PET (polyethylene terephthalate)-based electromagnetic shielding composite and preparation method thereof

A technology of polyethylene terephthalate and composite materials is applied in the field of preparation of polymer-based nanocomposite materials to achieve the effect of excellent electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

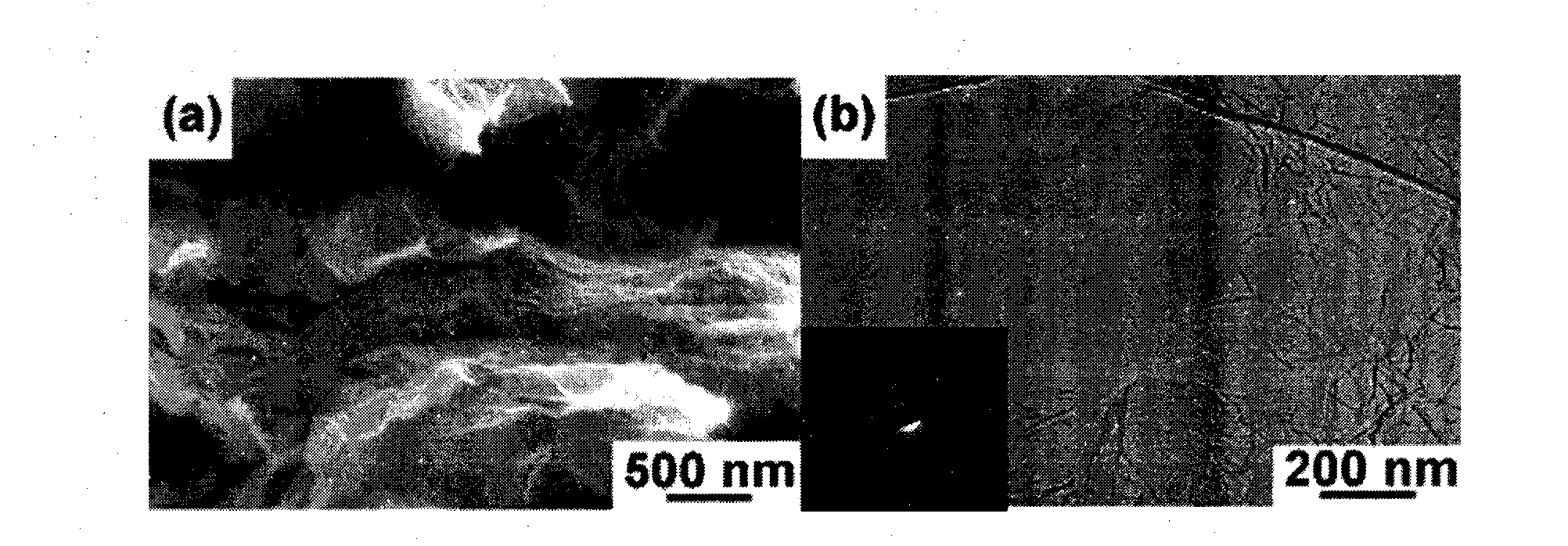

[0020] 1) Reductive exfoliation of graphite oxide into graphene at 1000°C for 0.5 min. The obtained graphene has a thickness of 0.35-10 nm and a diameter of 5-10 μm.

