Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Easy size control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature resistant hot rolling H section bar with low compression ratio and super-thick specification and production method thereof

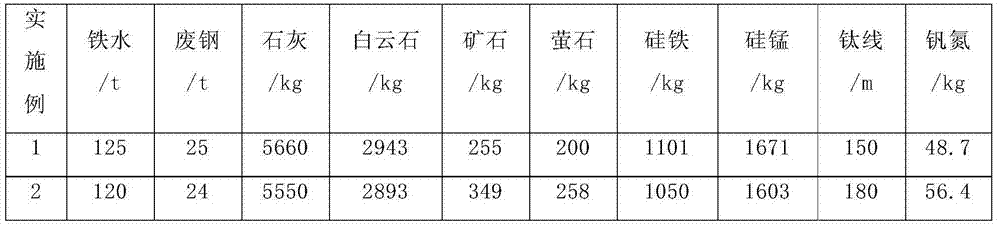

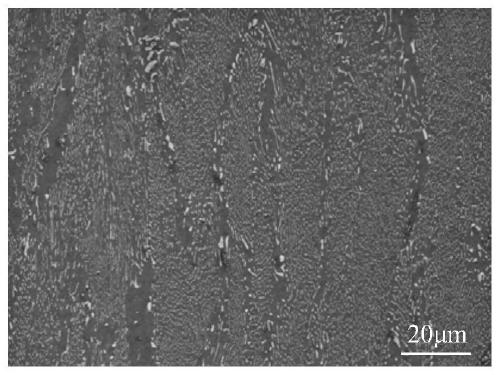

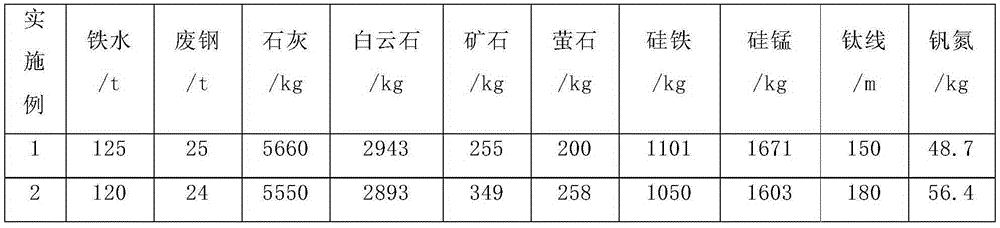

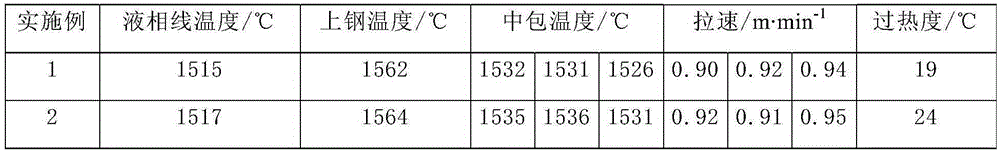

The invention discloses a low-temperature resistant hot rolling H section bar with low compression ratio and super-thick specification and a production method thereof and belongs to the field of hot rolling H section bars. The H section bar is prepared from the following chemical components in percentage by weight: 0.11-0.19% of C, 0.15-0.30% of Si, 1.30-1.55% of Mn, less than or equal to 0.02% of P, less than or equal to 0.008% of S, 0.008-0.020% of Ti, 0.015-0.055% of V and the balance of Fe and inevitable impurities. The production method of the H section bar sequentially comprises the following steps: smelting in a converter or electric furnace; LF (ladle furnace) refining; full protection continuous casting of a beam blank; heating; rolling; and cooling to finally obtain the low-temperature hot rolling H section bar, wherein the flange is over 30mm thick, the compression ratio is less than 3, and the surface is good in quality. The vertical average ballistic work at -20 DEG C is over 150J, so that the H section bar has a wide market application prospect.

Owner:LAIWU IRON & STEEL GRP

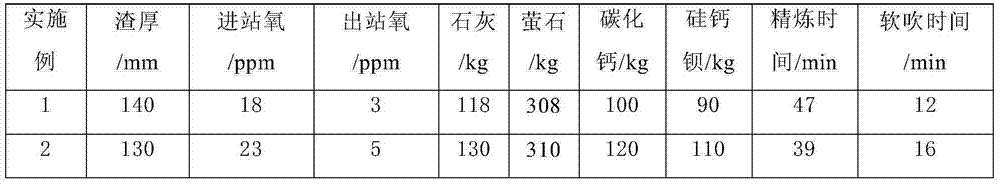

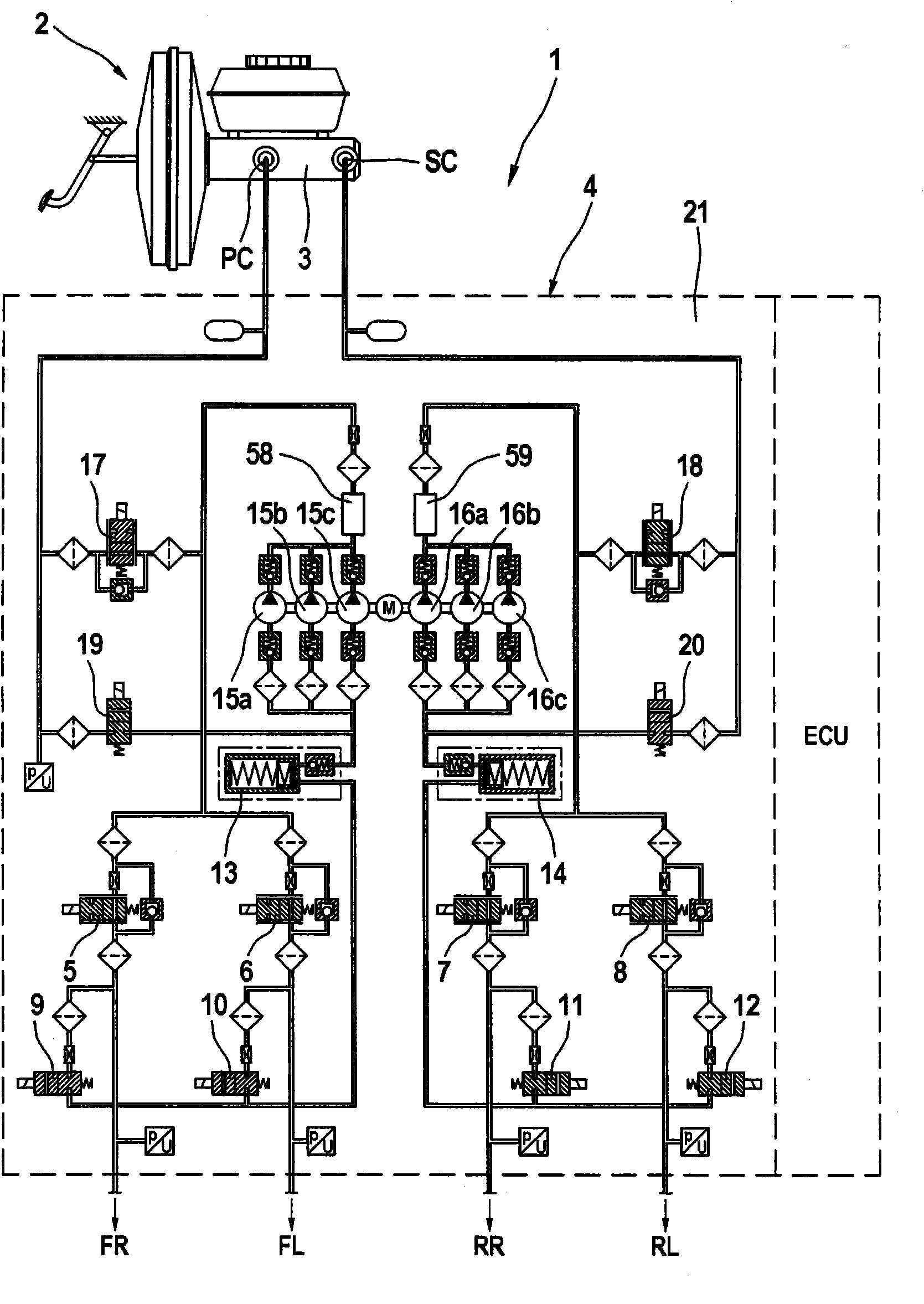

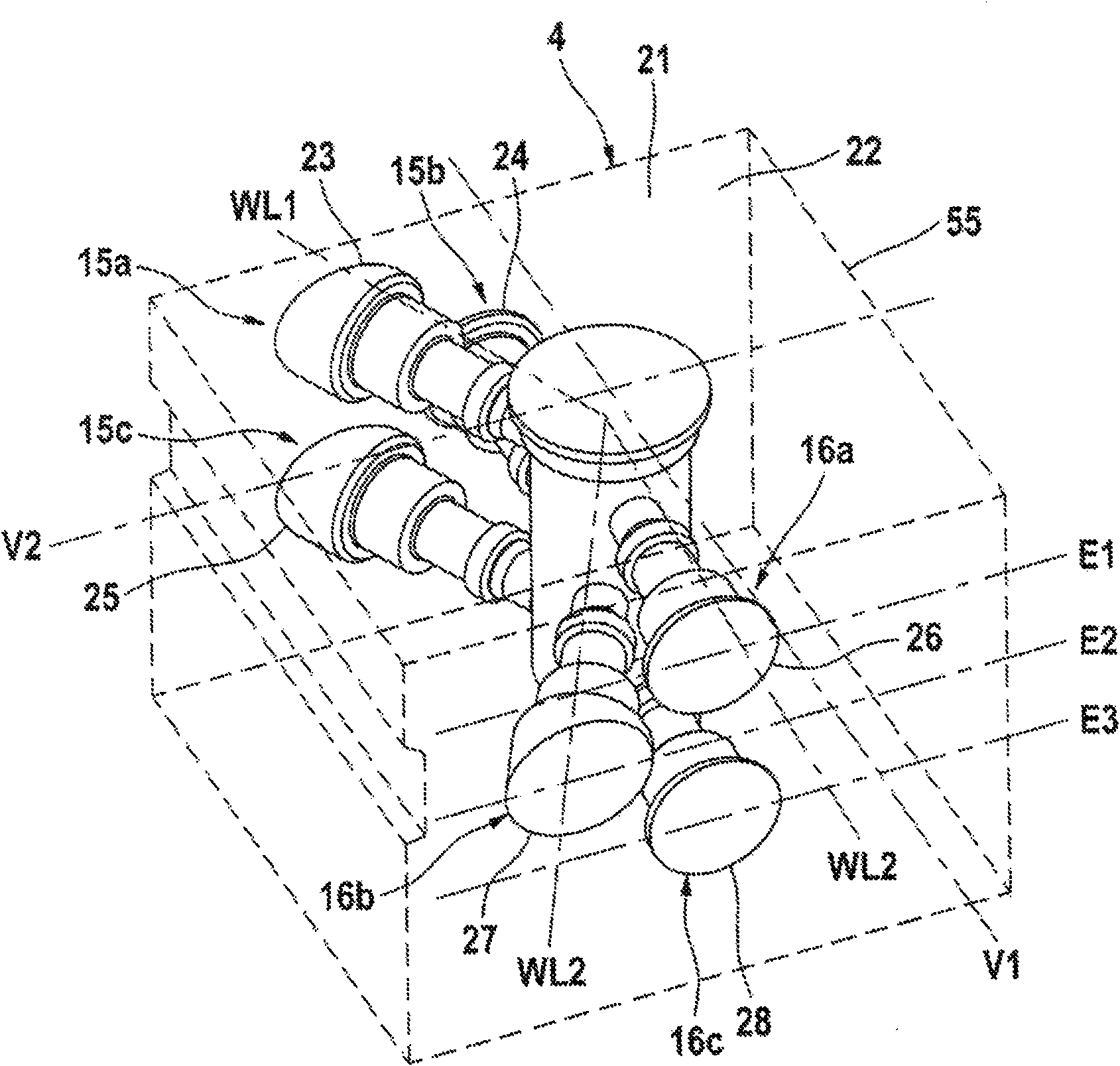

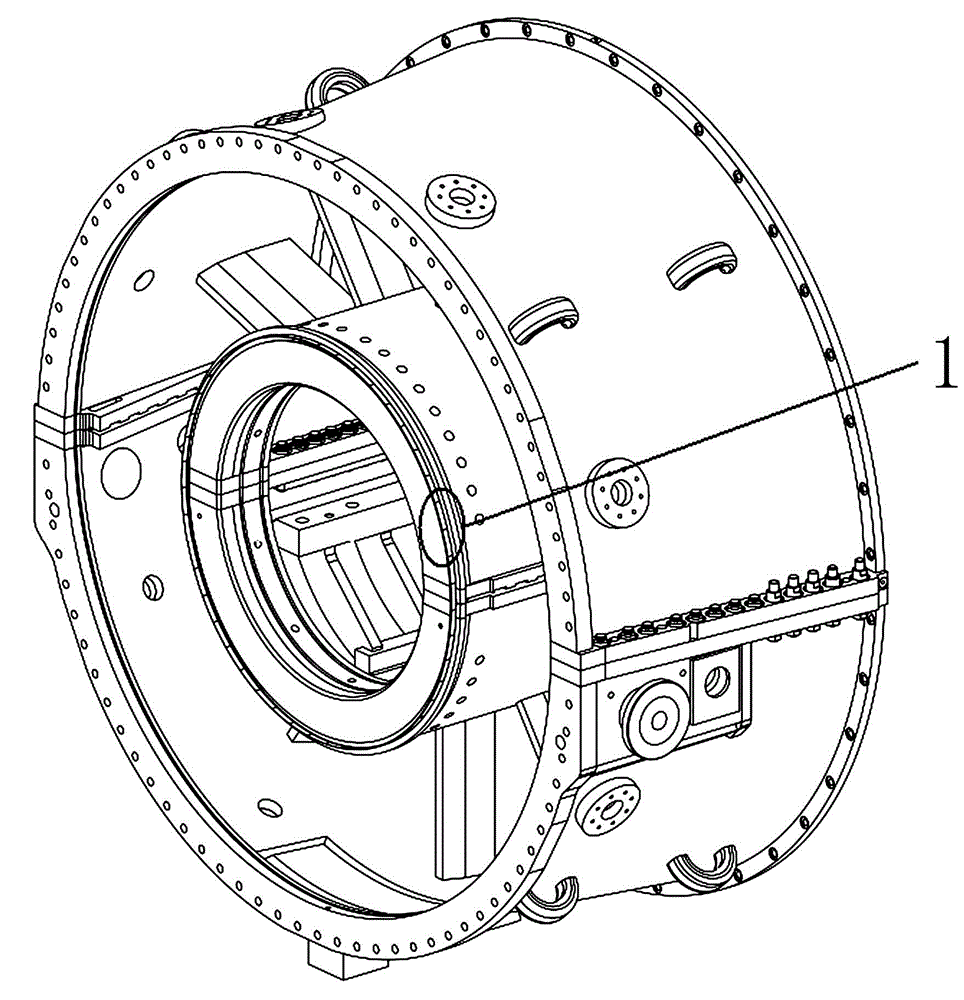

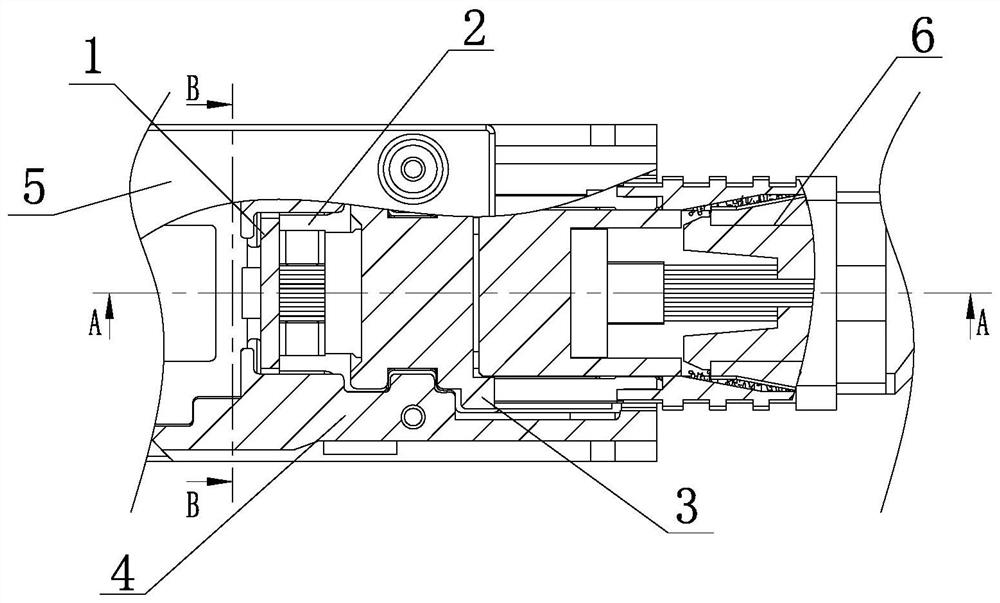

Hydraulic unit for slip-controlled braking systems

ActiveCN101827736AEasy programmingEasy size controlPositive displacement pump componentsPositive-displacement liquid enginesManufacturing technologyDrive shaft

