Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Effective plasticization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for compounding functional nanoparticles on surfaces of polymer filaments

ActiveCN103556451ADoes not affect mechanical propertiesRetain mechanical propertiesVegetal fibresFiberPolymer science

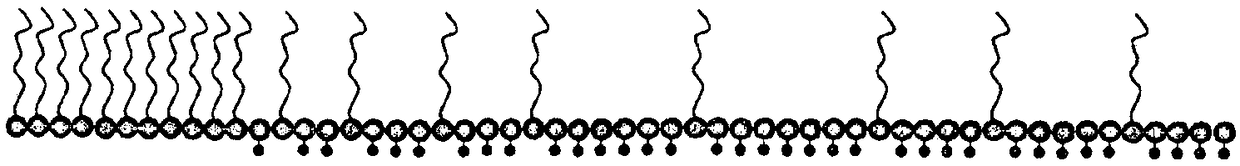

The invention relates to a method for compounding functional nanoparticles on surfaces of polymer filaments, belonging to the technical field of new fiber materials. The method comprises the steps of protein-based modification on surfaces of functional nanoparticles, preparation of a blended solution, formation of polymer filaments with surfaces compounded with the blended solution and control of thickness, phase inversion primary formation of the polymer filaments with surfaces compounded with the blended solution and thermosetting formation of the polymer filaments with surfaces compounded with the blended solution, thus obtaining the polymer filaments with surfaces compounded with the functional nanoparticles. In the preparation method, carbon nano tubes, graphene, carbon black, titanium dioxide, zinc dioxide, iron particles, iron oxide, aluminium oxide, silver particles and other nanoparticles can be compounded on the surfaces of the polymer filaments. The polymer filaments after compounding have good mechanical properties and functionality. The preparation method is simple to operate, dispenses with special equipment and achieves industrial production easily.

Owner:JIANGSU YIMAO FILTER MEDIA CO LTD

Non-brittle dried fruits and vegetables

This invention relates to non-brittle dried fruits and vegetables, especially non-brittle freeze-dried fruits and vegetables, and methods for preparing such fruits and vegetables. More specifically, this invention relates to non-brittle dried fruits and vegetables prepared by applying a surface coating of an aqueous solution of a polyhydric alcohol (preferably glycerol) prior to drying. Application of the aqueous solution of the polyhydric alcohol prior to drying appears to allow sufficient migration of polyhydric alcohol into the cellular structures, thereby plasticizing the cellular structures and minimizing damage to the cellular structures of the fruits and vegetables during and after drying and post-drying activities. The resulting plasticized product is rendered non-brittle as indicated by a drastic reduction of fines and / or broken pieces after drying and / or packaging, shipping, and storage as compared to conventionally dried fruits and vegetables.

Owner:KRAFT FOODS GRP BRANDS LLC

Alloy for recovering polyethylene glycol terephthalate/acrylonitrile-butadiene-styrene copolymer and preparation method thereof

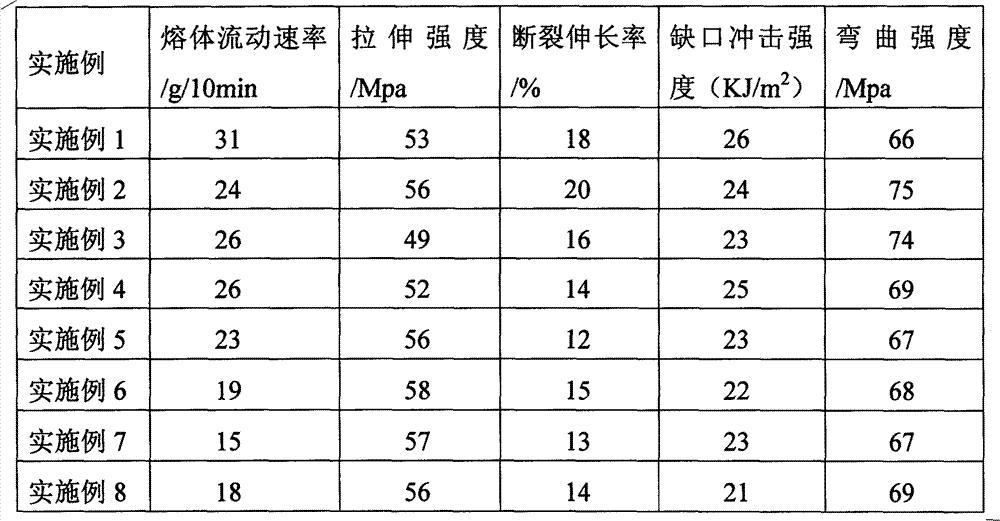

The invention relates to an alloy for recovering a polyethylene glycol terephthalate / acrylonitrile-butadiene-styrene copolymer and a preparation method thereof. The method comprises the following steps of: recovering 60-90% of PET (Polyethylene glycol Terephthalate), 2-30% of ABS (Acrylonitrile Butadiene Styrene) resin, 3-30% of an enhancer, 1-5% of a compatilizer, 0.1-0.5% of an antioxygen, 0.1-0.5% of rare-earth metal salt, 0.1-2% of a molecular weight modifier and 0-2% of other assistants in percentage by weight; uniformly mixing by a high speed mixer; adding into an extruder to obtain material strips, wherein the processing temperatures of the extruder from a feed inlet to a grinding mouth are sequentially 180 DEG C, 185 DEG C, 190 DEG C, 195 DEG C, 200 DEG C, 205 DEG C, 210 DEG C and 215 DEG C, and the rotating speed of a main machine of the extruder is 80-120r / min; and carrying out water cooling and dicing on the material strips to obtain the modified aggregates. Compared with the prior art, the alloy provided by the invention has the advantages of industrial production in batches, excellent tensile strength, high impact strength, mobility, chemical stability and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Resin particle dispersion liquid, and method for producing the same

InactiveUS7776994B2Easy to disperseEffective plasticizationLayered productsDevelopersOrganic acidPolyester

A resin particle dispersion liquid comprises: resin particles comprising polyester having terminal carboxyl groups, the polyester being obtained by polycondensation of a polycondensable monomer, wherein the polyester has the terminal carboxyl groups that are partially neutralized to form carboxyl anions, the resin particles in the resin particle dispersion liquid having a value of (da / (da+dc)) of from approximately 0.30 to approximately 0.90, when in an absorption spectrum of the resin particles measured with an infrared spectrometer, dc represents a peak intensity of the terminal carboxyl group in a range of from 1,780 to 1,680 cm−1, and da represents a peak intensity of the neutralized carboxyl anion in a range of from 1,670 to 1,550 cm−1, the polyester has an acid value of approximately 1 mg·KOH / g or more and less than approximately 15 mg·KOH / g before neutralization, the resin particles dispersion liquid comprises a divalent or higher organic acid in an amount of from approximately 0.1 to approximately 20 parts by weight per 100 parts by weight of the resin particles, and the resin particles have a median diameter of from approximately 0.1 to approximately 2.0 μm.

Owner:FUJIFILM BUSINESS INNOVATION CORP

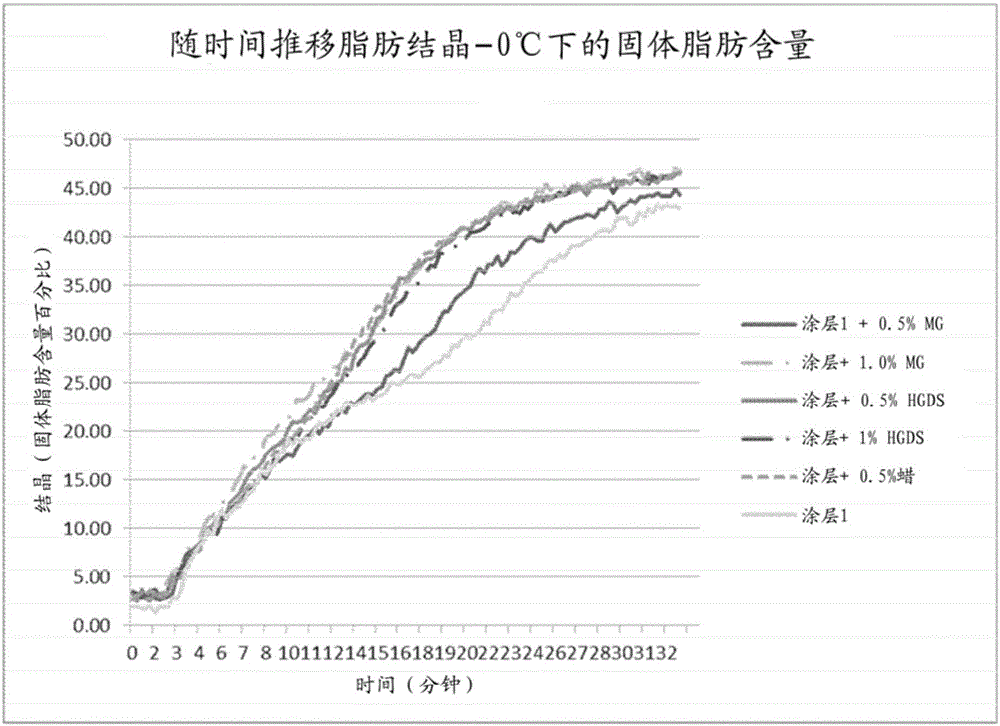

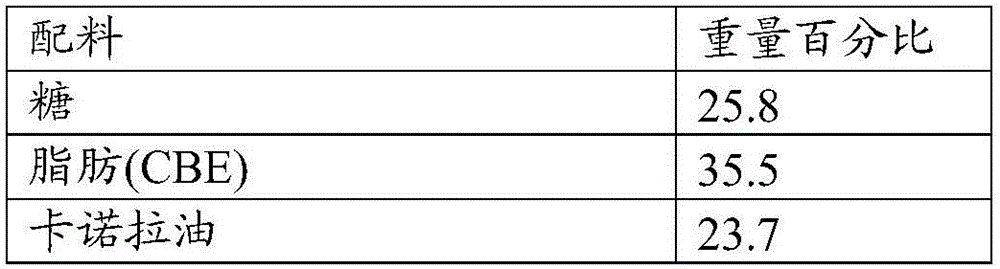

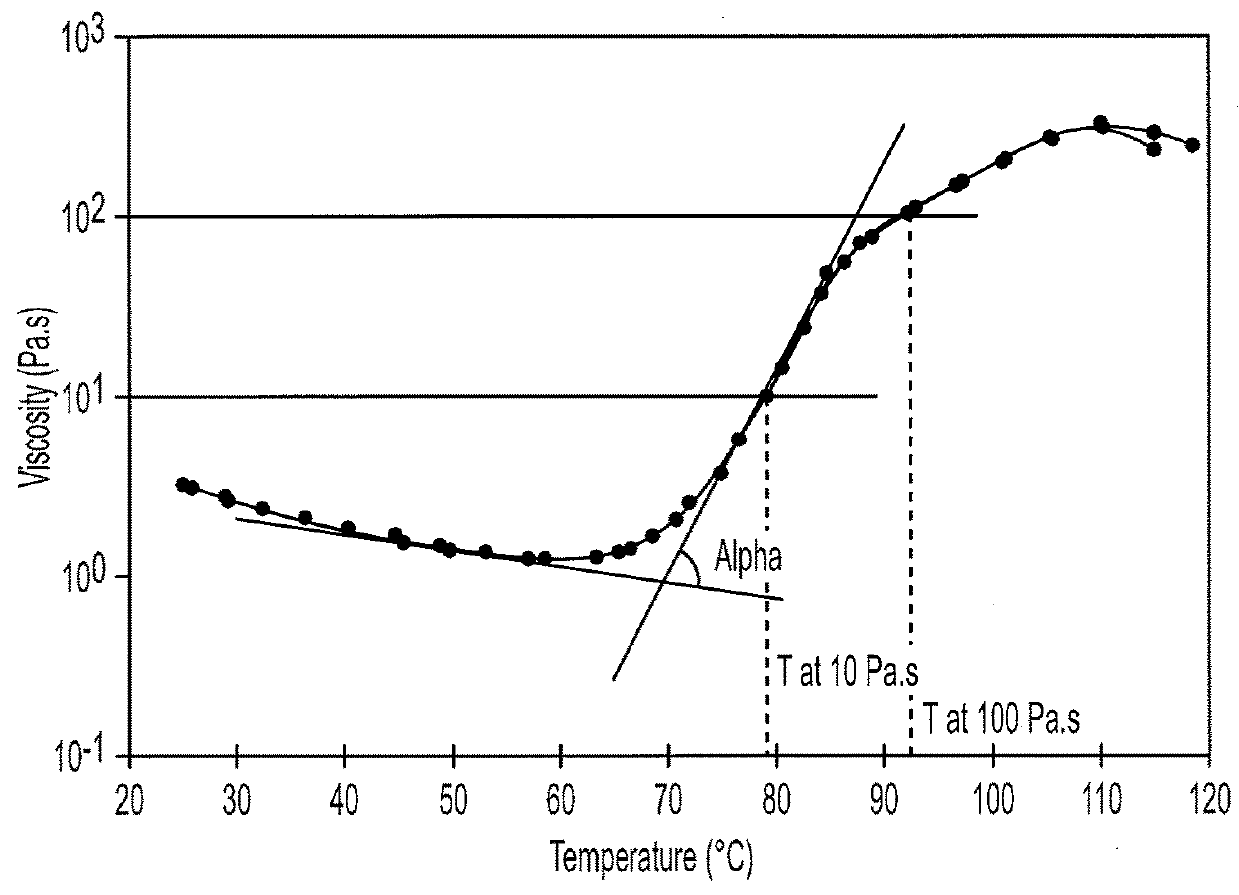

Fast plasticizing coating for frozen confection

The invention relates to a frozen confection coating comprising based on weight% a fat in an amount of between 35 - 65%; an emulsifier and / or an additive, wherein a total amount of the emulsifier and / or additive is between 0.1 - 5%, and wherein the emulsifier and / or the additive has a melting point greater than 40 DEG C. The invention also relates to a method for manufacture of the frozen confection coating.

