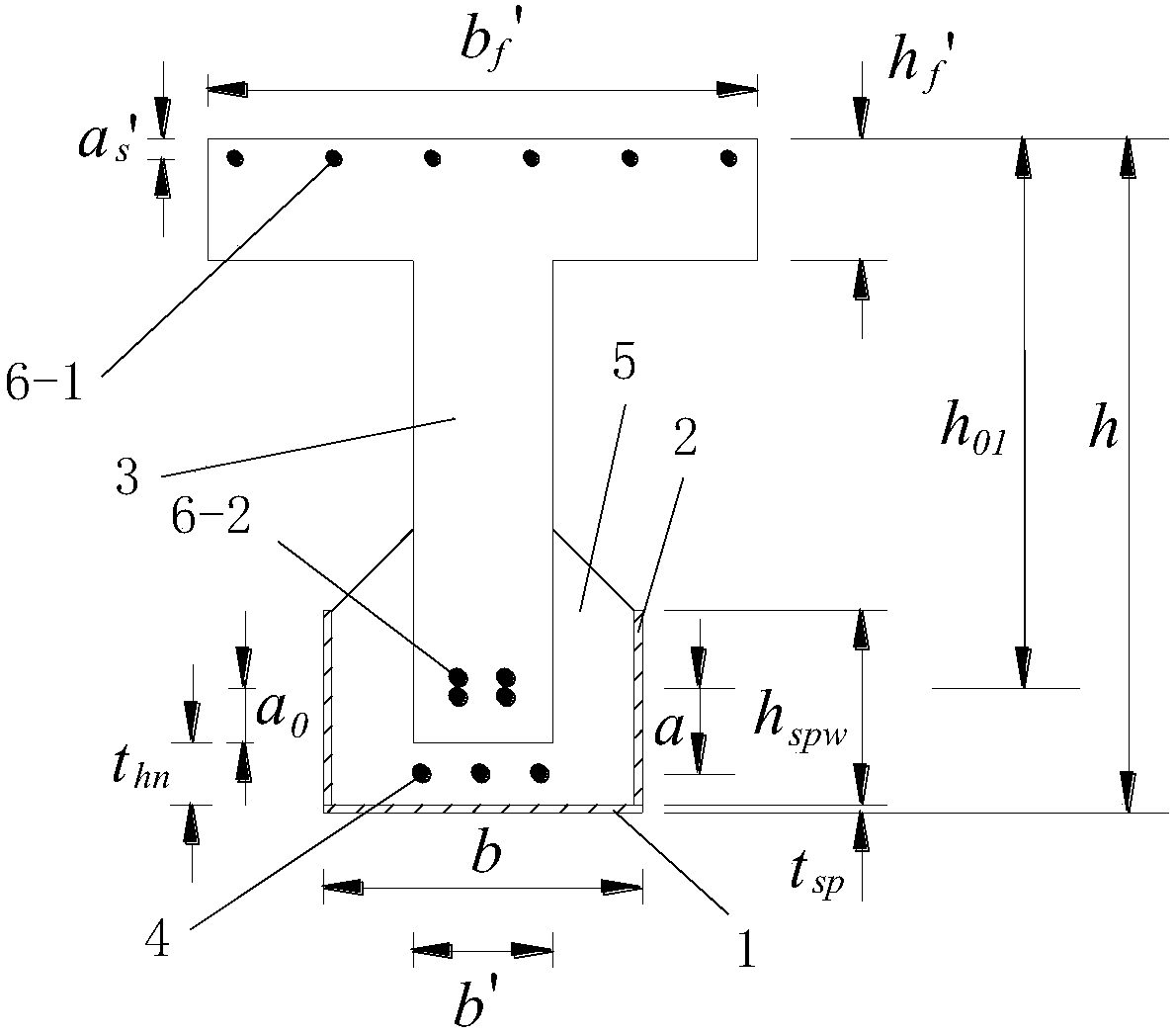

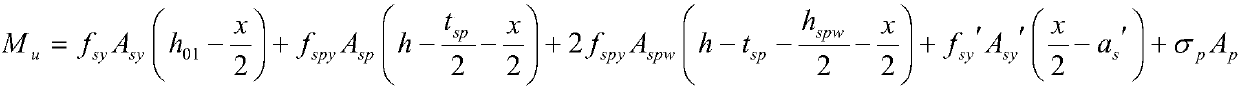

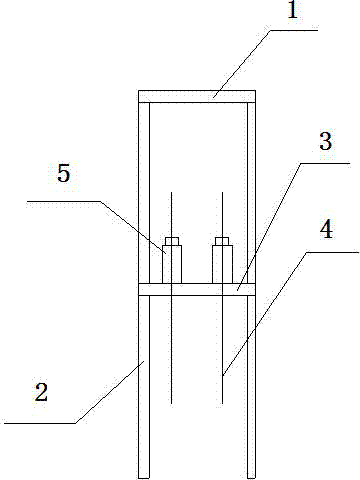

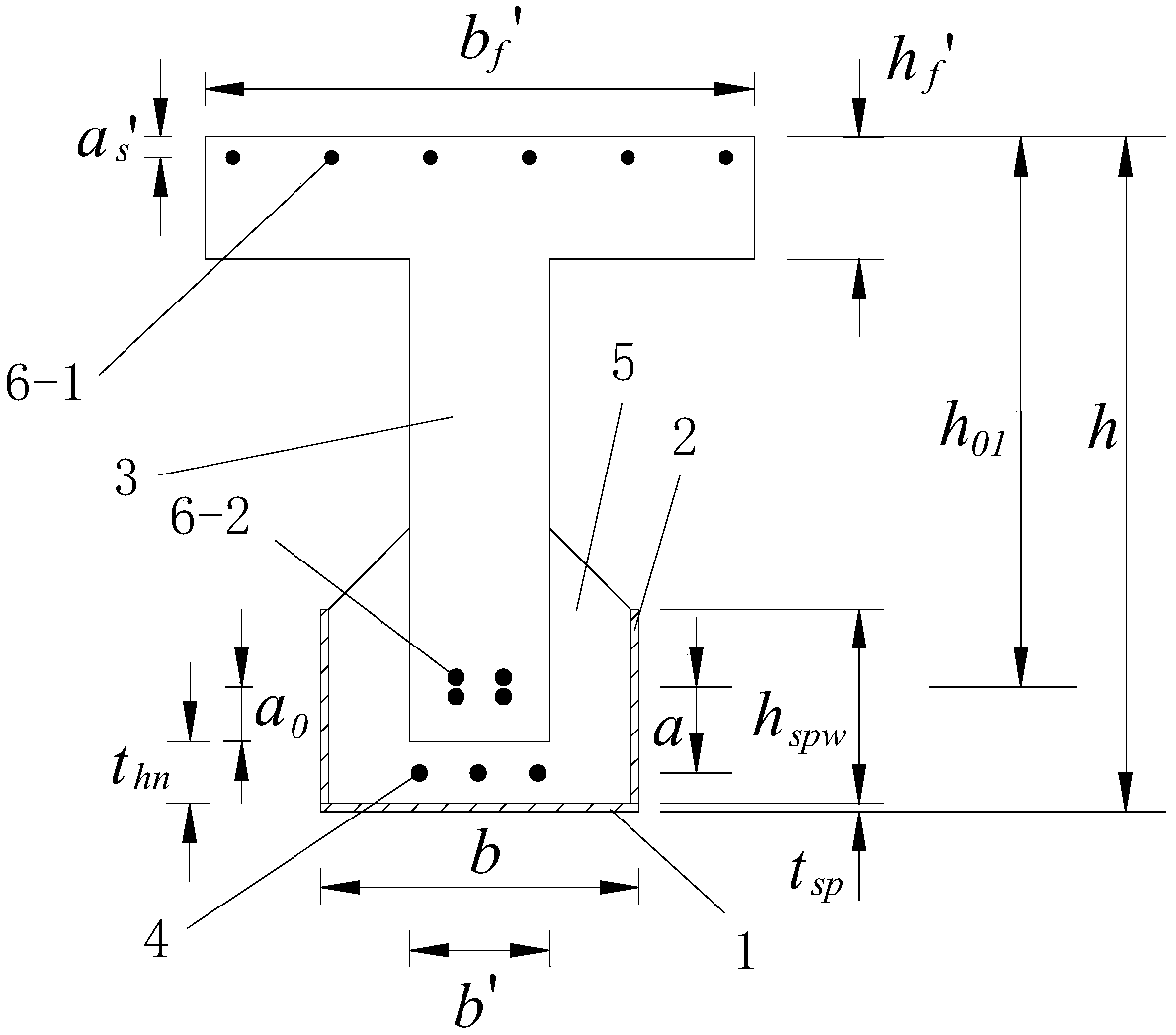

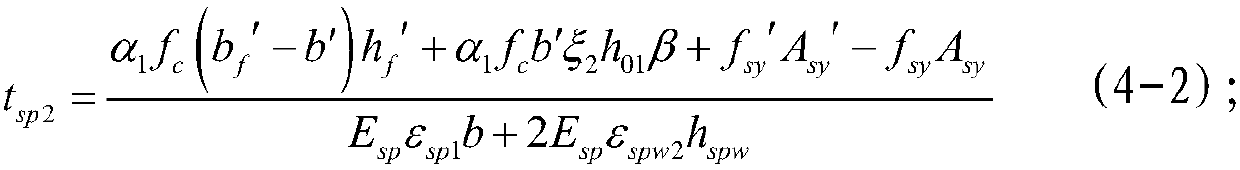

Unbonded prestress and steel-concrete composite reinforcement design method for concrete T-shaped beams