Owner:CONTINENTAL AUTOMOTIVE TECH GMBH

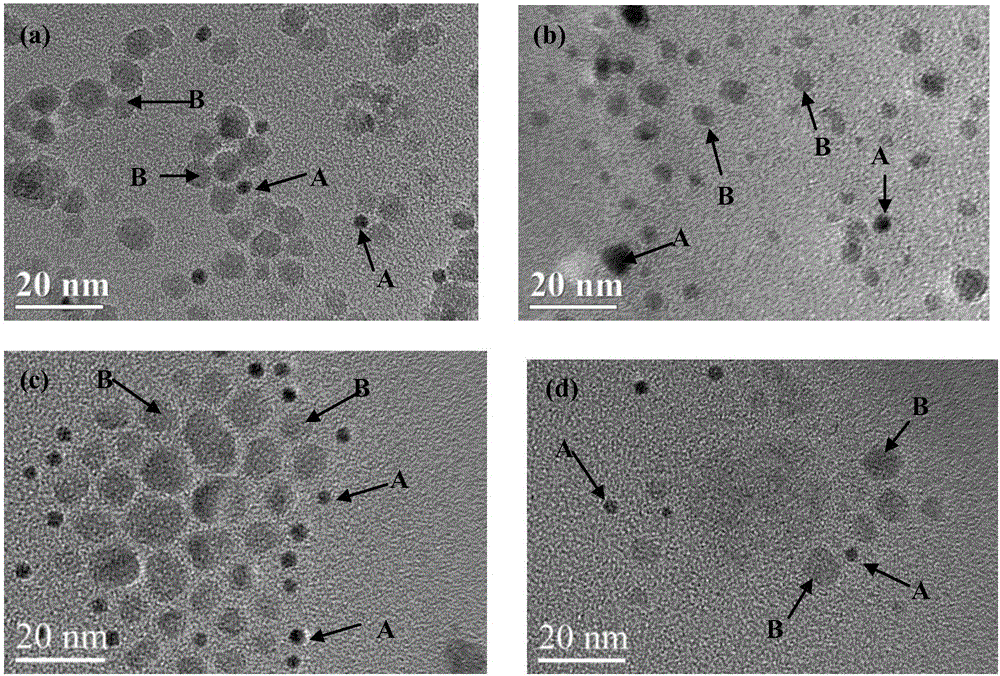

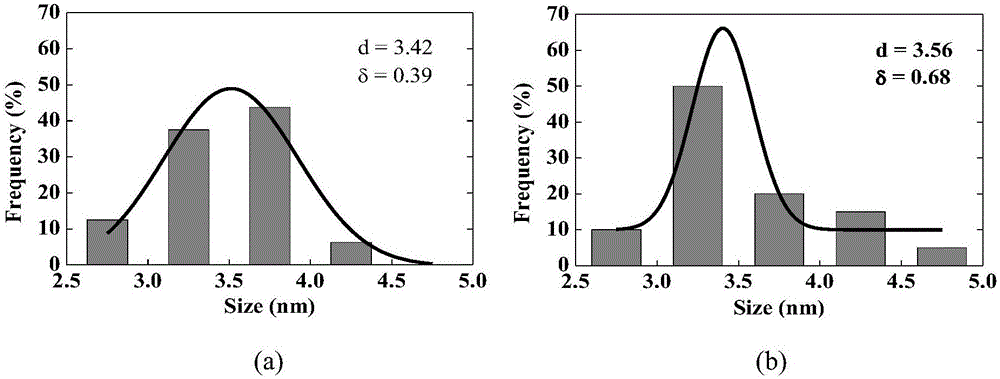

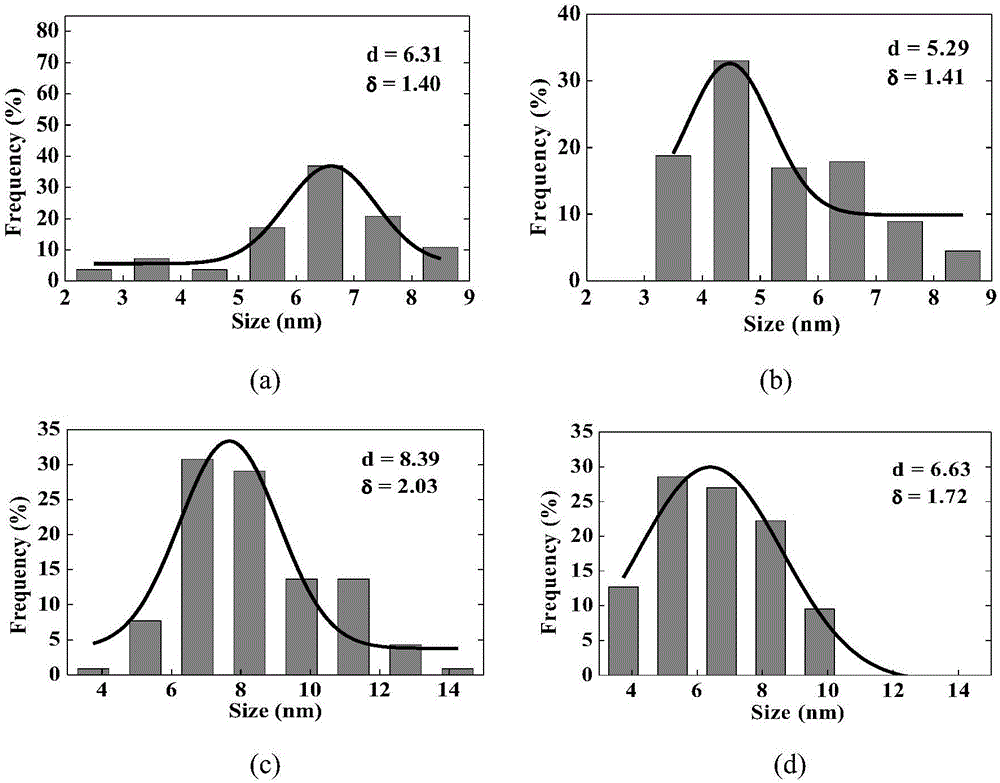

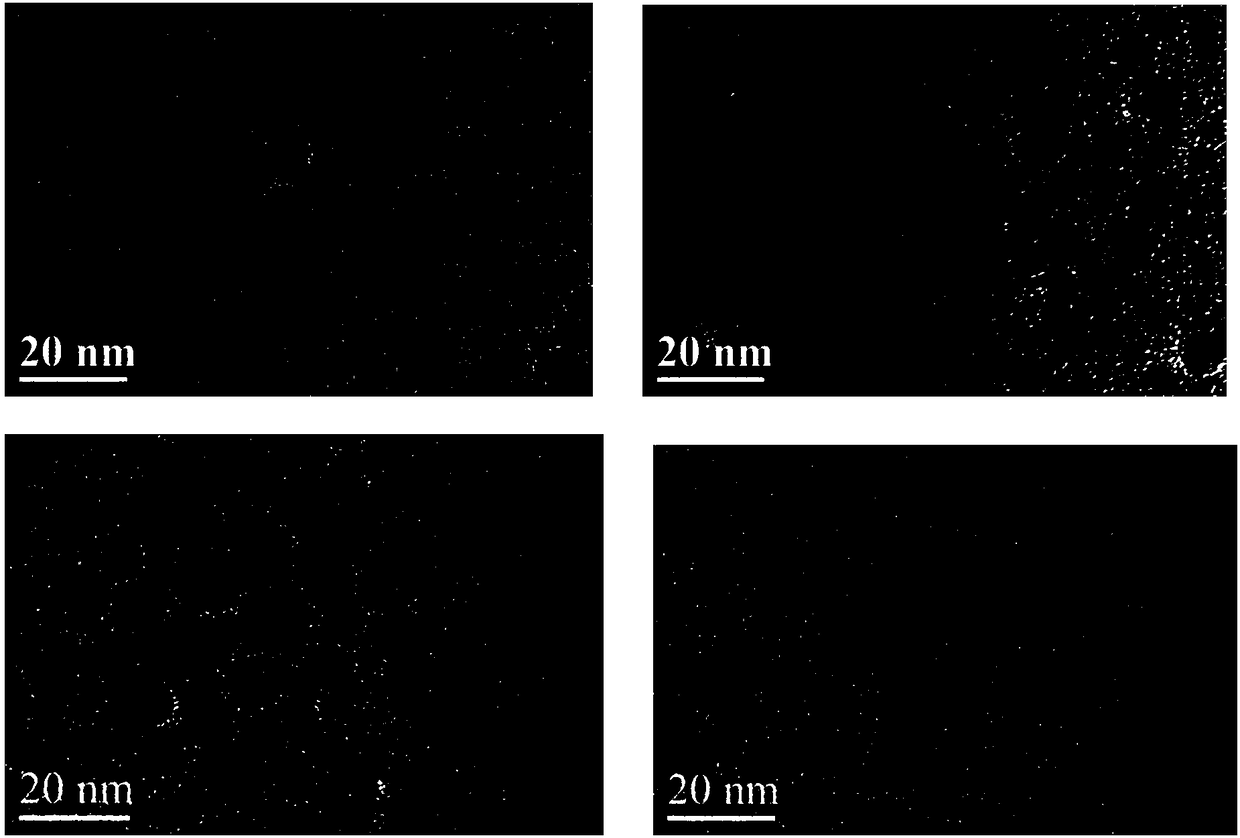

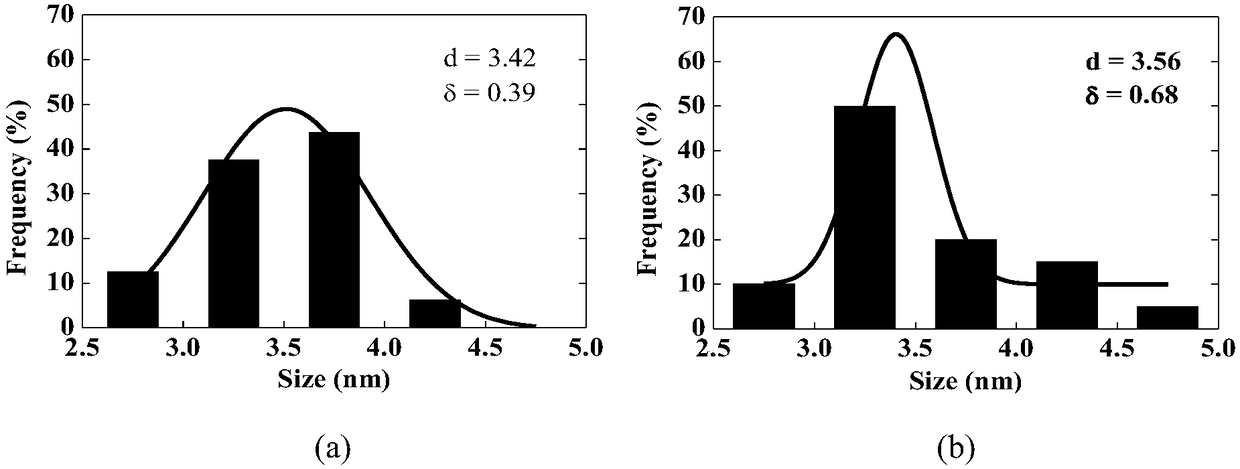

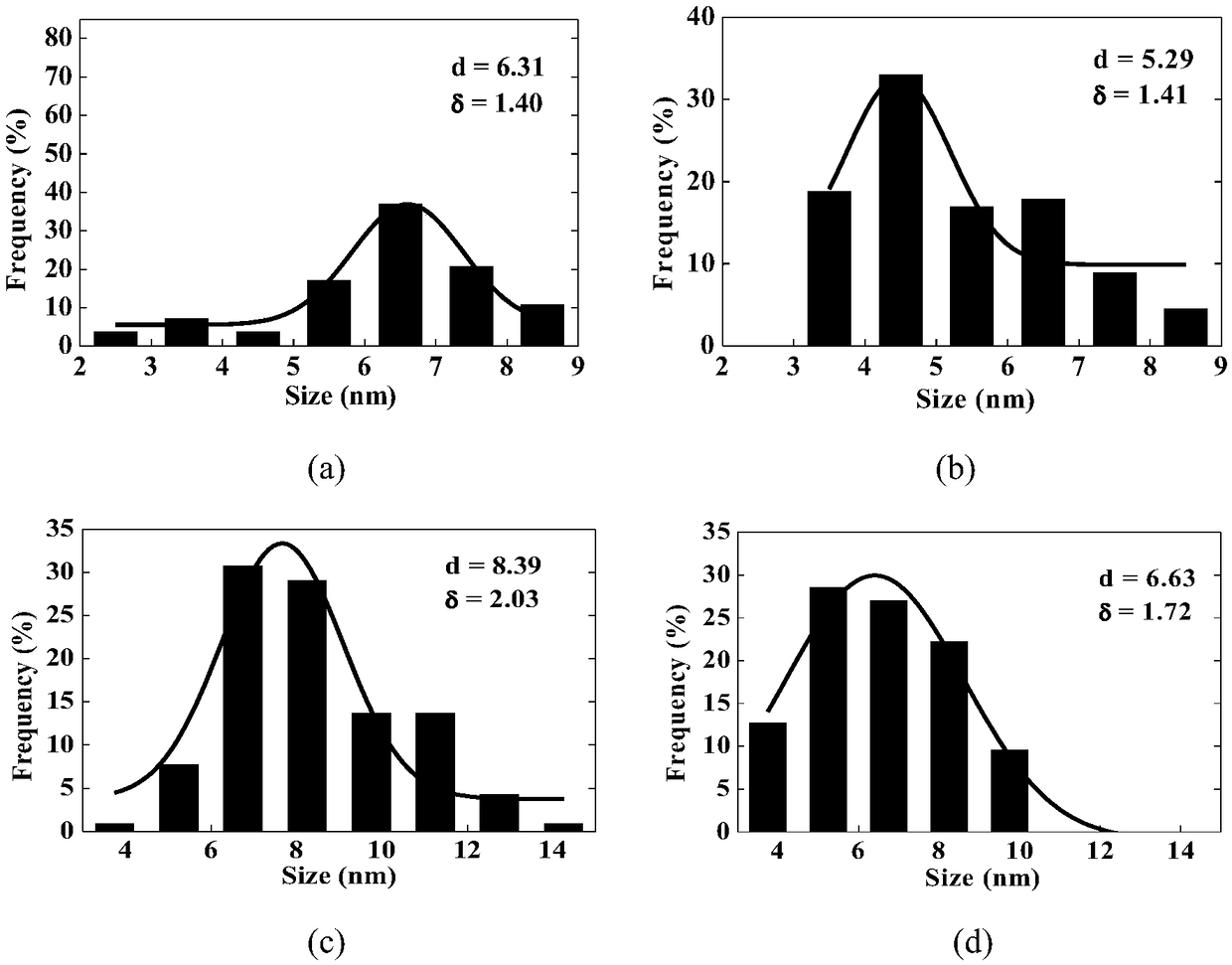

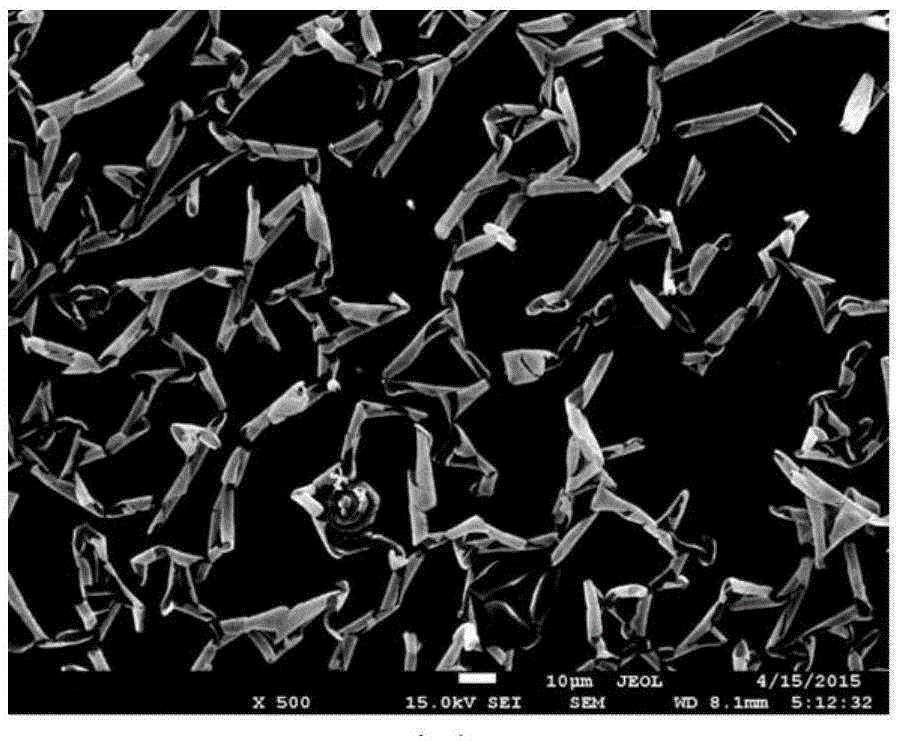

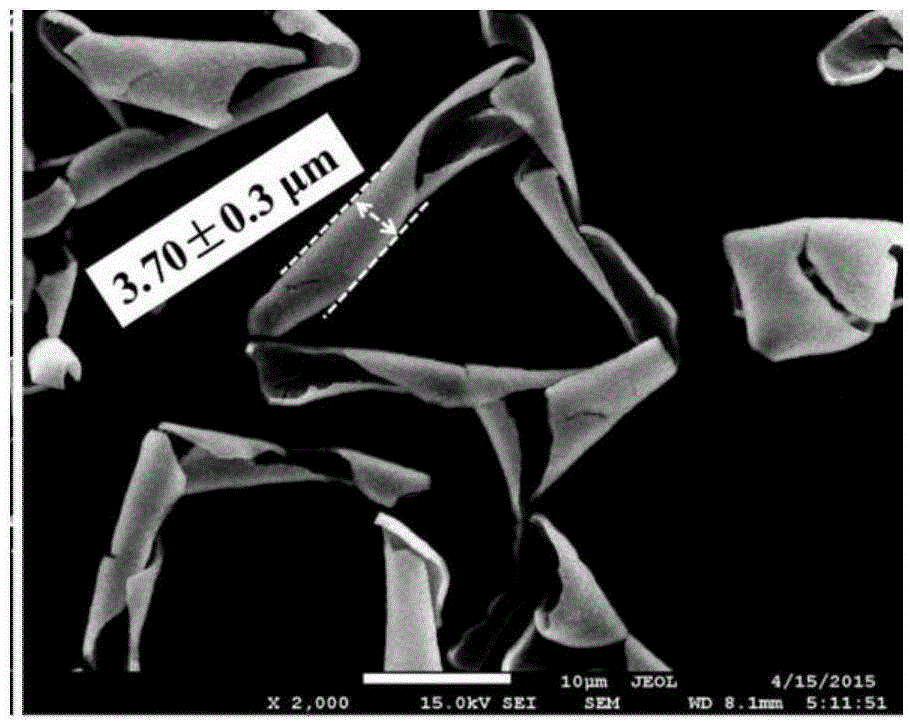

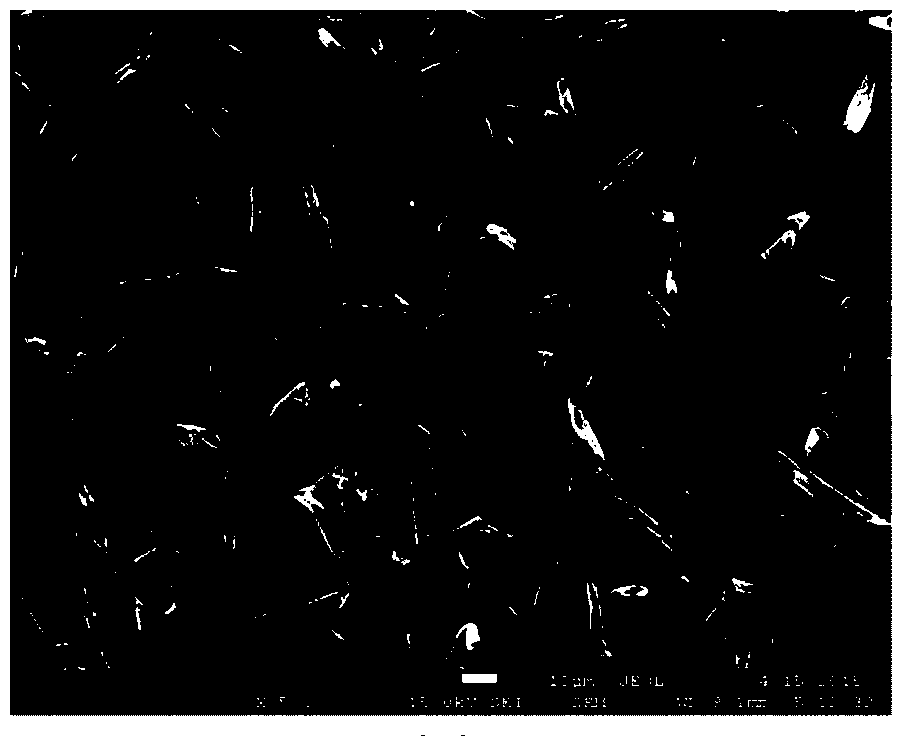

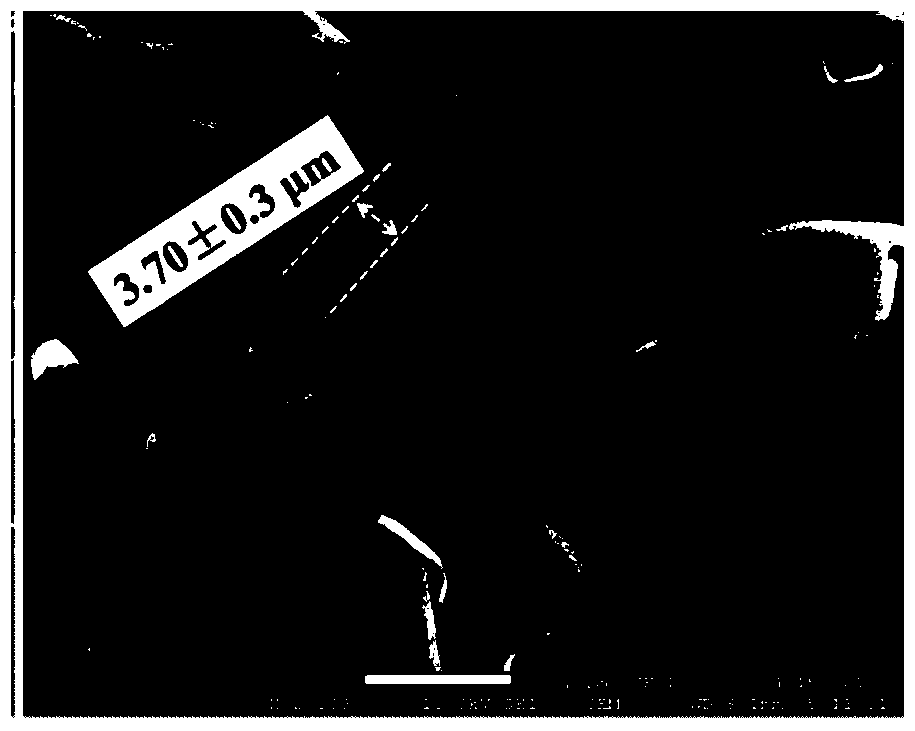

Preparation method for monodispersed FePt/Fe3O4 mixed nanoparticles

ActiveCN106735287AEasy to operateSimple preparation stepsTransportation and packagingMetal-working apparatusAlkaneComposite nanoparticles

The invention provides a preparation method for monodispersed FePt / Fe3O4 mixed nanoparticles and belongs to the technical field of nanometers. The preparation method comprises the steps that (1), in an inert gas atmosphere, oleic acid, oleylamine, a reducing agent and Pt (acac) 2 are sequentially added to a solvent, stirred uniformly and then preheated at the temperature of 100-120 DEG C for 5-30 min, Fe(CO)5 is added, the temperature is increased to 150-280 DEG C and kept for 1-2 h, and FePt nanoparticles are prepared; and (2), the FePt nanoparticles dispersed in an alkane solvent are added to a reaction solvent, the system is heated to 50-250 DEG C in a certain atmosphere, the temperature is kept for 0.5-4 h, and the monodispersed FePt / Fe3O4 mixed nanoparticles are prepared. By the adoption of the method, the FePt / Fe3O4 mixed nanoparticles prepared through an in-situ method have the remarkable beneficial effects of being low in cost, easy to operate, high in product quality, good in stability and the like, and the monodispersed FePt / Fe3O4 mixed nanoparticles prepared through the method provide the convenience condition to application and development of multifunctional composite nanoparticles.

Owner:NORTHEASTERN UNIV

Rolling machining method of sealing tooth section of exhaust connecting pipe

Provided is a rolling machining method of a sealing tooth section of an exhaust connecting pipe. The method comprises the steps that a sheet tooth section is machined; an installation groove for the tooth section is machined in the end face of the connecting pipe; the tooth section is machined to be of a circular arc shape with the radian approximate to that of an integrally-formed circular hole of the sealing tooth section; the tooth section is placed into the installation groove, and three points are uniformly and fixedly riveted on the rolling side to prevent the tooth section from moving; a rolling tool is installed on a vertical lathe, and the rolling machining portion of the connecting pipe is continuously rolled through the rolling tool to deform to extrude the tooth section; a correcting tool is installed on the vertical lathe, and correction is carried out on the inner side or the outer side of the tooth section through the correcting tool; finish turning is carried out on the tooth section. Through the steps, machining of the sealing tooth section of the exhaust connecting pipe is achieved, implementation is convenient, the operation process is simplified, and especially, the requirement for the machining precision of equipment is lowered.

Owner:YICHANG MARINE DIESEL ENGINE

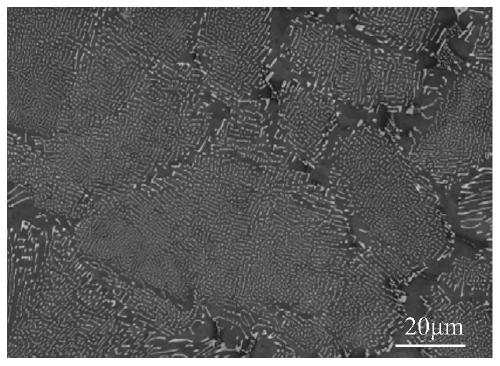

High-conductivity heat-resistant in-situ synthesized aluminum matrix composite material and preparation method thereof

The invention provides a high-conductivity heat-resistant in-situ synthesized aluminum matrix composite material and a preparation method thereof. The aluminum matrix composite material comprises thefollowing elements, in percentage by weight, of 5.00%-15.00% of Ce and the balance aluminum. According to the aluminum matrix composite material, the aluminum is taken as a matrix, cerium and aluminumelements form an Al11Ce3 intermetallic compound, the intermetallic compound is good in thermal stability and is acted as a reinforcing body of the composite material to effectively improve the strength and heat resistance of the material, the cerium element is low in solid solubility in the aluminum and has the effect of purifying the aluminum matrix, so that the influence of the solid solution impurity element on the conductivity is reduced, and the conductivity of the composite material is improved.