Owner:NESTEC SA

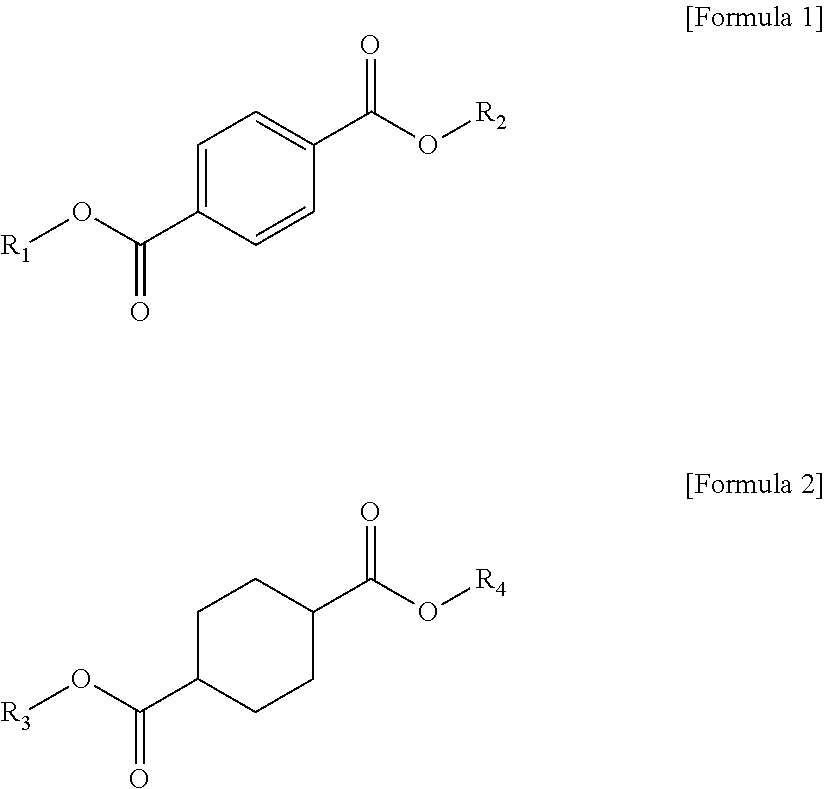

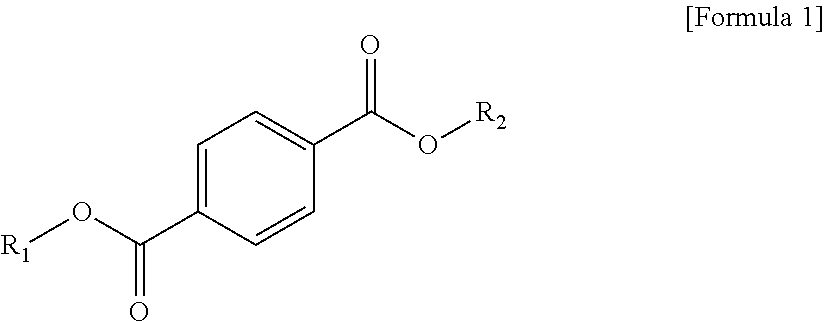

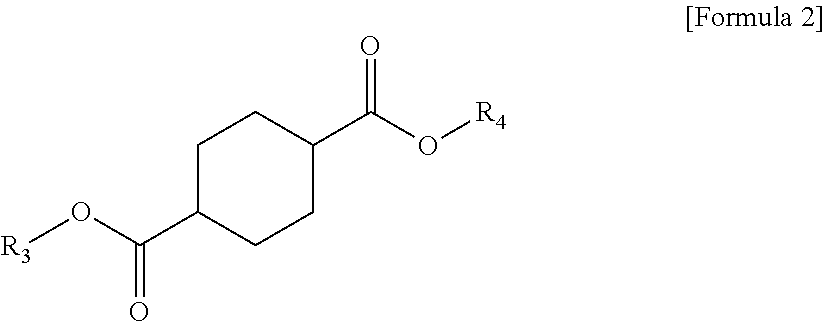

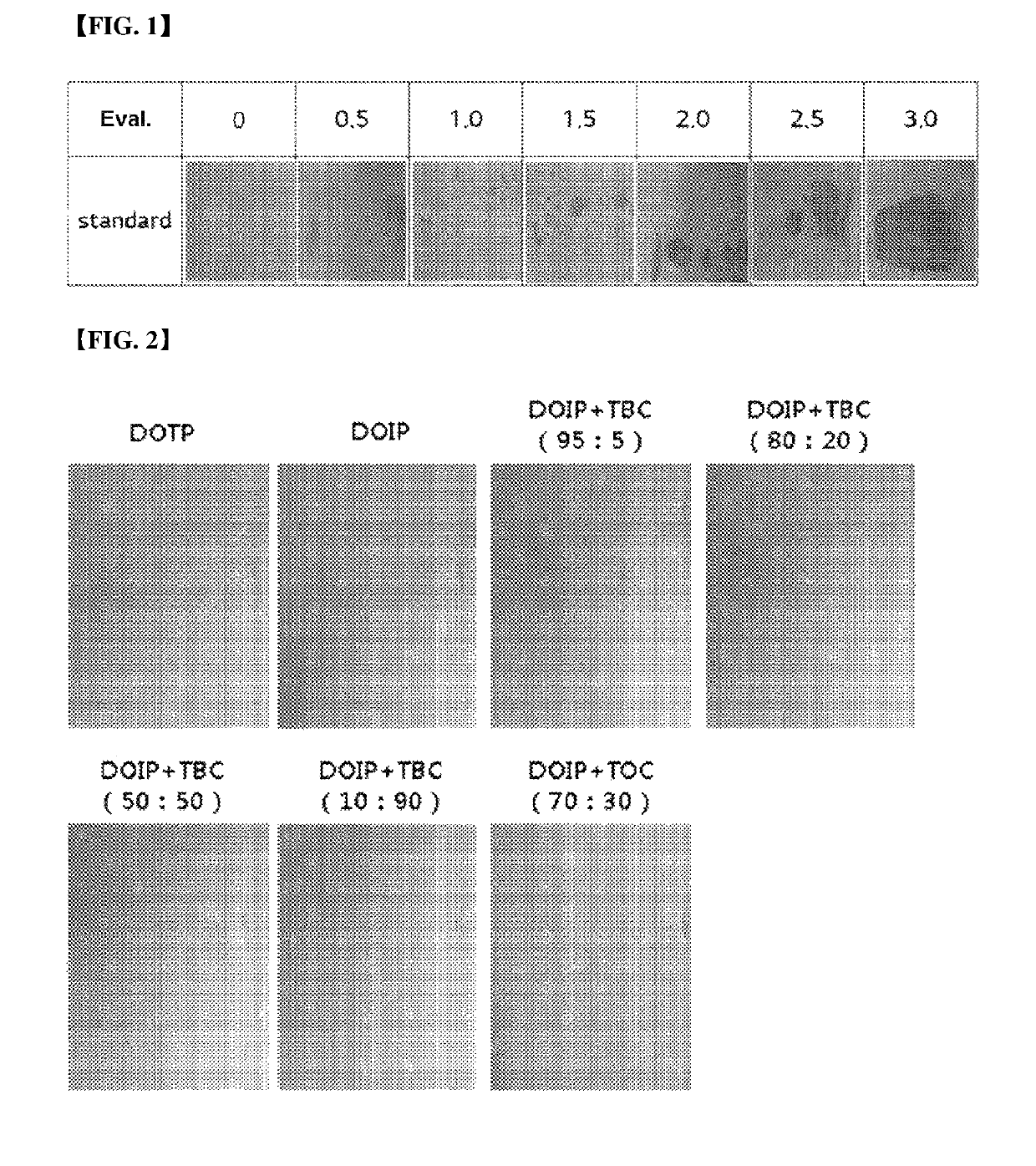

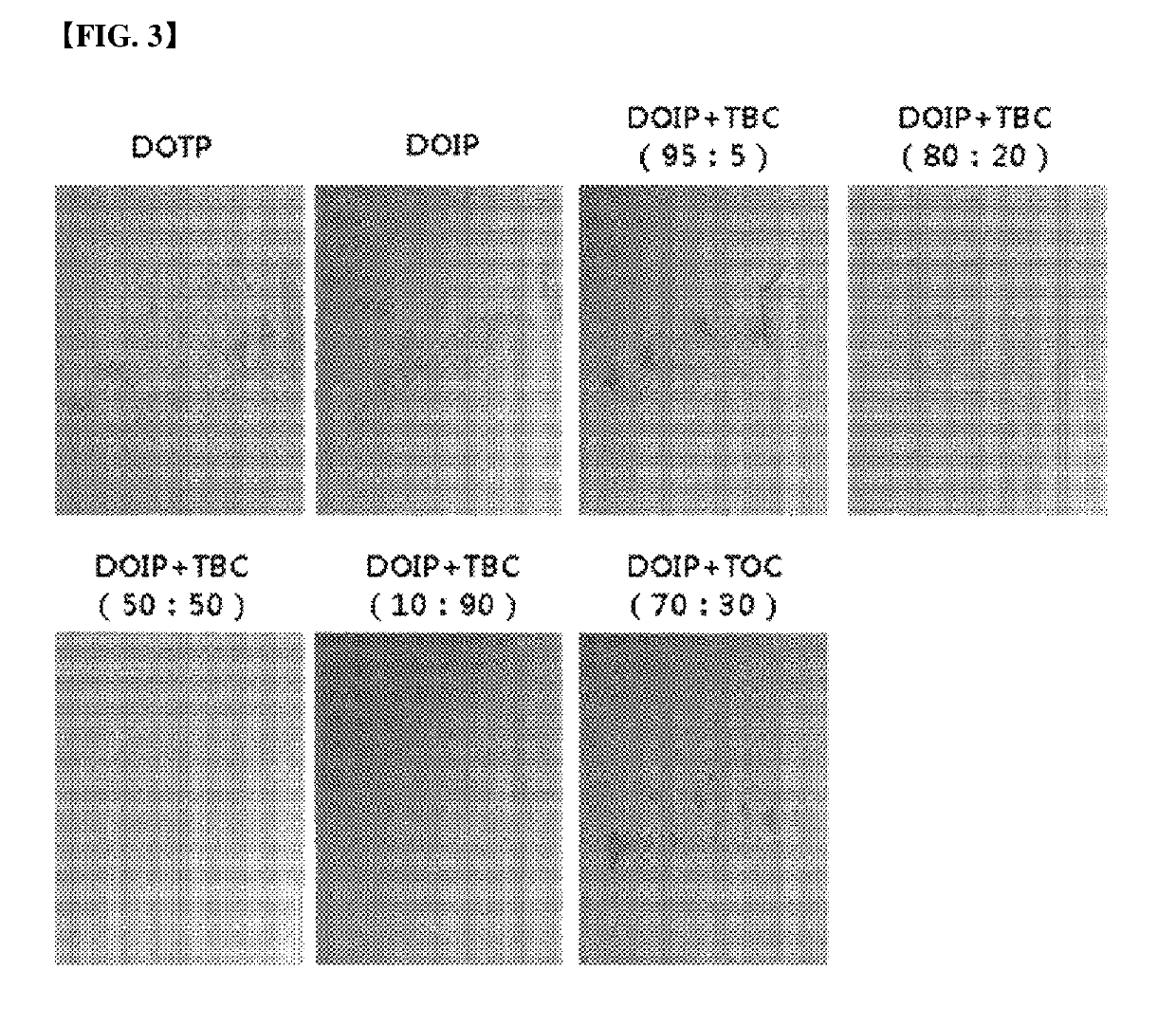

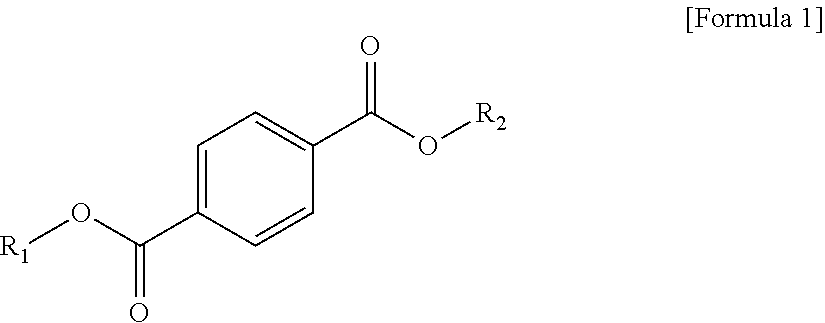

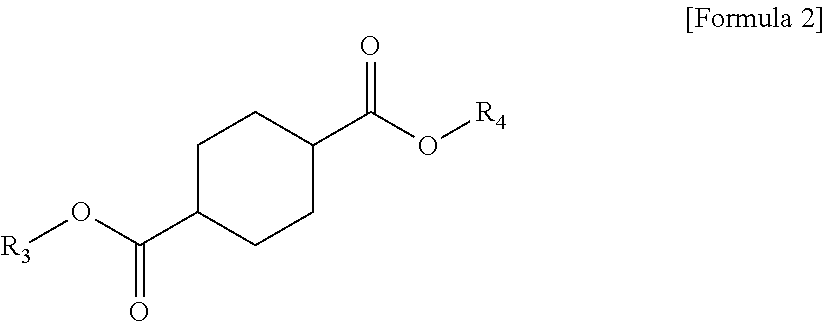

Plasticizer composition and resin composition including the same

ActiveUS20190048167A1High plasticizing efficiencyEasy to processOrganic compound preparationCarboxylic acid esters preparationPlasticizerUltimate tensile strength

The present invention relates to a plasticizer composition and a resin composition including the same, and can provide a plasticizer composition in which a terephthalate-based material and a cyclohexane 1,4-diester-based material are mixed, and the sum of carbon atoms of alkyl groups bonded to the two materials is in the range of 34 to 40, and by which environmental friendliness can be secured, mechanical properties such as tensile strength and an elongation rate and physical properties such as migration properties and volatile loss can be improved to levels equal to or higher than those of existing products, and effects of improving processability and plasticizing efficiency can be expected, and a resin composition including the same.

Owner:LG CHEM LTD

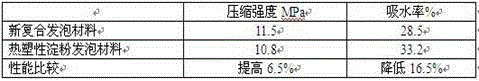

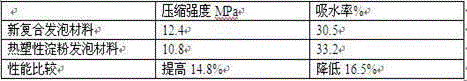

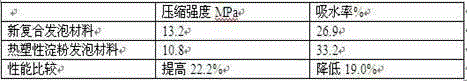

Cassava starch waste paper pulp composite foam material and preparation method thereof

The invention discloses a cassava starch waste paper pulp composite foam material and a preparation method thereof. After cassava starch, waste paper pulp fiber, lubricant and a compound plasticizer are mixed, the product is obtained by using a screw extruder through melt blending, extrusion and foaming. The melt blending components include, by mass, 60-80 parts of the cassava starch, 10-30 parts of the waste paper pulp fiber, 5-20 parts of the compound lubricant and the compound plasticizer accounting for 20-40% of the total amount of the starch. The cassava starch is modified into thermoplastic starch by adopting the plasticizer glycerin / urea. By adding the waste paper pulp fiber, on the one hand, a certain mechanical strength is provided, improvement of melt strength is promoted, bubbles are stabilized, and accordingly the compression strength of the material is improved; on the other hand, the water resistance of the material can be improved. The product is cheap, good in water resistance and compression strength, completely biodegradable, non-toxic and environmentally friendly.