ActiveCN105839551AThe method steps are simpleReasonable designBridge erection/assemblyBridge strengtheningRebarSteel plates

The invention discloses an unbonded prestress and steel-concrete composite reinforcement design method for concrete T-shaped beams. The unbonded prestress and steel-concrete composite reinforcement design method includes steps of firstly, determining unbonded prestress and steel plate-concrete composite reinforcement structures for the reinforcement T-shaped beams; secondly, determining structural parameters of the T-shaped beams prior to reinforcement; thirdly, determining structural parameters of the composite reinforcement structures, to be more specific, initializing the parameters, computing the maximum theoretical thicknesses of reinforcement steel plates, determining the thicknesses of the reinforcement steel plates and the thickness of concrete and determining the heights of longitudinal side steel plates and the widths of bottom steel plates. Each composite reinforcement structure comprises the corresponding bottom steel plate, the two longitudinal side steel plates and a steel bushing case, each steel bushing case comprises two end blocking steel plates, and a plurality of unbonded prestress reinforcing steel bars are arranged in each steel bushing case. The unbonded prestress and steel-concrete composite reinforcement design method has the advantages that the steps are simple, the unbonded prestress and steel-concrete composite reinforcement design method is reasonable in design and convenient to implement, good service effects can be realized, the structural parameters of the bridge composite reinforcement structures can be easily, conveniently and quickly determined, the bridge composite reinforcement structures designed by the aid of the unbonded prestress and steel-concrete composite reinforcement design method are economical and practical, and good reinforcement effects can be realized by the bridge composite reinforcement structures.

Owner:XIAN HIGHWAY INST

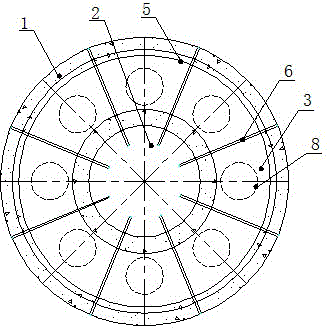

Assembled multi-pile foundation structure and construction method thereof

ActiveCN103912006AEliminate the demoulding processImprove construction efficiencyFoundation engineeringRebarPrecast concrete

The invention provides an assembled multi-pile foundation structure and a construction method thereof. The assembled multi-pile foundation structure comprises a concrete body, wherein a preserved foundation ring hole is formed in the center of the top surface of the concrete body, and a plurality of preserved pile holes are annularly and uniformly formed in the bottom surface of the concrete body corresponding to pipe piles. A land prefabricated concrete bearing platform (concrete bearing platform pouring jacket) is adopted, the conventional steel pouring jacket is replaced by the concrete bearing platform, and the prefabricated concrete bearing platform pouring jacket is taken as a concrete template as well as an important bearing structure. Compared with the conventional multi-pile foundation construction scheme adopted in offshore wind turbine generators, the assembled multi-pile foundation mounting method has the advantages that offshore form erecting and form stripping procedures are eliminated. Meanwhile, a large amount of offshore field binding of steel bars can be finished in a land prefabrication plant, the construction efficiency is increased greatly, the offshore bearing platform construction time is saved, and the construction cost is reduced.

Owner:POWERCHINA XIBEI ENG

Accelerating agent and preparation method thereof

ActiveCN101973722AEvenly distributed holesLarge amountSolid waste managementMass ratioSuperplasticizer

The invention discloses an accelerating agent, which is characterized by consisting of the following raw materials in part by weight: 10 to 30 parts of limestone, 18 to 36 parts of bauxite, 3 to 5 parts of desulfurated gypsum residue, 25 to 50 parts of fly ash, 6 to 15 parts of high-efficiency water reducing agent and 0.05 to 0.1 part of exciting agent, wherein the high-efficiency water reducing agent is a naphthalene sulfonate high-efficiency water reducing agent, and the exciting agent is mixed by lauryl sodium sulfate and methylcellulose according to a mass ratio of 1:1. The accelerating agent has high impermeability and freezing resistance and low rebound rate, is easy, convenient and practicable to construct and has no harm to skin and eyes of a constructor. Meanwhile, the desulfurated gypsum residue is used as a raw material, the secondary utilization of the desulfurated gypsum residue is realized, resources are saved, the problem of treating solid waste residue in an electric power plant is solved and the environment is protected.

Owner:山西科腾环保新材料股份有限公司

Box girder unbonded prestressing and steel plate-concrete combination reinforcing design method

ActiveCN106087778AThe method steps are simpleReasonable designBridge erection/assemblyBridge strengtheningSheet steelSteel jacket

The invention discloses a box girder unbonded prestressing and steel plate-concrete combination reinforcing design method. The method comprises the following steps that firstly, a combination reinforcing structure is determined, specifically, the reinforced box girder unbonded prestressing and steel plate-concrete combination reinforcing structure is determined, the combination reinforcing structure comprises a steel jacket case composed of a bottom steel plate, two longitudinal side steel plates and two end blocking steel plates, and a plurality of unbonded prestressed rebars are arranged in the steel jacket case; secondly, box girder structural parameters are determined before reinforcement; and thirdly, structural parameters of the combination reinforcing structure are determined, specifically, the parameters are initialized, the theoretical maximum thickness of the reinforcing steel plates is calculated, the thickness of the reinforcing steel plates and the thickness of concrete are determined, and the height of the longitudinal side steel plates and the width of the bottom steel plate are determined. The method is simple in step, reasonable in design, convenient to implement and good in application effect, the structural parameters of the bridge combination reinforcing structure can be determined easily, conveniently and rapidly, and the designed bridge combination reinforcing structure is economical, practical and good in reinforcing effect.

Owner:XIAN HIGHWAY INST

Unbounded prestress and steel plate-concrete combined reinforcing design method of T-type beam

ActiveCN105970837AThe method steps are simpleReasonable designBridge structural detailsBridge erection/assemblySteel jacketSheet steel

The invention discloses an unbounded prestress and steel plate-concrete combined reinforcing design method of a T-type beam. The method comprises the steps that first, a combined reinforcing structure is determined, specifically, the unbounded prestress and steel plate-concrete combined reinforcing structure of the reinforced T-type beam is determined and comprises a steel jacket box composed of a bottom steel board, two longitudinal side steel boards and two end portion sealing steel boards, and a plurality of unbounded prestress steel bars are arranged inside the steel jacket box; second, the structure parameters of the T-type beam are determined before reinforcement; and third, the structure parameters of the combined reinforcing structure are determined, specifically, the parameters are initialized, the maximum theory thickness of reinforcing steel boards is calculated, the thickness of the reinforcing steel boards and the thickness of concrete are determined, and the height of the longitudinal side steel boards and the width of the bottom steel board are determined. The method is simple in step, reasonable in design, convenient to implement, good in use effect, and capable of determining the structure parameters of the bridge combined reinforcing structure easily, conveniently and rapidly, and the designed bridge combined reinforcing structure is economical, practical and good in reinforcing effect.