Owner:SHANGHAI JIAO TONG UNIV

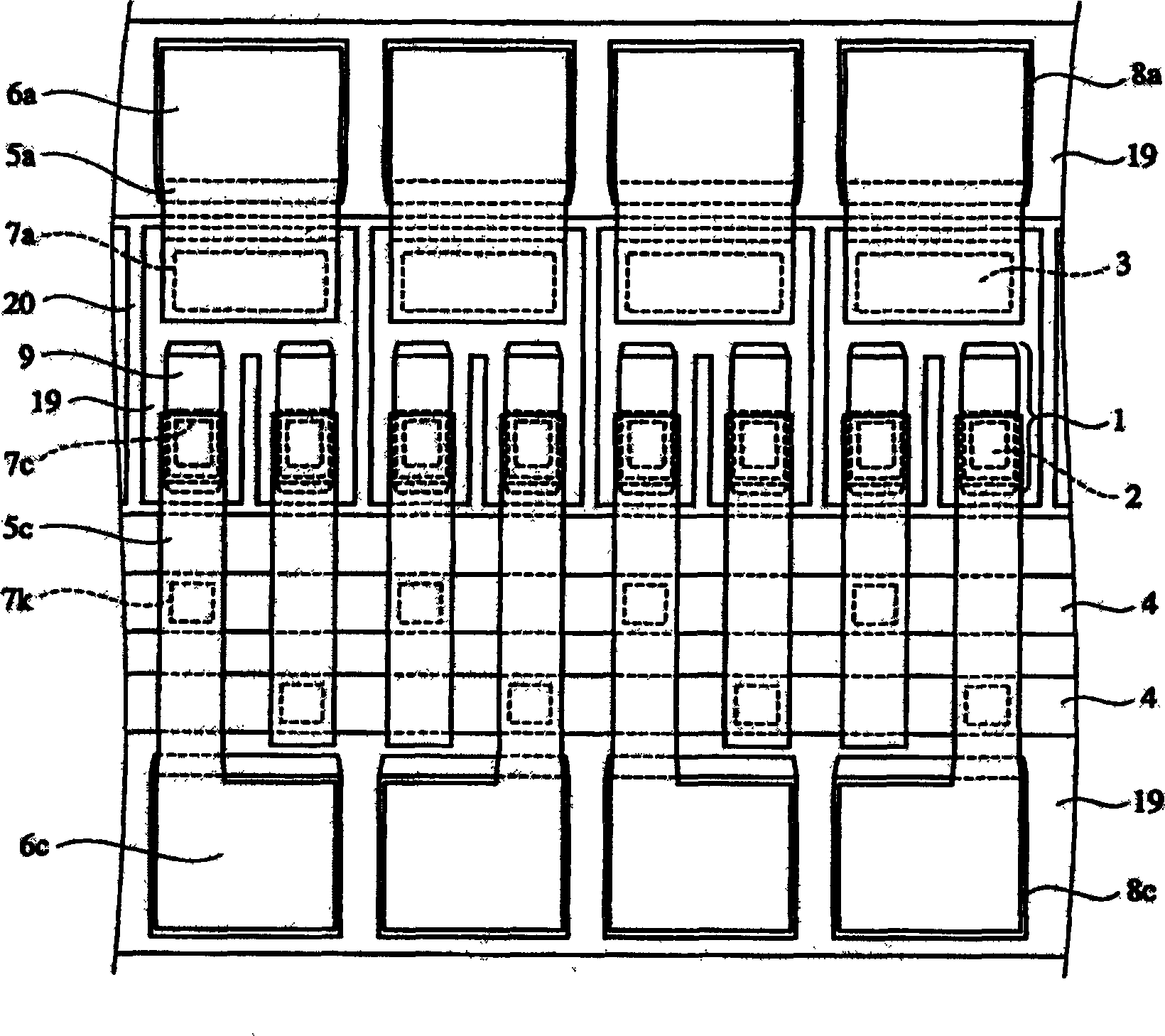

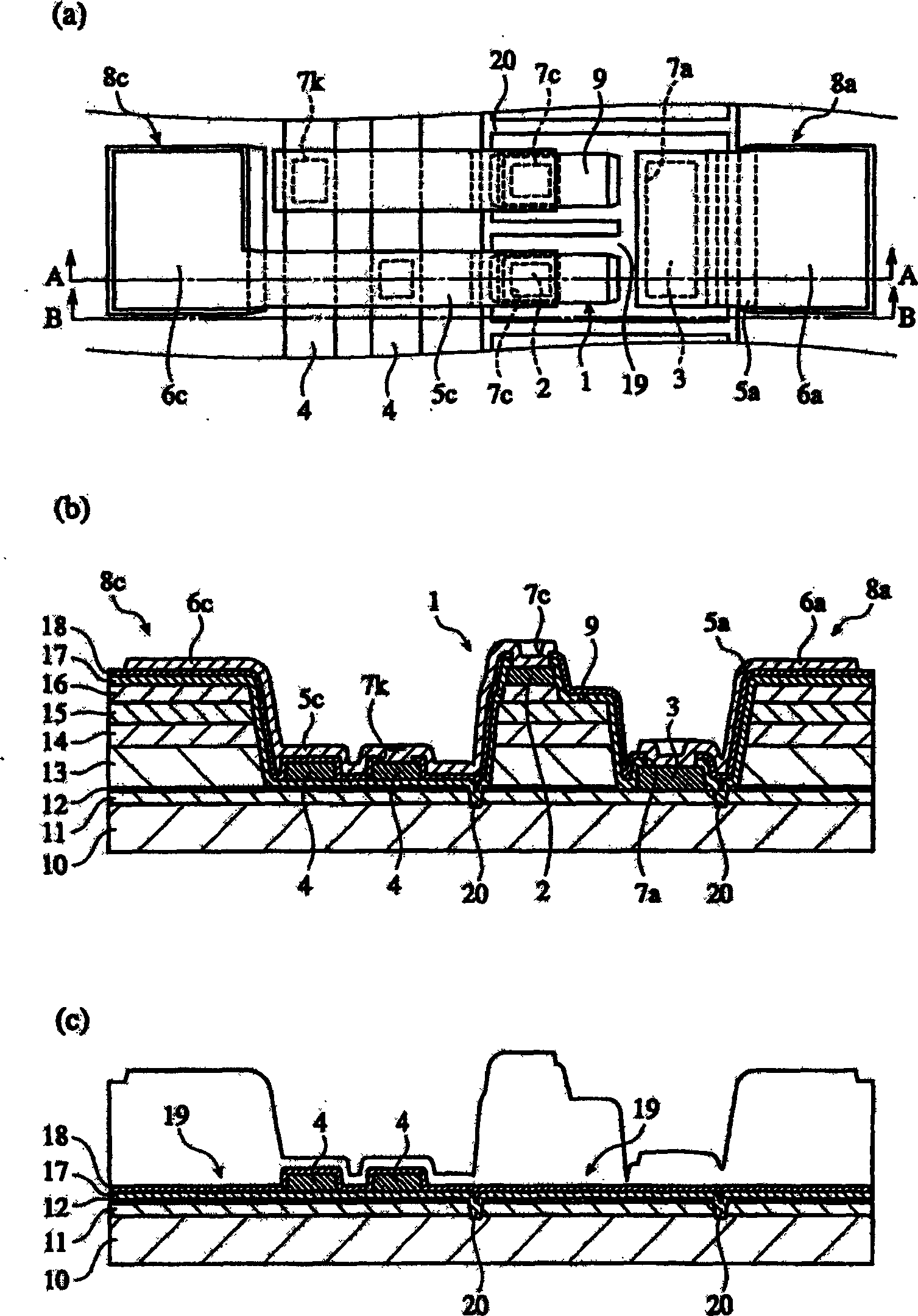

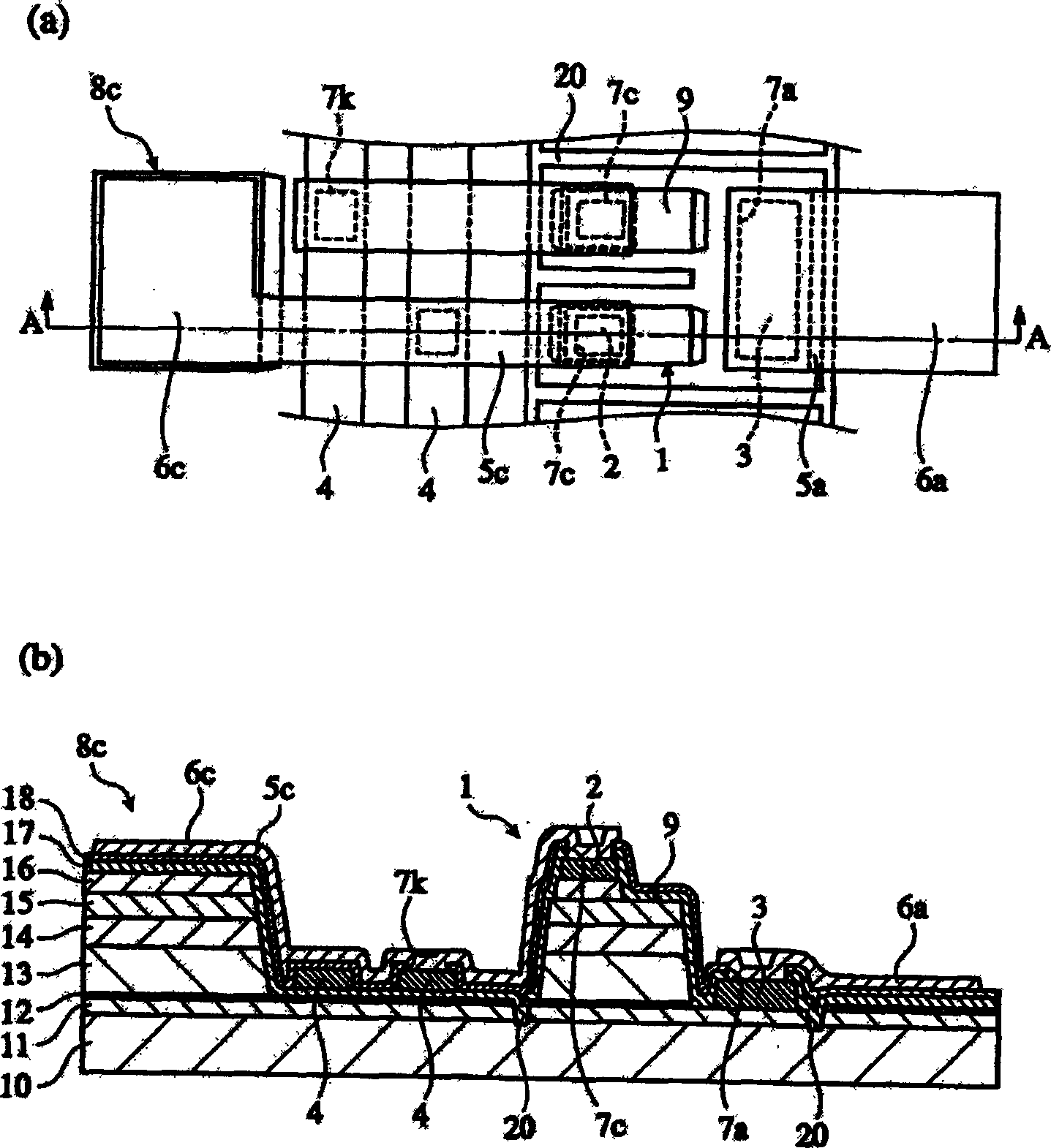

Luminous diode array

InactiveCN1527411AWill not short circuitDoes not increase the etch areaLaser detailsSolid-state devicesEngineeringLight-emitting diode

A light-emitting diode array comprising a conductive layer formed on a substrate, separate light-emitting portions formed on the conductive layer, a first electrode formed on at least part of an upper surface of each light-emitting portion, and a second electrode formed on the conductive layer adjacent to the light-emitting portions; the first electrode comprising a common switching electrode matrix; the second electrode comprising a common electrode divided such that one second electrode exists in every block; and at least one of bonding pads extending to the first common electrode and the second common electrode being formed on a bonding portion formed on the conductive layer like an island, whereby the bonding pads are separate from each other.

Owner:LEXTAR ELECTRONICS CORP

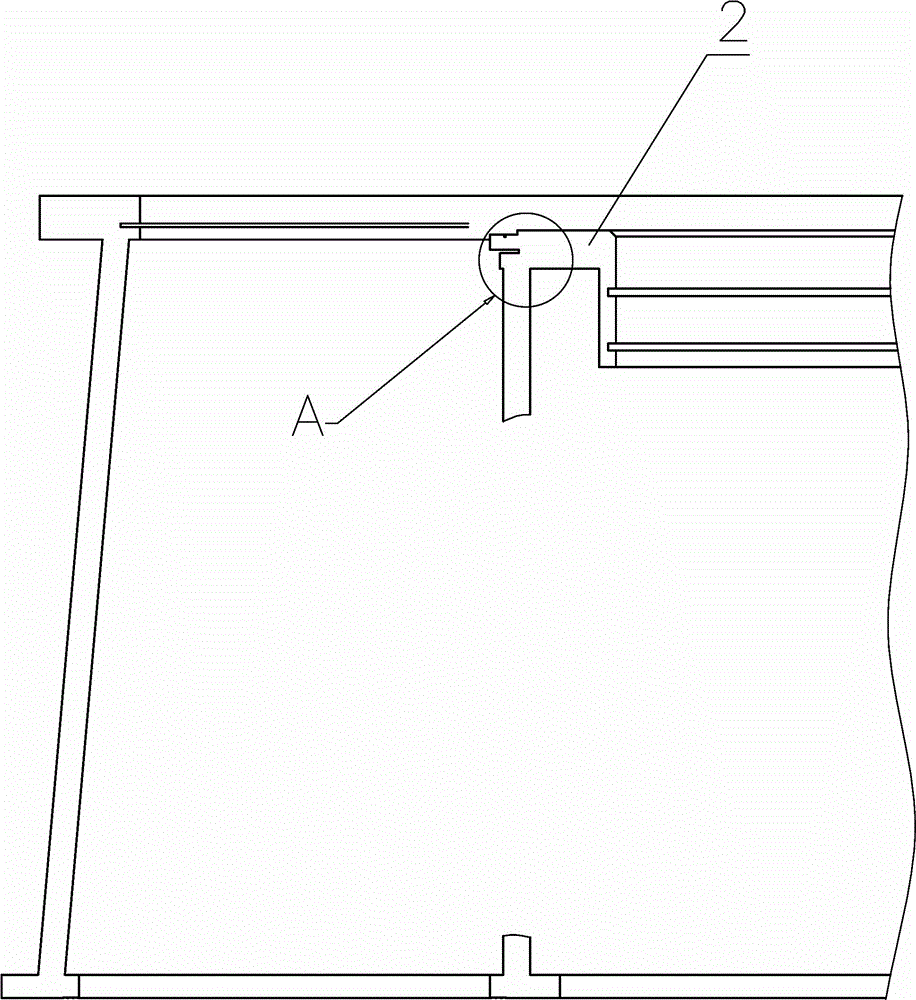

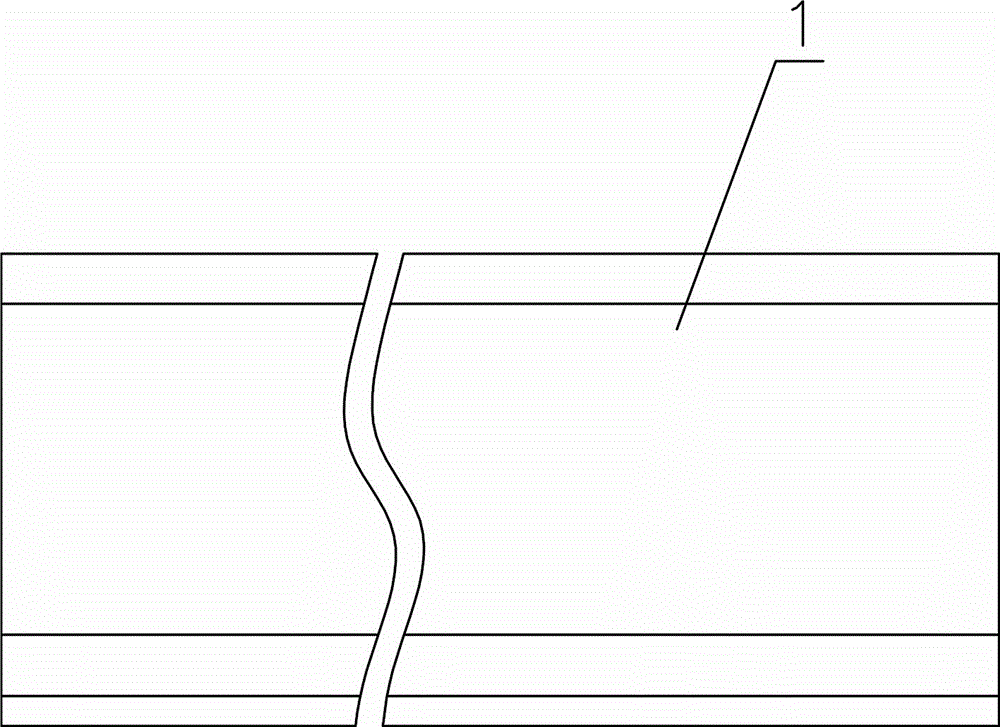

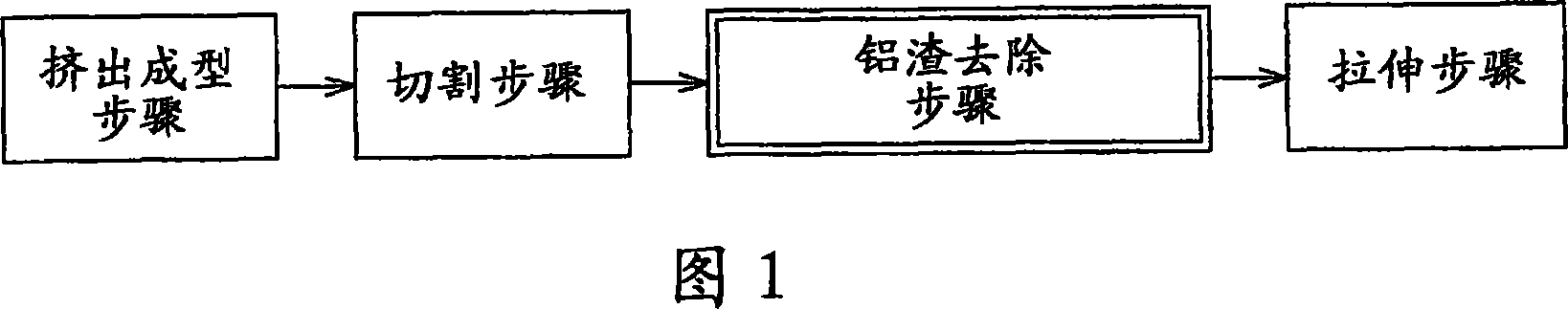

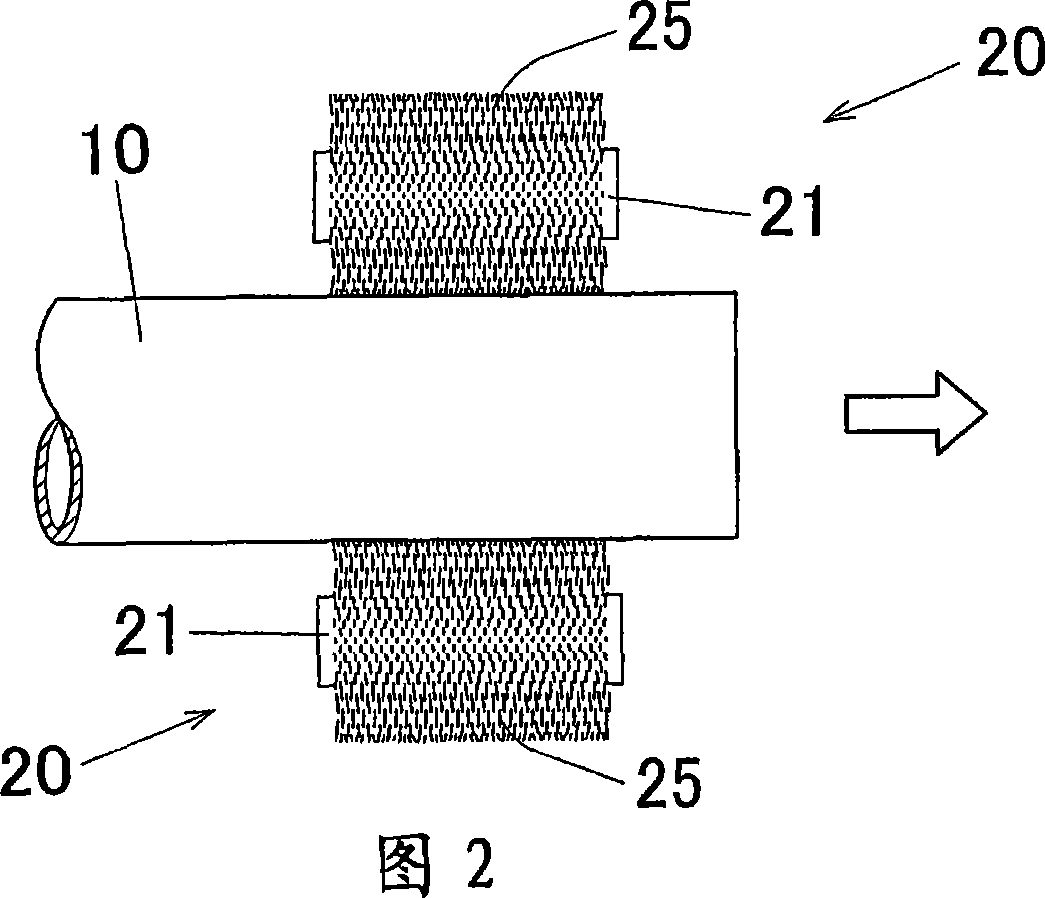

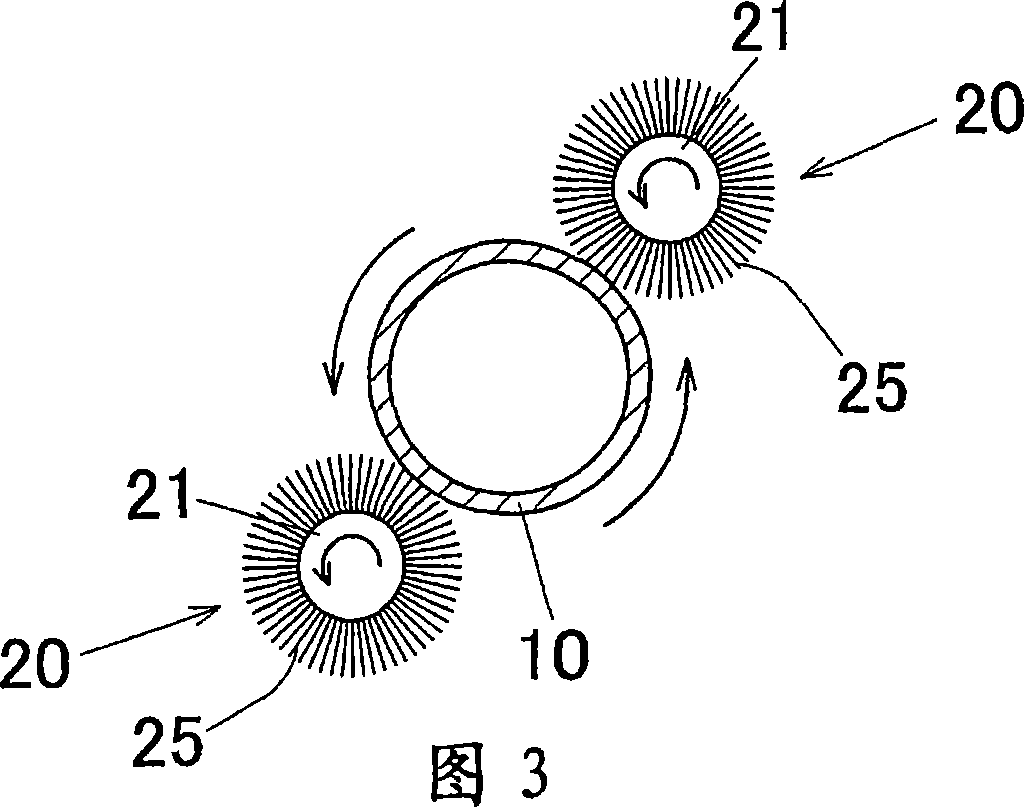

Aluminum pipe production method

InactiveCN101056723AQuality improvementImprove productivityTurning machine accessoriesElectrography/magnetographyMetallurgyIndustrial engineering

The invention is directed to an aluminum pipe product method comprising an extrusion step for obtaining an aluminum raw pipe (10) and a drawing step for executing a drawing process of the aluminum raw pipe (10). Before executing the drawing step, a slug removing step for removing aluminum slugs (1) adhering to a surface of the aluminum raw pipe (10) is executed by rubbing off the aluminum slugs (1). This can provide an aluminum pipe production method capable of preventing generation of defect protrusions while improving the productivity.

Owner:RESONAC HOLDINGS CORPORATION

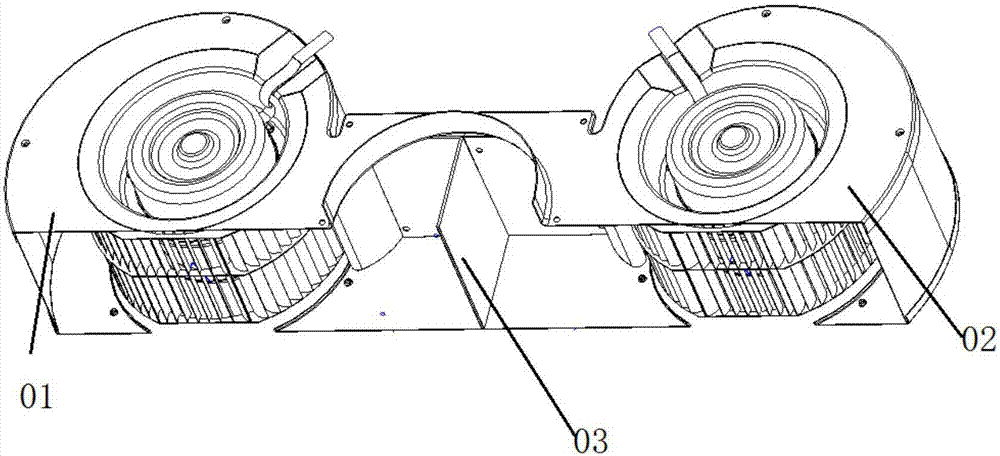

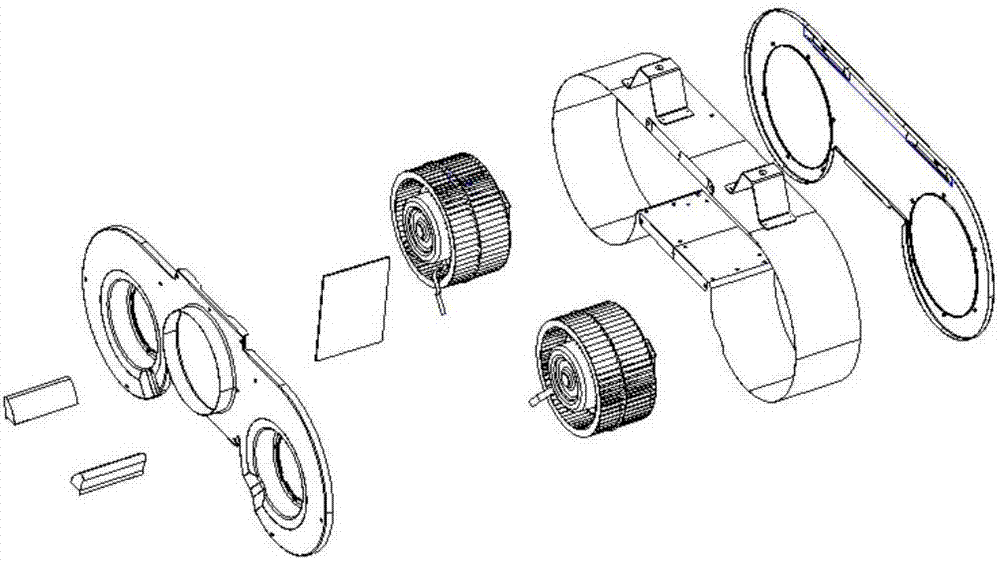

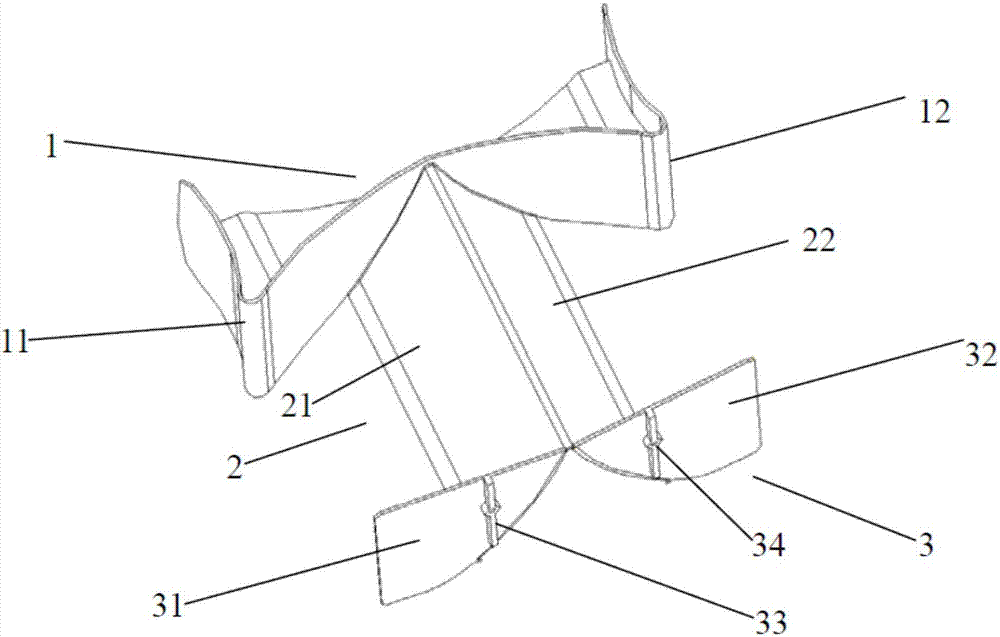

Cooking fume drainage structure applied in double-fan exhaust hood and double-fan exhaust hood

InactiveCN107023867AReduce impact backflowReduce noiseDomestic stoves or rangesLighting and heating apparatusEngineeringBackflow

The invention relates to the field of cooking fume diversion carried out by an exhaust hood, in particular to a cooking fume drainage structure applied in a double-fan exhaust hood and the double-fan exhaust hood. The cooking fume drainage structure is of an integral structure, and comprises a volute tongue and a diversion plate, wherein the volute tongue is located at the first end of an axial direction of the diversion plate, and is provided with a first volute shell installing position; the diversion plate is provided with a second volute shell installing position, and comprises a first fan diversion plate and a second fan diversion plate; both the first fan diversion plate and the second fan diversion plate are curved plates, and are arranged oppositely; and air outlet plate ends of the first fan diversion plate and the second fan diversion plate are intersected to form a herringbone shape. According to the cooking fume drainage structure applied in the double-fan exhaust hood and the double-fan exhaust hood provided by the invention, the diversion plate is formed by the first fan diversion plate and the second fan diversion plate which are the curved plates, form the herringbone shape, and face to a first volute shell and a second volute shell of the volute shell, cooking fume passes through the diversion plate, and the curved plate structure of the diversion plate can be beneficial to reducing the impact backflow of an airflow at an air outlet part, reducing the vortex phenomenon, and reducing the noise of fluid impact.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Environmentally-friendly breathable porous material and preparation method thereof

InactiveCN104311120AEasy to operateSimple production processCeramicwareFoaming agentMaterials science

The invention belongs to the technical field of foaming materials, and concretely relates to an environmentally-friendly breathable porous material. The material comprises 3-8 parts of a curing agent, 1-7 parts of a functional material, 2-5 parts of a solid pore forming agent and 0-2 parts of decomposable solid glue. The invention also provides a preparation method of the environmentally-friendly breathable porous material. The preparation method has the advantages of simple control of the size of pores in the material, obtaining of ideal size pores and capillary meso-pores by controlling the dimension and shape of the solid pore foaming agent, and easy development of the material performances of the material due to good connectivity of large and small pores of the material.

