A kind of magnesium oxysulfide reinforced truss plate

A technology of reinforced trusses and magnesium oxysulfide boards, which is applied to floors, building components, ceramic molding machines, etc., can solve problems such as easy corrosion of fiber gypsum boards, reduced structural safety, and swelling of fiber gypsum boards. Effects of plastering, weight reduction and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

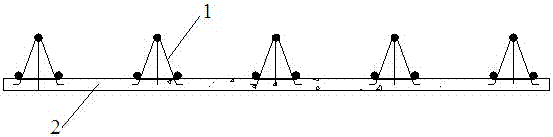

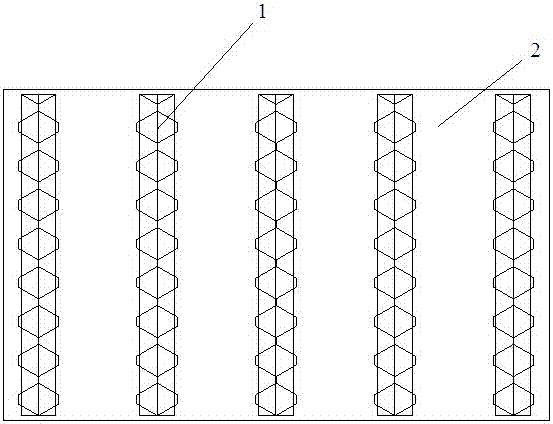

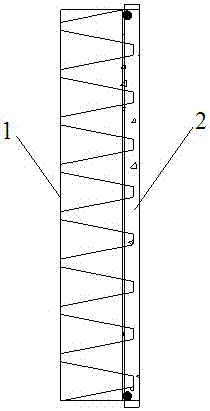

[0048] refer to Image 6 , this embodiment includes multiple rows of steel trusses 1 and two magnesium oxysulfide boards 2, the steel trusses 1 are arranged in parallel, the adjacent steel trusses 1 are in the opposite direction up and down, the bottom of the parallel steel truss 1 and the top of the inverted steel truss 1 Embed in one of the magnesium oxysulfide boards 2; the top of the parallel steel truss 1 and the bottom of the inverted steel truss 1 are buried in another magnesium oxysulfide board 2; the steel trusses 1 are parallel to each other, and the magnesium oxysulfide board 2 uses its own Solidification is fixed with reinforcement truss 1.

[0049] The manufacturing method of the single-sided panel embodiment 1 is as follows:

[0050] (1) Make steel bar truss 1;

[0051] (2) Magnesium sulfate is made into temperature and is 20~50 ℃ of aqueous solutions, and the mass concentration of magnesium sulfate aqueous solution is 10% to saturated concentration (the concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com