High-conductivity heat-resistant in-situ synthesized aluminum matrix composite material and preparation method thereof

An aluminum-based composite material, in-situ self-generated technology, applied in the field of metal-based composite materials, can solve problems such as reinforcement dispersion, insufficient electrical conductivity and heat resistance, damage to human health and equipment, and reduced electrical conductivity of composite materials, etc., to achieve simple regulation Ease of operation, less environmental damage, and the effect of improving ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

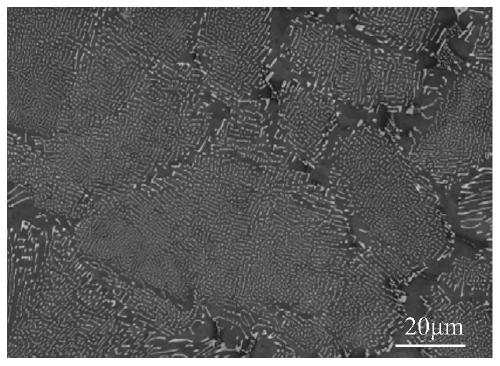

[0033] This embodiment provides an in-situ self-generated aluminum-based composite material with high conductivity and heat resistance. The aluminum-based composite material is composed of the following elements in weight percentage: Ce is 11.00%, other impurity elements are ≤0.10%, and the rest is aluminum.

[0034] In the aluminum-based composite material in this example, aluminum is used as the matrix, and cerium and aluminum elements form Al 11 Ce 3 The intermetallic compound has good thermal stability, and as a reinforcing phase of the composite material, the strength and heat resistance of the material are effectively improved. The cerium element has a low solid solubility in aluminum, and at the same time has the function of purifying the aluminum matrix, reducing the influence of solid-dissolved impurity elements on the electrical conductivity, and improving the electrical conductivity of the composite material.

[0035] The above-mentioned high-conductivity and heat-...

Embodiment 2

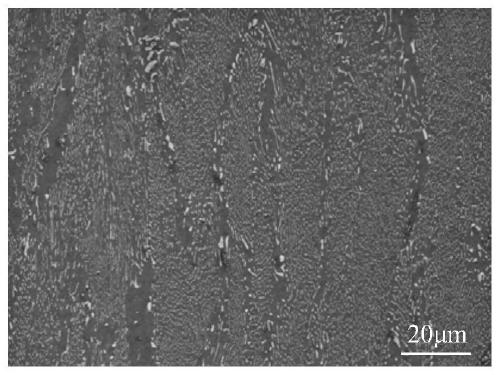

[0044] This embodiment provides an in-situ self-generated aluminum-based composite material with high conductivity and heat resistance. The aluminum-based composite material is composed of the following elements in weight percentage: Ce is 5.00%, other impurity elements are ≤0.10%, and the rest is aluminum.

[0045] The above-mentioned high-conductivity and heat-resistant in-situ self-generated aluminum-based composite material in this embodiment can be prepared by the following method, and the specific steps are as follows:

[0046] Step 1: select Al 99.7% industrial pure aluminum and place it in a smelting furnace to raise the temperature to 750° C. to melt into molten aluminum.

[0047] Step 2: Weigh the raw materials for preparing the aluminum-cerium master alloy according to the composition of Ce5%, add the aluminum-cerium master alloy to the aluminum liquid prepared in the step 1, and use graphite rods to continuously stir, so that the cerium is evenly stirred to obtain a...

Embodiment 3

[0053] An in-situ self-generated aluminum-based composite material with high conductivity and heat resistance, the aluminum-based composite material is composed of the following elements in weight percentage: Ce is 9.00%, other impurity elements are ≤0.10%, and the rest is aluminum.

[0054] The above-mentioned high-conductivity and heat-resistant in-situ self-generated aluminum-based composite material in this embodiment can be prepared by the following method:

[0055] Step 1: select Al 99.9% industrial pure aluminum and place it in a smelting furnace to raise the temperature to 730° C. to melt into molten aluminum.

[0056] Step 2: Weigh the aluminum-cerium master alloy preparation raw material according to the Ce 9% composition, add the aluminum-cerium master alloy to the aluminum liquid prepared in the step 1, and use graphite rods to continuously stir, so that the cerium is evenly stirred, and a mixed melt is obtained.

[0057] Step 3, adding a deslagging and degassing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com