Owner:CHANGZHOU U SHENG ELECTRONICS LTD

Low-compression-ratio ultra-thick specification low-temperature-resistant hot-rolled H-beam and production method thereof

The invention discloses a low-temperature resistant hot rolling H section bar with low compression ratio and super-thick specification and a production method thereof and belongs to the field of hot rolling H section bars. The H section bar is prepared from the following chemical components in percentage by weight: 0.11-0.19% of C, 0.15-0.30% of Si, 1.30-1.55% of Mn, less than or equal to 0.02% of P, less than or equal to 0.008% of S, 0.008-0.020% of Ti, 0.015-0.055% of V and the balance of Fe and inevitable impurities. The production method of the H section bar sequentially comprises the following steps: smelting in a converter or electric furnace; LF (ladle furnace) refining; full protection continuous casting of a beam blank; heating; rolling; and cooling to finally obtain the low-temperature hot rolling H section bar, wherein the flange is over 30mm thick, the compression ratio is less than 3, and the surface is good in quality. The vertical average ballistic work at -20 DEG C is over 150J, so that the H section bar has a wide market application prospect.

Owner:LAIWU IRON & STEEL GRP

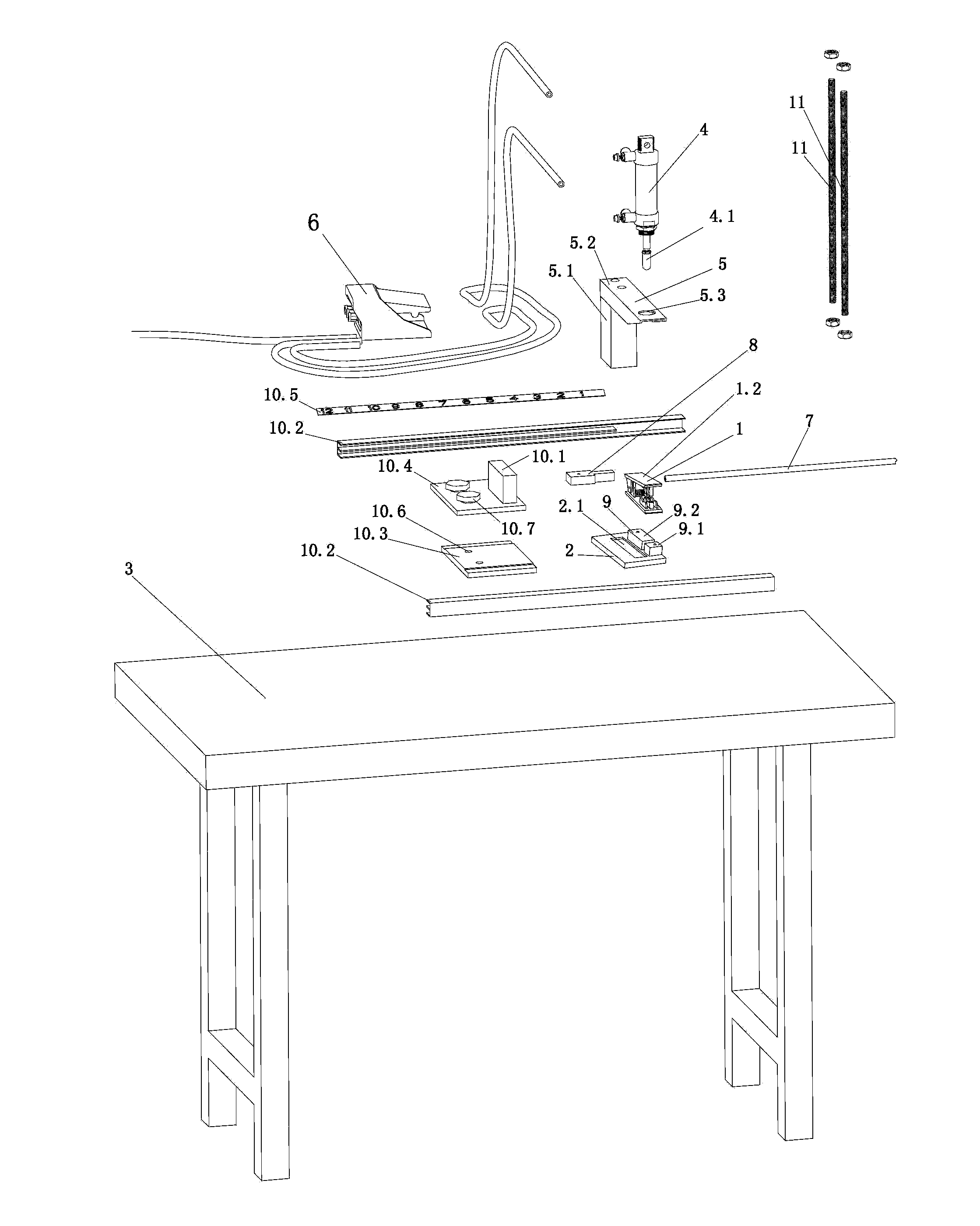

Pipe cutting device

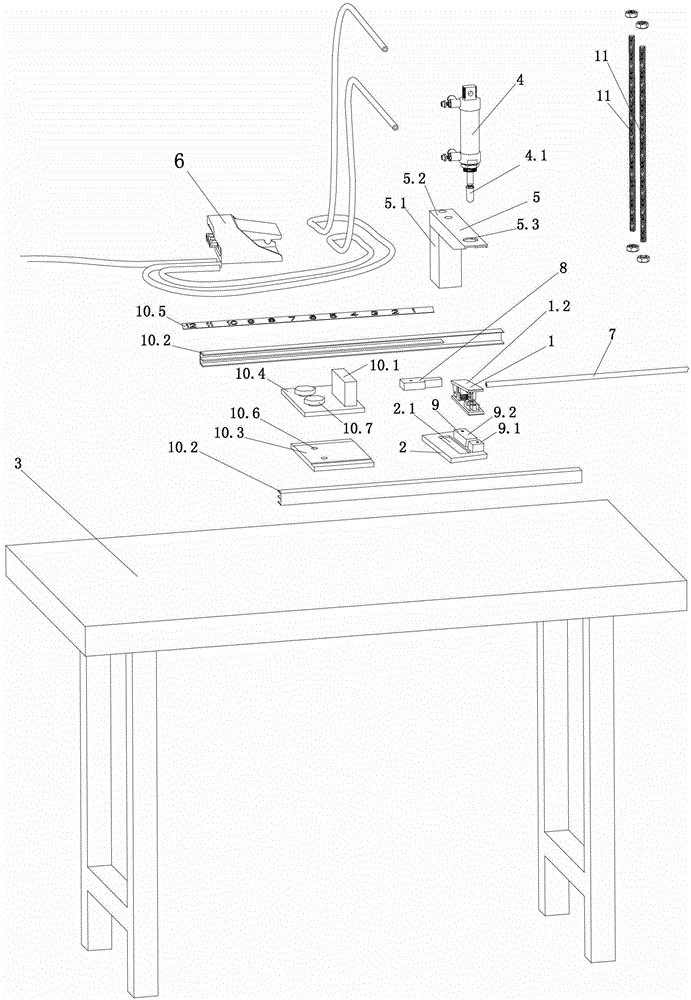

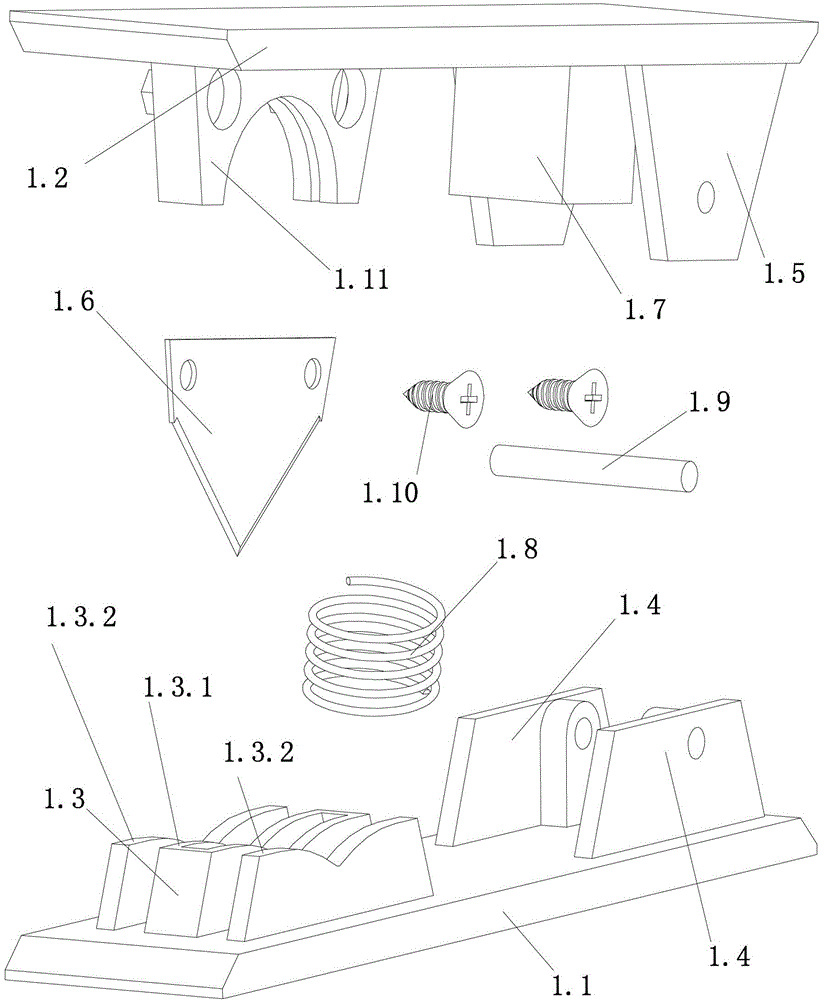

A pipe cutting device comprises a cutter assembly, an installation plate of the cutter assembly, a working platform, an air cylinder, an air cylinder frame, a foot switch, a fixed pressing block, an enhanced safety component and a size control device; the cutter assembly comprises a fixed bottom plate, a cutting knife fixing plate and a cutting knife fixing plate return spring; a hose supporting base group and a cutting knife fixing plate connecting base are fixedly arranged at front and back ends of the fixed bottom plate respectively, and the hose supporting base group comprises a main supporting base and a protective supporting base; the rear end of the cutting knife fixing plate is hinged to the cutting knife fixing plate connecting base; a piston head of the air cylinder abuts against the cutting knife fixing plate; the size control device comprises a size control stopping block; the fixed bottom plate is placed inside a positioning hole formed in the installation plate of the cutter assembly and is pressed against and fixed on the working platform through the fixed pressing block; the enhanced safety component is fixedly arranged on the right side of the hose supporting base group and comprises front and back enhanced safety blocks, highest points of the front and back enhanced safety blocks are higher than the highest position of a tip of a cutting knife, and the distance between the front and back enhanced safety blocks is 10-20mm larger than the diameter of a hose.

Owner:NINGBO SOOJEE SANITARY WARE

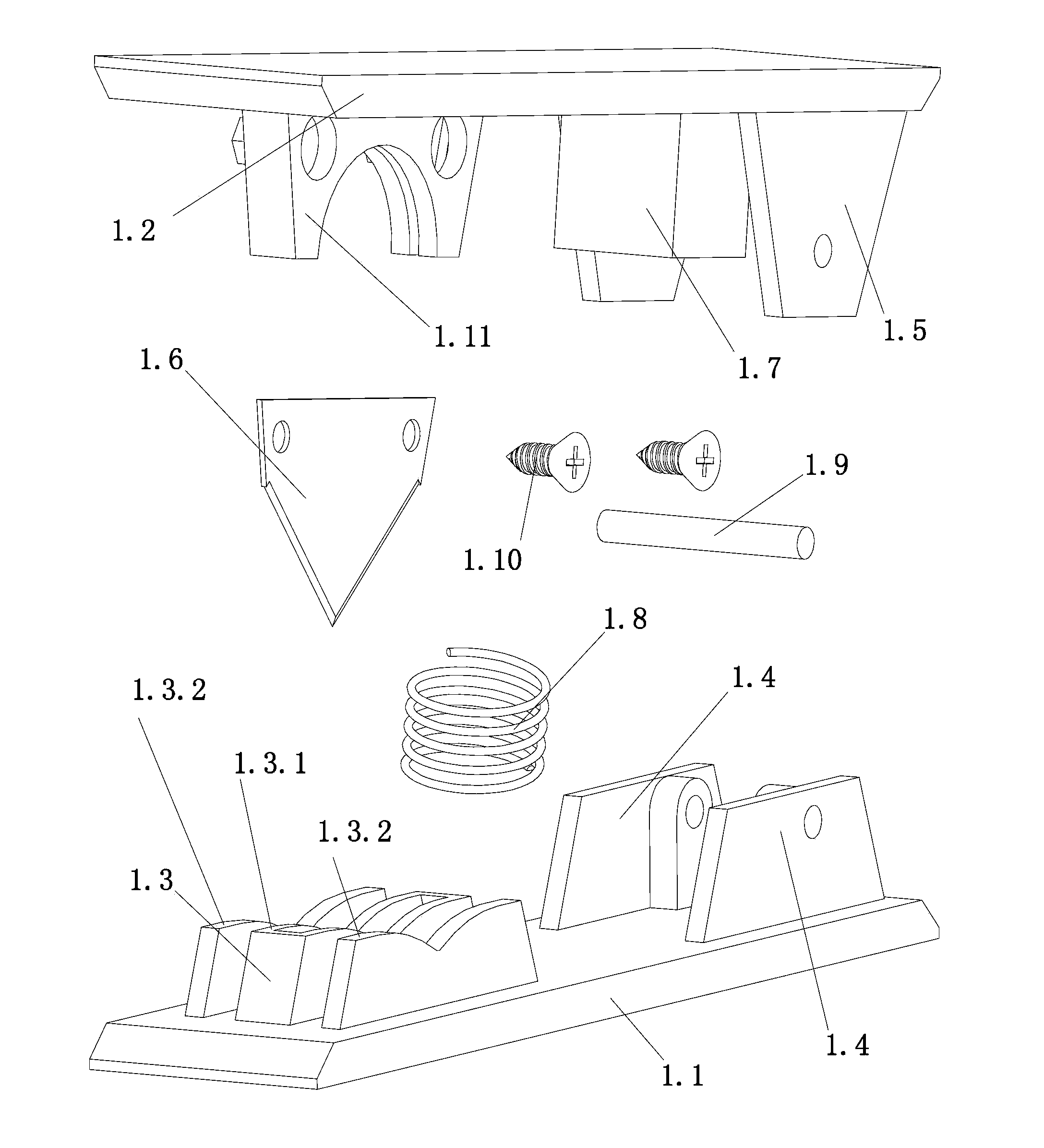

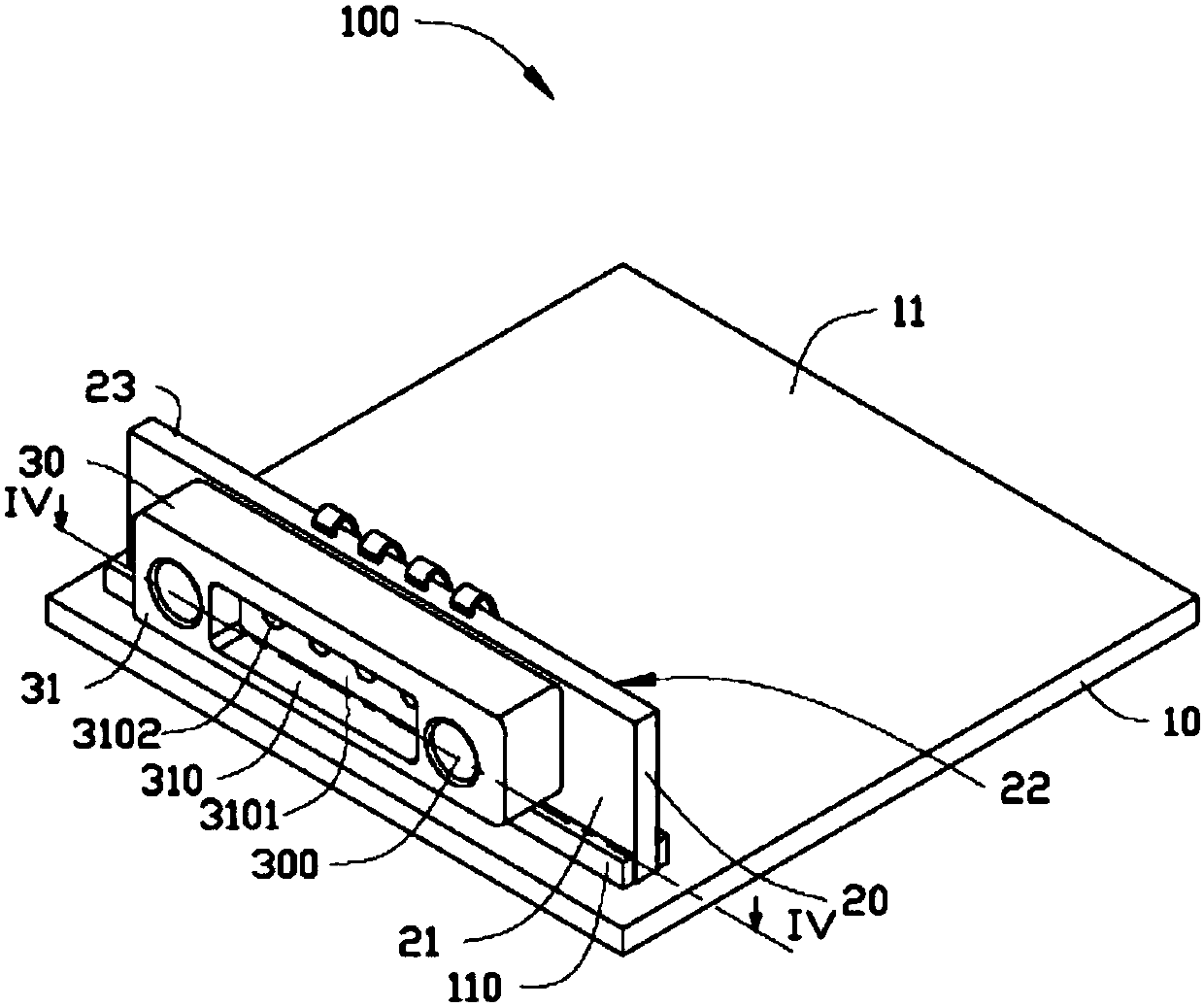

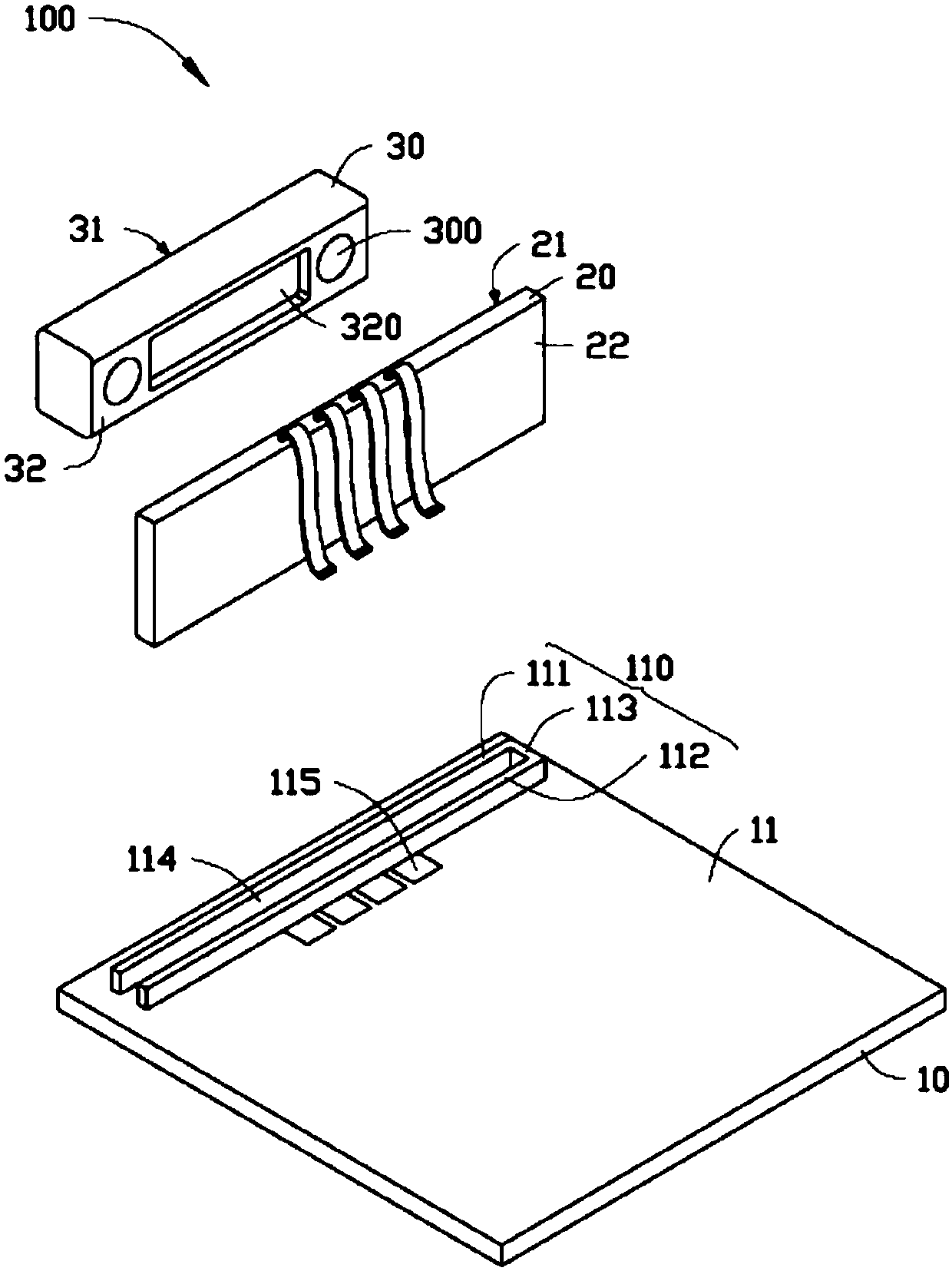

Photoelectric conversion module

The invention discloses a photoelectric conversion module which comprises a main circuit board and an optocoupler. The main circuit board comprises a bearing surface. The photoelectric conversion module further comprises a sub-circuit board. The sub-circuit board is vertically fixed on the bearing surface and is electrically connected with the main circuit board. The sub-circuit board comprises afirst surface perpendicular to the bearing surface. A number of photovoltaic elements are arranged on the first surface. The optocoupler is provided with a number of first coupling lenses and is fixedon the first surface of the sub-circuit board. Each first coupling lens is aligned by corresponding to a photoelectric element. The photoelectric conversion module provided by the invention has the advantage of easily light path alignment.

