Fast plasticizing coating for frozen confection

A frozen dessert and coating technology, which is applied in the coating and application of frozen desserts and foods, can solve the problems of coating cracking and fat shrinkage, and can reduce the level, shorten the solidification time, and accelerate the drying/solidification of the coating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

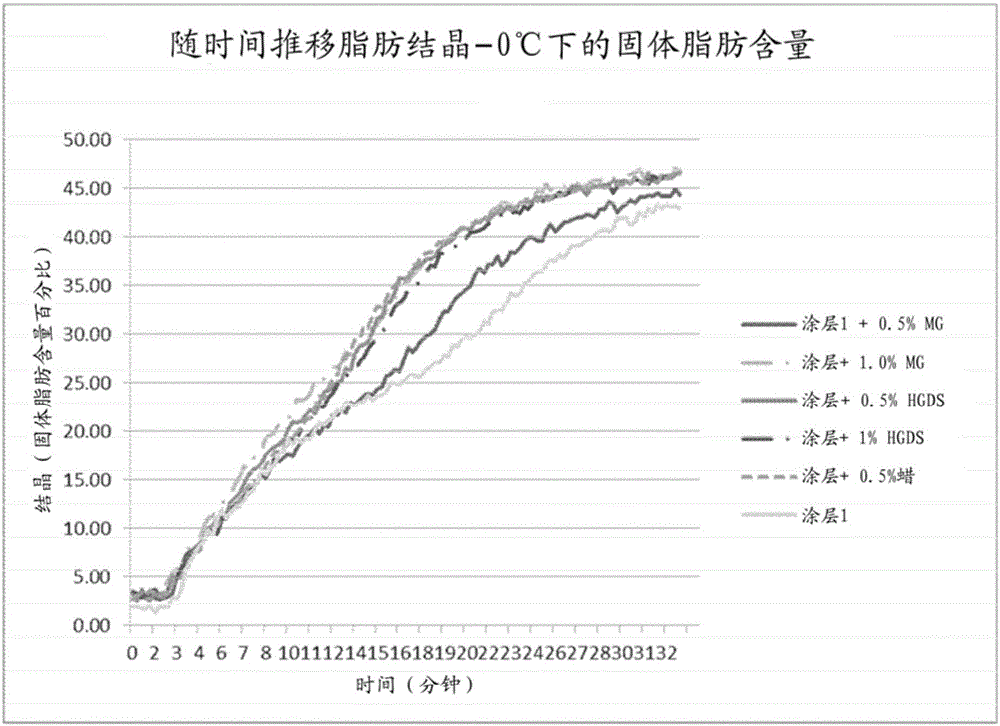

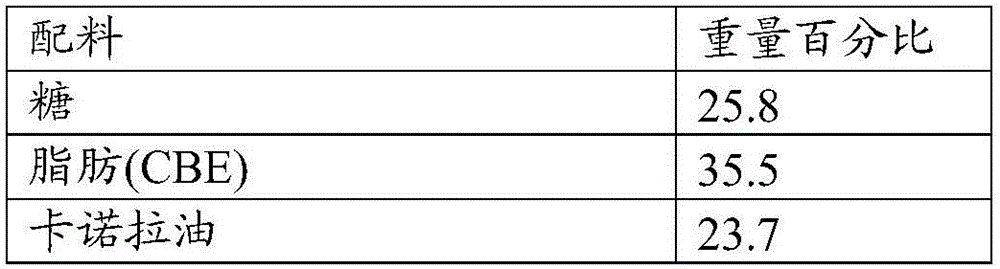

[0058] The effect of structuring agents was tested in two low SFA coatings with different fat content and SFA content. Coating 1 (high fat low SFA coating) contained 60% fat and 25% SFA and its formulation is given in Table 1.

[0059] The recipe for the high fat low SFA coating is as follows:

[0060] Table 1 - Formulation of Coating 1

[0061]

[0062]

[0063] The coating contained 25% saturated fat and the coating took a long time to set (more than 150 seconds). We added a structurant to this coating and measured the time to drip and time to dry.

[0064] Incorporation of emulsifiers / additives into coatings

[0065] Weigh a certain amount of emulsifier / additive, add it to the melted coating, heat the coating to 60°C to 70°C, stir until the additive is seen to melt / dissolve. Cool the coating, maintained at 39°C to 41°C, for dipping experiments.

[0066] Dip test

[0067] The low SFA coating (control) and the additive / emulsifier added coating were placed in...

Embodiment 2

[0073] Coating 2 was a lower fat coating than Coating 1 and contained only 14% SFA. The formulation of this low fat low SFA coating is as follows:

[0074] Table 3 - Formulation of Coating 2

[0075]

weight percentage

42.64

CBE

17.19

sunflower oil

20.99

cocoa powder

12.48

6.19

0.50

total

100.00

fat percentage

40.05

Percentage of SFA in coating

14%

[0076]Table 4 shows the dipping data for the ice cream bars. Coat 2 is a low fat, low SFA coating with a long dry time (over 150 seconds), such a long dry time is not practical in an industrial production line. Treatment 1, with the addition of 0.5% by weight of candelilla wax, had significantly shorter drip time and dry time than the low SFA coating without additive. Decreasing the drip time will increase the coat weight. This can be addressed by adding lower levels of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com