Silica gel packaging part for new energy battery and preparation method of silica gel packaging part

A packaging and new energy technology, applied in chemical instruments and methods, lamination devices, rubber layered products, etc., can solve the problems of new energy batteries fire and explosion, low flame retardancy of heat-conducting silica gel, parts heating and igniting, etc. Achieve the effects of improving protection, good flame retardancy, and improving insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

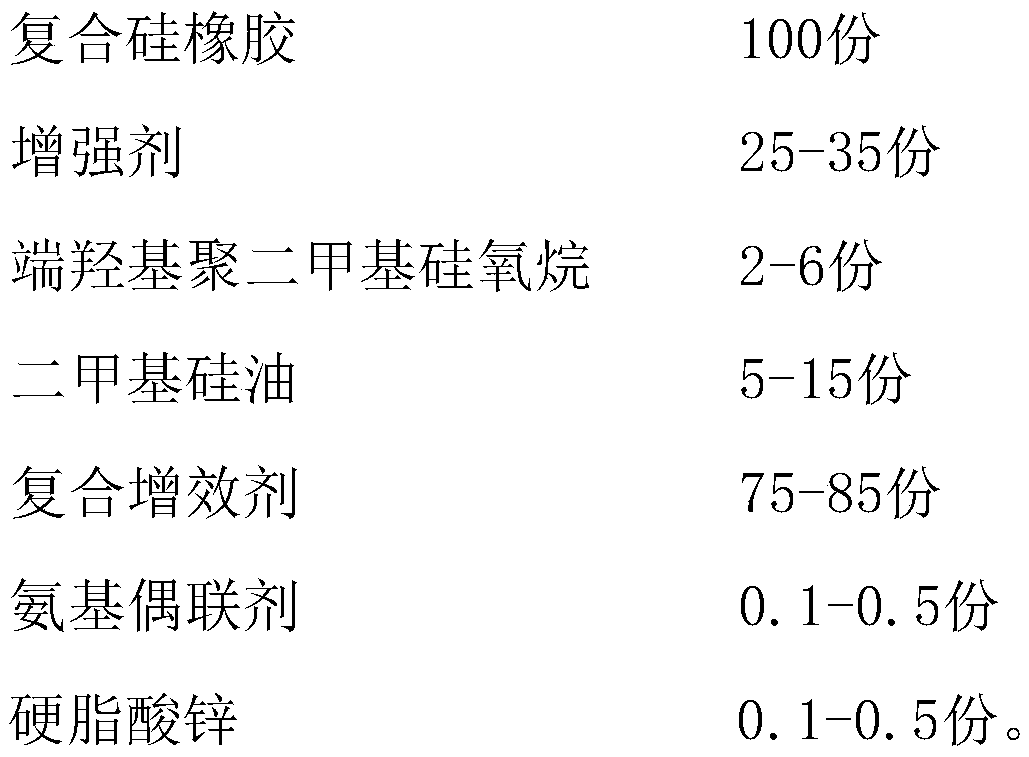

[0048] A silicone package for new energy batteries, the silicone package includes a silicone rubber layer and a glass fiber cloth layer coated on the outer surface of the silicone rubber layer, the silicone rubber layer includes the following raw materials in parts by weight:

[0049]

[0050]

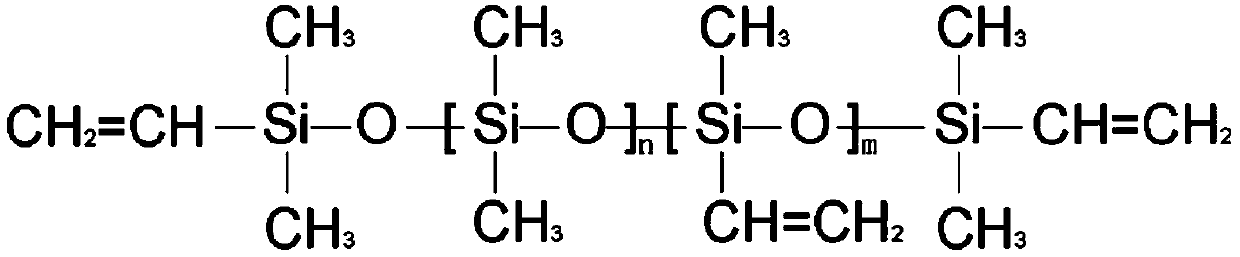

[0051] The composite silicone rubber is a mixture of methyl vinyl silicone rubber A, methyl vinyl silicone rubber B and methyl vinyl silicone rubber C in a weight ratio of 55:25:15; wherein the methyl vinyl The vinyl content of base silicone rubber A is 0.02%, the methyl content is 99.98%, and the molecular weight is 600,000; the vinyl content of the methyl vinyl silicone rubber B is 0.20%, the methyl content is 99.80%, and the molecular weight is 600,000; the vinyl content of the methyl vinyl silicone rubber C is 0.8%, the methyl content is 99.20%, and the molecular weight is 550,000.