Owner:SHENZHEN MLIAO TECH TRANSFER CENT CO LTD

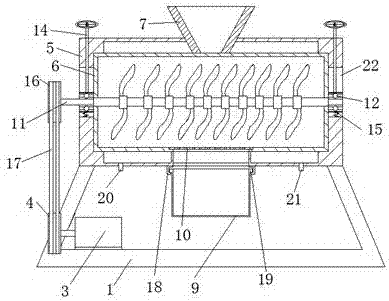

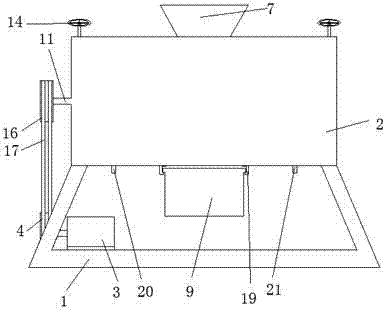

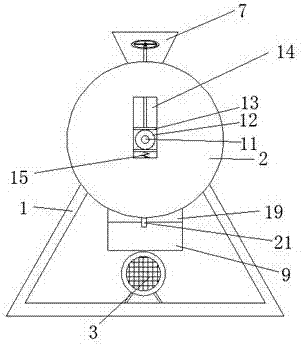

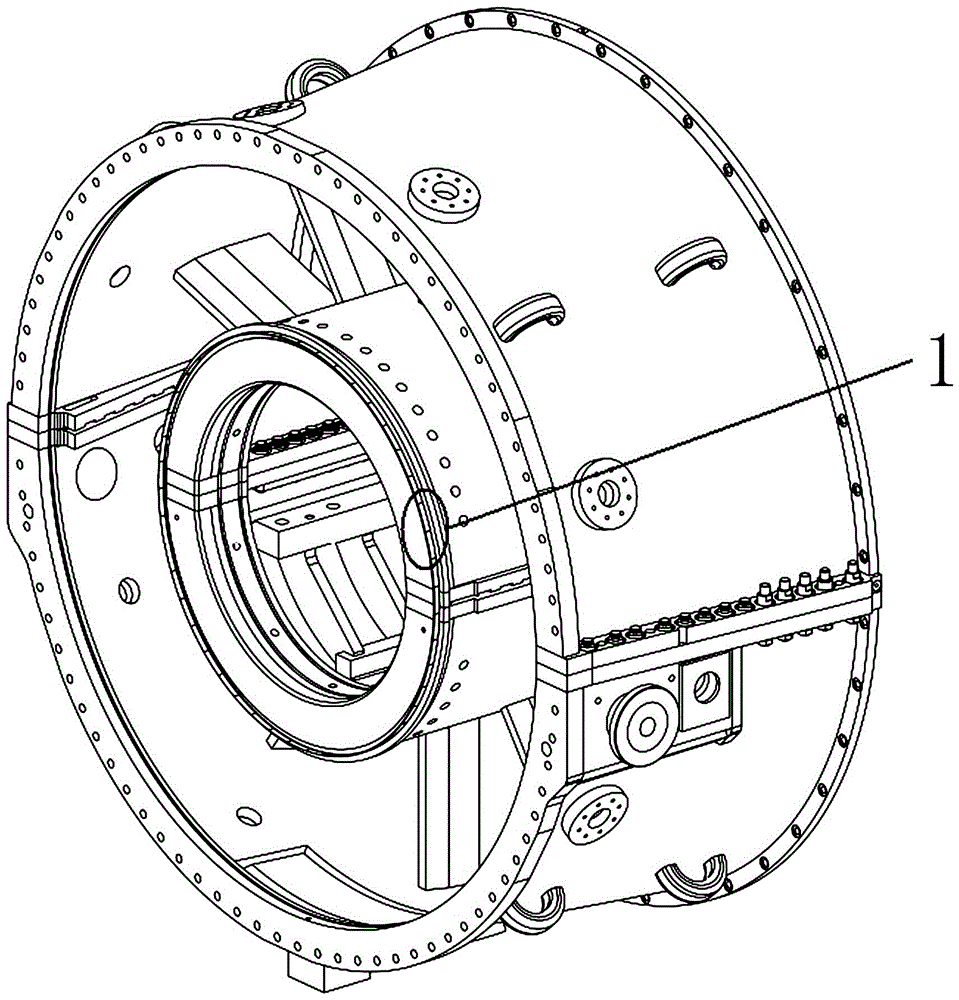

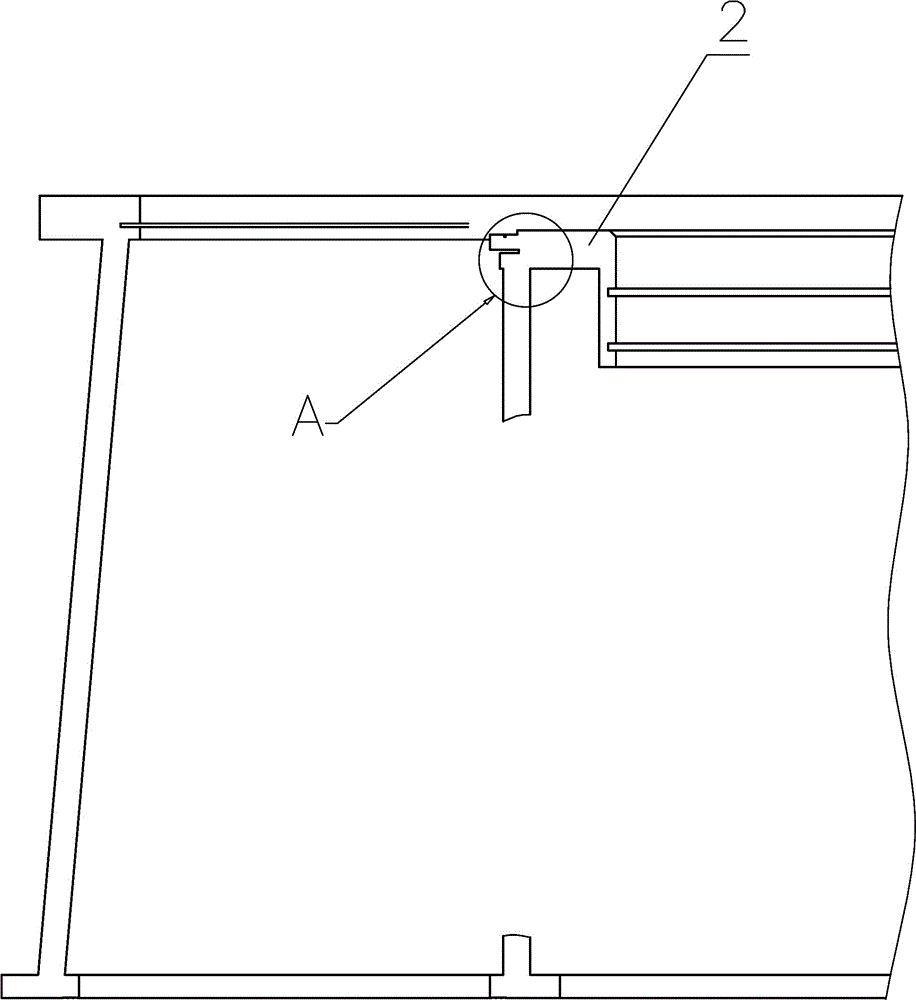

Smashing device for drone pupa

InactiveCN106925397AEasy size controlReasonable structural designGrain treatmentsEngineeringMechanical engineering

The invention discloses a drone pupa crushing device, which comprises a support and a crushing barrel; the upper and lower ends of the support are respectively provided with a crushing barrel and a motor, and a motor pulley is arranged on the shaft of the motor; Composed of barrels, the feed hopper and the discharge port are respectively set on the upper and lower sides of the crushing barrel; the lower side of the discharge port is provided with a storage box, and the discharge port is provided with a filter screen embedded in the material inner cylinder; the material In the inner cylinder, there is a roller tool holder horizontally, and bearings are arranged at both ends of the roller tool holder; the two bearings are arranged in the bearing sleeve, and the bearing sleeve is arranged in the adjustment groove at both ends of the crushing bucket, and the upper and lower ends of the bearing sleeve An adjusting screw and a compression spring are respectively arranged; the driven pulley is arranged on the left side of the roller tool rest, and the driven pulley is connected with the motor pulley through a belt. The invention has a reasonable structural design, can effectively reduce the influence of temperature during pulverization, and is more convenient to control the size of pulverized particles.

Owner:MINGGUANG HAOHAO BEES

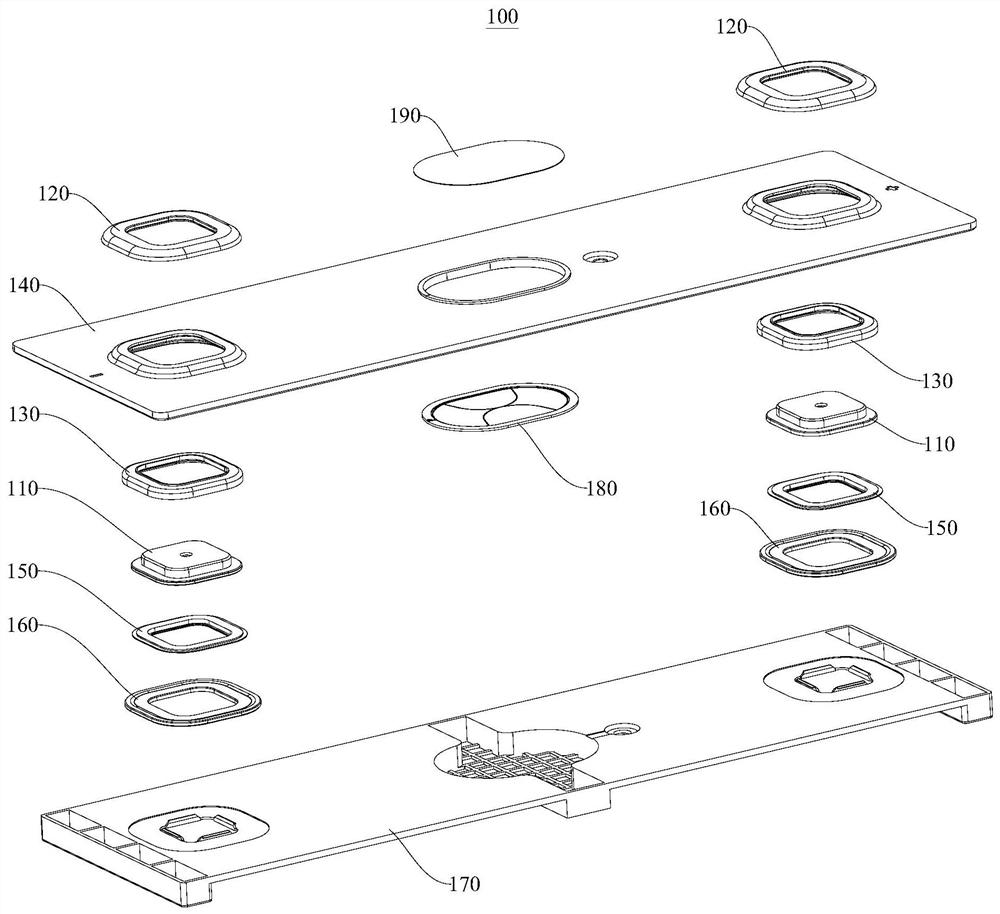

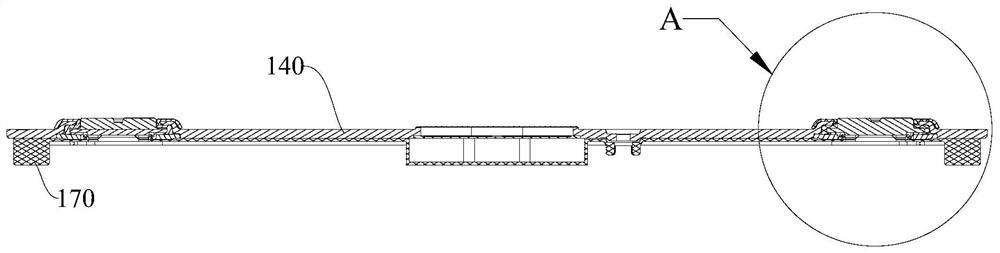

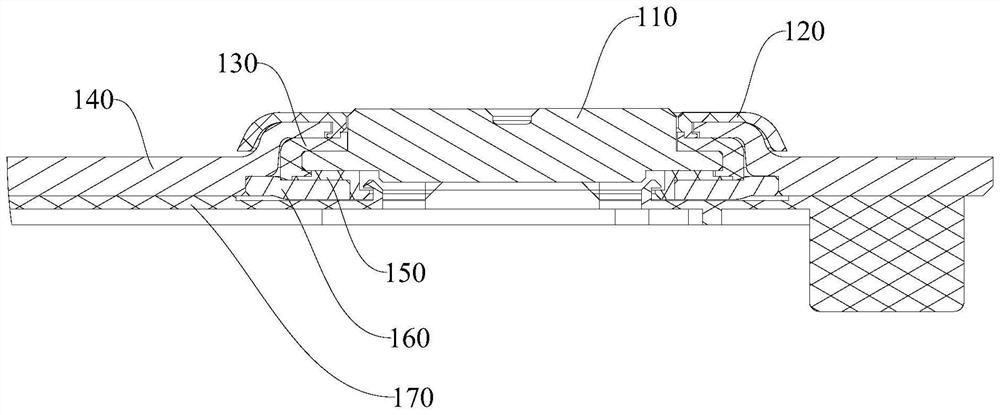

Secondary battery, top cover assembly and assembly method thereof

ActiveCN112201897BImprove versatilityAvoid sizeAssembling battery machinesFinal product manufactureElectrical batteryStructural engineering

Embodiments of the present invention provide a secondary battery, a top cover assembly and an assembly method thereof, relating to the field. The top cover assembly includes a pole, an upper plastic, a sealing ring, a top cover sheet, an insulating gasket, a fixing ring and a lower plastic. The sealing ring is sleeved on the circumference of the pole, the insulating gasket is connected with the fixed ring, and the upper plastic is connected with the top cover. The top cover sheet is provided with a pole hole, and the pole, sealing ring, insulating gasket and fixing ring are all assembled in the pole hole, and the sealing ring abuts between the pole and the hole wall of the pole hole. The fixing ring is fixedly connected with the top cover sheet, the insulating gasket is located between the pole and the fixing ring, and the two ends of the sealing ring are respectively connected with the upper plastic and the insulating gasket. The lower plastic is connected with the insulating gasket, and the pole is used for connecting with the cell of the secondary battery. The parts of the top cover assembly provided by the embodiments of the present invention have good versatility, are easy to manufacture, and are beneficial to improving production efficiency.