Owner:HUNAN UNIV OF TECH

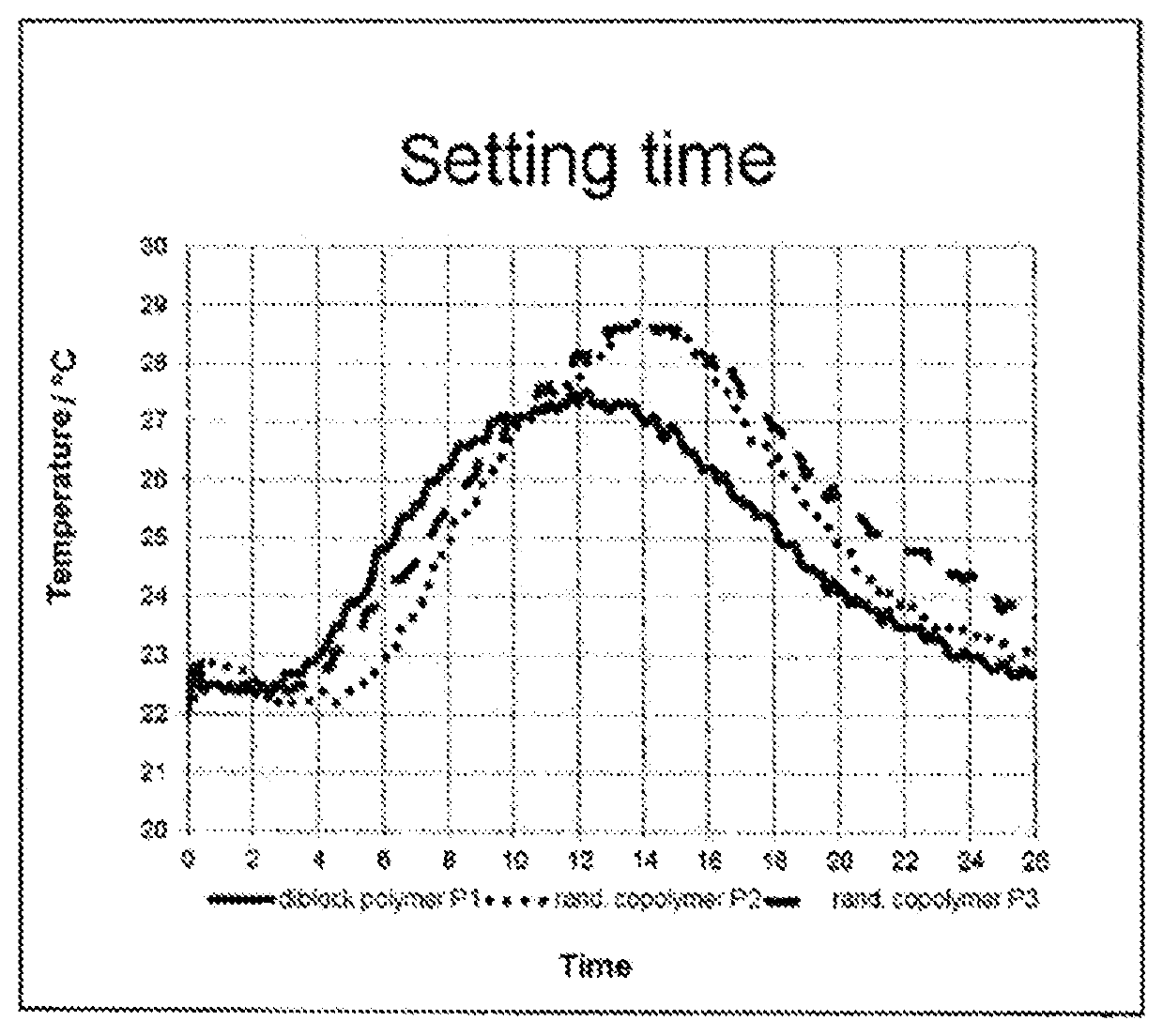

Additive containing a superplasticizer and a copolymer

ActiveCN108349825AFlexible and controlled productionEffective plasticizationPolymer scienceSuperplasticizer

The invention relates to an additive, in particular a dispersant for solid particles, in particular a dispersant for mineral binder compositions, comprising the following: a) a superplasticizer and b)a copolymer with a polymer backbone and side chains bonded thereto, comprising at least one ionizable monomer unit M1 and at least one side chain-supporting monomer unit M2. The copolymer has a non-random distribution of the monomer units M1 and / or the monomer units M2 in a direction along the polymer backbone, and the superplasticizer and the copolymer differ chemically and / or structurally.

Owner:SIKA TECH AG

Plasticizer composition, resin composition and method for preparing thereof

ActiveUS20170369656A1Improve propertiesMaintain good propertiesOrganic chemistryPlasticizerChloride vinyl

The present invention relates to a plasticizer composition, a resin composition and a method for preparing thereof. The present invention can provide a plasticizer composition, which can improve properties required to the plasticizer composition contained in a vinyl chloride-based resin composition, such as plasticizing efficiency, volatile loss, and migration resistance, to a level equal to or better than the existing plasticizer composition, and a resin composition comprising thereof.