Owner:XIAN HIGHWAY INST

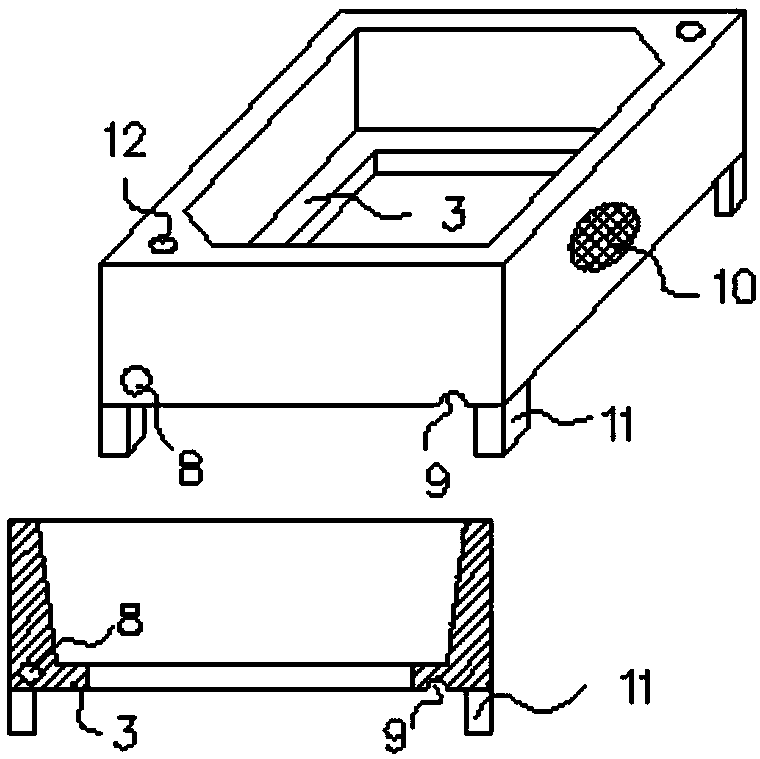

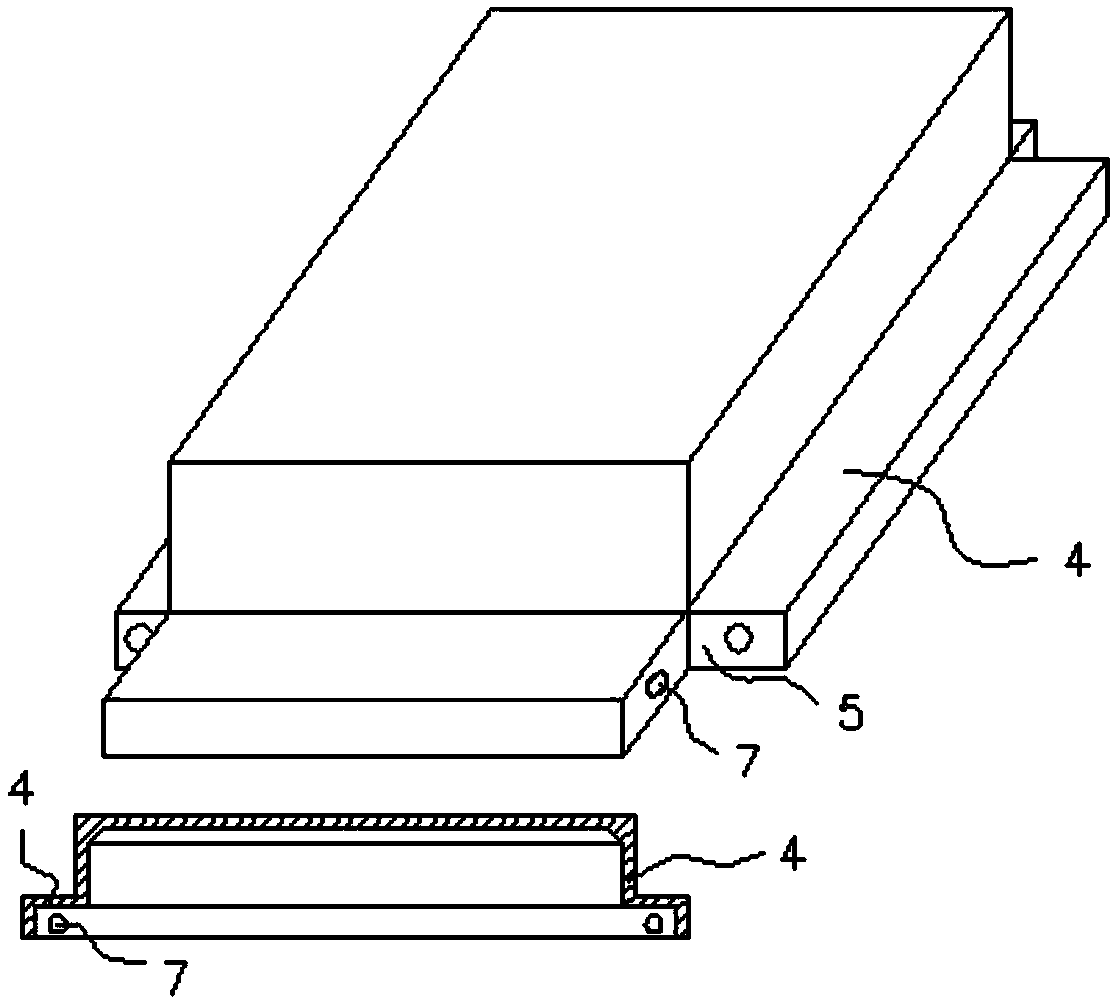

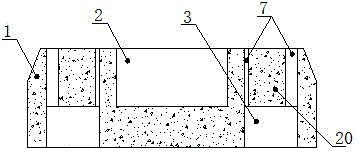

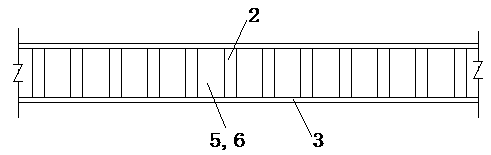

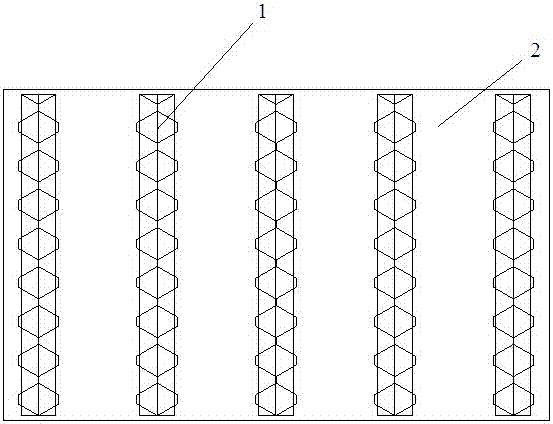

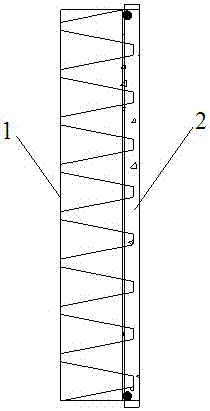

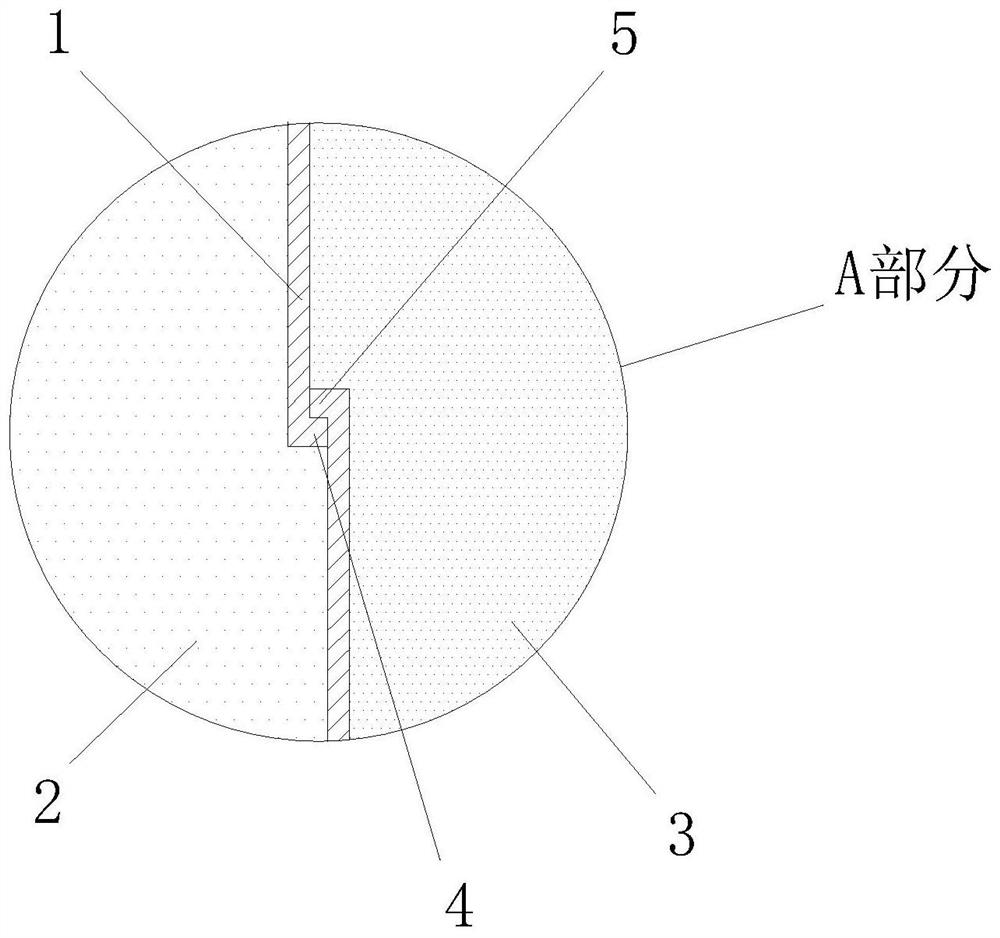

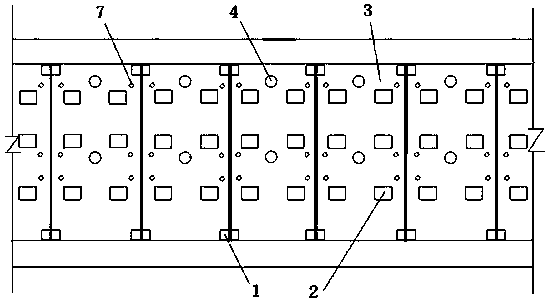

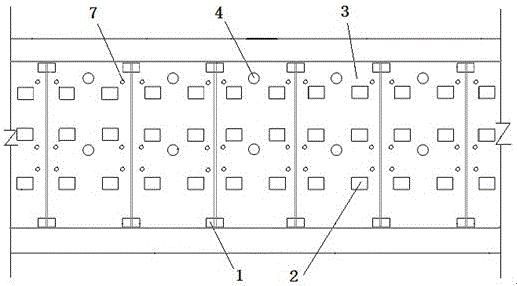

Formwork of self-balancing prefabricated face and cast-in-situ core infilled wall

ActiveCN103590516AImprove wear and tearImprove efficiencyWallsLogistics managementArchitectural engineering

The invention provides a formwork of a self-balancing prefabricated face and cast-in-situ core infilled wall. The formwork comprises positioning keys (1) arranged in the direction of an infilled wall body at intervals. The two sides of each positioning key (1) are prefabricated slabs (3) connected through connection keys (2), each prefabricated slab (3) is provided with a pulling connection hole (7), the middle and the upper end of each prefabricated slab are respectively provided with at least one pouring hole (4), and the outside of each prefabricated slab (3) is provided with a pressure applying device. The formwork has the advantages that materials used for the formwork are prefabricated in a large scale in a factory, requirements for core fillers of the wall body are low, the range of usable materials is wide, logistics cost of the materials is reduced, a construction formwork for wall face prefabrication is