Owner:兰钧新能源科技有限公司

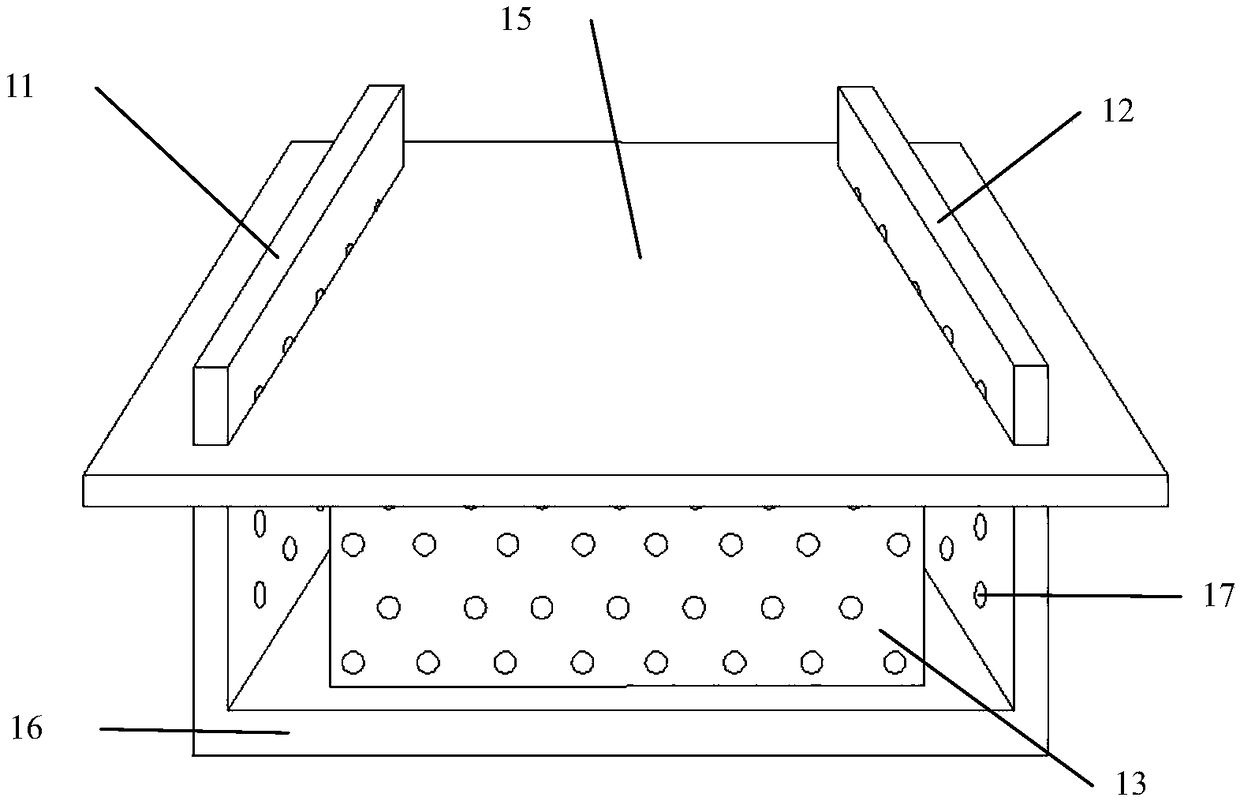

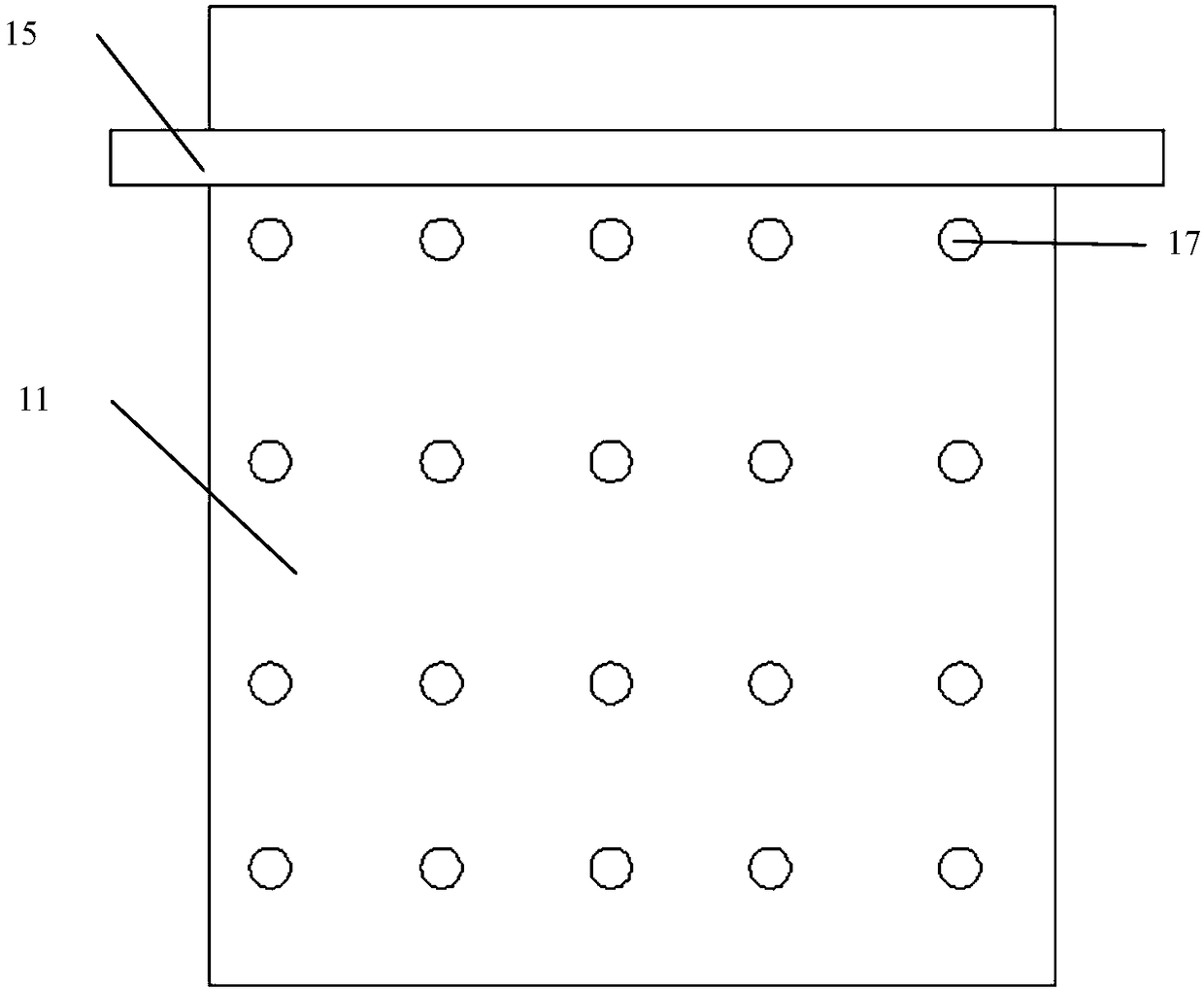

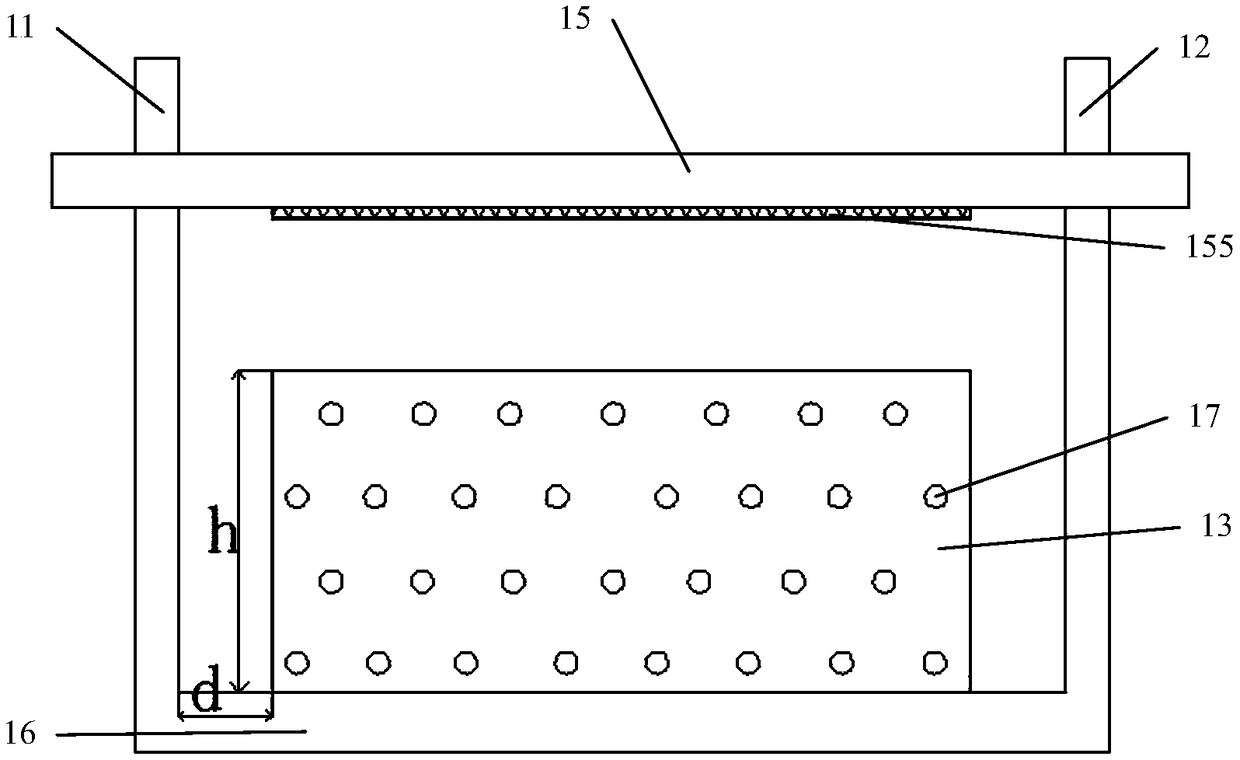

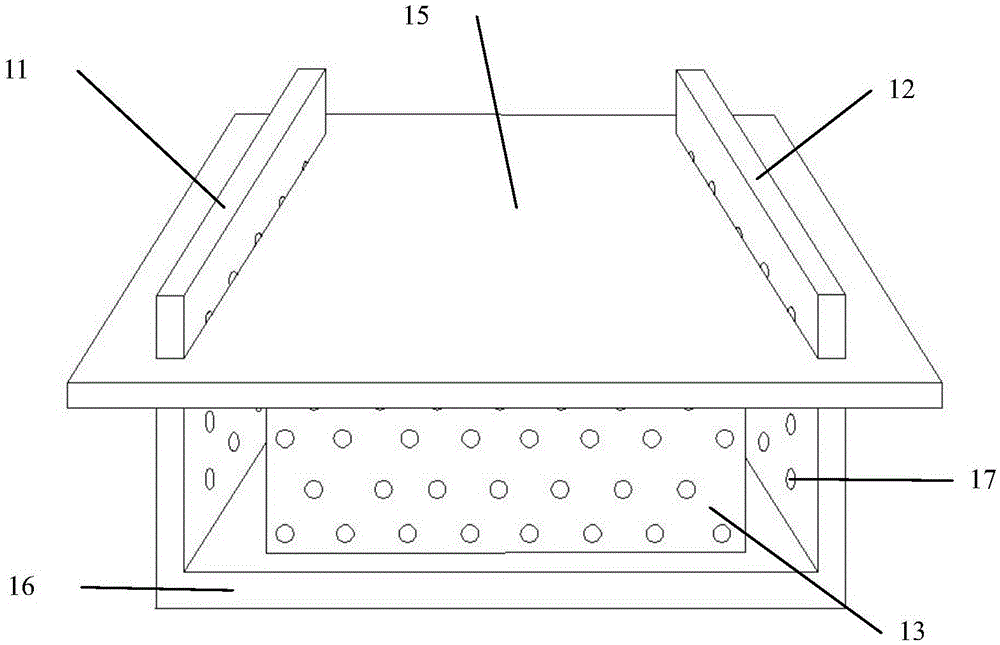

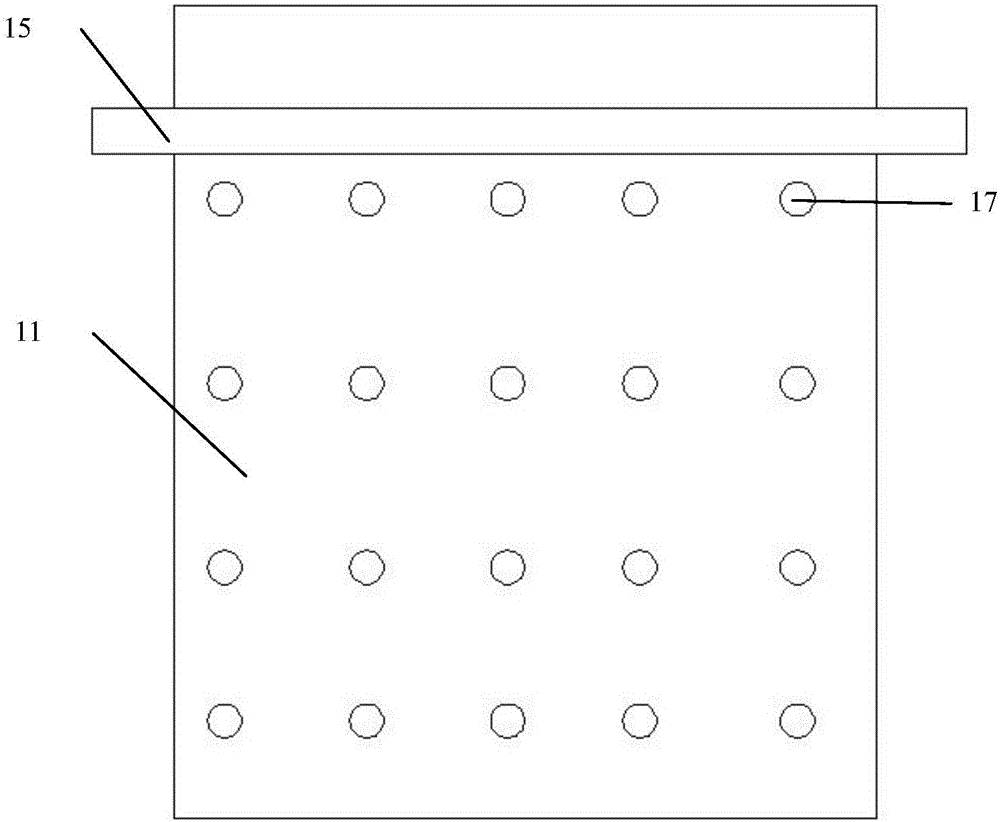

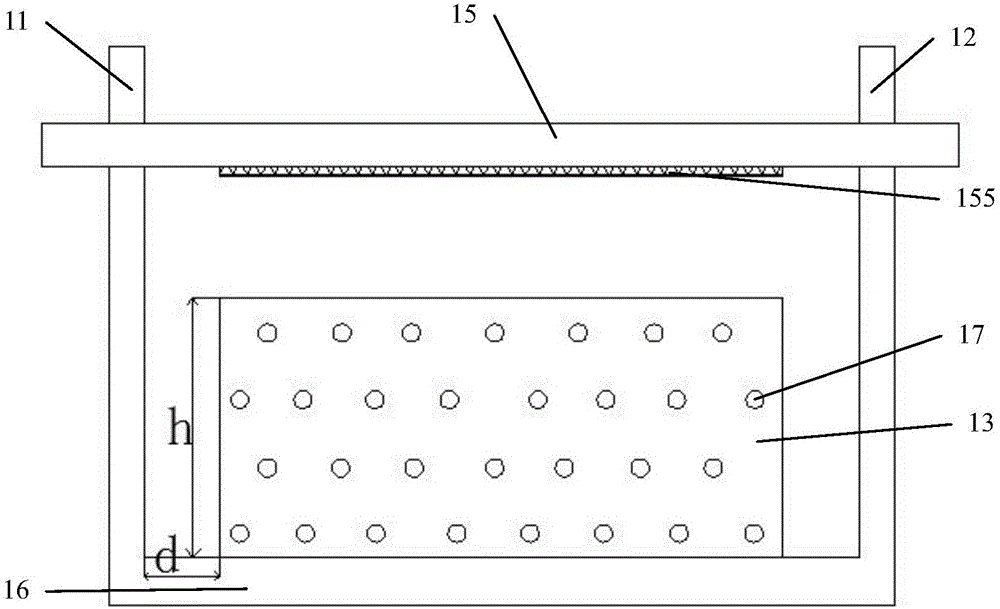

A device for sintering high temperature resistant materials and its application

ActiveCN106403606BImprove thermal conductivityUniform temperatureCharge composition/stateCharge treatment typeQuartzThermal conductivity

The invention relates to a device for sintering a high-temperature-resistant material and application of the device. The device comprises side panels, a top panel and a bottom panel, wherein the side panels are made of silicon carbide; at least four top grooves are formed in the top panel; the left top groove and the right top groove are through grooves; a front bottom groove and a rear bottom groove are formed in the bottom panel; the front panel and the rear panel are respectively inserted in the front bottom groove and the rear bottom groove; positions, which are close to the left side and the right side of the bottom panel, of the left side panel and the right side panel are connected with the bottom panel; a plurality of through holes are formed in each side panel; a gap is formed between each two optional adjacent side panels; and anti-sticking parts which are formed by quartz fabrics are respectively paved on the inner wall of the top panel and the inner wall of the bottom panel. The invention further provides application of the device in sintering of the high-temperature-resistant material. The device has the advantages of simple structure, convenience in use, high temperature resistance, good thermal conductivity and anti-sticking property, even temperature, controllable material shape, size, appearance and microstructure and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A preparation method of monodisperse fept/fe3o4 mixed nanoparticles

ActiveCN106735287BEasy to operateSimple preparation stepsTransportation and packagingMetal-working apparatusAlkaneHeat conservation

The invention discloses a method for preparing monodisperse FePt / Fe3O4 mixed nano particles, which belongs to the field of nanotechnology. The preparation method includes: (1) in an inert gas atmosphere, sequentially add oleic acid, oleylamine, reducing agent, and Pt(acac)2 into the solvent, stir evenly, preheat at 100-120° C. for 5-30 minutes, and add Fe (CO)5, heat up to 150-280°C and keep it warm for 1-2h to prepare FePt nanoparticles; (2) add FePt nanoparticles dispersed in alkane solvent to the reaction solvent, and heat the system to 50°C in a certain atmosphere. ~250°C, heat preservation for 0.5~4h, to prepare monodisperse FePt / Fe3O4 mixed nanoparticles. The method uses an in-situ method to prepare FePt / Fe3O4 mixed nanoparticles, which has the advantages of low cost, simple operation, high product quality, and good stability. This method is used to prepare monodisperse FePt / Fe3O4 mixed nanoparticles, which are multifunctional The application and development of composite nanoparticles provide convenient conditions.

Owner:NORTHEASTERN UNIV LIAONING

Rolling processing method of sealing tooth lobe of exhaust connection pipe

Provided is a rolling machining method of a sealing tooth section of an exhaust connecting pipe. The method comprises the steps that a sheet tooth section is machined; an installation groove for the tooth section is machined in the end face of the connecting pipe; the tooth section is machined to be of a circular arc shape with the radian approximate to that of an integrally-formed circular hole of the sealing tooth section; the tooth section is placed into the installation groove, and three points are uniformly and fixedly riveted on the rolling side to prevent the tooth section from moving; a rolling tool is installed on a vertical lathe, and the rolling machining portion of the connecting pipe is continuously rolled through the rolling tool to deform to extrude the tooth section; a correcting tool is installed on the vertical lathe, and correction is carried out on the inner side or the outer side of the tooth section through the correcting tool; finish turning is carried out on the tooth section. Through the steps, machining of the sealing tooth section of the exhaust connecting pipe is achieved, implementation is convenient, the operation process is simplified, and especially, the requirement for the machining precision of equipment is lowered.

Owner:YICHANG MARINE DIESEL ENGINE

Pipe cutting device

InactiveCN103419243BNot easy to fatigueEasy to cut to lengthMetal working apparatusEngineeringFront and back ends

A pipe cutting device comprises a cutter assembly, an installation plate of the cutter assembly, a working platform, an air cylinder, an air cylinder frame, a foot switch, a fixed pressing block, an enhanced safety component and a size control device; the cutter assembly comprises a fixed bottom plate, a cutting knife fixing plate and a cutting knife fixing plate return spring; a hose supporting base group and a cutting knife fixing plate connecting base are fixedly arranged at front and back ends of the fixed bottom plate respectively, and the hose supporting base group comprises a main supporting base and a protective supporting base; the rear end of the cutting knife fixing plate is hinged to the cutting knife fixing plate connecting base; a piston head of the air cylinder abuts against the cutting knife fixing plate; the size control device comprises a size control stopping block; the fixed bottom plate is placed inside a positioning hole formed in the installation plate of the cutter assembly and is pressed against and fixed on the working platform through the fixed pressing block; the enhanced safety component is fixedly arranged on the right side of the hose supporting base group and comprises front and back enhanced safety blocks, highest points of the front and back enhanced safety blocks are higher than the highest position of a tip of a cutting knife, and the distance between the front and back enhanced safety blocks is 10-20mm larger than the diameter of a hose.

Owner:NINGBO SOOJEE SANITARY WARE

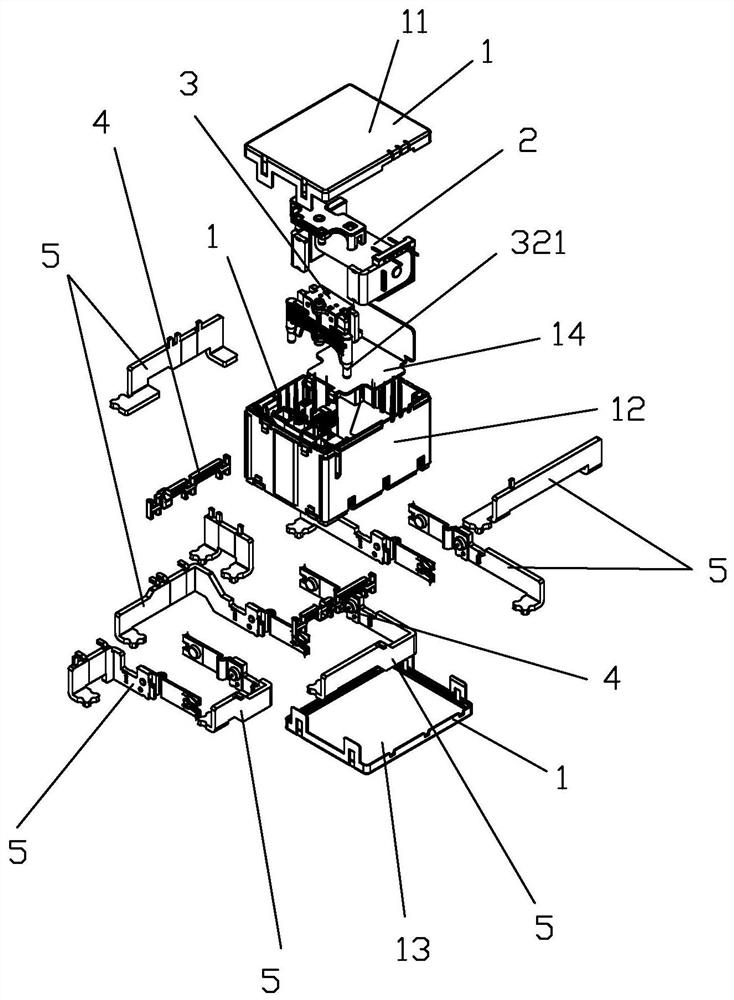

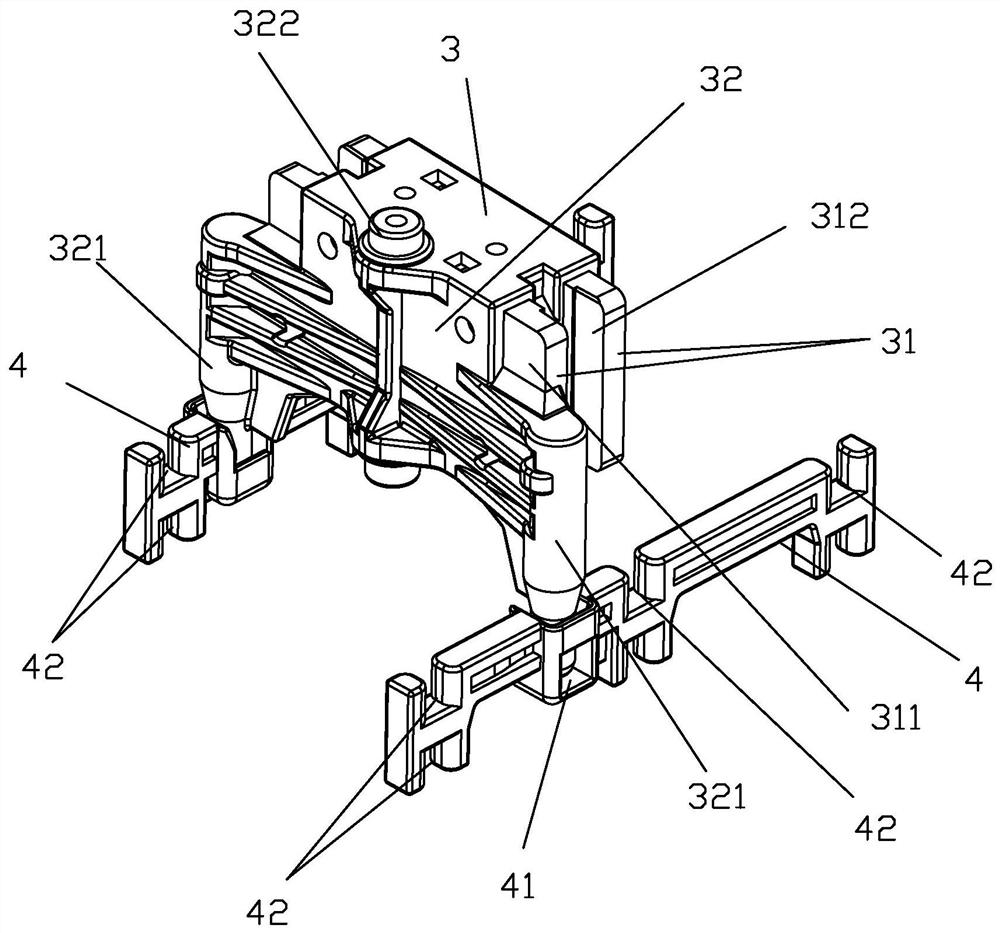

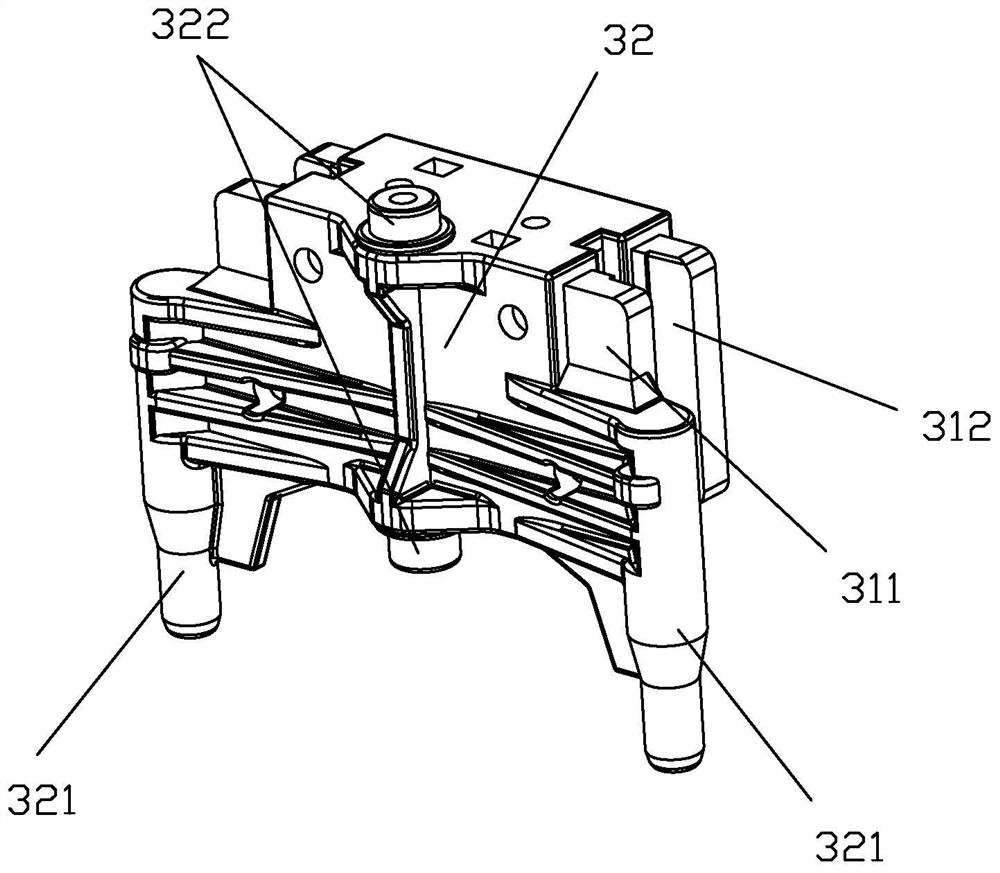

Single-throw duplex contactor, contactor moving contact device and contactor ceramic cover assembly

PendingCN112216563ASimplify the assembly processEasy size controlElectromagnetic relay detailsContactorEngineering

The invention relates to the field of contactor devices, in particular to a single-throw duplex contactor, a contactor moving contact device and a contactor ceramic cover assembly. A driving assemblyand a contact assembly are arranged; the contact assembly comprises a linkage plate, and two movable contact assemblies are oppositely arranged at the two ends of the linkage plate; due to the fact that the contact mode of the movable contact is adopted, the linkage design is adopted, the balance of the movable contact assembly is good, and the synchronism of attraction / release of the movable contact is greatly improved.

Owner:上海西艾爱电子有限公司

A low-temperature microwave preparation method of anatase titanium dioxide

ActiveCN108910943BEasy size controlImprove performancePhysical/chemical process catalystsTitanium dioxideEthylic acidPhysical chemistry

The invention belongs to the field of nanomaterials, and specifically relates to a low-temperature microwave preparation method of anatase titanium dioxide, comprising the following steps: step 1, adding ammonium hexafluorotitanate to absolute ethanol and stirring until completely dispersed, and then adding lithium hydroxide Continue to stir to form a dispersion; step 2, put the dispersion into a ball milling reactor for ball milling reaction for 1-2h to obtain a ball milling liquid; step 3, add hydrochloric acid solution to the ball milling liquid and stir evenly, then react with microwave at low temperature for 3-5h, After cooling, filter to obtain a white precipitate; step 4, put the white precipitate in an ethanol-acetic acid solution, ultrasonicate for 10-30min, filter and dry to obtain a white powder; step 5, put the white powder in a sealed reaction kettle Ultraviolet irradiation treatment for 2-3 hours to obtain anatase titanium dioxide particles. Based on the low-temperature microwave method, the invention solves the problems of harsh environment and high risk in the preparation of the existing titanium dioxide technology, and obtains the anatase titanium dioxide with simple size control and good performance.

