A high-strength low-rebound shotcrete and its construction technology

A technology of sprayed concrete and low resilience, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of unspecified spraying technology, unspecified strength, and unfavorable durability of concrete, so as to save costs Formwork removal process, good applicability and economy, and the effect of inhibiting alkali-aggregate reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

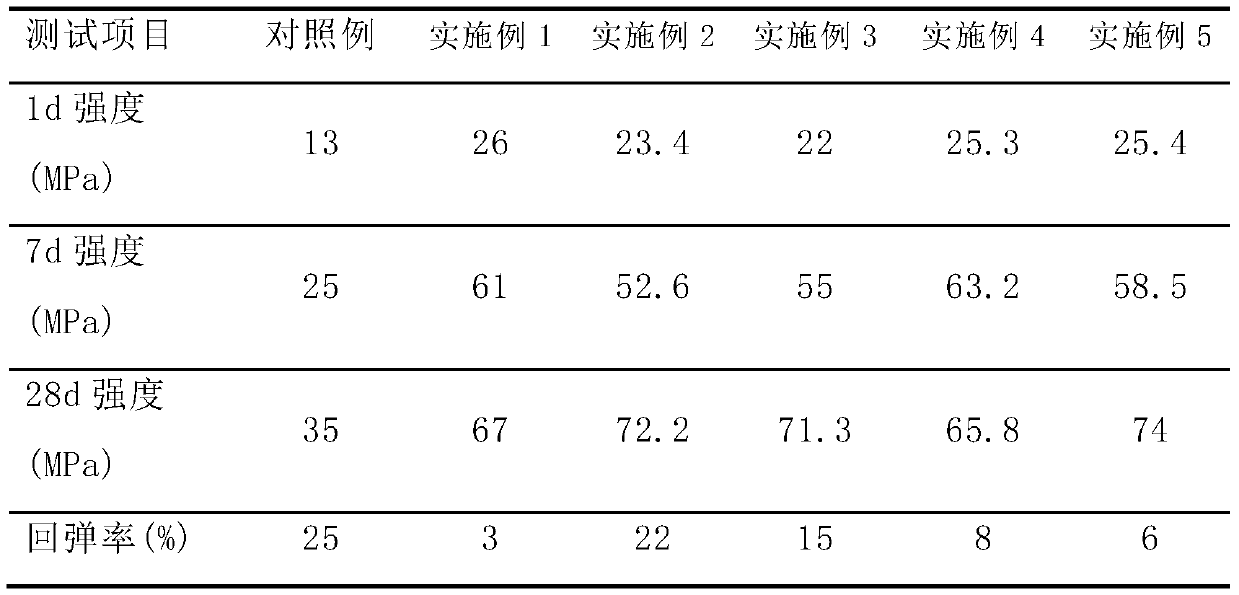

Examples

Embodiment 1

[0066] The formula of high-strength low-rebound shotcrete is as follows:

[0067] 367 kg of cement P·O4 2.5 grade, 74 kg of silica fume, 50 kg of grade I zeolite rock powder, 1240 kg of sand with an average particle size of 4.75 mm, 620 kg of crushed stone with an average particle size of 10 mm, and quick-setting aluminum sulfate alkali-free liquid 30 kilograms of agent, 8 kilograms of polycarboxylate high-performance water reducing agent, mix above-mentioned raw material evenly, get finished material L 1 .

[0068] The construction technology of high-strength and low-rebound shotcrete is as follows:

[0069] (1) Prepare high-strength and low-rebound shotcrete:

[0070] The water-cement ratio (referring to the ratio of the water consumption per cubic meter of concrete to the amount of all cementitious materials) is 0.34. Considering the rebound rate, the sand rate (sand rate SP=the amount of sand S / (the amount of sand S+the amount of stones G) ×100%; the mass of sand in the...

Embodiment 2

[0081] The formulation of high-strength shotcrete is as follows:

[0082] 367 kg of cement P·O4 2.5 grade, 74 kg of silica fume, 50 kg of grade I zeolite rock powder, 1116 kg of sand with an average particle size of 1.75 mm, 744 kg of gravel with an average particle size of 4.75 mm, 50 kg of 25 mm long steel fibers, 30 kilograms of aluminum sulfate alkali-free liquid quick-setting agent, 12 kilograms of polycarboxylate high-performance water reducer, mix the above-mentioned raw materials evenly, get the finished material L 2 .

[0083] The construction process of high-strength shotcrete is as follows:

[0084] (1) Prepare high-strength and low-rebound shotcrete: the water-binder ratio (referring to the ratio of water consumption per cubic meter of concrete to the amount of all cementitious materials) is 0.32, taking into account the rebound rate, sand rate (sand rate SP = sand The amount S / (the amount of sand S+the amount of stones G)×100%; the mass of sand in the concrete a...

Embodiment 3

[0095] The formulation of high-strength shotcrete is as follows:

[0096] 496 kg of cement P·O4 2.5 grade, 75 kg of silica fume, 50 kg of grade I zeolite rock powder, 992 kg of sand with an average particle size of 0.75 mm, 868 kg of gravel with an average particle size of 15 mm, 25 kg of 25 mm long steel fibers, sulfuric acid 20 kilograms of aluminum-based non-alkali liquid quick-setting agent, 10 kilograms of polycarboxylate high-performance water reducer, mix the above-mentioned raw materials evenly, and obtain the finished material L 3 .

[0097] The construction process of high-strength shotcrete is as follows:

[0098] (1) Prepare high-strength and low-rebound shotcrete: the water-binder ratio (referring to the ratio of water consumption per cubic meter of concrete to the amount of all cementitious materials) is 0.32, taking into account the rebound rate, sand rate (sand rate SP = sand The amount S / (the amount of sand S+the amount of stones G)×100%; it is the percentage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com