eliminated, external construction fixing measures of a cavity mold are eliminated, the construction process is simplified, prefabrication pressure is controllable and adjustable, the comprehensive economy index and the construction period of the formwork are superior to those of the prior art, and defects of the prior art are made up for.

Owner:盐城市双新建设投资有限公司

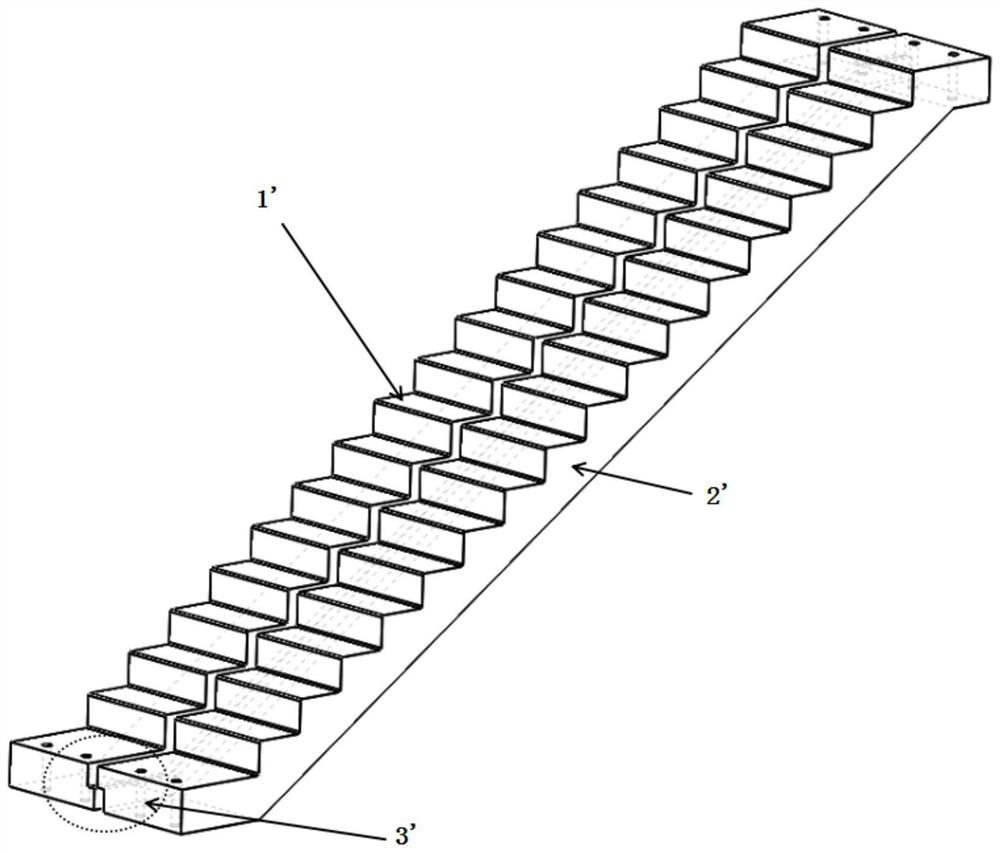

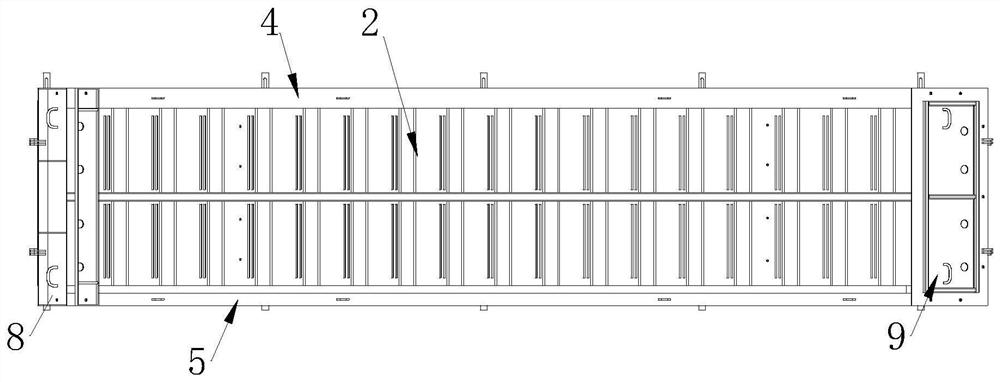

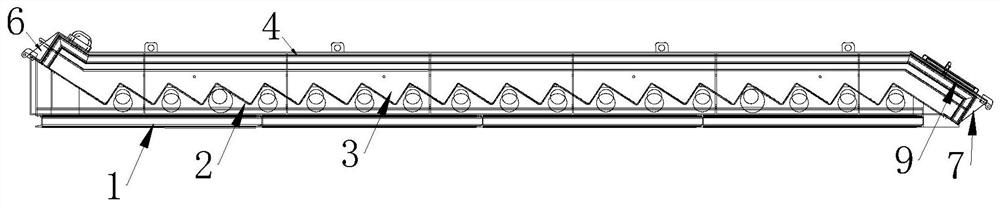

Split type prefabricated stair integrated forming die and stair production method

The invention relates to a prefabricated building, in particular to a split type prefabricated stair integrated forming die and a stair production method. A partition plate is arranged in the middle of a step forming face of the die, a first side flange is arranged on one side of the step forming face, a second side flange is arranged on the other side of the step forming face, a female tongue-and-groove forming boss is arranged on the upper portion of the inner side of the first side flange, a male tongue-and-groove forming concave portion is arranged on the lower portion of the inner side ofthe second side flange, a left sub-stair and a right sub-stair of a split type stair can be formed in the same die in a one-time pouring and tamping manner, and therefore the die cost of the prefabricated stair is reduced, the production efficiency is improved, and step dislocation generated when the left sub-stair and the right sub-stair are spliced is avoided.