Owner:SHAOXING UNIVERSITY

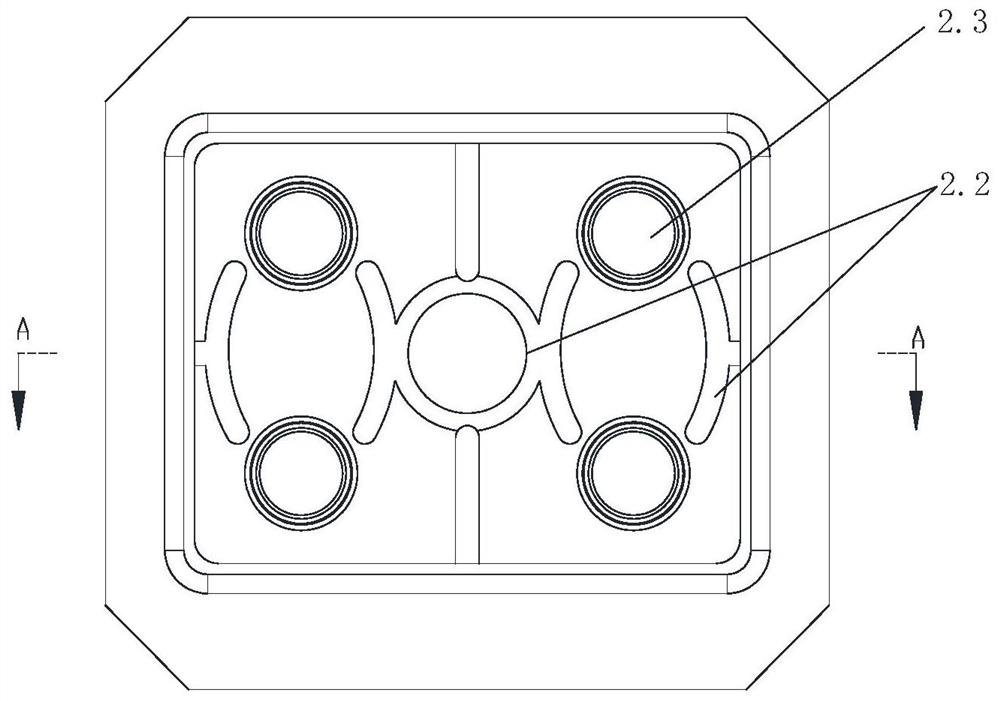

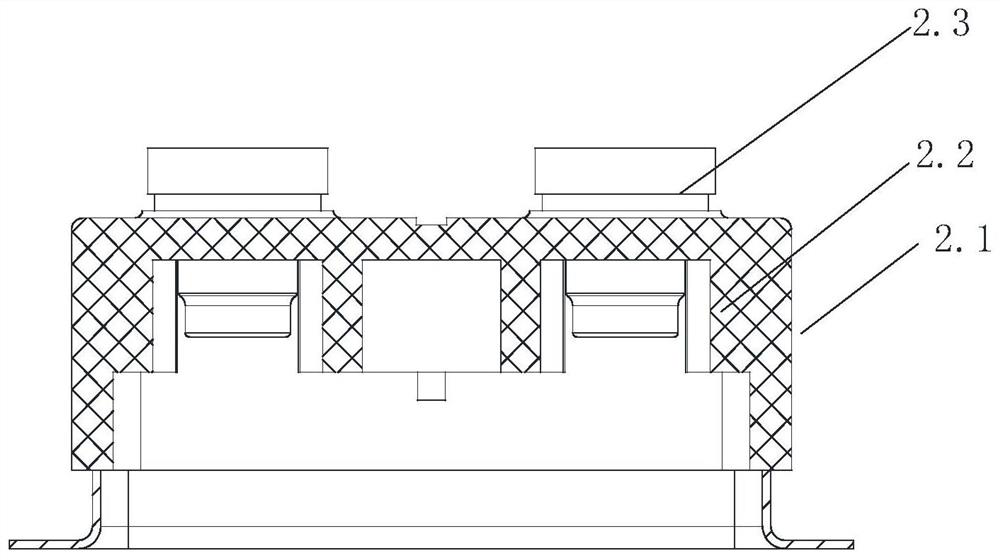

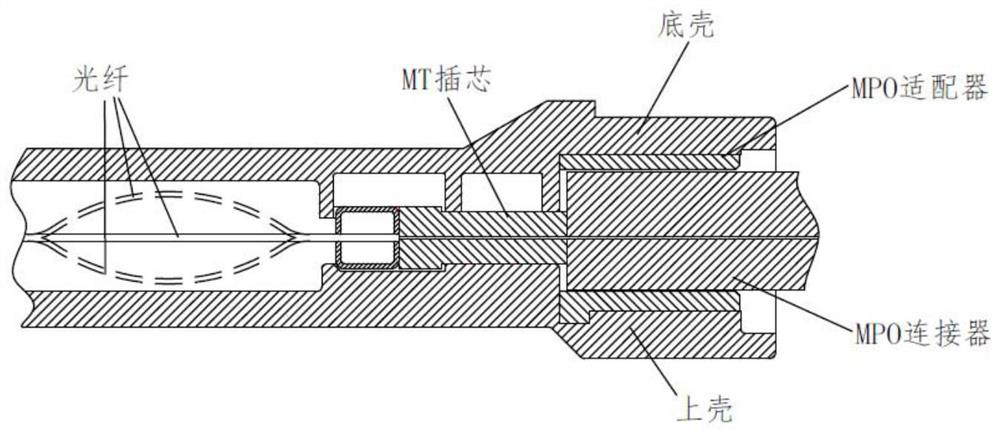

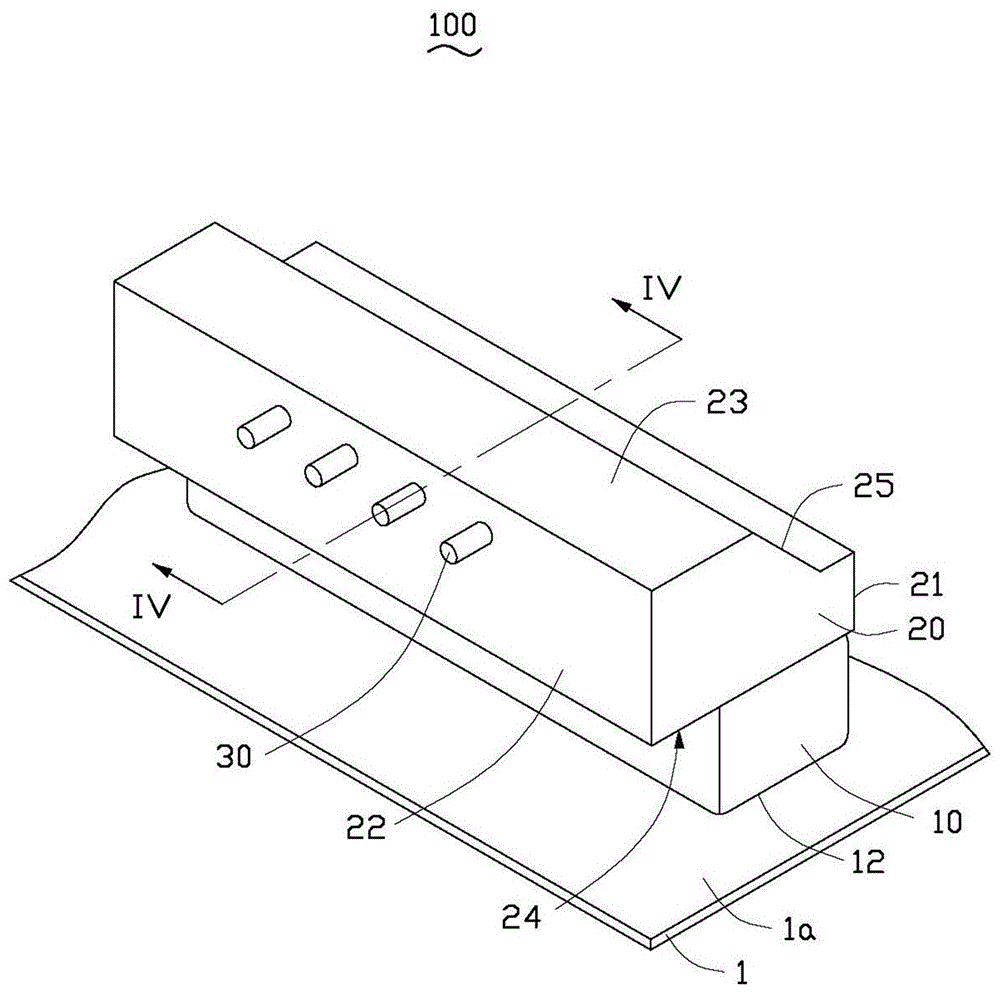

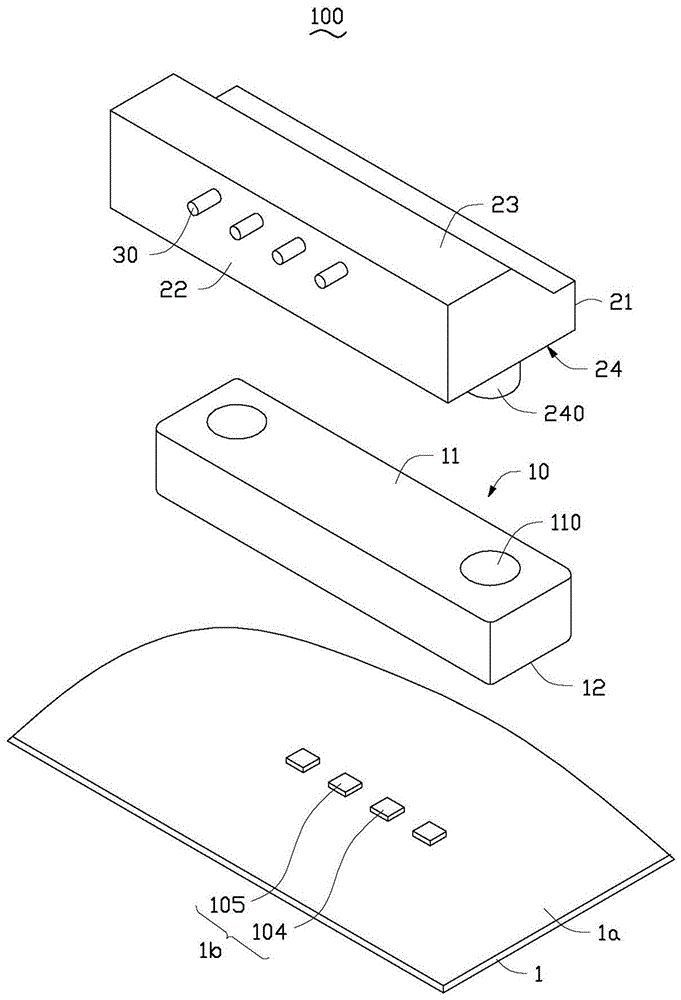

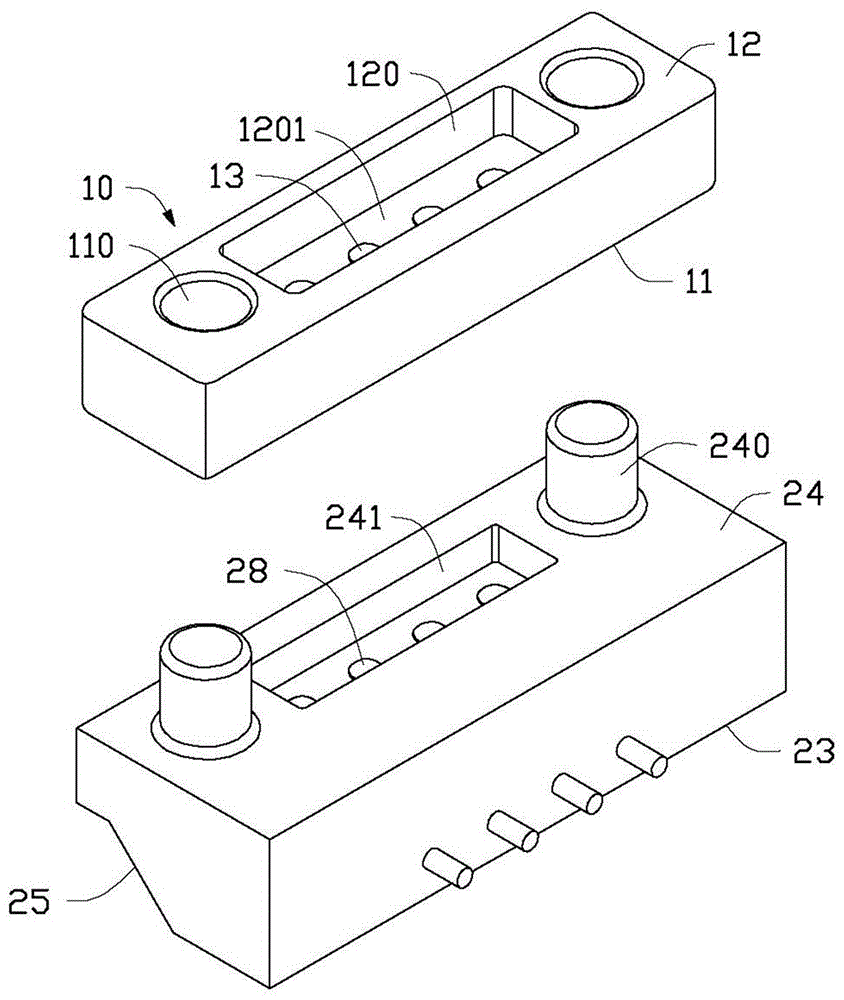

High-tolerance fixing structure of MT insertion core in optical module structure

ActiveCN113467002AHigh electromagnetic shieldingGuaranteed positioning error of optical end faceCoupling light guidesOptical ModulePlastic materials

The present invention provides a high-tolerance fixing structure of an MT insertion core in an optical module structure, the MT insertion core and the MPO adapter are firstly installed in a matched mode, then the MPO adapter and the MT insertion core are integrally installed on the bottom shell, the clamping piece made of the conductive plastic material is clamped between the MT insertion core and the bottom shell, and then other structural parts are installed. The size control is simple, the optical end face positioning error of the MPO connector and the MT insertion core is reduced, and the electromagnetic shielding performance can be enhanced.

Owner:BROADEX TECH

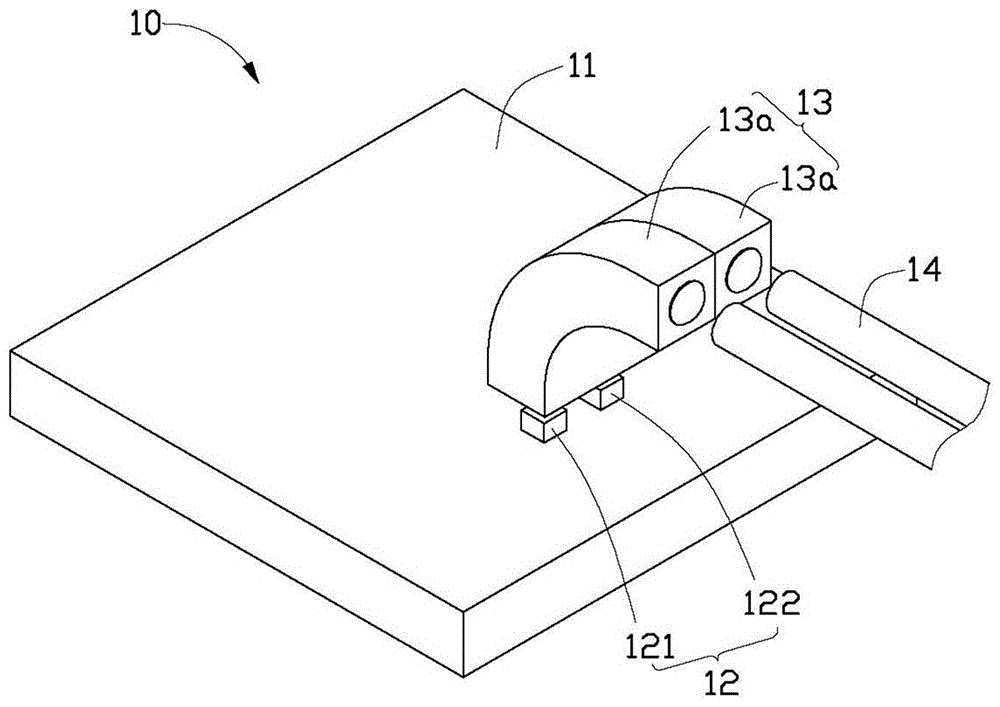

Optical conversion module and optical fiber coupling connector

An optical path conversion module, which is used in an optical fiber coupling connector, the optical fiber coupling connector includes a photoelectric module and an optical fiber, the optical path conversion module realizes the optical path conversion between the photoelectric module and the optical fiber, and the optical path conversion The module includes a light pipe with a 90 degree bend angle. The invention also provides an optical fiber coupling connector with the optical path conversion module.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

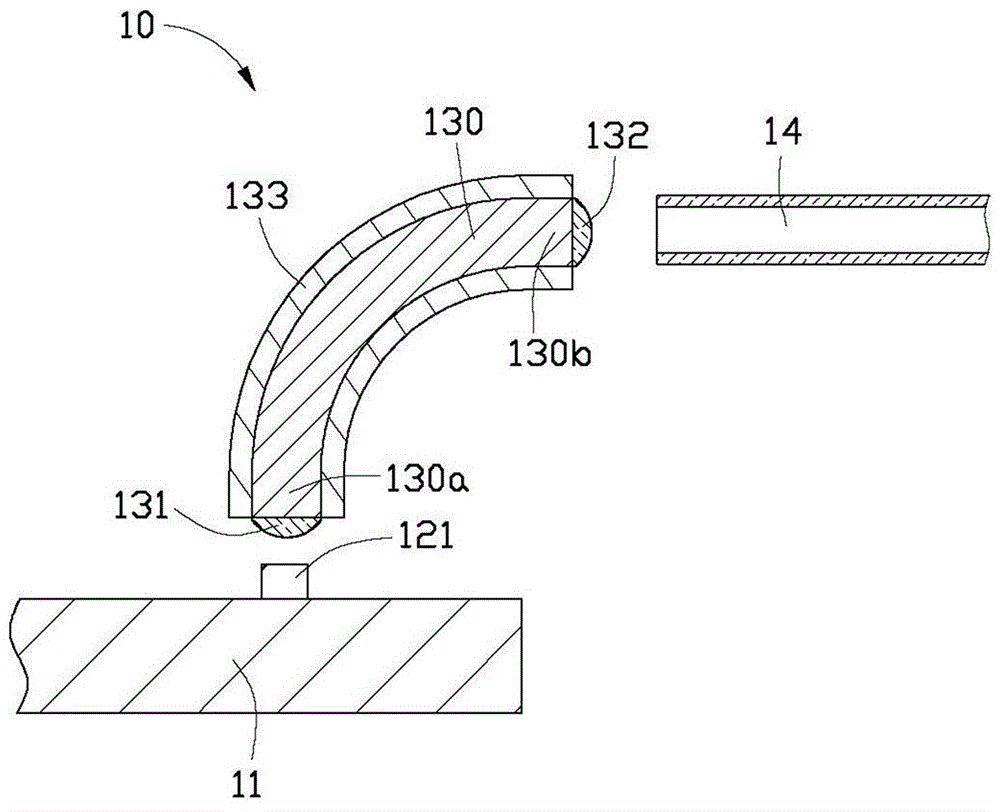

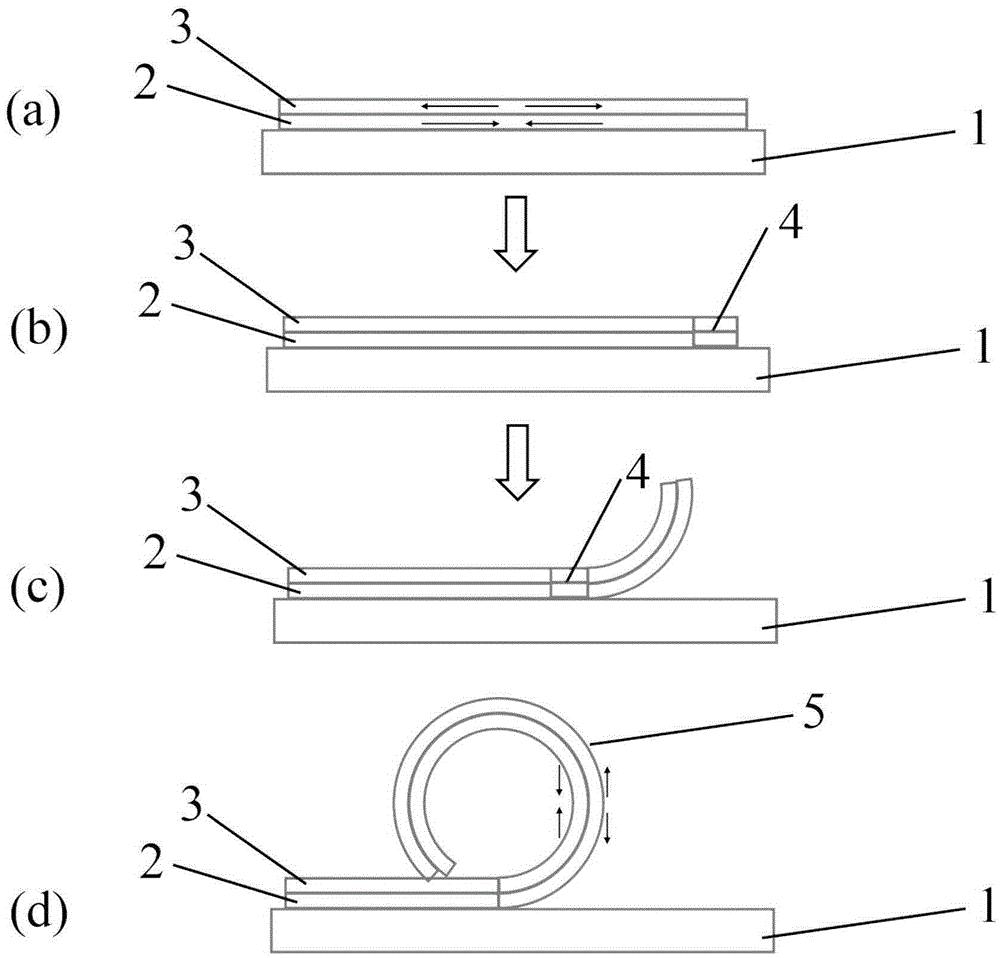

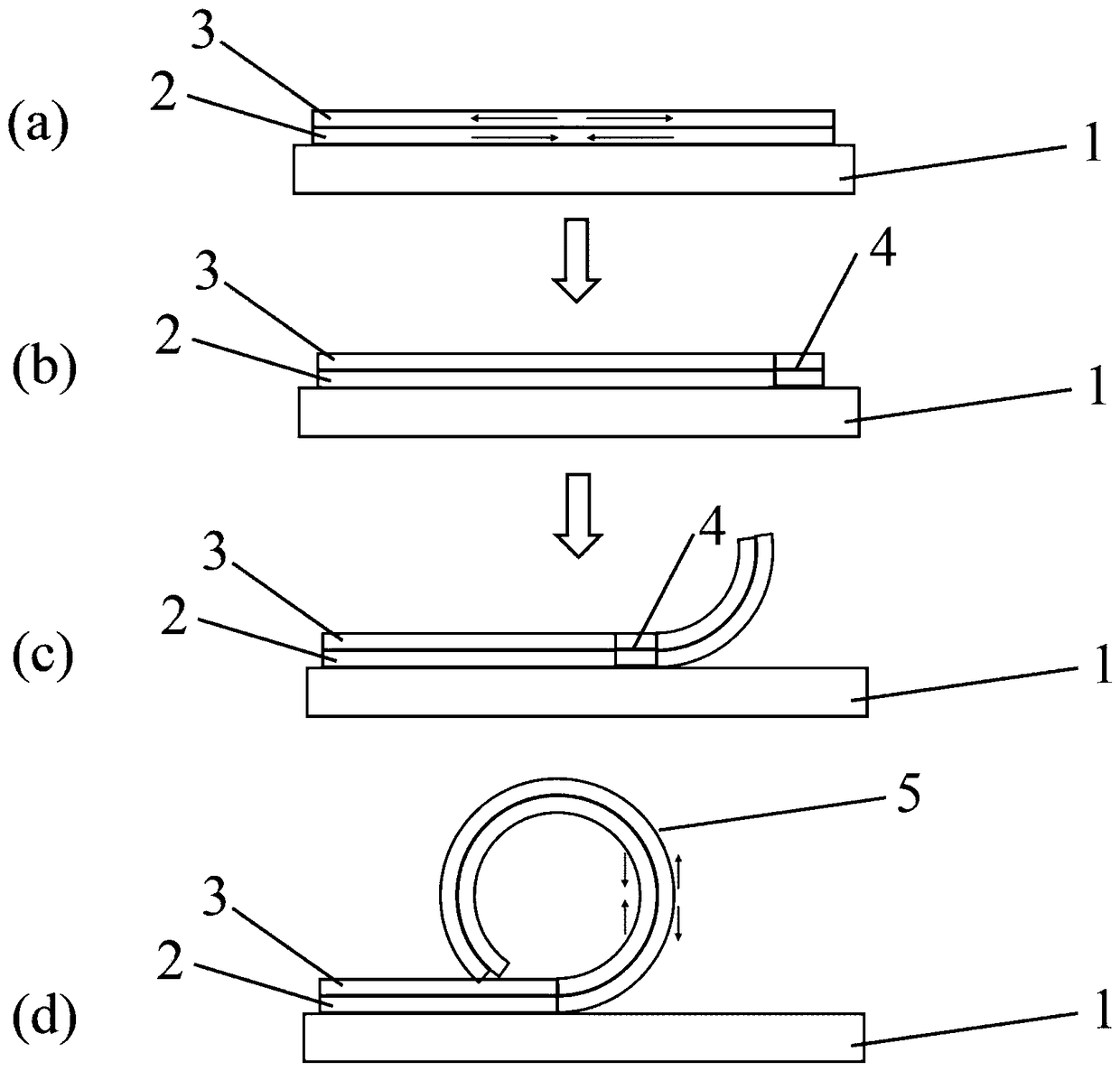

Preparation method of organic/inorganic hybrid double-layer nanofilm self-coiling pipe

InactiveCN105268024ASimple preparation processMild conditionsInorganic non-active ingredientsSurgeryMicro nanoImplant material

A preparation method of an organic / inorganic hybrid double-layer nanofilm self-coiling pipe comprises the following main steps: A, polishing a magnesium sheet, cleaning and drying in vacuum; B, putting the magnesium sheet from the step A into 2.5-3.5 mol / L of a NaOH solution to react at 50-70 DEG C for 3-4 h, so as to obtain a Mg(OH)2 thin film on the surface of the magnesium sheet; C, preparing a phytic acid solution with its pH value being 5-6 and concentration being 4-6 mg / mL; D, placing the magnesium sheet from the step B into a phytic acid solution and standing for 1-30 min so as to form a double-layer nanofilm on the magnesium sheet; and E, cleaning the magnesium sheet from the step D and drying the magnesium sheet in vacuum for 6-24 h until the organic / inorganic hybrid double-layer nanofilm on the magnesium sheet is separated from the magnesium sheet and is coiled so as to obtain the self-coiling pipe. The micro-nano self-coiling pipe prepared by the method is degradable, is nontoxic to human body and is especially applicable to be used as an implant material or drug carrier material in the field of biomedicine. In addition, preparation efficiency is high, the technology is simple, conditions are mild, and the structure and size of the micro-nano pipe are easy to regulate and control.

