Light-weight epoxy resin composite material and preparation method thereof

A technology of epoxy resin and composite materials, applied in the field of electromagnetic shielding materials and polymer conduction, can solve the problems of inability to obtain higher electrical conductivity and electromagnetic shielding performance, poor mechanical properties of materials, and inability to resist corrosion, and achieve good industrialization. Promising, productive, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

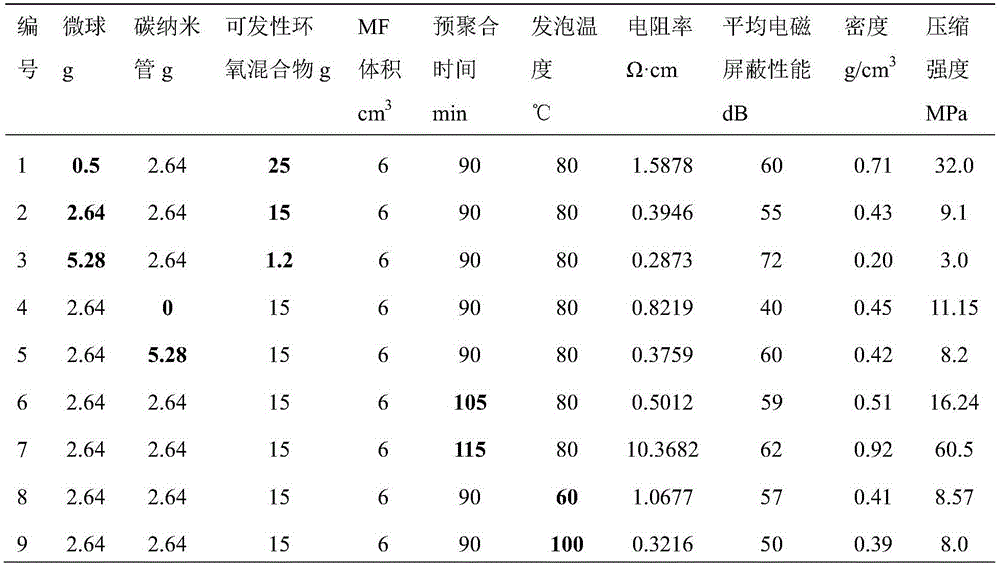

Embodiment 1

[0084] (1) Preparation of expandable epoxy resin mixture

[0085] Take 100g of E51 epoxy resin, add multi-walled carbon nanotubes according to the ratio in Table 1, and mix at least five times on a three-roll shear mixer to obtain a uniformly dispersed carbon nanotube / epoxy resin mixture. Then add polymer expanded microspheres EXPANCEL in sequence TM 031DU40, 32g polyether amine curing agent BAXXODUR TM EC301, and mix well to get the expandable epoxy resin mixture.

[0086] (2) Preparation of silver-plated melamine formaldehyde (MF) foam

[0087] The MF open-cell foam (BasotectW) with a size of 4cm×3cm×0.5cm was placed in an ethanol solution, and cleaned under ultrasound for 30min to remove surface impurities; the cleaned MF foam was placed at a temperature of 65°C and a concentration of 12g Soak in about 30min in the sodium hydroxide solution of / L, to roughen the surface, then take out the distilled water and wash; place the hydrochloric acid solution of stannous chloride...

Embodiment 2

[0093] (1) Prepare the expandable epoxy resin mixture.

[0094] Take 100g of NPEL-128 epoxy resin, add 3g of multi-walled carbon nanotubes, and mix on a three-roll shear mixer to obtain a uniformly dispersed carbon nanotube / epoxy resin mixture. Then add 1.5g polymer expansion microsphere EXPANCEL TM 051DU40, 50g polyamide curing agent V140, stir well to get the expandable epoxy resin mixture.

[0095] (2) Preparation of nickel-plated polyurethane (PU) foam.

[0096] Put the PU (4cm×3cm×0.5cm) foam in an ethanol solution and clean it under ultrasonic for 30min to remove surface impurities; put the cleaned PU foam in sodium hydroxide with a temperature of 65°C and a concentration of 12g / L Soak in the solution for about 30min to roughen the surface, then take out the distilled water and wash it; soak the roughened PU foam in the hydrochloric acid solution of stannous chloride (12g / LSnCl 2 and 5ml / L conc 2 ) for 20 minutes; place the activated PU foam in a nickel plating sol...

Embodiment 3

[0100] (1) Prepare the expandable epoxy resin mixture.

[0101] Take 100g of E51 epoxy resin, add 3.5g of conductive carbon black, then mix on a three-roller shear mixer to obtain a mixture of conductive carbon black / epoxy resin, and then add a certain amount of surface coupling treated carbon black according to the formula in Table 2. Glass hollow microspheres (3M TM , particle size 15-120μm), and then add 15g of triethanolamine / triethylenetetramine (4:3) and mix well to obtain the expandable epoxy resin mixture.

[0102] (2) Preparation of nickel-plated PVC foam.

[0103] Put the open-cell PVC foam (4cm×3cm×0.5cm) in distilled water and clean it under ultrasonic for 30min to remove surface impurities; put the cleaned PVC foam in the hydrogen oxidation solution with a temperature of 50°C and a concentration of 12g / L Soak in sodium solution for about 30 minutes to roughen the surface, then take out distilled water and wash it; place the roughened PVC foam in a hydrochloric a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com