Owner:XIANGTAN YUANDA RESIDENTIAL IND CO LTD

Design method of unbonded prestress and steel plate-concrete composite reinforcement of box girder

ActiveCN106087778BThe method steps are simpleReasonable designBridge erection/assemblyBridge strengtheningSteel jacketSheet steel

The invention discloses a box girder unbonded prestressing and steel plate-concrete combination reinforcing design method. The method comprises the following steps that firstly, a combination reinforcing structure is determined, specifically, the reinforced box girder unbonded prestressing and steel plate-concrete combination reinforcing structure is determined, the combination reinforcing structure comprises a steel jacket case composed of a bottom steel plate, two longitudinal side steel plates and two end blocking steel plates, and a plurality of unbonded prestressed rebars are arranged in the steel jacket case; secondly, box girder structural parameters are determined before reinforcement; and thirdly, structural parameters of the combination reinforcing structure are determined, specifically, the parameters are initialized, the theoretical maximum thickness of the reinforcing steel plates is calculated, the thickness of the reinforcing steel plates and the thickness of concrete are determined, and the height of the longitudinal side steel plates and the width of the bottom steel plate are determined. The method is simple in step, reasonable in design, convenient to implement and good in application effect, the structural parameters of the bridge combination reinforcing structure can be determined easily, conveniently and rapidly, and the designed bridge combination reinforcing structure is economical, practical and good in reinforcing effect.

Owner:XIAN HIGHWAY INST

A kind of magnesium oxysulfide reinforced truss plate

ActiveCN104929291BImprove water resistanceHigh strengthFloorsCeramic shaping apparatusRebarMagnesium

Owner:湖南愿景住宅工业科技有限公司

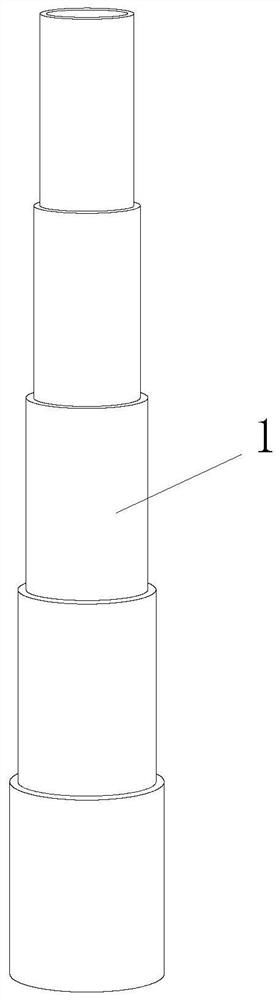

Composite pole tower with vertical skeleton and preparation method thereof

The invention discloses a composite pole tower with a vertical skeleton and a preparation method of the composite pole tower. The composite pole tower comprises the vertical skeleton, a foam inner core and a composite outer layer; the vertical skeleton is formed by a plurality of sections of hollow cylinders which are sequentially connected in a sleeved mode; the vertical skeleton is filled with the foam inner core; and the outer surface of the vertical skeleton is wrapped with the composite outer layer. The composite pole tower and the preparation method thereof have the advantages that the vertical skeleton is additionally arranged in the pole tower, thus the strength of the pole tower is improved, and the pole tower is not prone to being broken; the vertical skeleton is formed by the multiple hollow cylinders which are movably connected in the sleeved mode, the hollow cylinders are simple in forming process, small in size and convenient to transport, during assembling, no any auxiliary connection piece is needed, the hollow cylinders can be automatically formed only by being pulled to be suspended after being stacked, and the production efficiency can be improved; a process omits a demoulding working procedure; and the foam inner core is directly formed in the vertical skeleton, through the foaming process of the foam inner core, a certain expansion extrusion effect on the vertical skeleton can be generated, thus the vertical skeleton is shaped, and the vertical skeleton can be protected from being corroded.

Owner:HEFEI HAIYIN TOWER

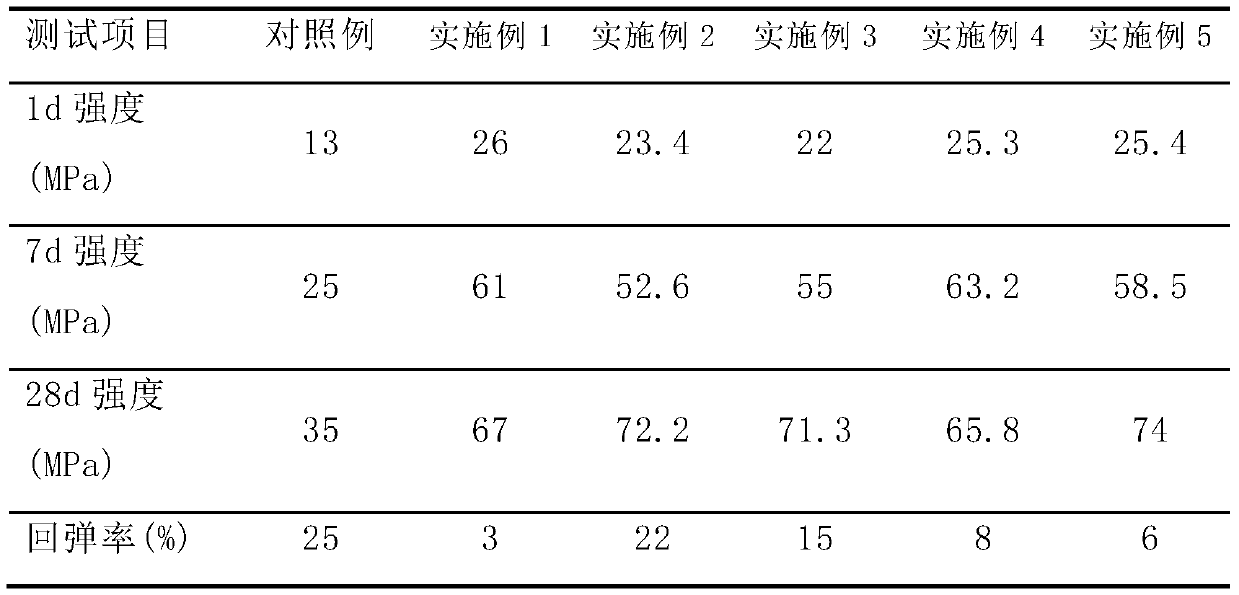

A high-strength low-rebound shotcrete and its construction technology

ActiveCN108046712BHigh rebound rateQuality improvementBuilding material handlingShotcreteAlkali free

The invention relates to high-strength low-resilience rate shotcrete and a construction process thereof, and belongs to the technical field of building concrete. The shotcrete is prepared from the following components in percentage by weight: 15 to 20 percent of cement, 3 to 4 percent of silica fume, 2 to 3 percent of natural zeolite powder, 40 to 50 percent of sand, 25 to 35 percent of gravel, 0to 2 percent of steel fibres, 0.8 to 1.2 percent of a liquid alkali-free accelerating agent and 0.3 to 0.5 percent of a polycarboxylate high-performance water reducing agent. The shotcrete disclosed by the invention is high in strength, and does not have a strength reducing phenomenon in a later stage; moreover, the resilience rate of the shotcrete is reduced to 3 percent; and compared with the construction technology, a large number of raw materials can be saved, and green healthy and sustainable development in the industry of building materials is truly realized.