[0052] The chemical formulas of the above-mentioned methyl vinyl silicone rubber A, methyl vi...

Embodiment 2

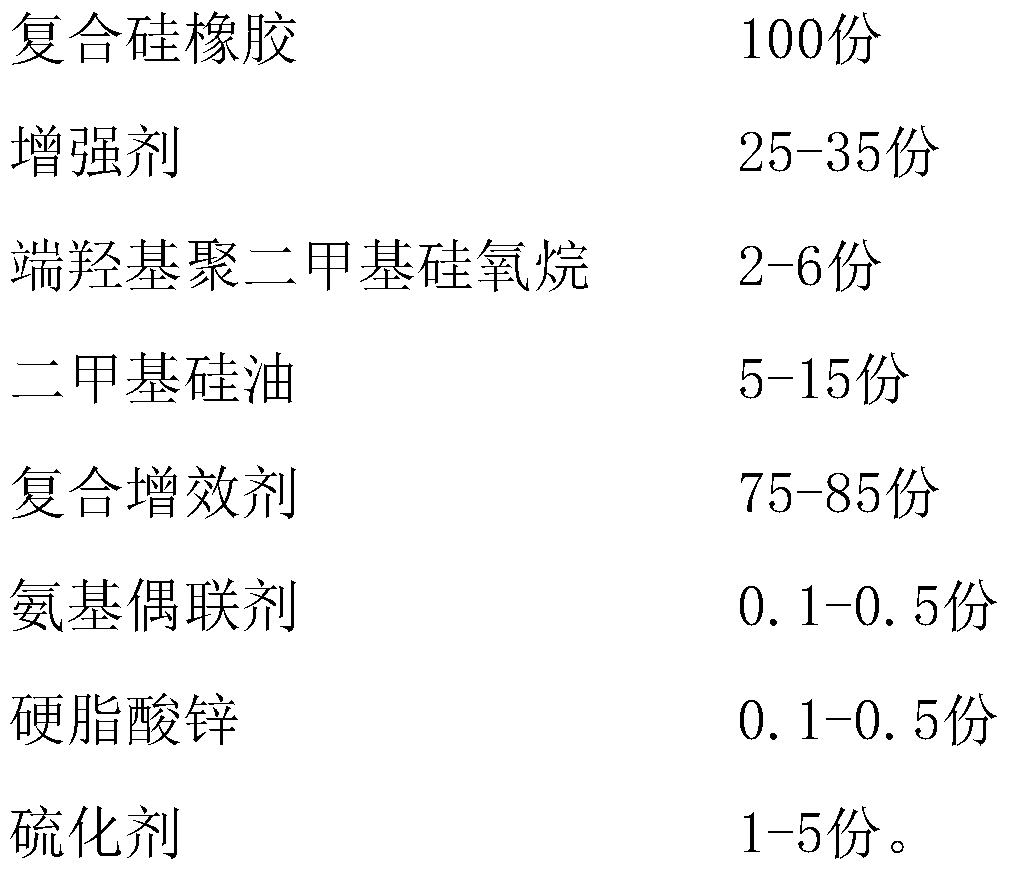

[0071] A silicone package for new energy batteries, the silicone package includes a silicone rubber layer and a glass fiber cloth layer coated on the outer surface of the silicone rubber layer, the silicone rubber layer includes the following raw materials in parts by weight:

[0072]

[0073] The composite silicone rubber is a mixture of methyl vinyl silicone rubber A, methyl vinyl silicone rubber B and methyl vinyl silicone rubber C in a weight ratio of 58:28:13; wherein the methyl vinyl The vinyl content of base silicone rubber A is 0.04%, the methyl content is 99.96%, and the molecular weight is 620,000; the vinyl content of the methyl vinyl silicone rubber B is 0.21%, the methyl content is 99.79%, and the molecular weight is 620,000; the vinyl content of the methyl vinyl silicone rubber C is 0.9%, the methyl content is 99.10%, and the molecular weight is 580,000.

[0074] The chemical formulas of the above-mentioned methyl vinyl silicone rubber A, methyl vinyl silicone...

Embodiment 3

[0093] A silicone package for new energy batteries, the silicone package includes a silicone rubber layer and a glass fiber cloth layer coated on the outer surface of the silicone rubber layer, the silicone rubber layer includes the following raw materials in parts by weight:

[0094]

[0095] The composite silicone rubber is a mixture of methyl vinyl silicone rubber A, methyl vinyl silicone rubber B and methyl vinyl silicone rubber C in a weight ratio of 60:30:10; wherein the methyl vinyl The vinyl content of base silicone rubber A is 0.06%, the methyl content is 99.94%, and the molecular weight is 650,000; the vinyl content of the methyl vinyl silicone rubber B is 0.22%, the methyl content is 99.78%, and the molecular weight is 650,000; the vinyl content of the methyl vinyl silicone rubber C is 1.0%, the methyl content is 99.00%, and the molecular weight is 600,000.

[0096] The chemical formulas of the above-mentioned methyl vinyl silicone rubber A, methyl vinyl silicone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com