A kind of preparation method of TRC formwork reinforced concrete column

A reinforced concrete column and high-performance concrete technology, which is applied in the preparation of reinforced concrete columns and the preparation of TRC formwork reinforced concrete columns, can solve problems such as increasing cost and time, and achieve increased bonding and mechanical occlusion, high-efficiency reinforcement, and improved durability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of TRC formwork reinforced concrete column of the present invention, concrete steps are as follows:

[0030] a. adopt high tensile strength and good corrosion resistance fiber braided net, impregnate the fiber braided net or reinforce the fiber braided net with steel mesh lining; described fiber braided net adopts carbon fiber, aramid fiber, alkali-resistant glass fiber , basalt fiber, polyvinyl alcohol fiber, or polyethylene fiber weaving, or weaving with two different fibers according to the radial and weft directions of weaving. The impregnation process: first impregnate with epoxy resin, and perform sandblasting before impregnating the fiber woven mesh with epoxy resin and before curing, wherein the mass ratio of epoxy resin, curing agent and diluent for impregnating the fiber woven mesh is 65 ~70: 60~80: 30~35, the sand is generally made of silica sand;

[0031] b. Install the inner mold, the square column uses thin wood as the mold, and the...

Embodiment 1

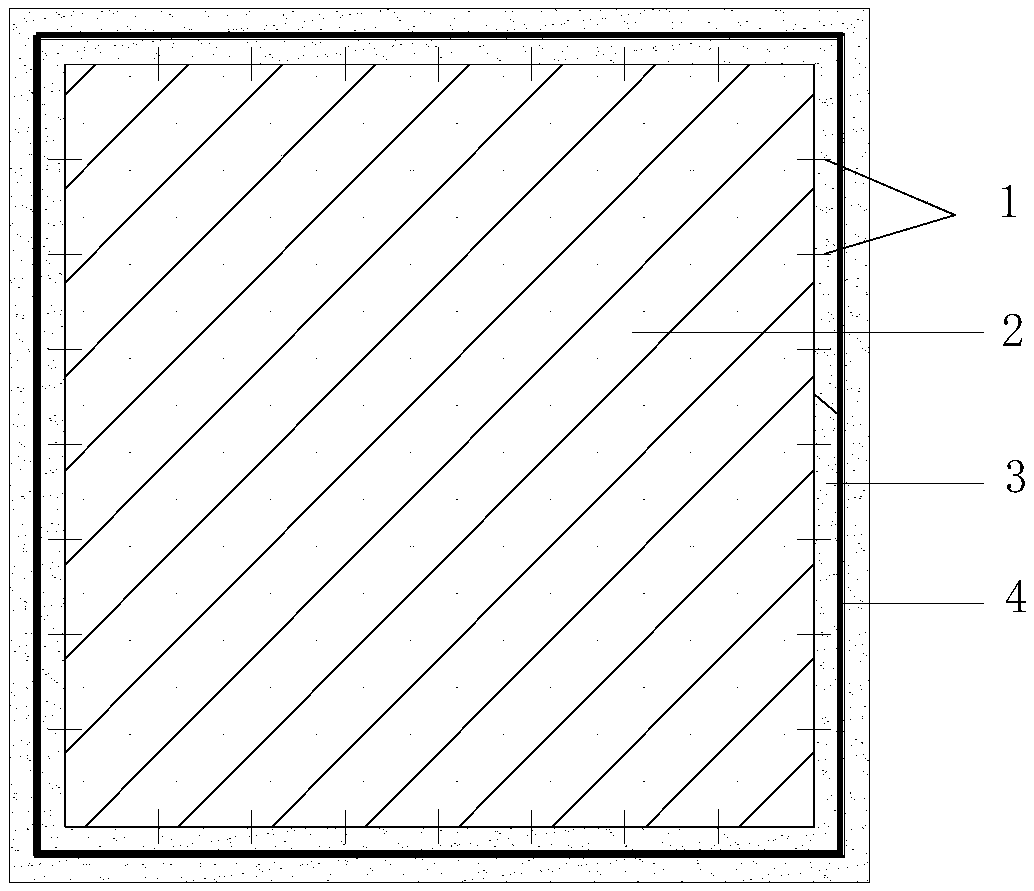

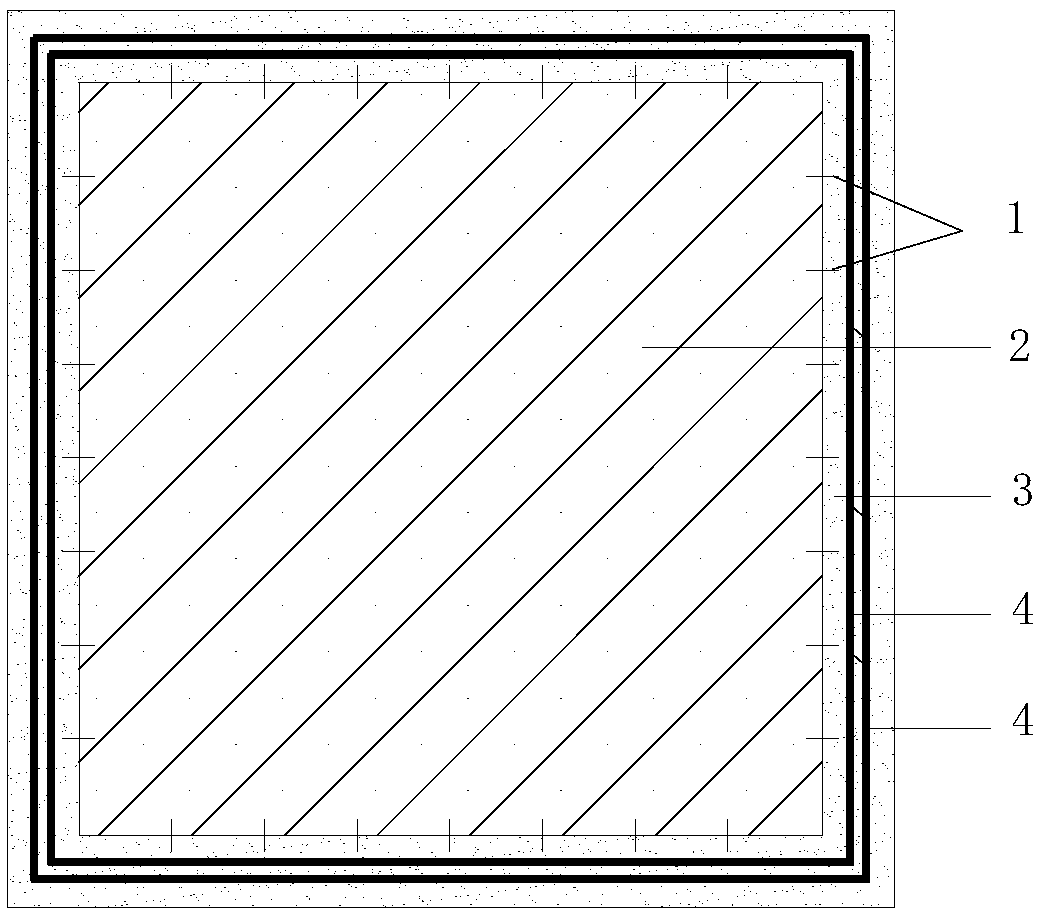

[0042] Embodiment 1, as figure 1 as shown,

[0043] 1. The fiber woven mesh is dipped in glue or the steel wire mesh is lined to fix the fiber woven mesh

[0044] The fiber woven mesh is woven from fiber coarse sand seams, which is a high-performance soft fabric. The untreated fiber woven mesh is not easy to be laid vertically in the concrete member independently, and the fiber woven mesh is hardened by dipping, or steel wire mesh is used. To fix untreated fiber woven mesh. Dipping can make the inner and outer layers of fibers bear even force, and can connect the organic thread and roving used for stitching the fiber woven net into one, which can increase the bonding and mechanical interlocking, and form a protective layer on the surface of the fiber woven net, which can effectively Avoid the erosion of lye in the concrete to the fiber woven mesh and enhance the durability of the permanent formwork. The specific production method is as follows: first impregnate with epoxy r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com