Owner:CHINA ACAD OF BUILDING RES +2

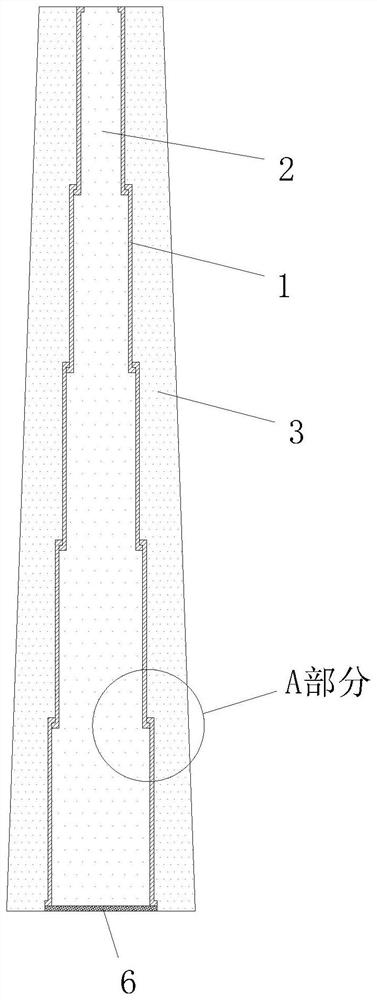

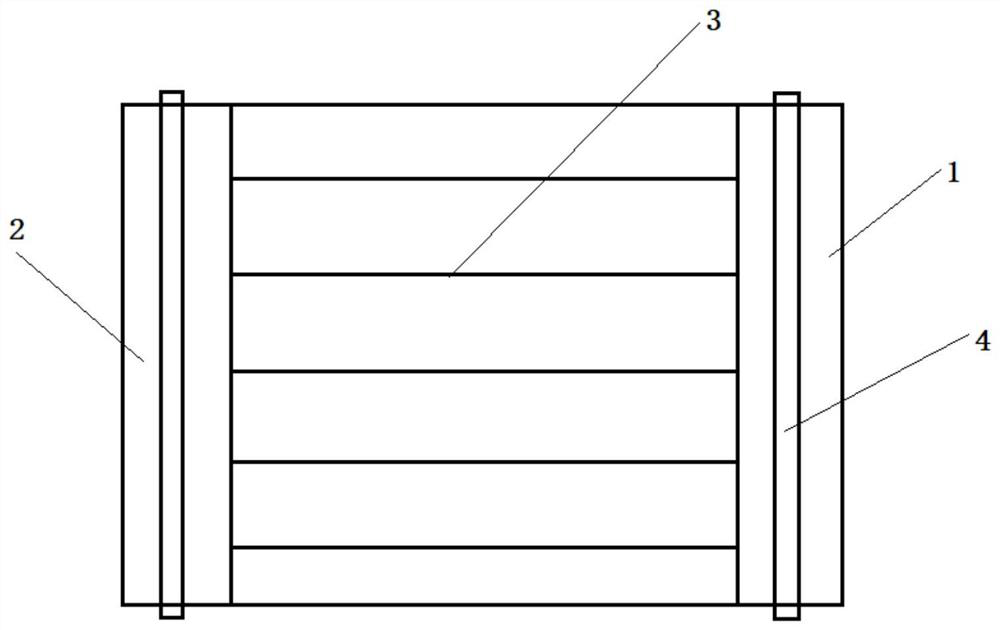

Prefabricated anti-water-seepage dismounting-free shear wall form board

InactiveCN111749375APrecise size controlQuality assuranceConstruction materialWallsMortise and tenonButt joint

A prefabricated anti-water-seepage dismounting-free shear wall form board comprises an inner form board (1), an outer form board (2) and an inner and outer form board connecting part (3), and the inner form board (1), the outer form board (2) and the inner and outer form board connecting part (3) are rigidly connected. Mortise and tenon joint structures are arranged on the edges of the inner formboard (1) and the outer form board (2), and the adjacent inner form board (1) and outer form board (2) are in butt joint and assembled correspondingly through the mortise and tenon joint structures. Sealing strips (4) are arranged on the inner sides of mortise structures of the mortise and tenon joint structures, during form board assembling, the corresponding mortise and tenon joint structures are in butt joint, and the sealing strips (4) effectively avoid seepage of water in concrete. Supporting structures are arranged on the outer sides of the inner form board (1) and the outer form board (2). The inner form board (1) and the outer form board (2) each comprise an outer layer, an inner layer and a steel bar mesh embedded in the inner layer. By means of the prefabricated anti-water-seepage dismounting-free shear wall form board, adverse factors brought by traditional form boards are reduced, meanwhile, structure durability is improved, the later maintenance cost of the structure is reduced, and the service life of the structure is finally prolonged.

Owner:北京启顺京腾科技有限责任公司

Design method of unbonded prestress and steel-concrete composite reinforcement of concrete T-beam

ActiveCN105839551BThe method steps are simpleReasonable designBridge erection/assemblyBridge strengtheningShaped beamT-beam

The invention discloses an unbonded prestress and steel-concrete composite reinforcement design method for concrete T-shaped beams. The unbonded prestress and steel-concrete composite reinforcement design method includes steps of firstly, determining unbonded prestress and steel plate-concrete composite reinforcement structures for the reinforcement T-shaped beams; secondly, determining structural parameters of the T-shaped beams prior to reinforcement; thirdly, determining structural parameters of the composite reinforcement structures, to be more specific, initializing the parameters, computing the maximum theoretical thicknesses of reinforcement steel plates, determining the thicknesses of the reinforcement steel plates and the thickness of concrete and determining the heights of longitudinal side steel plates and the widths of bottom steel plates. Each composite reinforcement structure comprises the corresponding bottom steel plate, the two longitudinal side steel plates and a steel bushing case, each steel bushing case comprises two end blocking steel plates, and a plurality of unbonded prestress reinforcing steel bars are arranged in each steel bushing case. The unbonded prestress and steel-concrete composite reinforcement design method has the advantages that the steps are simple, the unbonded prestress and steel-concrete composite reinforcement design method is reasonable in design and convenient to implement, good service effects can be realized, the structural parameters of the bridge composite reinforcement structures can be easily, conveniently and quickly determined, the bridge composite reinforcement structures designed by the aid of the unbonded prestress and steel-concrete composite reinforcement design method are economical and practical, and good reinforcement effects can be realized by the bridge composite reinforcement structures.

Owner:XIAN HIGHWAY INST

Novel tamping process method for middle and small size refined steel ladle permanent layer

The invention relates to a novel tamping process method for a middle and small size refined steel ladle permanent layer, in particular to a quite efficient permanent layer tamping structure and belongs to the category of the steel ladle bricklaying process. In specific operation, bricks on a working layer serve as molds, the permanent layer is directly tamped between the working layer and a thermal insulating layer and maintained for a period of time, the permanent layer rapidly enters a baking period, so that ladle repair time is further shortened, and repairing and bricklaying are better and more effective; mold cost is omitted and ladle bricklaying time is greatly shortened. The method is wide in application prospect, lays a firm foundation for effective operation of the metallurgy bricklaying process and points a new direction for development of the permanent layer tamping process.

Owner:HARBIN ELECTRIC MASCH CO LTD

Slip form lifting frame

InactiveCN102518296AReduce investmentGood corrosion resistant materialForms/shuttering/falseworksChinese charactersArchitectural engineering

The invention discloses a slip form lifting frame, which relates to a construction device and comprises a lifting frame body in a shape like a Chinese character 'ka'. The lifting frame body consists of a horizontally-arranged top cross beam, a support beam parallel to the top cross beam and two vertically-arranged columns. The top cross beam and the support beam are made of No.12 channel steel, two jacks are arranged on the upper surface of the support beam, and support rods are arranged on the jacks and is formed by welding steel pipes according to the diameter of phi 48*3.5mm. The surfaces of the top cross beam, the support beam, the columns and the support rods are all provided with glass reinforced plastic anticorrosive layers. The slip form lifting frame can be used for implementing slip form construction, reducing input of delivery pumps, tower cranes and other devices and lighting device weight. In addition, concrete is continuously operated, no construction joint exists, project quality is reliable, construction process is quick, work efficiency is improved, construction safety is guaranteed, and the slip form lifting frame has practical applicability.

