High electromagnetic shielding effectiveness magnesium alloy and preparation method thereof

An electromagnetic shielding and magnesium alloy technology, applied in the field of high electromagnetic shielding efficiency magnesium alloy and its preparation, magnesium alloy, to achieve the effect of short process, high electromagnetic shielding performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the heat-resistant rare earth magnesium alloy of the present embodiment is made up of the following components by weight percentage: 3% Sn, 1% Zn, 0.2% Ca, 0.3% Ce, all the other are Mg and unavoidable impurity, impurity total The amount is less than 0.12wt.%.

[0024] (1) Alloy smelting and casting: the raw materials used are industrial pure magnesium ingots, pure zinc particles, pure tin particles, Mg-30% Ca master alloy, Mg-40% Ce master alloy; cast by semi-continuous casting method. in SF 6 +CO 2 Under the protection of gas, put the magnesium ingot into the crucible and heat it up to 730°C to remove slag after melting. Add pure zinc particles, pure tin particles, Mg-30% Ca master alloy and Mg-40% Ce according to the proportion of the above alloy components. Master alloy; adding method: preheat pure zinc particles, pure tin particles, Mg-30% Ca master alloy and Mg-40% Ce master alloy at 150°C for 30 minutes, and press them below the liquid surface qui...

Embodiment 2

[0029]Embodiment 2: the heat-resistant rare earth magnesium alloy of the present embodiment is made up of the following components by weight percentage: 3% Sn, 2% Zn, 0.2% Ca, 0.3% Ce, the rest is Mg and unavoidable impurity, impurity total The amount is less than 0.12wt.%. The method of alloy smelting and casting-homogenization-machining-hot rolling-solution aging to obtain the magnesium alloy of this example is the same as that of Example 1, except that the composition ratio of the smelted alloy is different.

Embodiment 3

[0030] Embodiment 3: the heat-resistant rare earth magnesium alloy of the present embodiment is made up of the following components by weight percentage: 3% Sn, 3% Zn, 0.2% Ca, 0.3% Ce, all the other are Mg and unavoidable impurity, impurity total The amount is less than 0.12wt.%. The method of alloy smelting and casting-homogenization-machining-hot rolling-solution aging to obtain the magnesium alloy of this example is the same as that of Example 1, except that the composition ratio of the smelted alloy is different.

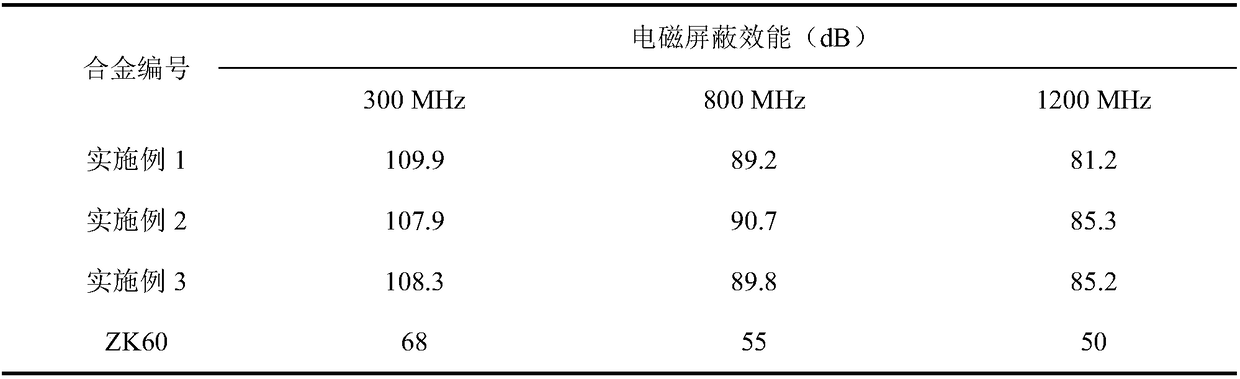

[0031] Table 1 Magnesium alloy material electromagnetic shielding performance of the present invention

[0032]

[0033] The room temperature mechanical property of table 2 magnesium alloy material of the present invention

[0034]

[0035] The electromagnetic shielding performance of the magnesium alloy material of the present invention at 1200MHz is listed in Table 1. Compared with the ZK60 alloy, the SE value of the magnesium alloy of the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com