Owner:LG CHEM LTD

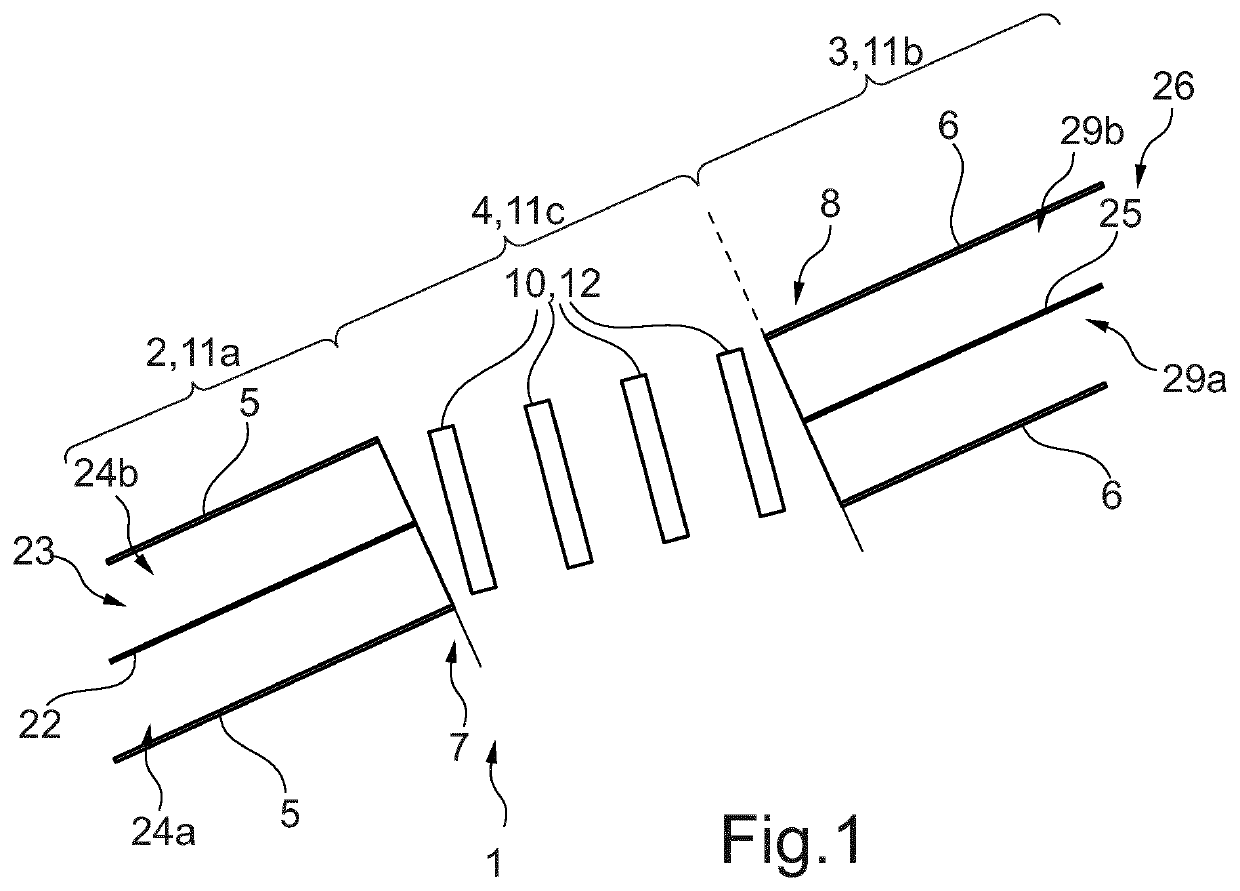

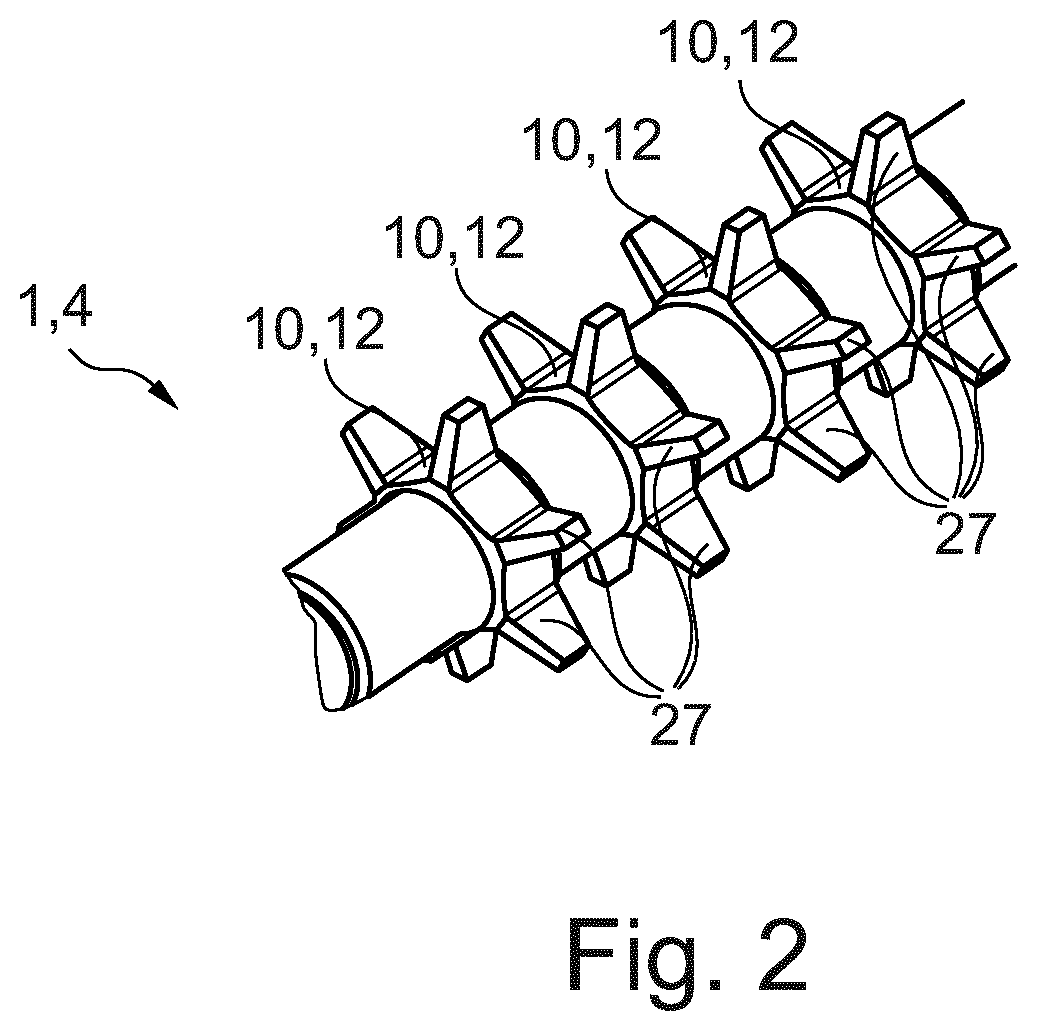

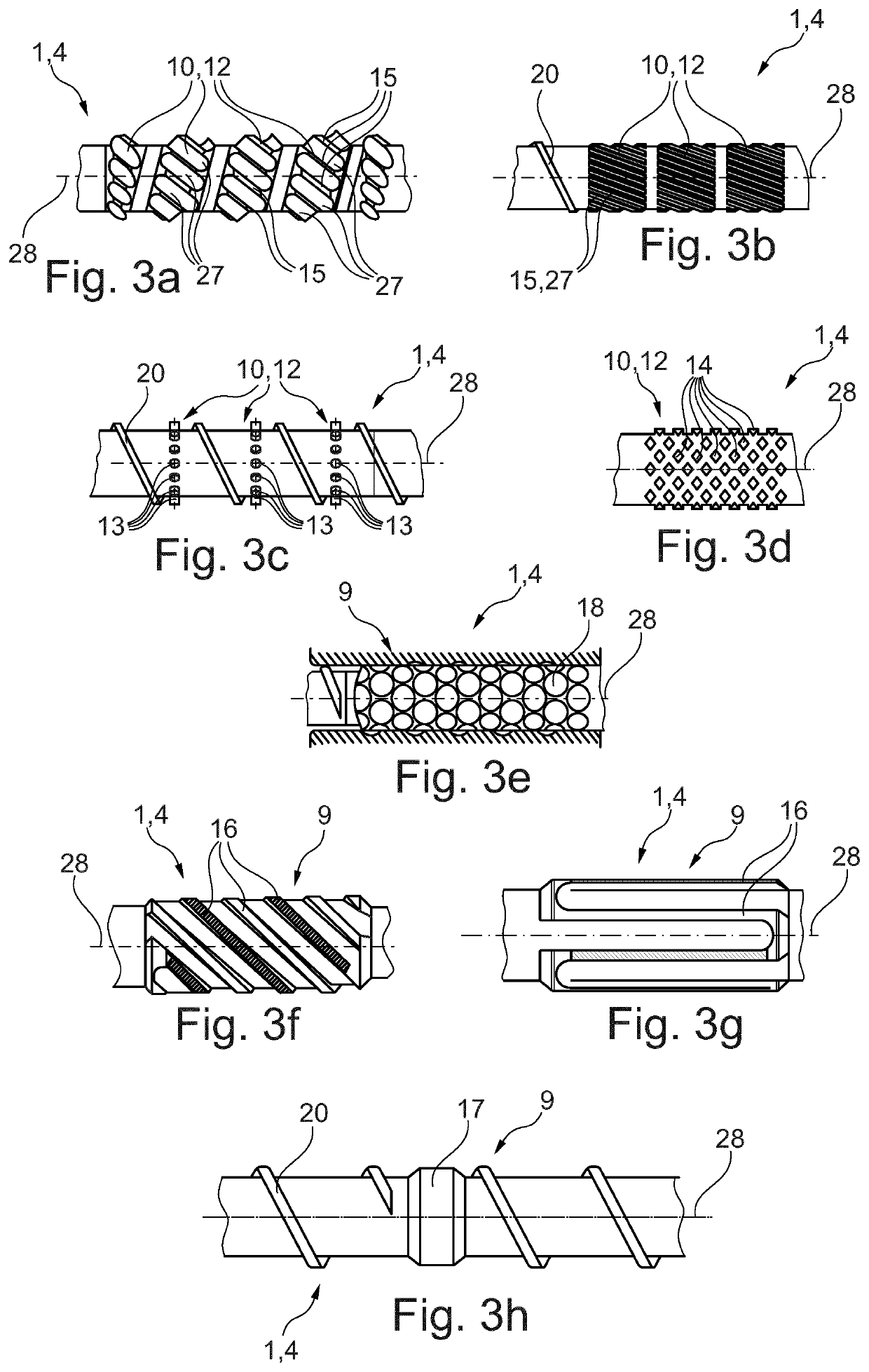

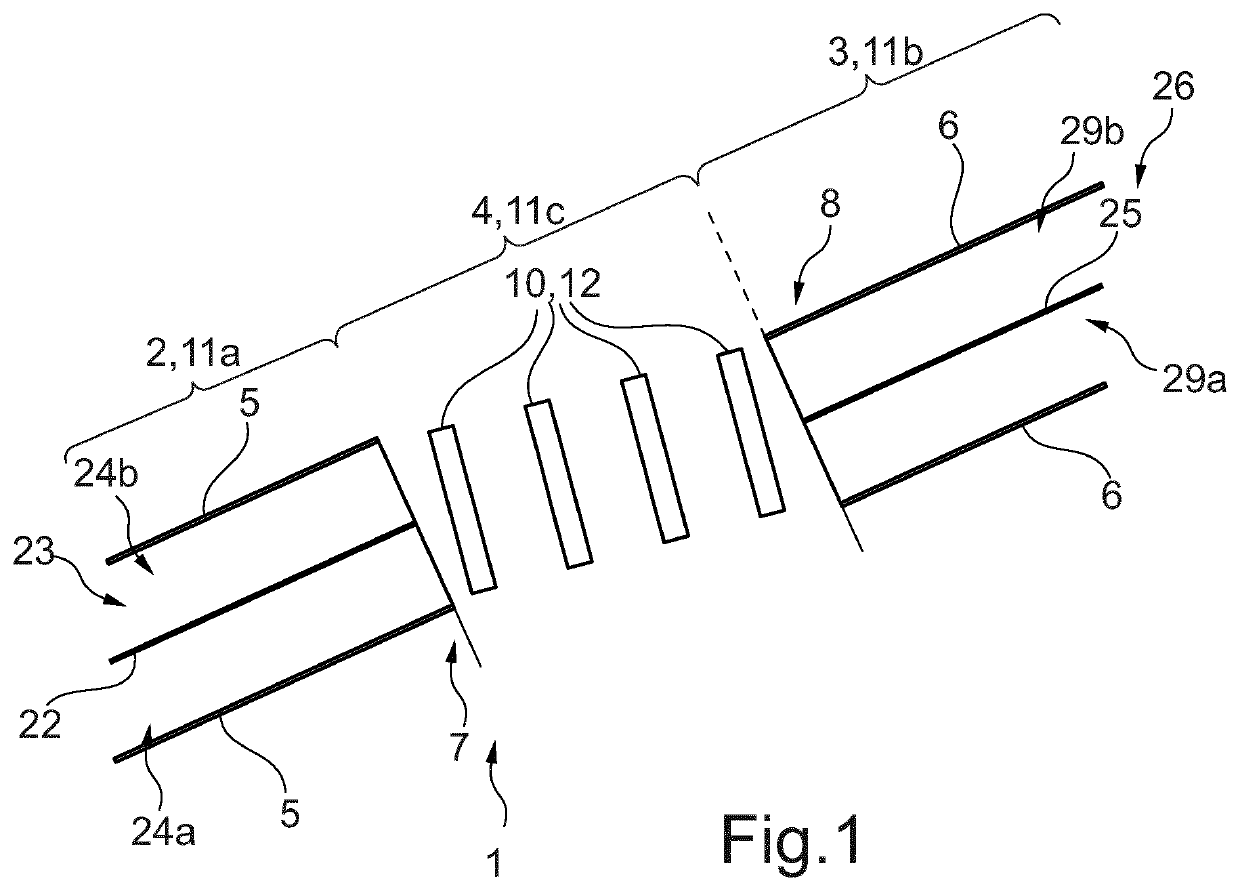

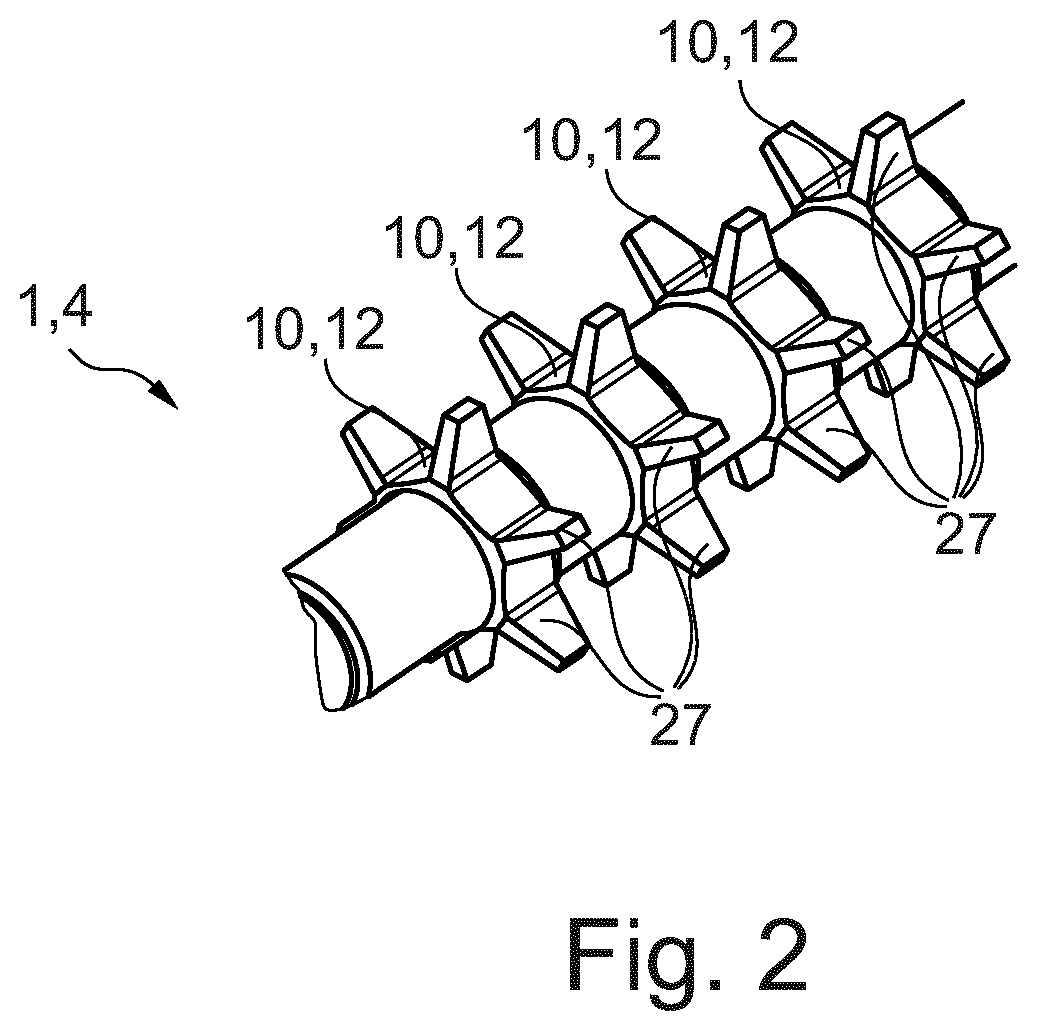

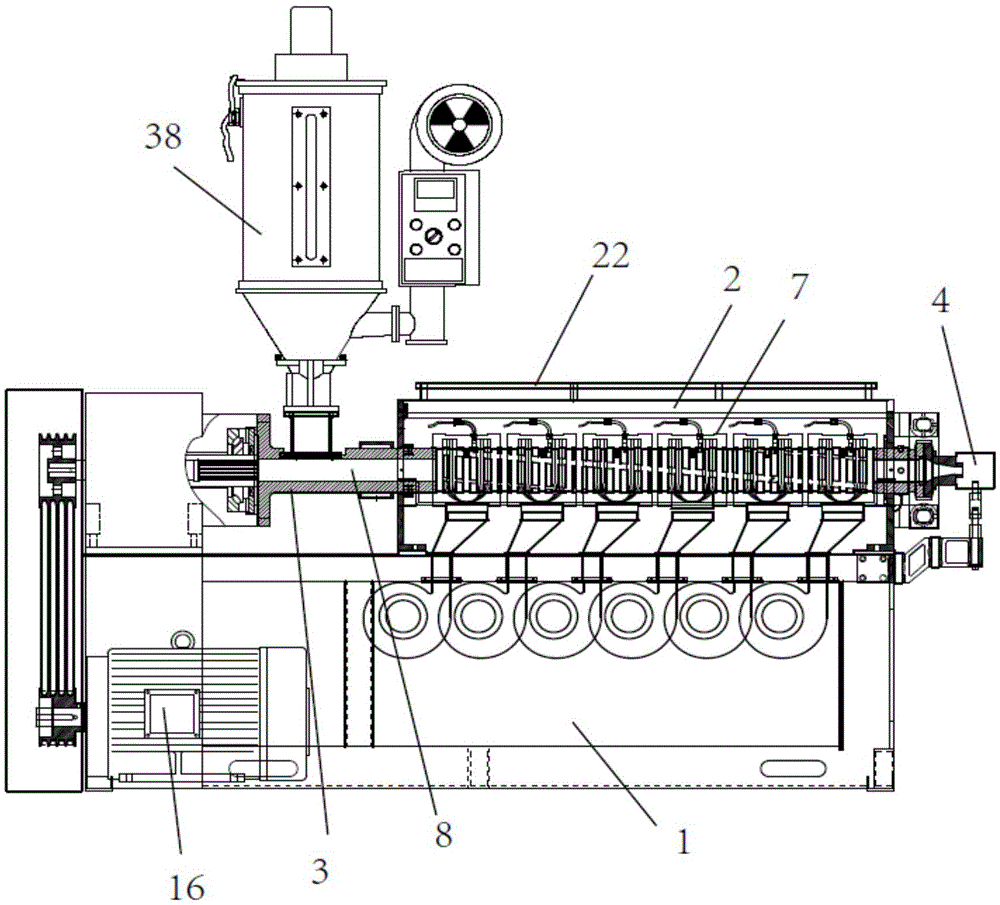

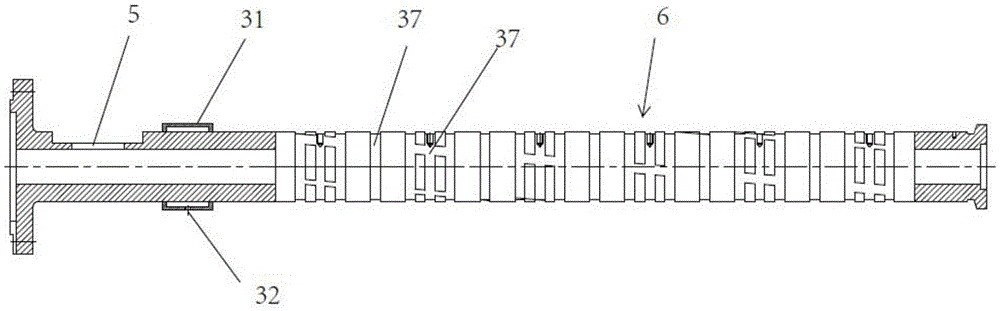

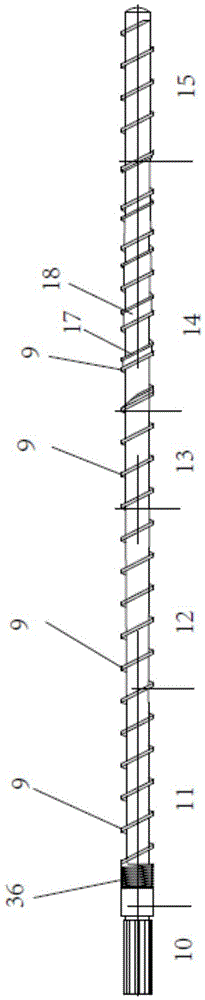

Extruder screw, extrusion device having an extruder screw and method for plasticizing a plastic

ActiveUS11273420B2Effective plasticizationRotary stirring mixersTransportation and packagingPolymer sciencePlasticulture

Owner:KRAUSSMAFFEI EXTRUSION GMBH

Extruder screw, extrusion device having an extruder screw and method for plasticizing a plastic

ActiveUS20210402358A1Improve distributionGood fragmentationRotary stirring mixersTransportation and packagingPolymer sciencePlasticulture

An extruder screw for plasticizing at least one plastic or plastic mixture, including a melting zone, a shaft zone and a mixing zone arranged between the melting zone and the shaft zone, wherein a conveying flight is formed in the melting zone and in the shaft zone, which extends helically along a longitudinal axis of the screw, wherein a conveying flight of the melting zone ends at an end of the melting zone towards the mixing zone and a conveying flight of the shaft zone begins at an end towards the mixing zone. A flight depth of the melting zone continuously decreases along the longitudinal axis of the screw to the mixing zone. Further, an extrusion device having the extruder screw and to a method for plasticizing at least one plastic or plastic mixture.

Owner:KRAUSSMAFFEI EXTRUSION GMBH

Resin particle dispersion liquid, toner for developing electrostatic image and method for producing the same, developer for developing electrostatic image, and method for forming image

InactiveUS20080038646A1Easy to disperseEffective plasticizationLayered productsDevelopersOrganic acidPolyester

A resin particle dispersion liquid comprises: resin particles comprising polyester having terminal carboxyl groups, the polyester being obtained by polycondensation of a polycondensable monomer, wherein the polyester has the terminal carboxyl groups that are partially neutralized to form carboxyl anions, the resin particles in the resin particle dispersion liquid having a value of (da / (da+dc)) of from approximately 0.30 to approximately 0.90, when in an absorption spectrum of the resin particles measured with an infrared spectrometer, dc represents a peak intensity of the terminal carboxyl group in a range of from 1,780 to 1,680 cm−1, and da represents a peak intensity of the neutralized carboxyl anion in a range of from 1,670 to 1,550 cm−1, the polyester has an acid value of approximately 1 mg·KOH / g or more and less than approximately 15 mg·KOH / g before neutralization, the resin particles dispersion liquid comprises a divalent or higher organic acid in an amount of from approximately 0.1 to approximately 20 parts by weight per 100 parts by weight of the resin particles, and the resin particles have a median diameter of from approximately 0.1 to approximately 2.0 μm.

Owner:FUJIFILM BUSINESS INNOVATION CORP

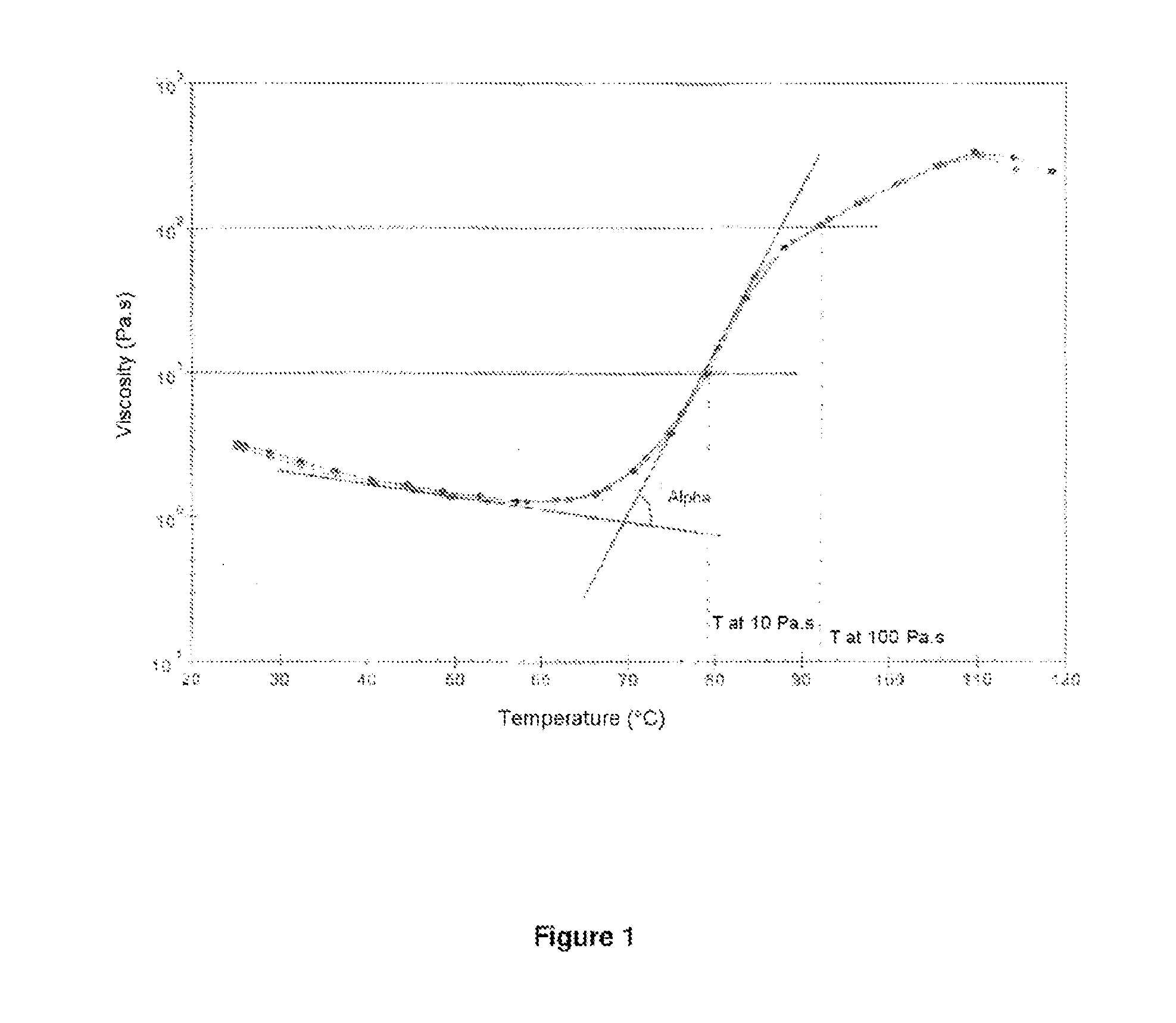

Plasticiser compositions comprising gelification accelerators based on ester(s) of 1,4 : 3,6-dianhydrohexitol having low molar weight

