Design method of unbonded prestress and steel plate-concrete composite reinforcement of T-beam

A design method and technology of prestressed steel bars, applied in the direction of bridge reinforcement, bridge construction, bridges, etc., can solve the problems of affecting aesthetics, concentration, poor dynamic performance of prestressed steel bars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Such as figure 1 The shown design method of unbonded prestress of T-beam and steel-concrete combination reinforcement includes the following steps:

[0085] Step 1. Determine the combined reinforcement structure: Determine the unbonded prestress and steel plate-concrete combined reinforcement structure of the reinforced T-beam 3; the reinforced T-beam 3 is a reinforced concrete beam;

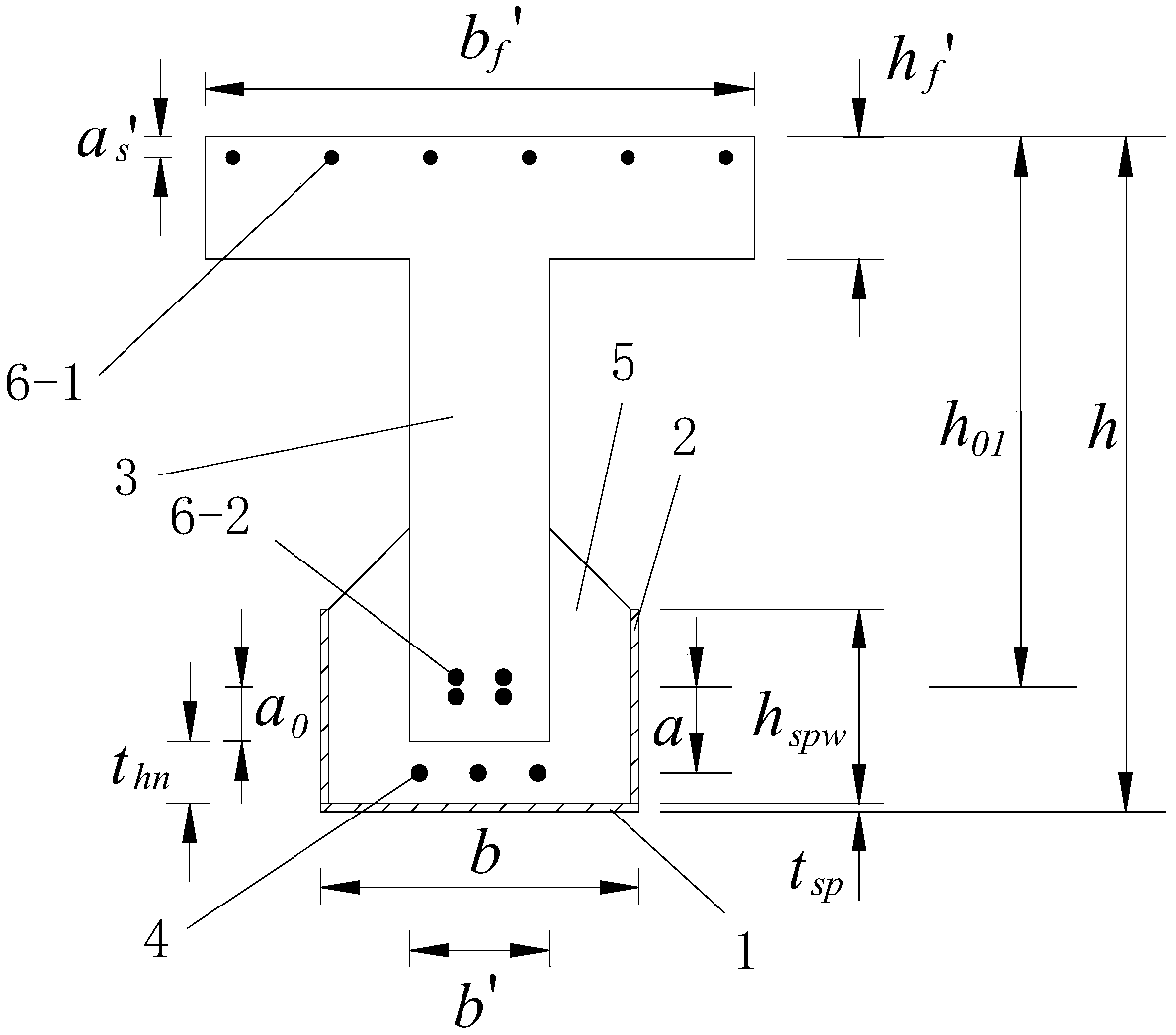

[0086] Such as figure 2 As shown, the unbonded prestressed and steel-steel-concrete combined reinforcement structure includes a bottom steel plate 1 arranged below the area to be reinforced of the reinforced T-beam 3, two respectively arranged on the left and right sides of the area to be reinforced The longitudinal side steel plate 2 and the two end-blocking steel plates respectively arranged at the front and rear ends of the area to be reinforced, the bottom steel plate 1 and the two longitudinal side steel plates 2 are arranged in the longitudinal bridge direction, the bottom steel plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com