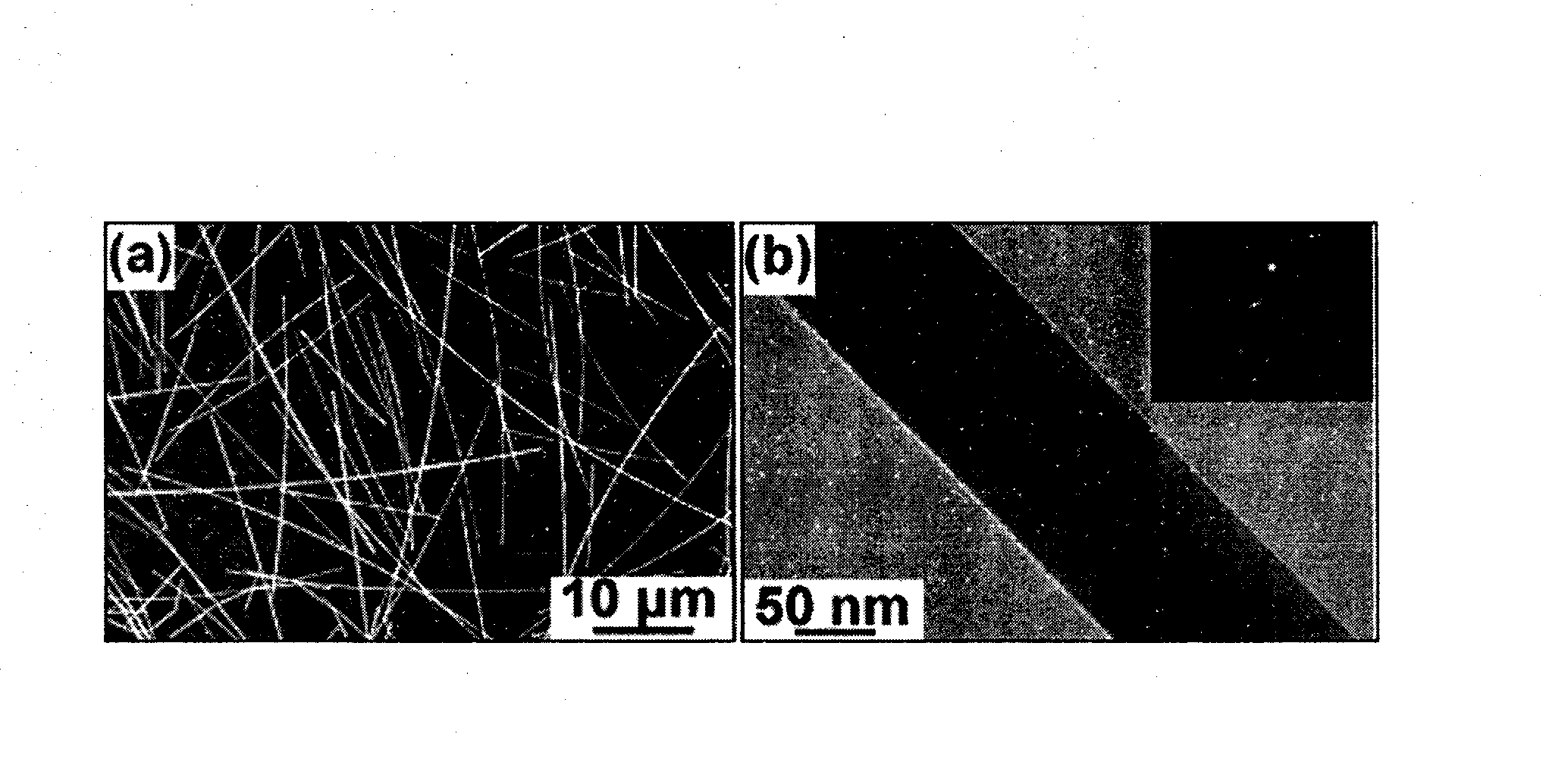

[0021] 2) In 10mL0.1mM FeCl 3 Add 0.15M PVP to the ethylene glycol solution, stir until the PVP is completely dissolved, then add 10mL 0.1M AgNO dropwise 3 solution, stirred for 10 minutes. Then the mixed solution was transferred to a hydrothermal synthesis reactor and reacted at 160° C. for 2 hours. Natural cooling, that is, silver nanowires with a diameter of 40-50 nm and a length of 20-50 μm are obtained.

[0022] 3) take by weighing step 1) 0.05 gram of graphene gained, take by weighing 0.05 gram of silver nanowire of step 2) gained, take by weighing PET100 gram, join in the twin-screw extruder and mix together, the work of twin-screw extruder The temperature is 280 degrees Celsius, and the rotation speed is 100 rpm. Then, after extruding and granulating, the materials are re-added to the twin-screw ext...

Embodiment 2

[0025] 1) Reductive exfoliation of graphite oxide into graphene at 600°C for 3 minutes. The obtained graphene has a thickness of 5-20 nm and a diameter of 10-20 μm.

[0026] 2) In 200mL0.1mM FeCl 3 Add 0.15M PVP to the ethylene glycol solution, stir until the PVP is completely dissolved, then add 200mL 0.1M AgNO dropwise 3 solution, stirred for 20 minutes. Then the mixed solution was transferred to a hydrothermal synthesis reactor and reacted at 160° C. for 3 hours. Cool naturally to obtain silver nanowires with a diameter of 80-100 nm and a length of 10-30 μm.

[0027] 3) take by weighing step 1) 2 grams of graphene gained, take by weighing step 2) 2 grams of silver nanowires gained, take by weighing PET100 grams, join in the twin-screw extruder and mix together, the work of twin-screw extruder The temperature is 300 degrees Celsius, and the rotation speed is 300 rpm. Then, after extruding and granulating, the materials are re-added to the twin-screw extruder for mixing....

Embodiment 3

[0030] 1) Reductive exfoliation of graphite oxide into graphene at 800°C for 2 minutes. The obtained graphene has a thickness of 1-10 nm and a diameter of 5-15 μm.

[0031] 2) In 400mL0.1mM FeCl 3 Add 0.15M PVP to the ethylene glycol solution, stir until the PVP is completely dissolved, then add 400mL 0.1M AgNO dropwise 3 solution, stirred for 20 minutes. Then the mixed solution was transferred to a hydrothermal synthesis reactor and reacted at 160° C. for 4 hours. Cool naturally to obtain silver nanowires with a diameter of 80-100 nm and a length of 10-30 μm.

[0032] 3) take by weighing step 1) 3 grams of graphene gained, take by weighing step 2) 4 grams of silver nanowires gained, take by weighing PET100 grams, join in the twin-screw extruder and mix together, the work of the twin-screw extruder The temperature is 300 degrees Celsius, and the rotation speed is 300 rpm. Then, after extruding and granulating, the materials are re-added to the twin-screw extruder for mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com