ActiveUS20150125613A1Effective plasticizationImprove cold resistanceOrganic chemistryWater-repelling agents additionDianhydrohexitolPhthalic acid

Disclosed is a composition that can rapidly plasticise polymers, including, in relation to the total mass of (A) and (B): between 0.1 and 99 mass-% of at least one ester of 1,4:3,6-dianhydrohexitol (A), having a molar mass varying between 255 and 345 g·mol−1 and selected from among monoesters and diesters of isosorbide, isomannide and isoidide; and between 1 and 99.9 mass-% of at least one compound (B) having a molar mass greater than 345 g·mol−1 and selected from among the esters of 1,4:3,6-dianhydrohexitol, the esters of cyclohexane polycarboxylic acid, the esters of phthalic acid, and glycerol esters. Also disclosed is a method for the production of a plasticised object using constituents (A) and (B), as well as to the use of the ester compound (A) as a polymer gelification accelerator.

Owner:ROQUETTE FRERES SA

Plasticizer composition, resin composition and method for preparing thereof

ActiveUS10377864B2Improve propertiesEffective plasticizationOrganic chemistryPlasticizerChloride vinyl

The present invention relates to a plasticizer composition, a resin composition and a method for preparing thereof. The present invention can provide a plasticizer composition, which can improve properties required to the plasticizer composition contained in a vinyl chloride-based resin composition, such as plasticizing efficiency, volatile loss, and migration resistance, to a level equal to or better than the existing plasticizer composition, and a resin composition comprising thereof.