Owner:谭官勤

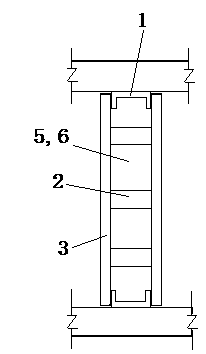

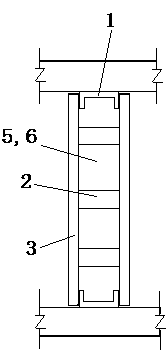

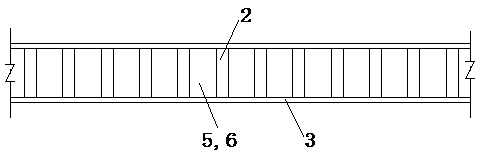

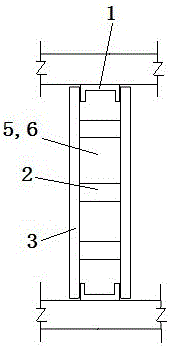

A kind of preparation method of TRC formwork reinforced concrete column

ActiveCN106760207BAvoid erosionEven by forceStrutsForms/shuttering/falseworksFiberReinforced concrete column

A preparation method for a TRC formwork reinforced concrete column comprises the following steps that a fiber woven mesh with high tensile resist strength and good decay resistance is adopted, and the fiber woven mesh is dipped into glue or strengthened through a steel wire mesh liner; an inner mould is mounted, shear resistant hooks are mounted in drill holes of the inner mould in an inserting mode, and the fiber woven mesh is fixed to the outer side of the inner mould; an outer mould is built on the outer side of the fiber woven mesh, prepared high-performance concrete is slowly poured into space formed by the inner mould, the fiber woven mesh and the outer mould, and manufacturing of a TRC formwork is finished; and after a TRC formwork layer reaches the set strength, formwork disassembling is carried out, the concrete is poured into the TRC formwork, and preparing of the TRC formwork reinforced concrete column is finished. Compared with the prior art, time and labor are saved, the cost is reduced, and the construction efficiency is improved; the bearing capacity and ductility of the reinforced concrete column are improved, and the durability of components in severe environments such as a cold environment and an alkalinity environment is improved; and strengthening of a building is more efficient, simpler, cheaper and more environmentally friendly.

Owner:CHINA UNIV OF MINING & TECH

Design method of unbonded prestress and steel-concrete composite reinforcement of concrete box girder

ActiveCN106120574BThe method steps are simpleReasonable designBridge erection/assemblyBridge strengtheningSteel jacketSheet steel

Owner:XIAN HIGHWAY INST

Design method of unbonded prestress and steel plate-concrete composite reinforcement of T-beam

ActiveCN105970837BThe method steps are simpleReasonable designBridge structural detailsBridge erection/assemblySteel jacketT-beam

The invention discloses an unbounded prestress and steel plate-concrete combined reinforcing design method of a T-type beam. The method comprises the steps that first, a combined reinforcing structure is determined, specifically, the unbounded prestress and steel plate-concrete combined reinforcing structure of the reinforced T-type beam is determined and comprises a steel jacket box composed of a bottom steel board, two longitudinal side steel boards and two end portion sealing steel boards, and a plurality of unbounded prestress steel bars are arranged inside the steel jacket box; second, the structure parameters of the T-type beam are determined before reinforcement; and third, the structure parameters of the combined reinforcing structure are determined, specifically, the parameters are initialized, the maximum theory thickness of reinforcing steel boards is calculated, the thickness of the reinforcing steel boards and the thickness of concrete are determined, and the height of the longitudinal side steel boards and the width of the bottom steel board are determined. The method is simple in step, reasonable in design, convenient to implement, good in use effect, and capable of determining the structure parameters of the bridge combined reinforcing structure easily, conveniently and rapidly, and the designed bridge combined reinforcing structure is economical, practical and good in reinforcing effect.

Owner:XIAN HIGHWAY INST

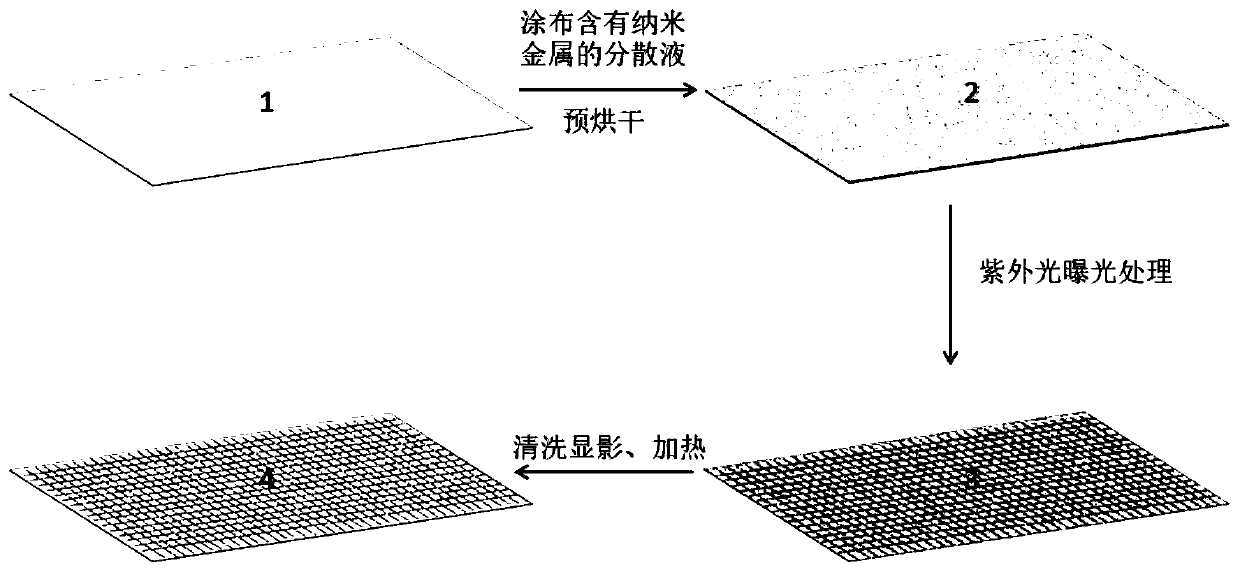

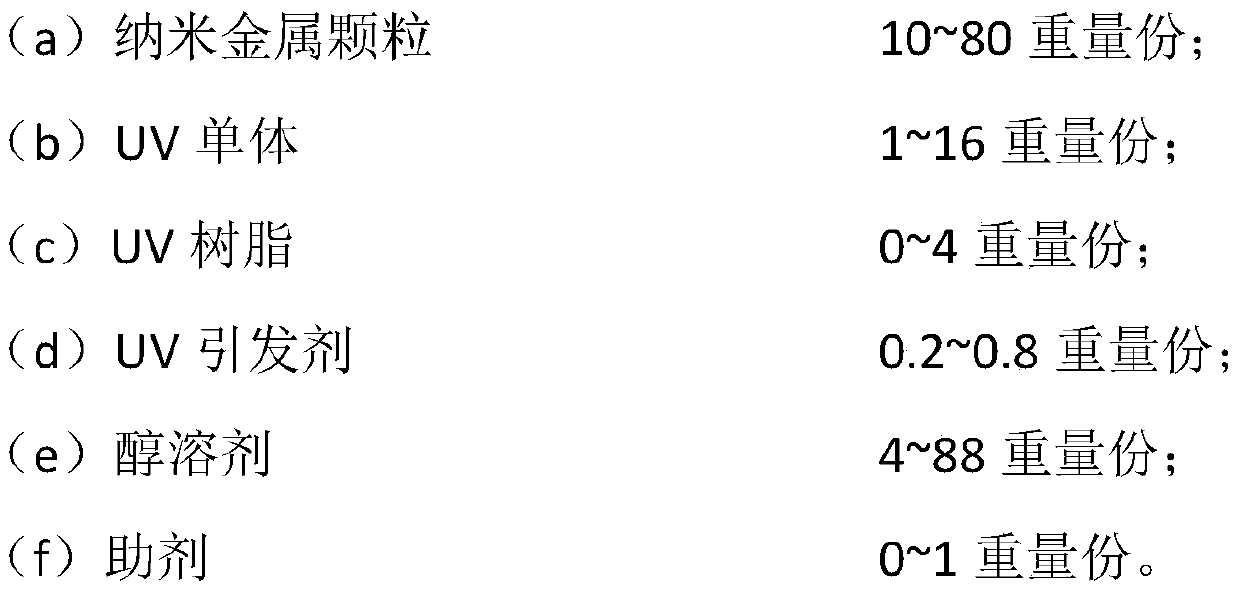

Transparent conductive substrate and its preparation method and application

ActiveCN109448918BThickness is easy to controlEliminate the demoulding processConductive layers on insulating-supportsApparatus for heat treatmentMetal coatingConductive materials