Owner:SOUTHWEST JIAOTONG UNIV

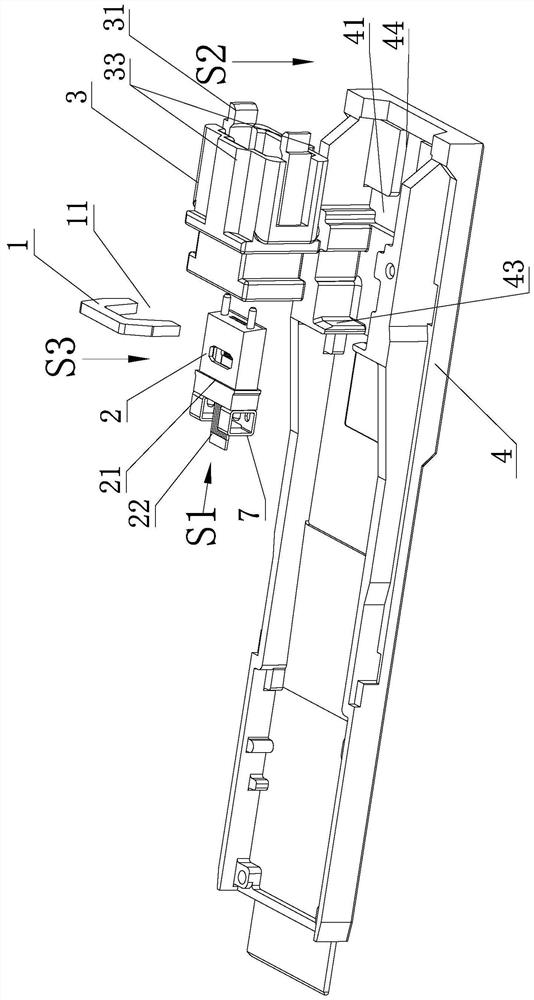

Electromagnetic relay with pushing card

PendingCN113410102AIncrease push and pull strengthFix stability issuesElectromagnetic relay detailsMechanical engineeringHot Temperature

The invention discloses an electromagnetic relay with a pushing card. The electromagnetic relay comprises a shell, a magnetic circuit part, an armature assembly, the pushing card and a contact part. The armature assembly comprises an armature and a plastic part wrapping a part of the armature. The plastic part is provided with a plastic pushing arm which extends towards the pushing card; in the armature, a metal embedded part integrally extends towards the plastic pushing arm, and the plastic pushing arm completely wraps the metal embedded part. The push-and-pull strength of the plastic push arm of the armature assembly can be improved, the armature assembly can adapt to larger counter force transmitted by the movable contact spring through the push clamp when being applied to multiple groups of movable contact springs, and the electromagnetic relay is not prone to deformation when heated and absorbing water in a high-temperature and high-humidity environment, so that the stability of a product in an attraction state is guaranteed.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

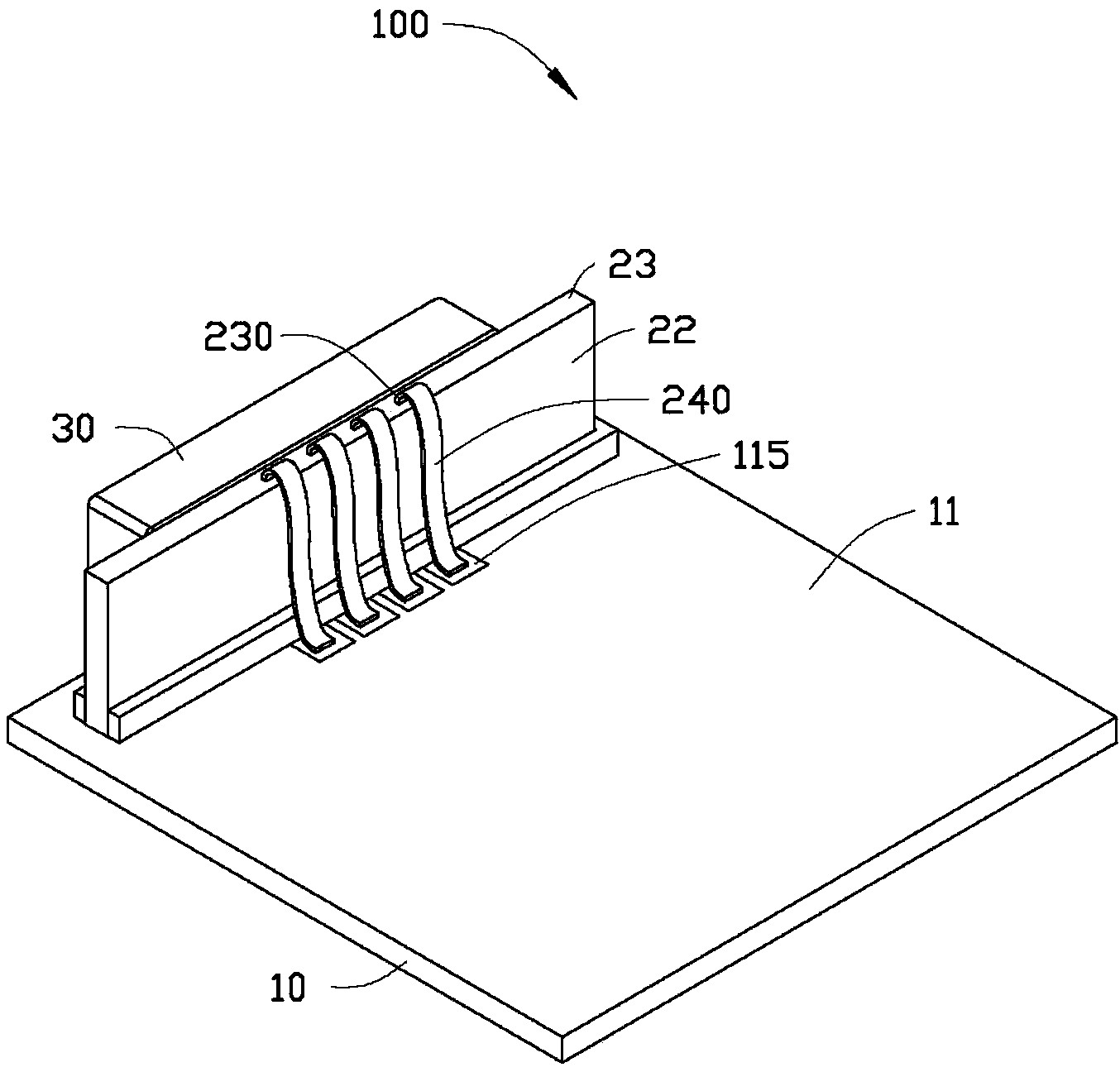

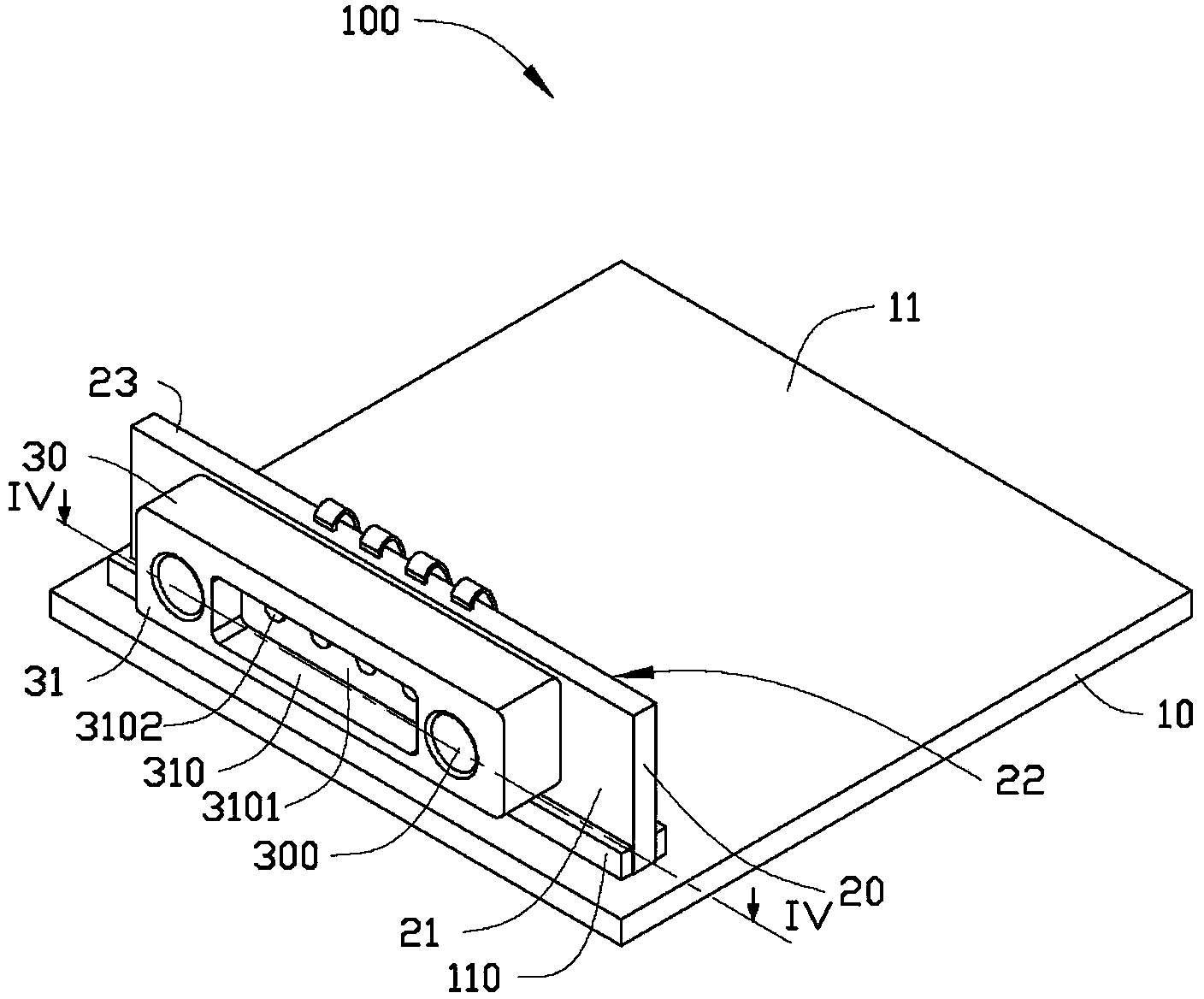

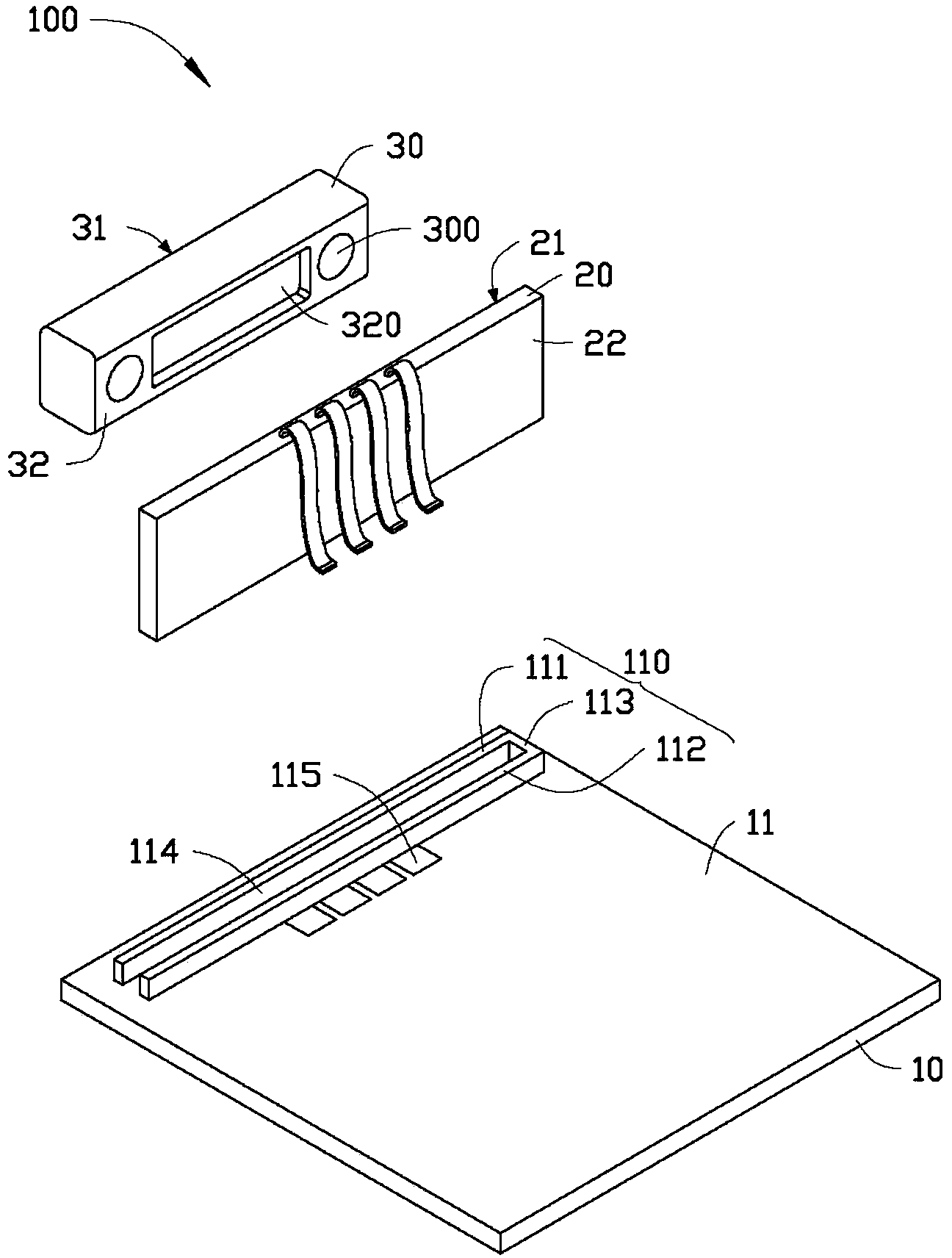

Photoelectric conversion module

InactiveCN103792625AEasy size controlEasy alignmentCoupling light guidesCouplingPhotoelectric conversion

A photoelectric conversion module comprises a main circuit board and a photoelectric coupling member, and the main circuit board comprises a bearing surface. The photoelectric conversion module further comprises a sub-circuit board, and the sub-circuit board is vertically fixed on the bearing surface and is electrically connected with the main circuit board. The sub-circuit board comprises a first surface vertical with the bearing surface, and a plurality of photoelectric elements is arranged on the first surface. The photoelectric coupling member is equipped with a plurality of first coupling lenses and is fixed on the first surface of the sub-circuit board, and the first coupling lenses align the photoelectric elements correspondingly. The photoelectric conversion module of the present invention aligns a light path easily.

Owner:SHENZHEN XUNFENG TECH

A preparation method of organic/inorganic hybrid double-layer nano-film self-rolling tube

InactiveCN105268024BNo toxic damageConvenient Chemical GraftingInorganic non-active ingredientsSurgeryMicro nanoPhytic acid

A method for preparing an organic / inorganic hybrid double-layer nano-membrane self-rolling tube, the steps mainly include: A, grinding and polishing the magnesium sheet, cleaning, and vacuum drying; B, placing the magnesium sheet in the step A in 2.5-3.5mol In the NaOH solution of / L, under 50-70 ℃, react 3-4h, obtain Mg(OH) on the magnesium sheet surface Thin film; Acid solution; D, the magnesium sheet of step B is placed in the phytic acid solution, let stand for 1-30min, promptly forms double-layer nano film on the magnesium sheet; E, after cleaning the magnesium sheet of D step, in 40-60 ℃ , and vacuum-dried for 6-24 hours, the organic / inorganic hybrid double-layer nano-film on the magnesium sheet is separated from the magnesium sheet and curled to obtain a self-rolling tube. The micro-nano self-rolling tubes prepared by this method are degradable and non-toxic to the human body, and are especially suitable for use in the biomedical field as implant materials or drug carrier materials; And the size is easy to adjust.

Owner:SOUTHWEST JIAOTONG UNIV

Device for sintering high-temperature-resistant material and application of device

ActiveCN106403606AImprove thermal conductivityUniform temperatureCharge composition/stateCharge treatment typeTemperature resistanceQuartz

The invention relates to a device for sintering a high-temperature-resistant material and application of the device. The device comprises side panels, a top panel and a bottom panel, wherein the side panels are made of silicon carbide; at least four top grooves are formed in the top panel; the left top groove and the right top groove are through grooves; a front bottom groove and a rear bottom groove are formed in the bottom panel; the front panel and the rear panel are respectively inserted in the front bottom groove and the rear bottom groove; positions, which are close to the left side and the right side of the bottom panel, of the left side panel and the right side panel are connected with the bottom panel; a plurality of through holes are formed in each side panel; a gap is formed between each two optional adjacent side panels; and anti-sticking parts which are formed by quartz fabrics are respectively paved on the inner wall of the top panel and the inner wall of the bottom panel. The invention further provides application of the device in sintering of the high-temperature-resistant material. The device has the advantages of simple structure, convenience in use, high temperature resistance, good thermal conductivity and anti-sticking property, even temperature, controllable material shape, size, appearance and microstructure and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

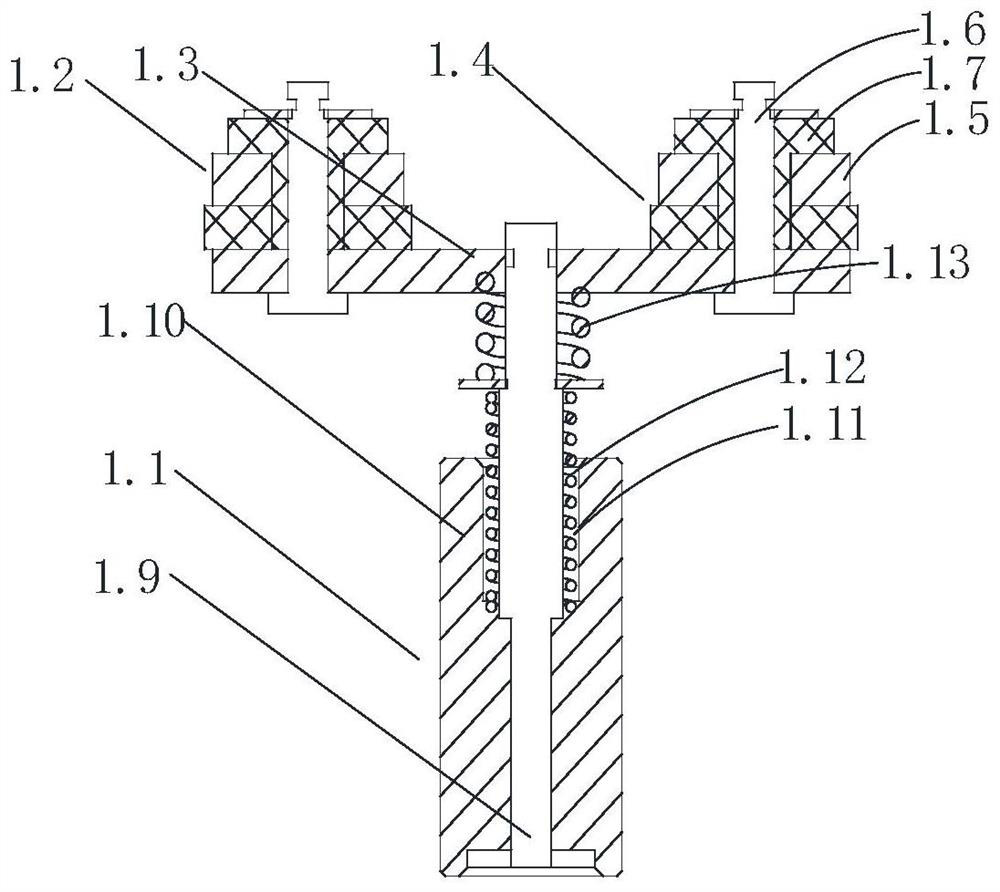

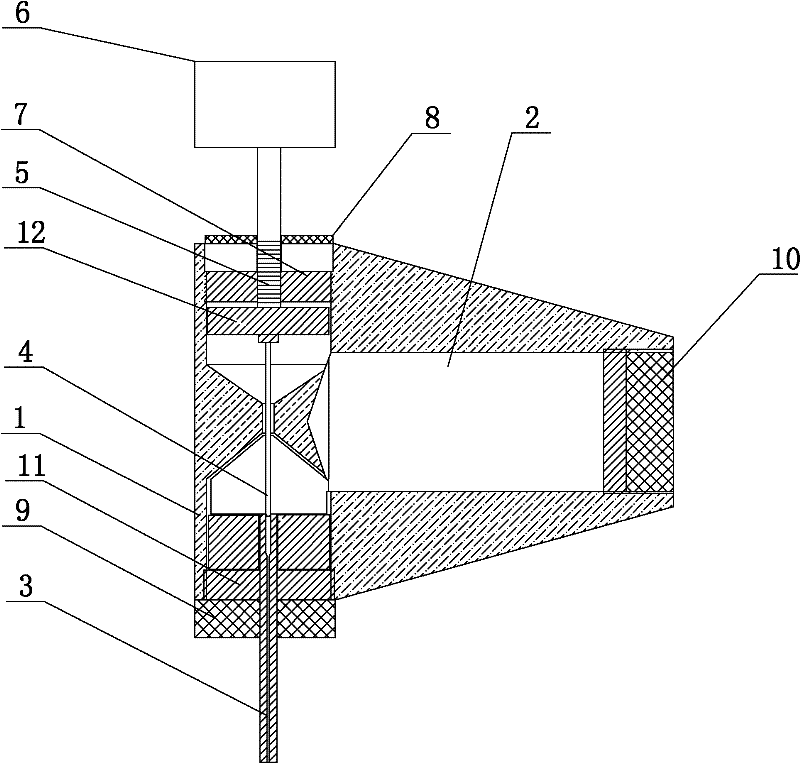

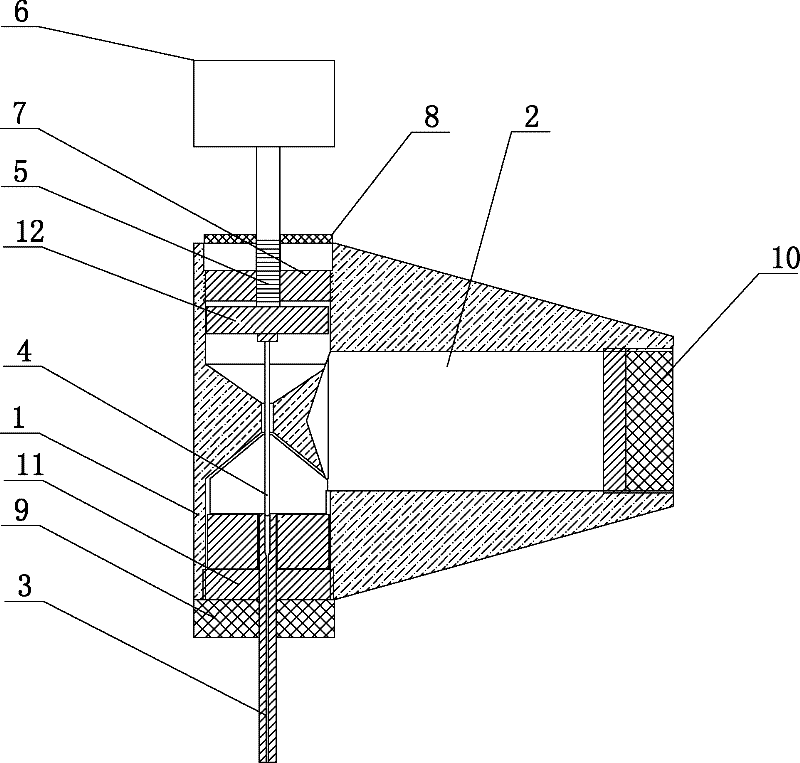

Hanging mercury electrode device used for measuring electrochemical heavy metals

ActiveCN101799445BCompact structureSimple and fast operationMaterial electrochemical variablesCapillary TubingEngineering

The invention discloses a hanging mercury electrode device used for measuring electrochemical heavy metals, which comprises a cavity, a mercury storing cup, a capillary tube, a sealing needle, a lifting rod and a lifting drive component, wherein the sealing needle and the liquid inlet end of the capillary tube are arranged in the cavity; the output end of the lifting drive component is connected with the upper end of the sealing needle by the lifting rod and drives the sealing needle to make the up and down movement; the lower end of the sealing needle is matched with the liquid inlet of the capillary tube to control the make and break of feed liquid; the liquid inlet of the capillary tube is communicated with the mercury storing cup. The invention is the hanging mercury electrode device used for measuring the electrochemical heavy metals, which has simple and compact structure, convenient operation, high degree of automation, extremely good uniformity of hanging mercury sizes and convenient control of mercury drop sizes.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Photoelectric conversion module

Provided is a photoelectric conversion module group which comprises a photoelectric coupling piece, a bridge-connecting device and multiple optical fibers. The photoelectric coupling piece can be detachably installed on the bridge-connecting device. The photoelectric coupling piece is provided with multiple first coupling lenses. The bridge-connecting device comprises a first external side surface, a second external side surface, a first end surface and a second end surface. The second external side surface extends towards the first external side surface so that multiple aligning holes are arranged, and the multiple optical fibers are respectively accommodated in the multiple aligning holes. The first end surface extends towards the first external side surface so that an inclined surface which is inclined is formed. One angle is formed by the first end surface and the inclined surface. The second end surface is also provided with a groove. The bottom part of the groove is provided with multiple second coupling lenses which are corresponding to the first coupling lenses. Each second coupling lens is arranged on an optical path which corresponds to the optical signal of the corresponding optical fiber and is reflected by the inclined surface. Each second coupling lens is correspondingly aligned with one first coupling lens. According to the photoelectric conversion module group, the optical path is easy to align.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

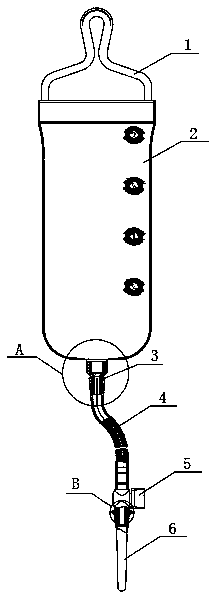

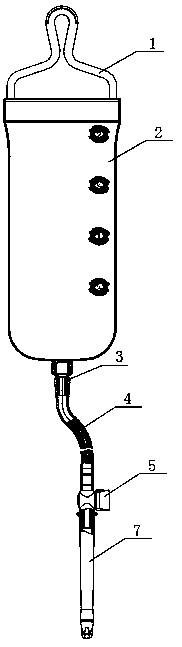

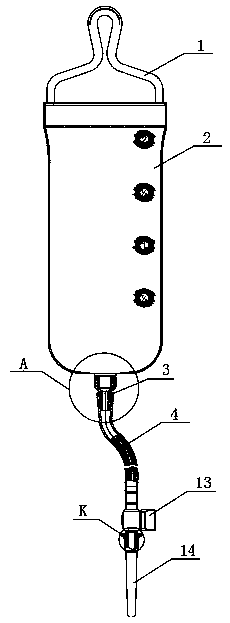

Folding easy-to-clean enema bag and assembly method thereof

The present invention relates to a folding easy-to-clean enema bag. The folding easy-to-clean enema bag comprises a bag body and a large-aperture square frame is arranged at a top part of the bag body; a handle is arranged on the large-aperture square frame; a lower part of the bag body is provided with a soft external thread joint and the soft external thread joint is sealedly connected with an internal thread connection member; and a lower part of the internal thread connection member is tightly fitted with a corrugated pipe. A medicine filling mouth of the enema bag uses a large aperture square frame structure which is convenient for filling medicine liquid and washing the enema bag; the bag body is made of a thin soft material which is convenient for turning the bag body for cleaning;periphery of the bag body uses a foldable type structure design which is convenient for storing and carrying; an assembly method is special and convenient for one-time assembly, and saves costs; the bag body is in a threaded connection with a pipe assembly, and the connection is firm and not easy to fall off; the pipe assembly is provided with a flow two-way control valve which can easily controlamount of the medicine liquid; and besides, two different-shaped enema tip nozzles are provided and convenient to select according to needs, improve washing treatment comfort of patients and are convenient to use.

Owner:NINGBO ALBERT NOVOSINO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com