Owner:LG CHEM LTD

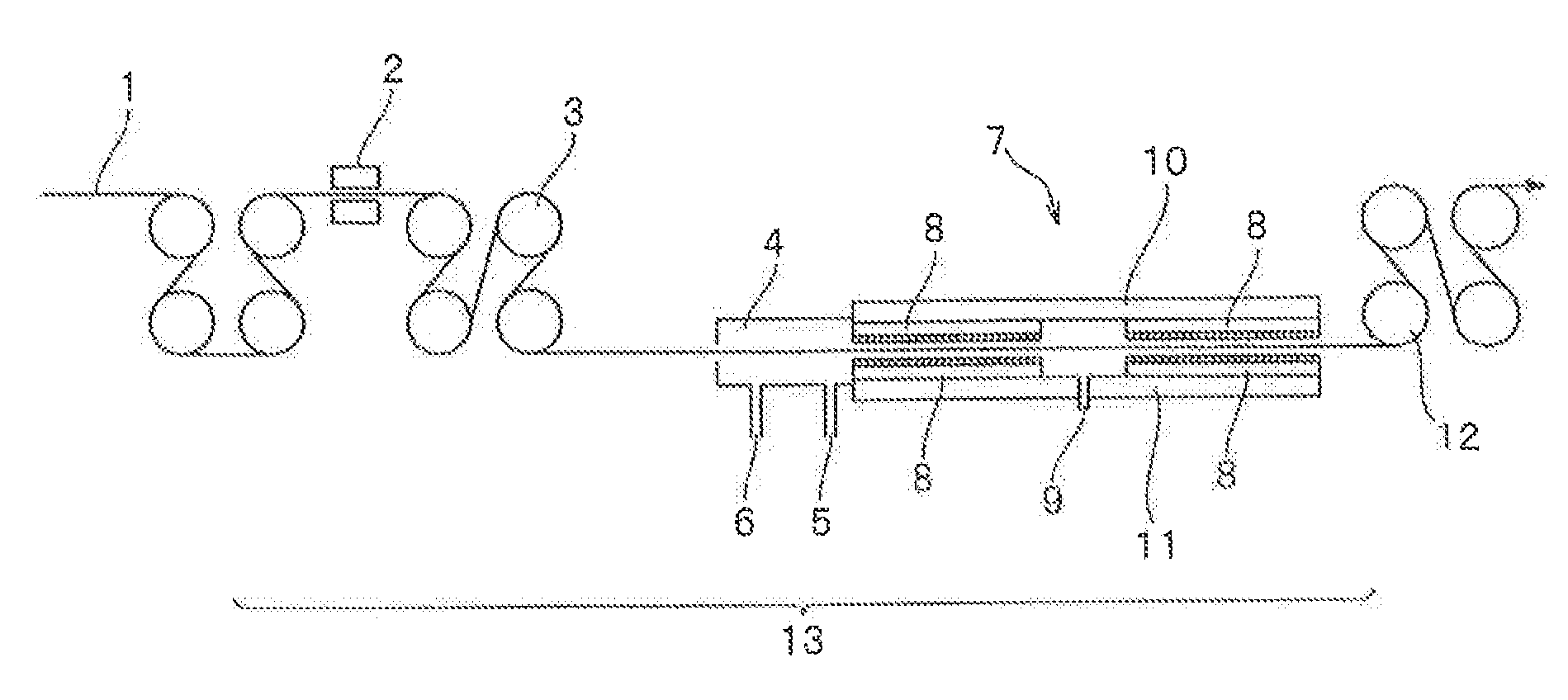

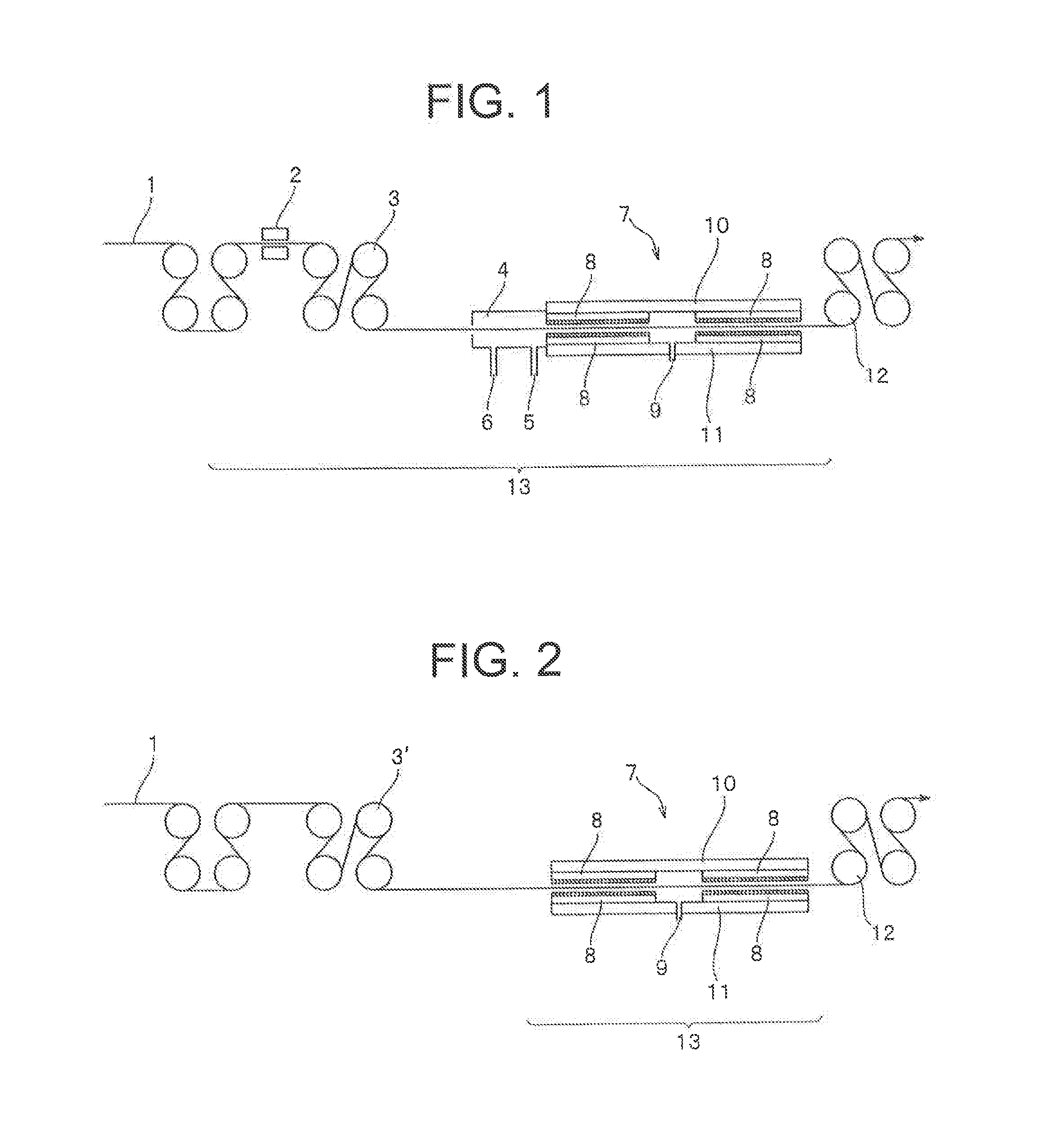

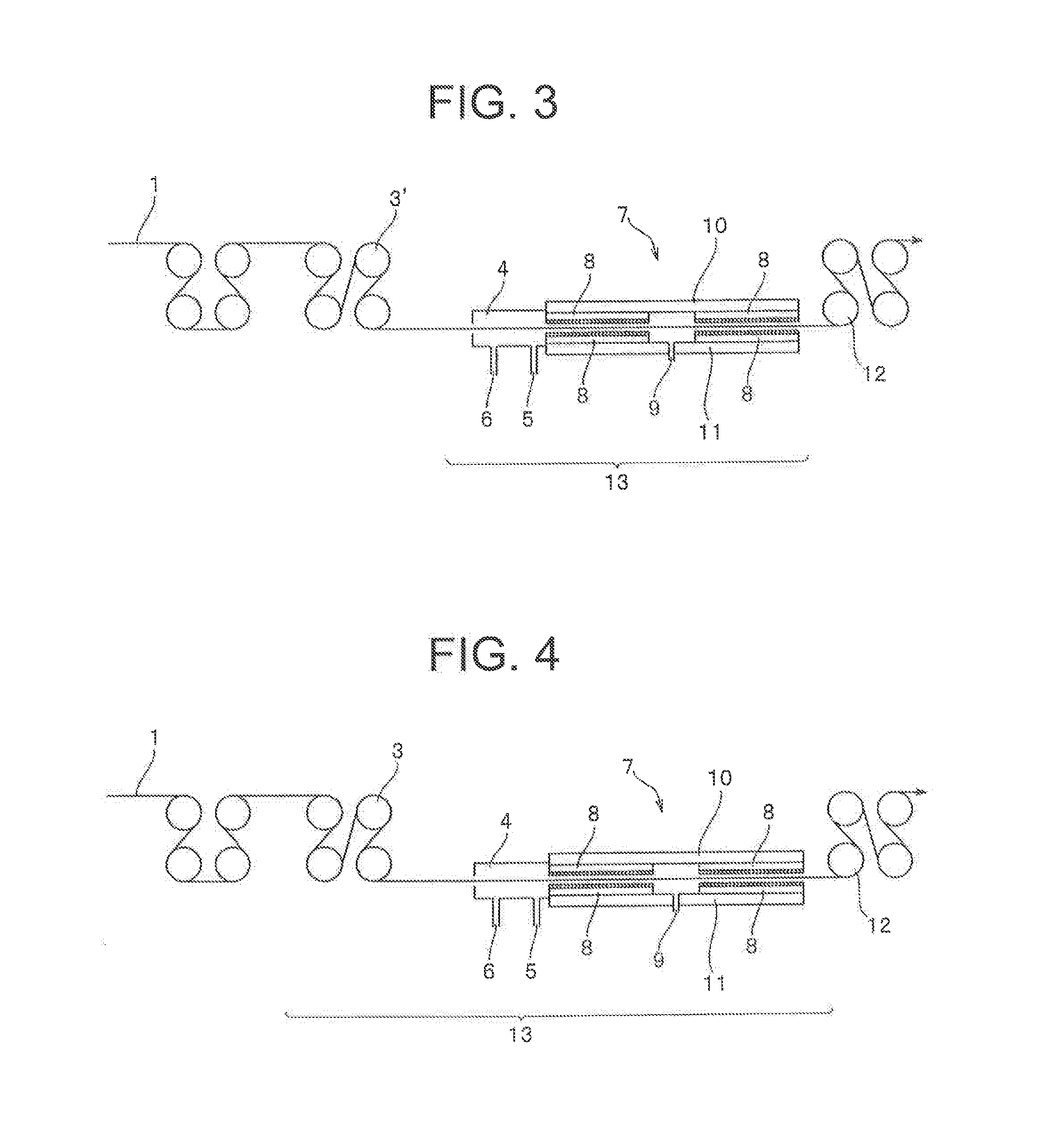

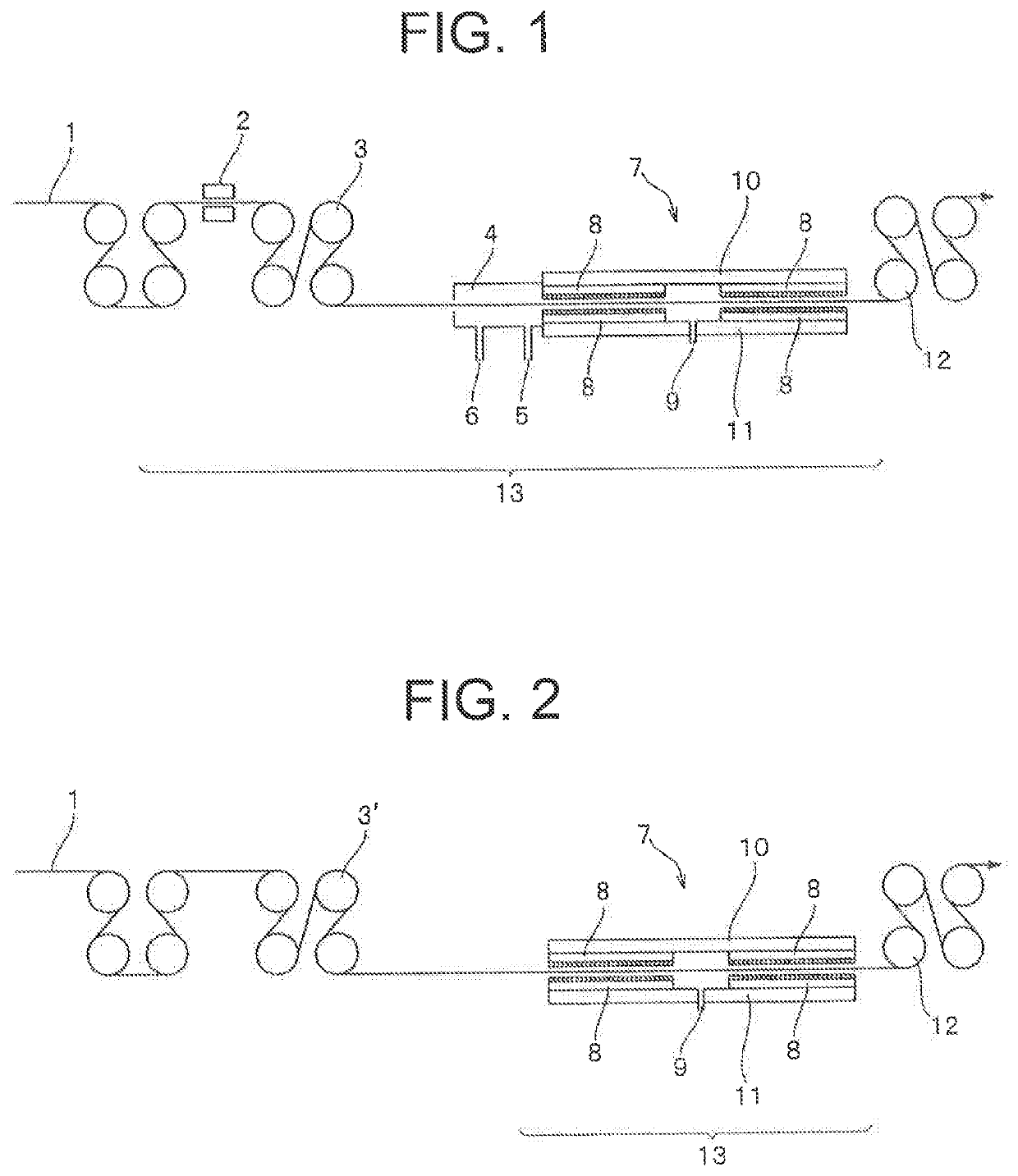

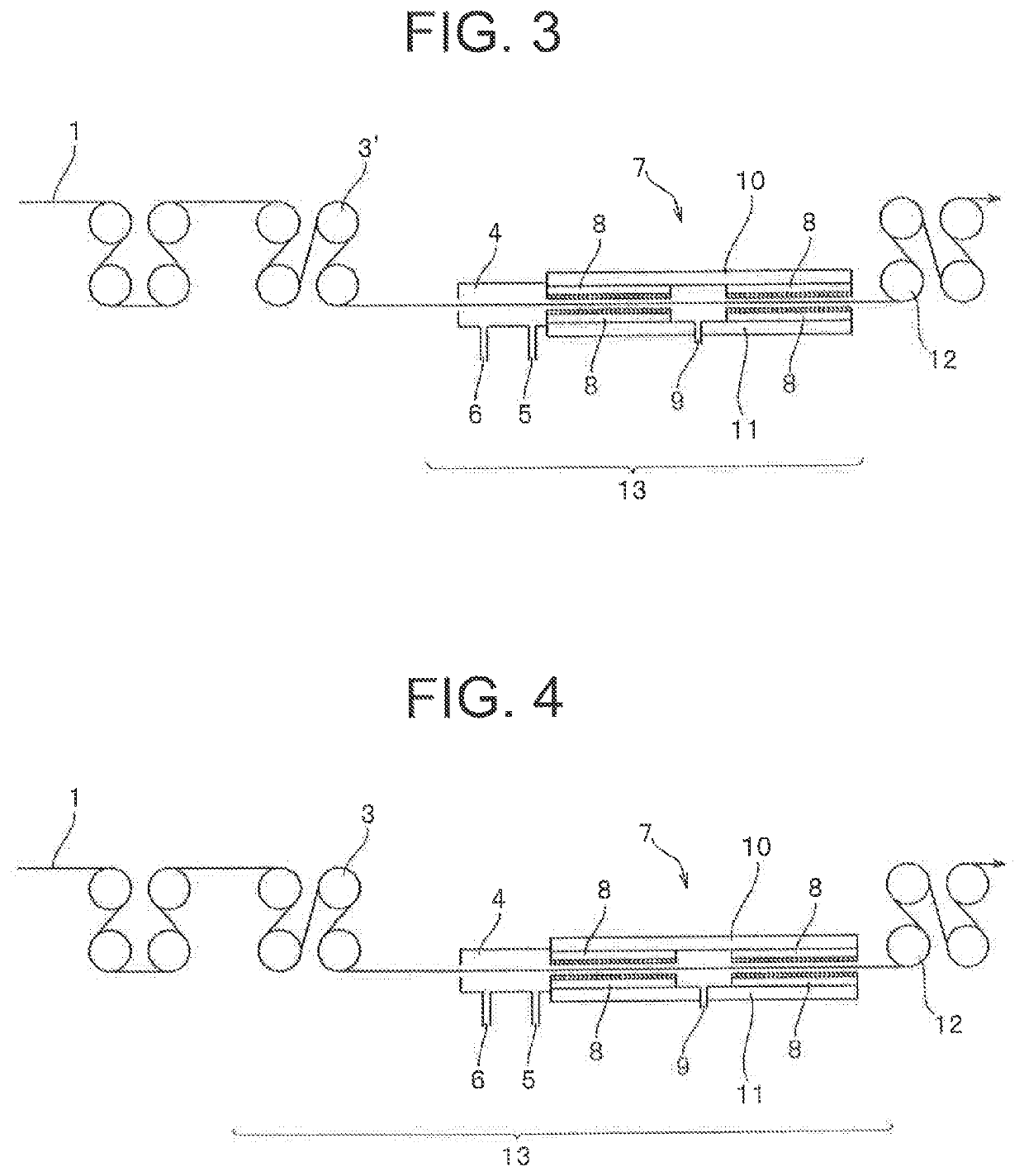

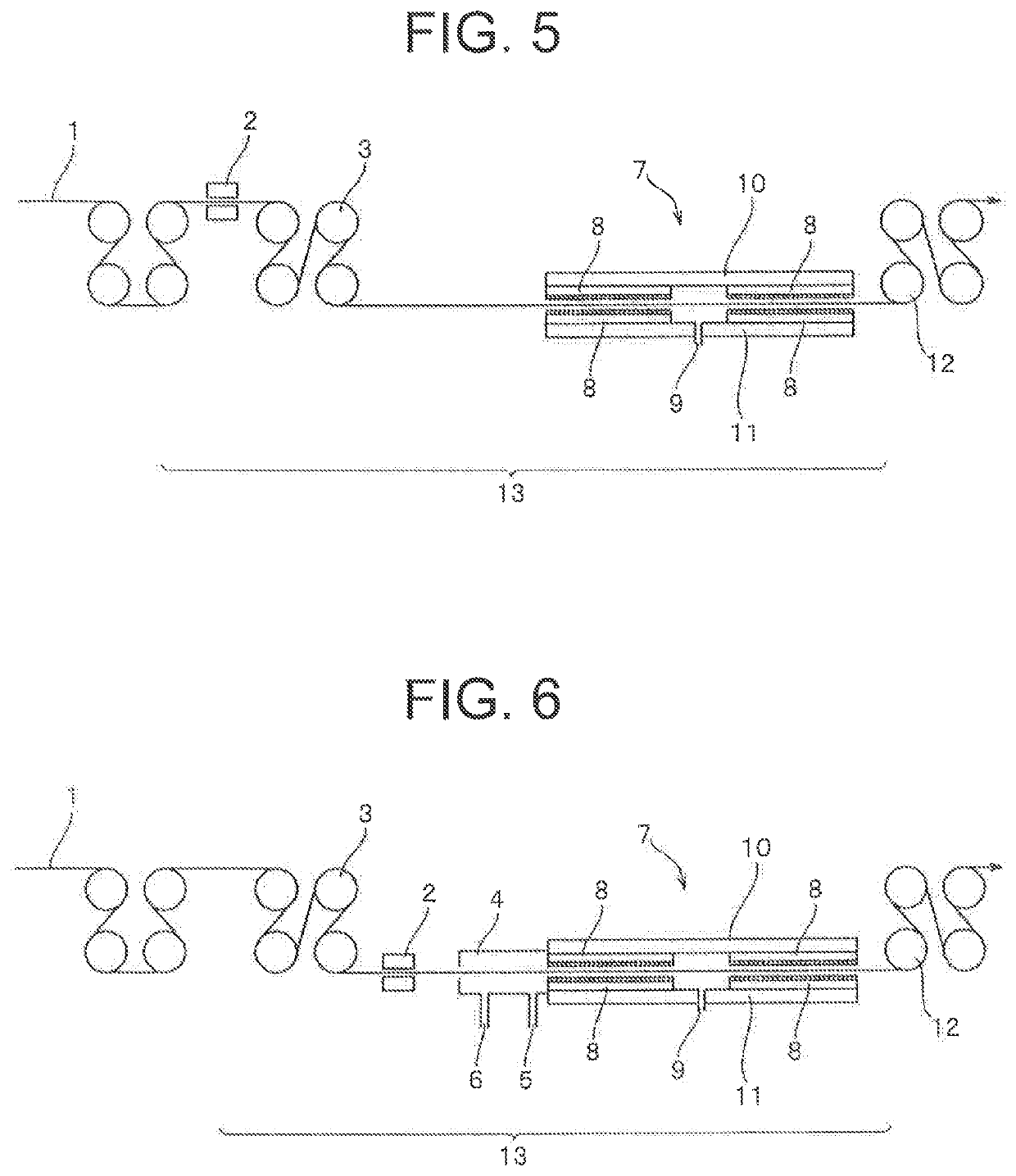

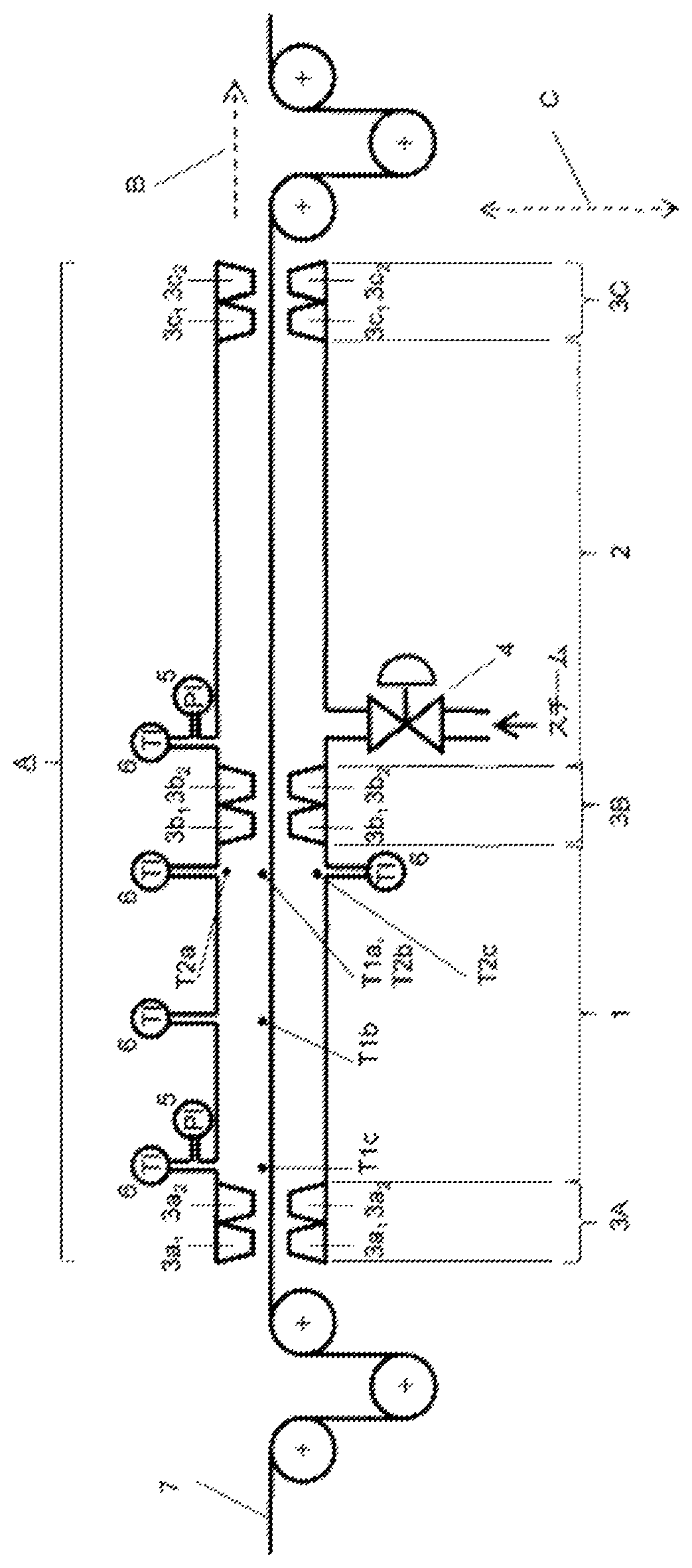

Process for manufacturing carbon-fiber precursor acrylic fiber bundle and steam drawing apparatus

ActiveUS20160151959A1Improve plasticizing effectTrouble with breakage can be preventedFilament manufactureCeramic shaping apparatusCarbon fibersFiber bundle

This process for manufacturing a carbon-fiber precursor acrylic fiber bundle and this steam drawing apparatus are characterized in that the drawing of an acrylic fiber bundle with a pressured-steam drawing apparatus is conducted by: opening an acrylic fiber bundle by blowing a fluid thereto; supplying humidifying steam to the opened acrylic fiber bundle at a fiber temperature of 80 to 130° C. to adjust the water content of the fiber bundle to 3 to 7%; and thereafter drawing the resulting acrylic fiber bundle in a pressurized-steam atmosphere. Thus, the present invention can prevent the breaking of a single fiber, the fluffing of the fiber bundle, and the breaking of the whole of the fiber bundle, though such defects are susceptible to occurring in a case where an acrylic fiber bundle is drawn by steam drawing at a high draw ratio, at a higher speed, or into a fiber having a small denier.

Owner:MITSUBISHI CHEM CORP

Plasticiser compositions comprising gelification accelerators based on ester(s) of 1,4 : 3,6-dianhydrohexitol having low molar weight

ActiveUS10005894B2Effective plasticizationImprove cold resistanceOrganic chemistryCeramic shaping apparatusDianhydrohexitolPhthalic acid

Disclosed is a composition that can rapidly plasticize polymers, including, in relation to the total mass of (A) and (B): between 0.1 and 99 mass-% of at least one ester of 1,4:3,6-dianhydrohexitol (A), having a molar mass varying between 255 and 345 g·mol−1 and selected from among monoesters and diesters of isosorbide, isomannide and isoidide; and between 1 and 99.9 mass-% of at least one compound (B) having a molar mass greater than 345 g·mol−1 and selected from among the esters of 1,4:3,6-dianhydrohexitol, the esters of cyclohexane polycarboxylic acid, the esters of phthalic acid, and glycerol esters. Also disclosed is a method for the production of a plasticized object using constituents (A) and (B), as well as to the use of the ester compound (A) as a polymer gelification accelerator.