The present invention discloses a transparent conductive substrate and a preparation method thereof, and applications, pertaining to the field of transparent conductive materials. The preparation method of the transparent conductive substrate comprises the following steps: (A) uniformly coating a dispersion liquid containing nano-metal on the surface of a transparent conductive substrate (1), performing pre-drying, and obtaining a substrate (2) coated with a nano-metal coating layer; and (B) performing ultraviolet exposure treatment on the substrate (2) coated with the nano-metal coating layer, forming a light-cured shaped conductive grid (3) containing the nano-metal, performing cleaning development and heating, and obtaining a transparent conductive substrate (4), wherein the grid line width of the light-cured shaped conductive grid (3) <= 20 [mu]m. The nano-metal is an ultraviolet sensitive material. According to the method, the thickness of a conductive layer is easy to control, the preparation method is simple, and the transparent conductive substrate with large area and controllable conductivity can be rapidly prepared. The prepared transparent conductive substrate has the advantages of stable transparency and conductivity, high transparency and high yield rate.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Accelerating agent and preparation method thereof

ActiveCN101973722BEvenly distributed holesA large amountSolid waste managementSuperplasticizerMethyl cellulose

The invention discloses an accelerating agent, which is characterized by consisting of the following raw materials in part by weight: 10 to 30 parts of limestone, 18 to 36 parts of bauxite, 3 to 5 parts of desulfurated gypsum residue, 25 to 50 parts of fly ash, 6 to 15 parts of high-efficiency water reducing agent and 0.05 to 0.1 part of exciting agent, wherein the high-efficiency water reducing agent is a naphthalene sulfonate high-efficiency water reducing agent, and the exciting agent is mixed by lauryl sodium sulfate and methylcellulose according to a mass ratio of 1:1. The accelerating agent has high impermeability and freezing resistance and low rebound rate, is easy, convenient and practicable to construct and has no harm to skin and eyes of a constructor. Meanwhile, the desulfurated gypsum residue is used as a raw material, the secondary utilization of the desulfurated gypsum residue is realized, resources are saved, the problem of treating solid waste residue in an electric power plant is solved and the environment is protected.

Owner:山西科腾环保新材料股份有限公司

A self-balancing prefabricated surface, cast-in-place core-filled wall formwork

ActiveCN103590516BImprove wear and tearImprove efficiencyWallsLogistics managementArchitectural engineering

The invention provides a self-balancing prefabricated surface and cast-in-place core filled wall formwork, which includes positioning keys (1) arranged at intervals along the direction of the filling wall, and the two sides of the positioning key (1) are connected by connecting keys (2). The prefabricated slab (3), the prefabricated slab (3) is provided with a tie hole (7). The middle and upper end of the prefabricated slab (3) has at least one pouring hole (4), and the outer side of the prefabricated slab (3) has a pressure device. The present invention has the advantages that: the materials for the formwork are prefabricated in batches in factories, the wall core material is low and the materials are widely used, and the logistics cost of materials is reduced. Wall prefabrication saves construction formwork, and cavity formwork saves external construction fixing measures, which simplifies the construction process. The prefabrication pressure is controllable and adjustable, and its comprehensive economic index and construction period are superior to the prior art, thereby making up for the deficiencies of the prior art.

Owner:盐城市双新建设投资有限公司

Knotting process for permanent layer of small and medium-sized refining ladle

The invention relates to a novel tamping process method for a middle and small size refined steel ladle permanent layer, in particular to a quite efficient permanent layer tamping structure and belongs to the category of the steel ladle bricklaying process. In specific operation, bricks on a working layer serve as molds, the permanent layer is directly tamped between the working layer and a thermal insulating layer and maintained for a period of time, the permanent layer rapidly enters a baking period, so that ladle repair time is further shortened, and repairing and bricklaying are better and more effective; mold cost is omitted and ladle bricklaying time is greatly shortened. The method is wide in application prospect, lays a firm foundation for effective operation of the metallurgy bricklaying process and points a new direction for development of the permanent layer tamping process.

Owner:HARBIN ELECTRIC MASCH CO LTD

A self-balancing prefabricated face, cast-in-place core-filled wall

Owner:盐城市双新建设投资有限公司

Integrated beam-slab-column formwork structure system and construction method

The invention relates to the technical field of construction engineering, in particular to an integrated beam-slab-column formwork structure system and a construction method. The structural system is a frame structure formwork system composed of unremovable column formwork, beam formwork, beam-column joint formwork and floor formwork; the column formwork, beam-column joint formwork, beam formwork and floor formwork are respectively spliced by corresponding formwork units Composition; the demolition-free formwork unit is made of a thin-walled shell structure, used as a formwork when pouring concrete, and later used as a decoration material, one side is treated with a rough surface, and the other side is smooth; the joints of the formwork units are embedded with each other in the form of concave-convex grooves; The outer side of the demolition formwork is fastened with fastening hoops to resist the lateral pressure of cast-in-place concrete; the beam-column joint formwork makes the integrated beam-slab-column formwork structural system suitable for prefabricated structural components, and is also suitable for on-site cast-in-place; prefabricated components or cast-in-place concrete A building unit that forms a frame structure, and multiple building units form a multi-storey or high-rise frame structure.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

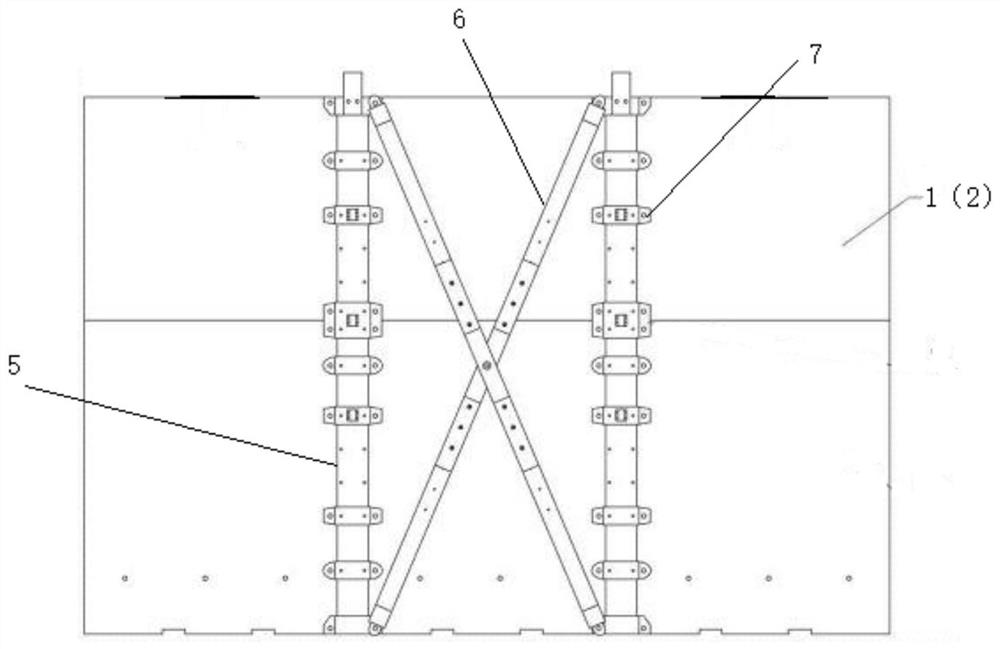

Assembled laminated floor slab and its construction method based on tool-type hanging formwork

ActiveCN109577534BReduce construction errorsEasy constructionFloorsBuilding material handlingSupporting systemFloor slab

The invention relates to an assembled composite floor slab based on tool type template lifting. The assembled composite floor slab comprises a composite floor slab shaping supporting system, a composite floor slab cast-in-situ belt template lifting system, a composite floor slab and beam connecting structure and a composite floor slab and wall connecting structure, the composite floor slab shapingsupporting system comprises an adjustable lifting beam, a prefabricated floor slab and independent supports, limiting screws are pre-embedded on a lower floor slab, the independent supports are erected among the limiting screws and comprise frame grid plate bases lower vertical rods, sleeving connection type upper vertical rods, protection frames and tool beams from bottom to top, the prefabricated floor slabs are hosted to tool beams of the independent supports by the adjustable lifting beam and adjusted flat by fine-adjustable supporting seats at the bottoms of the protection frames, and ahoisting rope is arranged on the adjustable lifting beam. The composite floor slab has the advantages that a unit-type adjustable shaping supporting system replaces a traditional independent steel support, the fine-adjustable supporting seats are additionally arranged, construction errors of the composite floor slab can be reduced, and deformation in the construction stage of a laminated cast-in-place layer is decreased.

Owner:SHENZHEN JIANAN GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com