High-tolerance fixing structure of MT insertion core in optical module structure

A fixed structure, optical module technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of difficulty in stabilizing MPO connectors, increasing the positioning error of the optical end face, and different positioning benchmarks, achieving enhanced electromagnetic shielding performance, The effect of reducing the positioning error of the optical end face and simple size control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

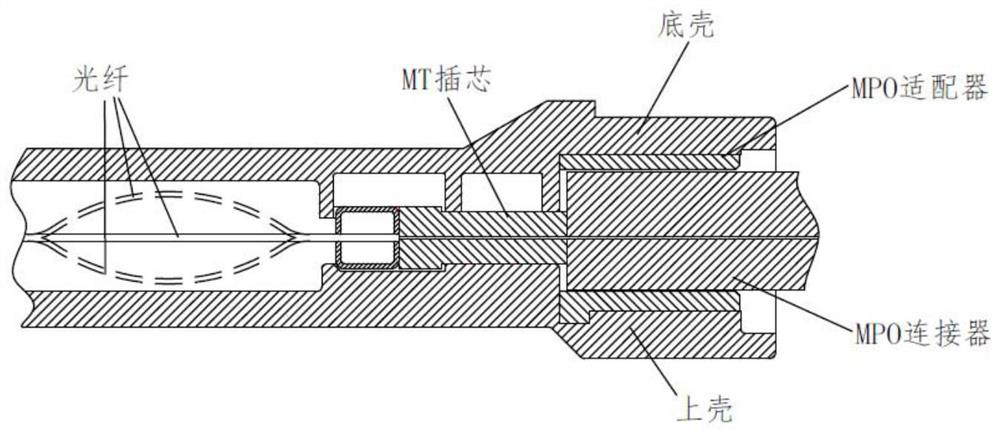

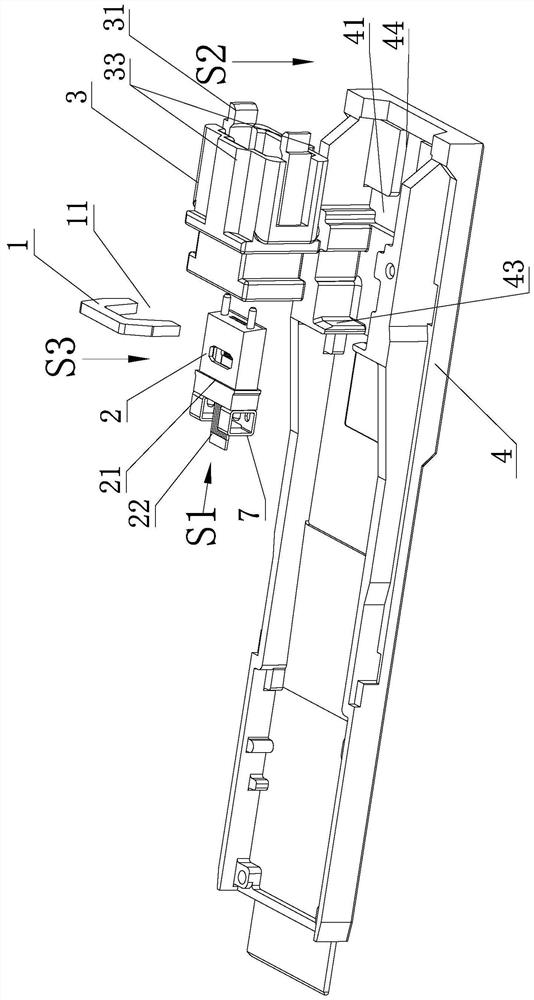

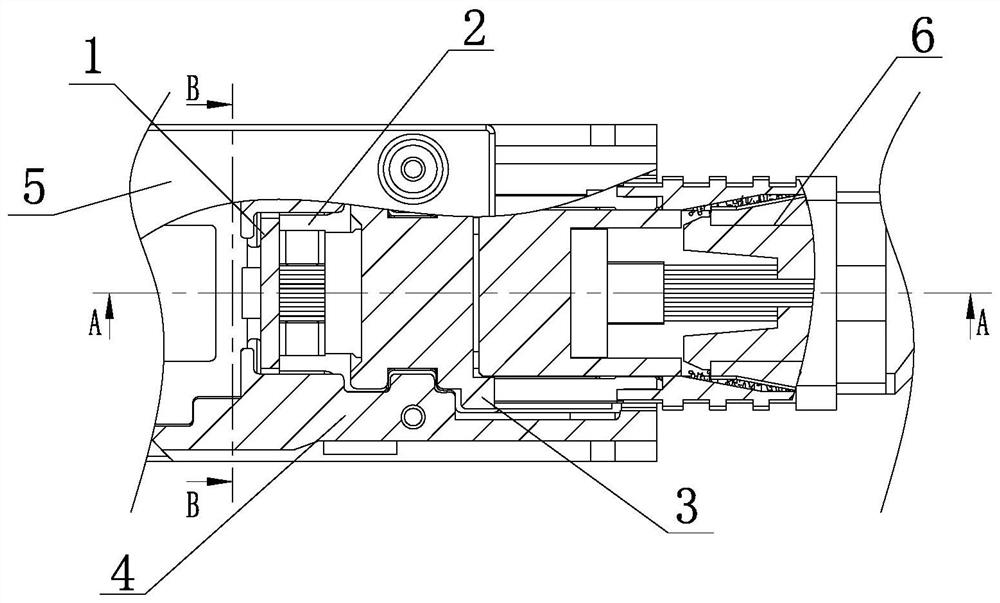

[0020] Refer to attached picture. An optical module structure described in this embodiment includes an upper cover 5 , a bottom case 4 , an MPO adapter 3 , an MT ferrule 2 and a clamping piece 1 .

[0021] One end of the MPO adapter 3 is provided with a buckle 31 for connecting to the MPO connector 6 ; the inner end is provided with a mounting groove 32 positioned with the MT ferrule 2 . The front part of the MT ferrule 2 is inserted into the installation groove 32 of the MPO adapter 3 and installed to the position where the step surface 21 of the MT ferrule coincides with the end face of the MPO installation groove.

[0022] The bottom case 4 is provided with a mounting groove 41 , and after the installation of the MT ferrule 2 and the MPO adapter 3 is completed, they are integrally installed in the mounting groove 41 of the bottom case. The rear end of the MT ferrule 2 is provided with a pin seat 7 as a sheet metal support, and the length dimension of the pin seat 7 is redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com