Owner:ROQUETTE FRERES SA

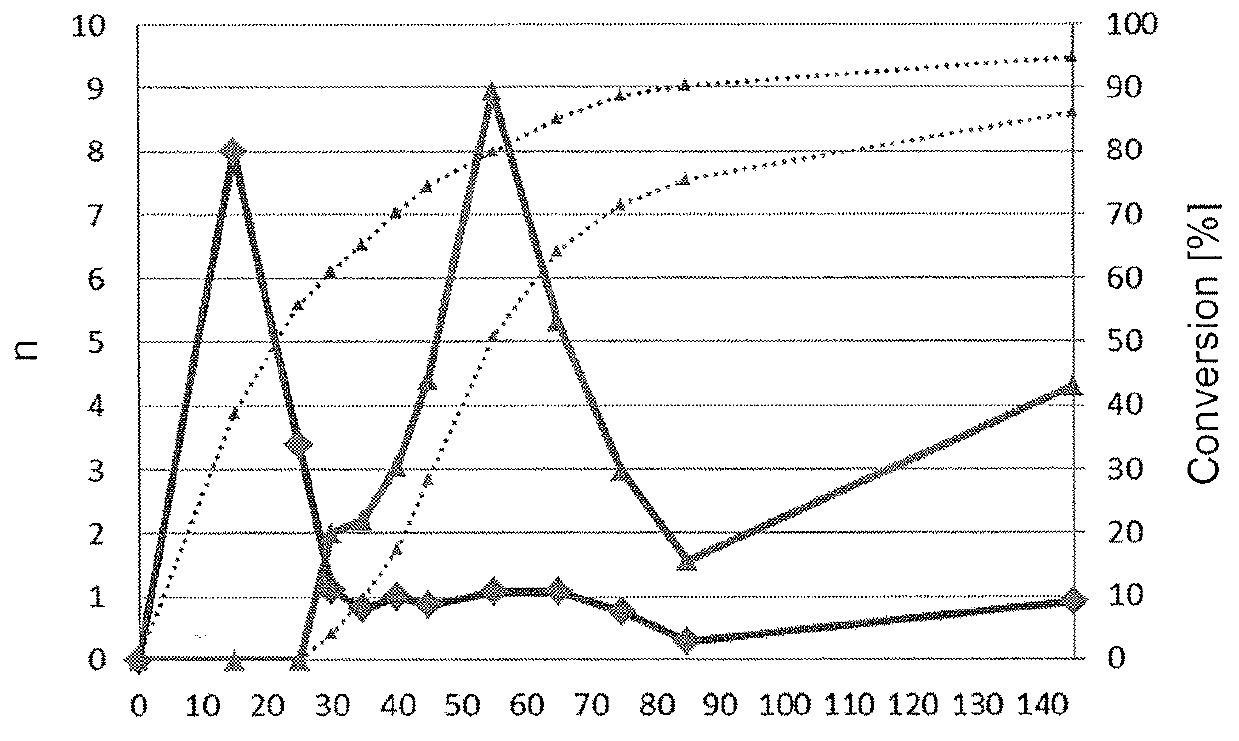

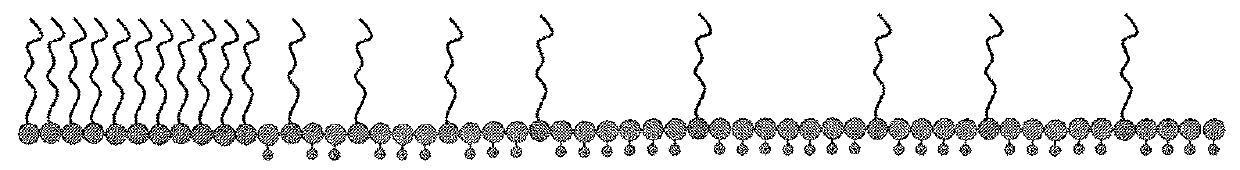

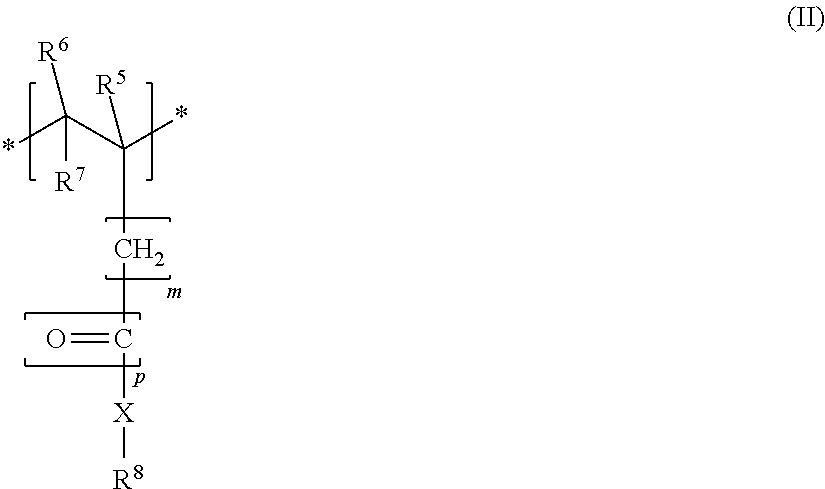

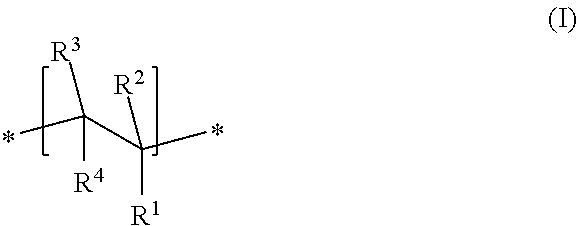

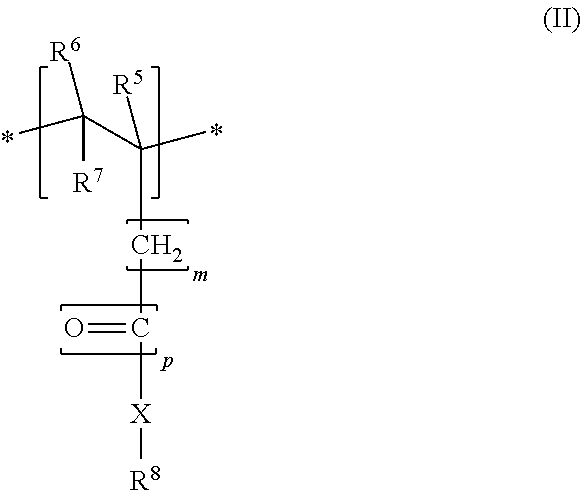

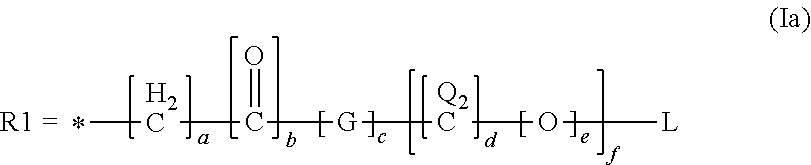

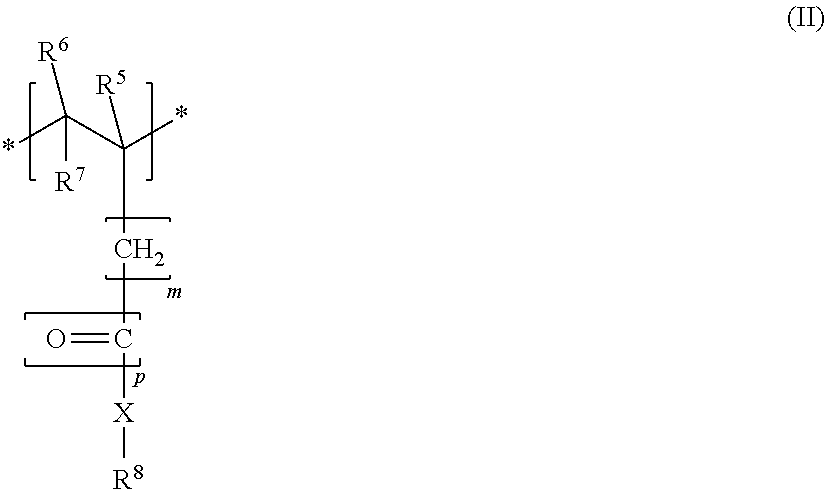

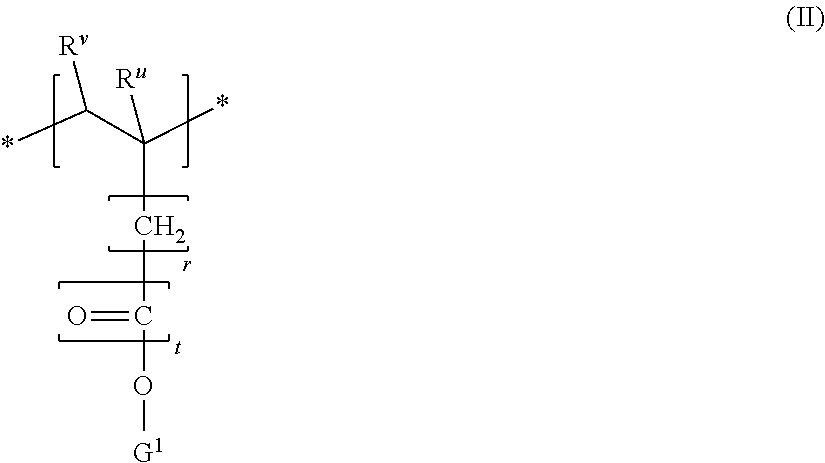

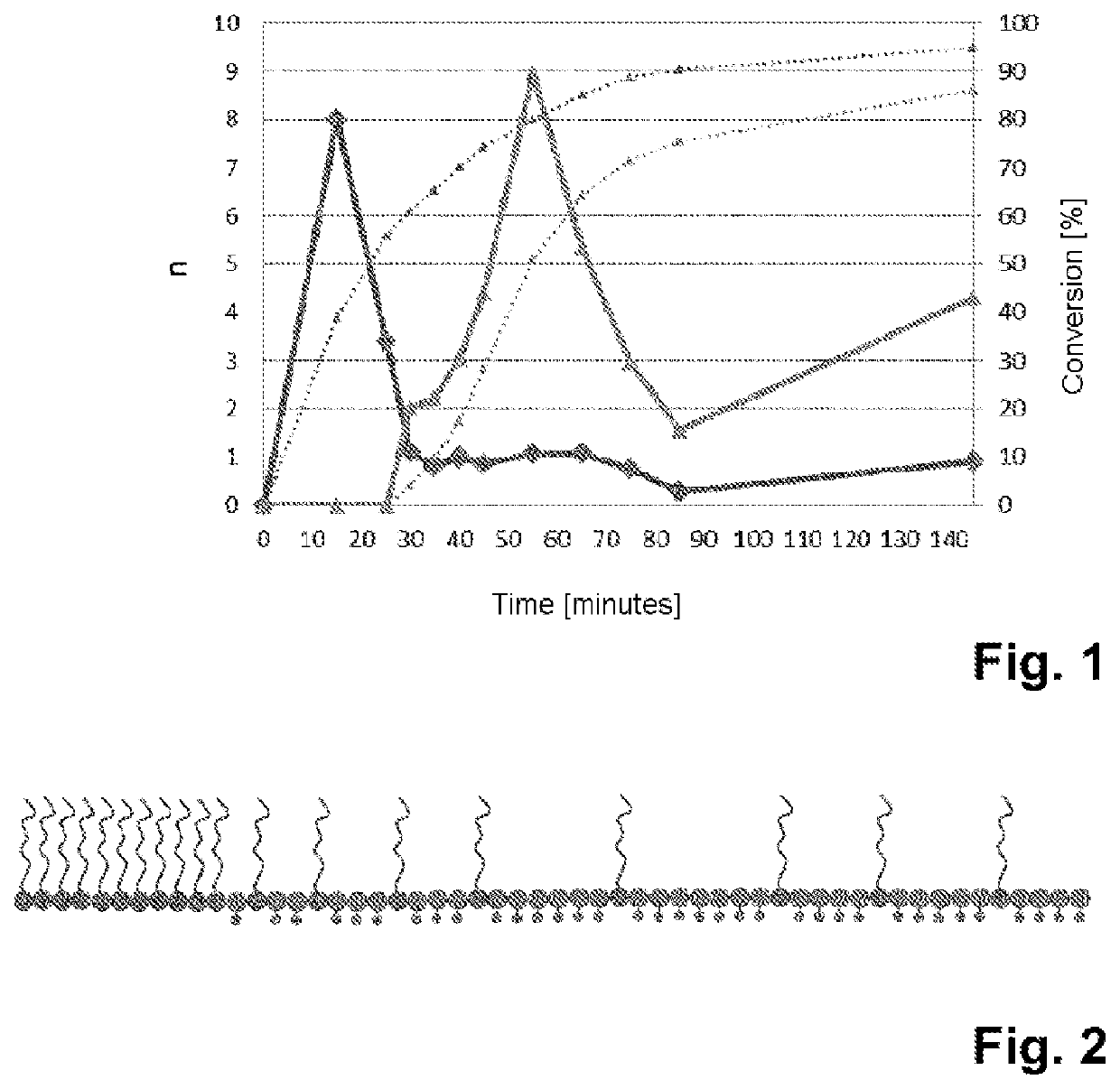

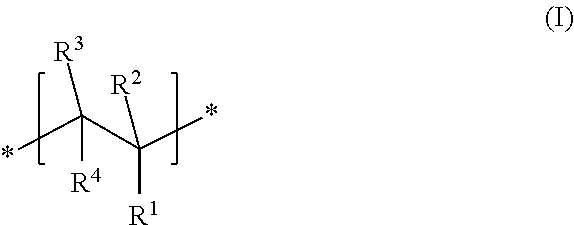

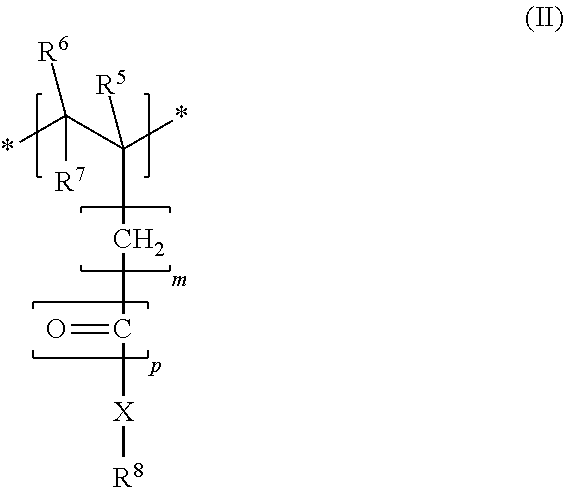

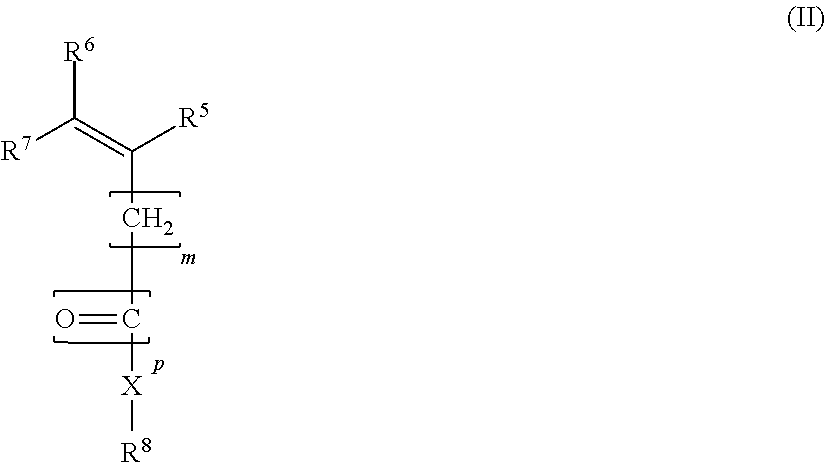

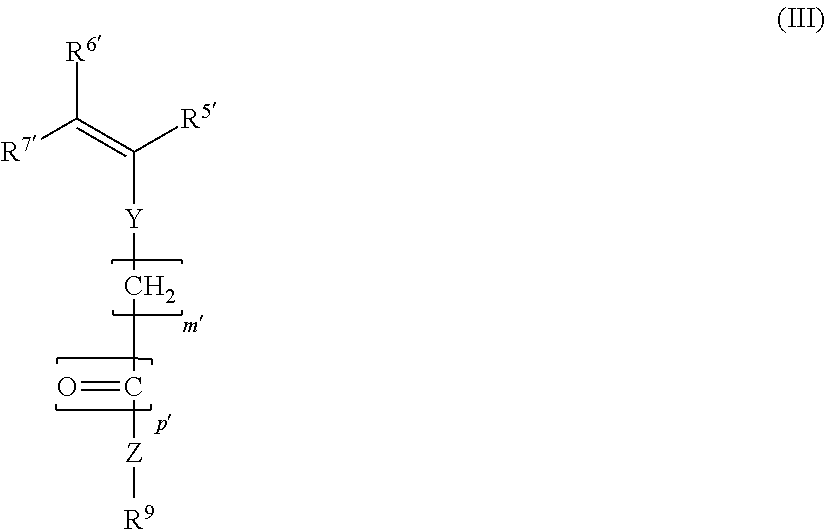

Copolymers having a gradient structure

The present invention relates to a copolymer, especially for use as a dispersant for solid particles, in particular for use as dispersant for mineral binder compositions, having a polymer backbone and side chains bonded thereto, comprising at least one ionizable monomer unit M1 and at least one side chain-bearing monomer unit M2, wherein the copolymer has a gradient structure in at least one section A in a direction along the polymer backbone with regard to the ionizable monomer unit M1 and / or with regard to the side chain-bearing monomer unit M2.

Owner:SIKA TECH AG

Block copolymer

A block copolymer, in particular for use as a dispersant for mineral binder compositions, including at least one first block A and at least one second block B, wherein the first block A has a monomer unit M1 and the second block B has a monomer unit M2. To this end a proportion of monomer units M2 which is in any case present in the first block A is less than 25 mol %, in particular less than or equal to 10 mol %, based on all the monomer units M1 in the first block A and a proportion of monomer units M1 which is in any case present in the second block B is less than 25 mol %, in particular less than or equal to 10 mol %, based on all the monomer units M2 in the second block B.

Owner:SIKA TECH AG

Copolymers having phosphorus group-carrying monomeric units

A copolymer, in particular a dispersant for solid particles, in particular a dispersant for mineral binder compositions, including a polymer backbone and sidechains bound thereto. Said copolymer includes at least one phosphorus group-carrying monomeric unit M1 and at least one sidechain-carrying monomeric unit M2, the copolymer having, in a direction along the polymer backbone, a non-random distribution of the monomeric units M1 and / or of the monomeric units M2.

Owner:SIKA TECH AG

Process for steam drawing carbon-fiber precursor acrylic fiber bundle

ActiveUS10604871B2Avoid breakingStably obFilament manufactureMonocomponent synthetic polymer artificial filamentPolymer scienceCarbon fibers

This process for manufacturing a carbon-fiber precursor acrylic fiber bundle and this steam drawing apparatus are characterized in that the drawing of an acrylic fiber bundle with a pressured-steam drawing apparatus is conducted by: opening an acrylic fiber bundle by blowing a fluid thereto; supplying humidifying steam to the opened acrylic fiber bundle at a fiber temperature of 80 to 130° C. to adjust the water content of the fiber bundle to 3 to 7%; and thereafter drawing the resulting acrylic fiber bundle in a pressurized-steam atmosphere. Thus, the present invention can prevent the breaking of a single fiber, the fluffing of the fiber bundle, and the breaking of the whole of the fiber bundle, though such defects are susceptible to occurring in a case where an acrylic fiber bundle is drawn by steam drawing at a high draw ratio, at a higher speed, or into a fiber having a small denier.

Owner:MITSUBISHI CHEM CORP

Block copolymer

Owner:SIKA TECH AG

Copolymers having a gradient structure

The present invention relates to a copolymer, especially for use as a dispersant for solid particles, in particular for use as dispersant for mineral binder compositions, having a polymer backbone and side chains bonded thereto, comprising at least one ionizable monomer unit M1 and at least one side chain-bearing monomer unit M2, wherein the copolymer has a gradient structure in at least one section A in a direction along the polymer backbone with regard to the ionizable monomer unit M1 and / or with regard to the side chain-bearing monomer unit M2.

Owner:SIKA TECH AG

Additive containing a superplasticizer and a copolymer

The present invention relates to admixtures, especially a dispersant for solid particles, in particular a dispersant for mineral binder compositions, comprising:a) a superplasticizer andb) a copolymer having a polymer backbone and side chains bonded thereto, comprising at least one ionizable monomer unit M1 and at least one side chain-bearing monomer unit M2, wherein the copolymer has a nonrandom distribution of the monomer units M1 and / or the monomer units M2 in a direction along the polymer backbone,and wherein the superplasticizer and the copolymer differ from a chemical and / or structural point of view.

Owner:SIKA TECH AG

Dispersant for calcium sulphate-based compositions

Owner:SIKA TECH AG

Liquid plasticising composition

A composition that is liquid at room temperature includes at least one 1,4:3,6-dianhydrohexitol diester (A); and at least one compound (B), selected from modified fatty acids and modified fatty acid esters, the compound including at least one epoxy and / or acetyl function. The liquid composition includes at least 60% by weight of constituents (A) and (B).

