Assembled multi-pile foundation structure and construction method thereof

A pile foundation and prefabricated technology, applied in basic structure engineering, construction, etc., can solve the problems of complex construction process, long period, strict requirements on foundation flatness, etc., to save construction time, improve construction efficiency, and save formwork The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

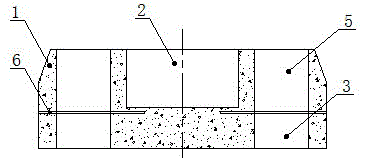

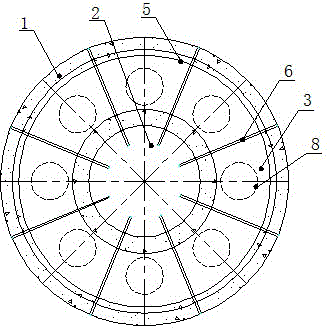

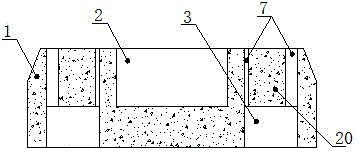

[0056] figure 1 Shown is a prefabricated multi-pile foundation structure (also known as precast concrete cap box), specifically a prefabricated concrete cap with ring holes 5 reserved for pile sockets, including a concrete body 1, which is arranged on the concrete body 1 The reserved foundation annular hole 2 at the center of the top surface, the reserved pile socket annular hole 5 penetrates the top and bottom surfaces of the concrete body 1 and is located at the edge of the concrete body 1 (that is, near the outer circumference of the axial direction), and the reserved pile A plurality of connecting steel beams 6 arranged in the circumferential direction are arranged between the inner and outer ring surfaces of the ring hole 5, combined with figure 2 It can be seen that the reserved pile socket ring hole 5 between adjacent connecting steel beams 6 forms a reserved pile socket hole 3, and the reserved pile socket hole 3 is arranged at the position corresponding to the pipe p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com