Alloy for recovering polyethylene glycol terephthalate/acrylonitrile-butadiene-styrene copolymer and preparation method thereof

A polyethylene terephthalate and styrene copolymer technology, which is applied in the field of preparation of recycled PET/ABS alloy, can solve the problem of narrow controllable temperature range of alloy processing, low molecular weight of recycled PET, and difficulty in guaranteeing product quality and other problems, to achieve the effect of improving the overall performance, excellent processability, and preventing the decline of the mechanical properties of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

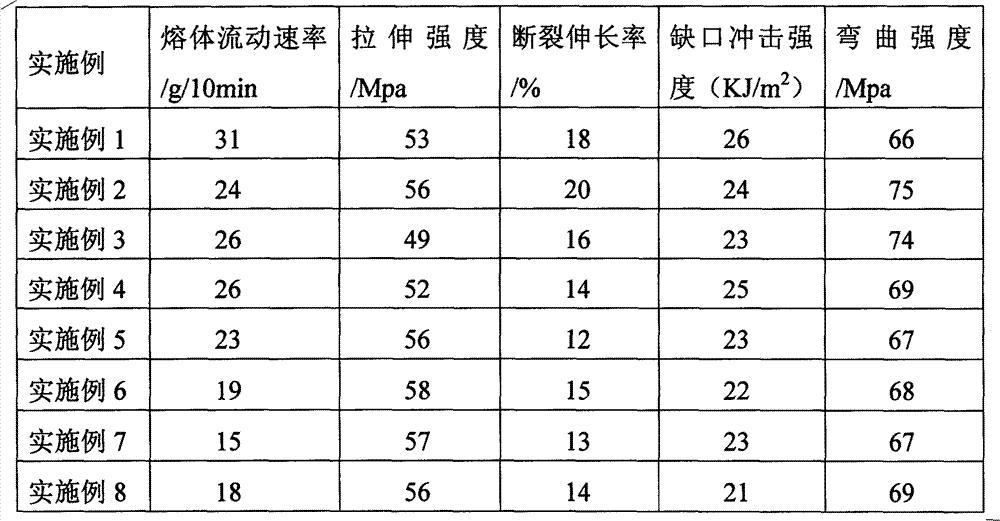

[0042] Take by weighing 60.0% of dried reclaimed PET flakes by weight ratio, ABS resin is 16.0%, ABS-g-MAH compatibilizer is 2.5%, reinforcing agent is 20%, diisocyanate is 0.5%, antioxidant 1010 is 0.2%, antioxidant 168 is 0.3%, lanthanum acetate is 0.4%, light stabilizer V703 is 0.1%. The above-mentioned components are mixed evenly by a high-speed mixer and then added from the discharge port of the extruder. The temperature of each section of the extruder from the discharge port to the grinding port is between 180-200 °C, and the speed of the main engine is 80r / min. . Alloy materials are granulated by melt blending and extruding. The SEM photo of gained recycled PET / ABS alloy is as follows figure 1 The material test results are shown in Table 1.

Embodiment 2

[0044] Weigh 60.0% of dried recycled PET flakes by weight, ABS resin is 11.0%, reinforcing agent is 25%, ABS-g-GMA compatibilizer is 2.0%, and epoxy molecular weight regulator ADR4370S is 0.7% %, antioxidant 1010 is 0.2%, antioxidant 168 is 0.3%, gallium acetate is 0.5%, antistatic agent 129 is 0.3%. The above-mentioned components are mixed evenly by a high-speed mixer and then added from the discharge port of the extruder. The temperature of each section of the extruder from the discharge port to the grinding port is between 180-200 °C, and the main engine speed is 90r / min. . The SEM photo of gained recycled PET / ABS alloy is as follows figure 2 The material test results are shown in Table 1.

Embodiment 3

[0046] Take by weighing 70.0% of the reclaimed PET flakes that dry well, the ABS resin is 12.0%, the reinforcing agent is 15%, the ABS-g-GMA compatibilizer is 1.0%, the epoxy molecular weight regulator is 1.0%, anti- Oxygen 1010 is 0.2%, antioxidant 168 is 0.3%, and lanthanum acetate is 0.5%. The above-mentioned components are mixed evenly by a high-speed mixer and then added from the discharge port of the extruder. The temperature of each section of the extruder from the discharge port to the grinding port is between 180-200 °C, and the speed of the main engine is 100r / min. . The material test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com