Owner:ROQUETTE FRERES SA

Method for manufacturing acrylonitrile based fiber bundle and method for manufacturing carbon fiber bundle

ActiveUS11286581B2Easy to processRaise the draw ratioArtificial thread manufacturing machinesArtificial filament heat treatmentCarbon fibersFiber bundle

A drawing method is provided which enables a pressurized steam drawing of an acrylonitrile-based fiber bundle used as the precursor fiber of the carbon fiber bundle. In particular, a drawing method is provided which realizes a high processability when this treatment is conducted at a high draw ratio and high speed. This invention is a method for producing an acrylonitrile-based fiber bundle which includes the steps of spinning a spinning solution containing an acrylonitrile-based copolymer, and subjecting the fiber bundle to a pressurized steam drawing in a pressurized steam drawing apparatus (A) having at least two zones which are a preheating zone on the fiber bundle inlet side and a heating zone on the fiber bundle exit side, the two zones being separated by a seal member. The preheating zone is in a pressurized steam atmosphere at 0.05 to 0.35 MPa, the heating zone is in a pressurized steam atmosphere at 0.45 to 0.70 MPa, temperature difference ΔT1 in the preheating zone of the steam drawing apparatus in the fiber bundle-moving direction defined in the specification is up to 5° C., and temperature difference ΔT2 in the preheating zone of the steam drawing apparatus in the cross-sectional direction of the steam drawing apparatus defined in the specification is up to 5° C.

Owner:TORAY IND INC

Novel efficient energy-saving low smoke zero halogen extruder

The invention discloses a novel efficient energy-saving low smoke zero halogen extruder. The novel efficient energy-saving low smoke zero halogen extruder comprises a rack, and a spiral cylinder is arranged on the rack. A plurality of heating partitions are evenly arranged on the cylinder wall of the spiral cylinder and are sleeved with an electromagnetic heating device in a fixed mode. A threaded rod is arranged in the spiral cylinder, and extruding threads are arranged on the surface of the threaded rod. The surface of the threaded rod is sequentially divided into a power input part, a feeding section, a primary compression section, a primary fusion section, a secondary compression and fusion section and a metering section. The power input part is connected with a power mechanism. Distances and depths of the threads at the feeding section are equal. Distances of the threads at the primary compression section are equal, and the depths of the threads at the primary compression section are not equal and gradually become larger. Raw materials are fused at the primary fusion section and extruded into the secondary compression and fusion section. An assisting thread matched with the extruding threads is arranged on the surface of the secondary compression and fusion section, and the secondary compression and fusion section conducts compression and fusion at the same time. The novel efficient energy-saving low smoke zero halogen extruder is reasonable in design, convenient to operate, capable of effectively controlling temperature and environmentally friendly, the production speed is increased, and energy is saved.

Owner:KUNSHAN FUCHUAN ELECTRICAL MACHINERY TECH

Additive containing a superplasticizer and a copolymer

The present invention relates to admixtures, especially a dispersant for solid particles, in particular a dispersant for mineral binder compositions, comprising:a) a superplasticizer andb) a copolymer having a polymer backbone and side chains bonded thereto, comprising at least one ionizable monomer unit M1 and at least one side chain-bearing monomer unit M2, wherein the copolymer has a nonrandom distribution of the monomer units M1 and / or the monomer units M2 in a direction along the polymer backbone,and wherein the superplasticizer and the copolymer differ from a chemical and / or structural point of view.

Owner:SIKA TECH AG

Plasticizer composition and resin composition including the same

ActiveUS10731026B2Easy to processEffective plasticizationOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePlasticizer

The present invention relates to a plasticizer composition and a resin composition including the same, and can provide a plasticizer composition in which three types of terephthalate-based materials and three types of cyclohexane 1,4-diester-based materials are mixed, and by which environmental friendliness can be secured, mechanical properties such as tensile strength and an elongation rate, physical properties such as migration properties and volatile loss can be improved to levels equal to or higher than those of existing products, and effects of improving processability and plasticizing efficiency can be expected, and a resin composition including the same.

Owner:LG CHEM LTD

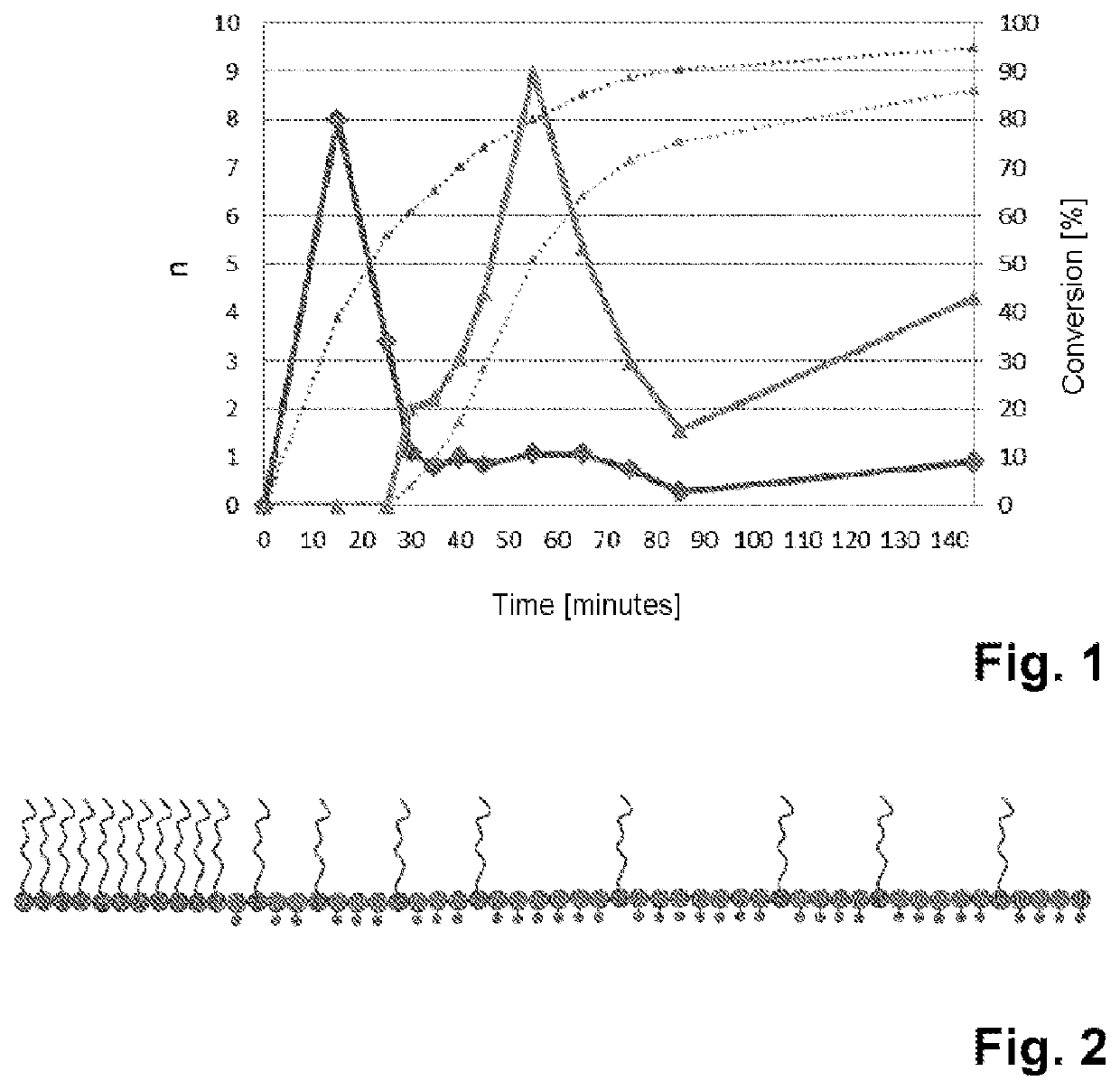

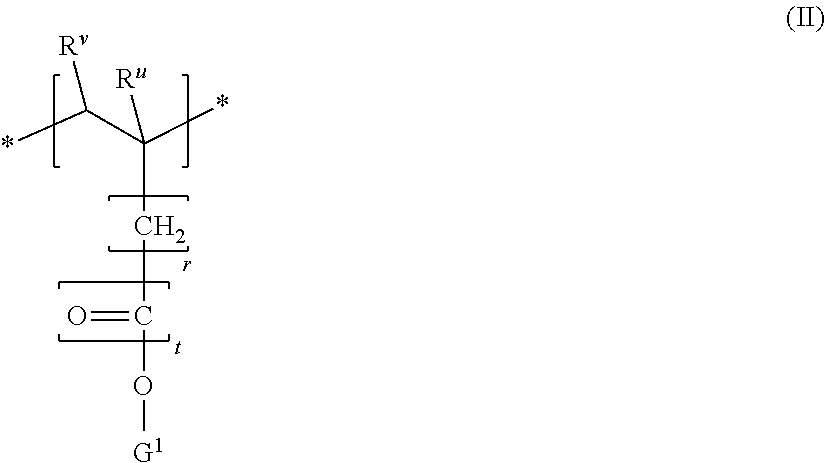

Production of dispersants by nitroxide-mediated solution polymerization

Owner:SIKA TECH AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com