Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Dense connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

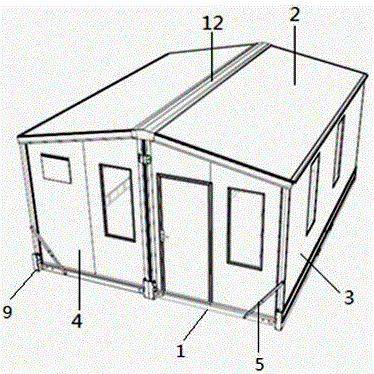

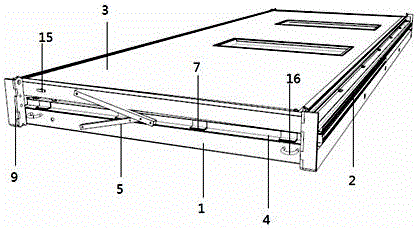

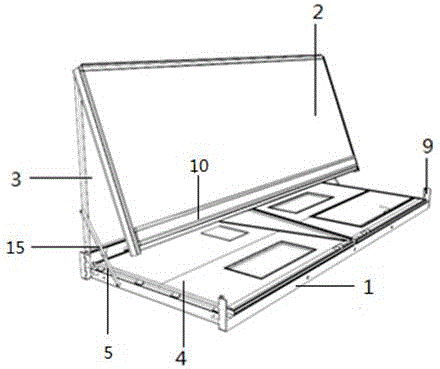

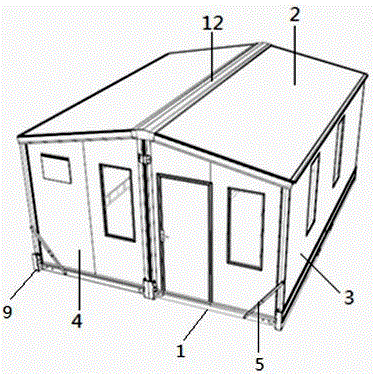

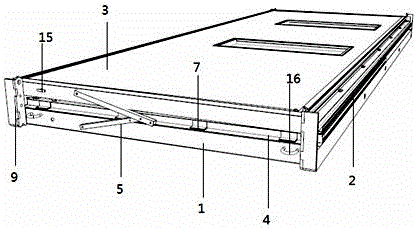

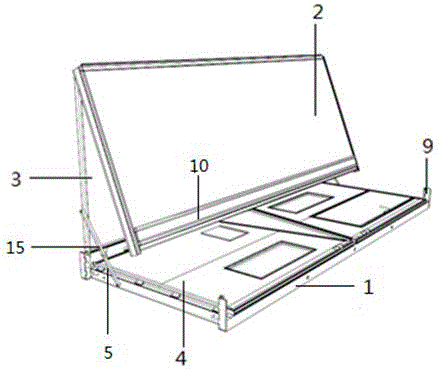

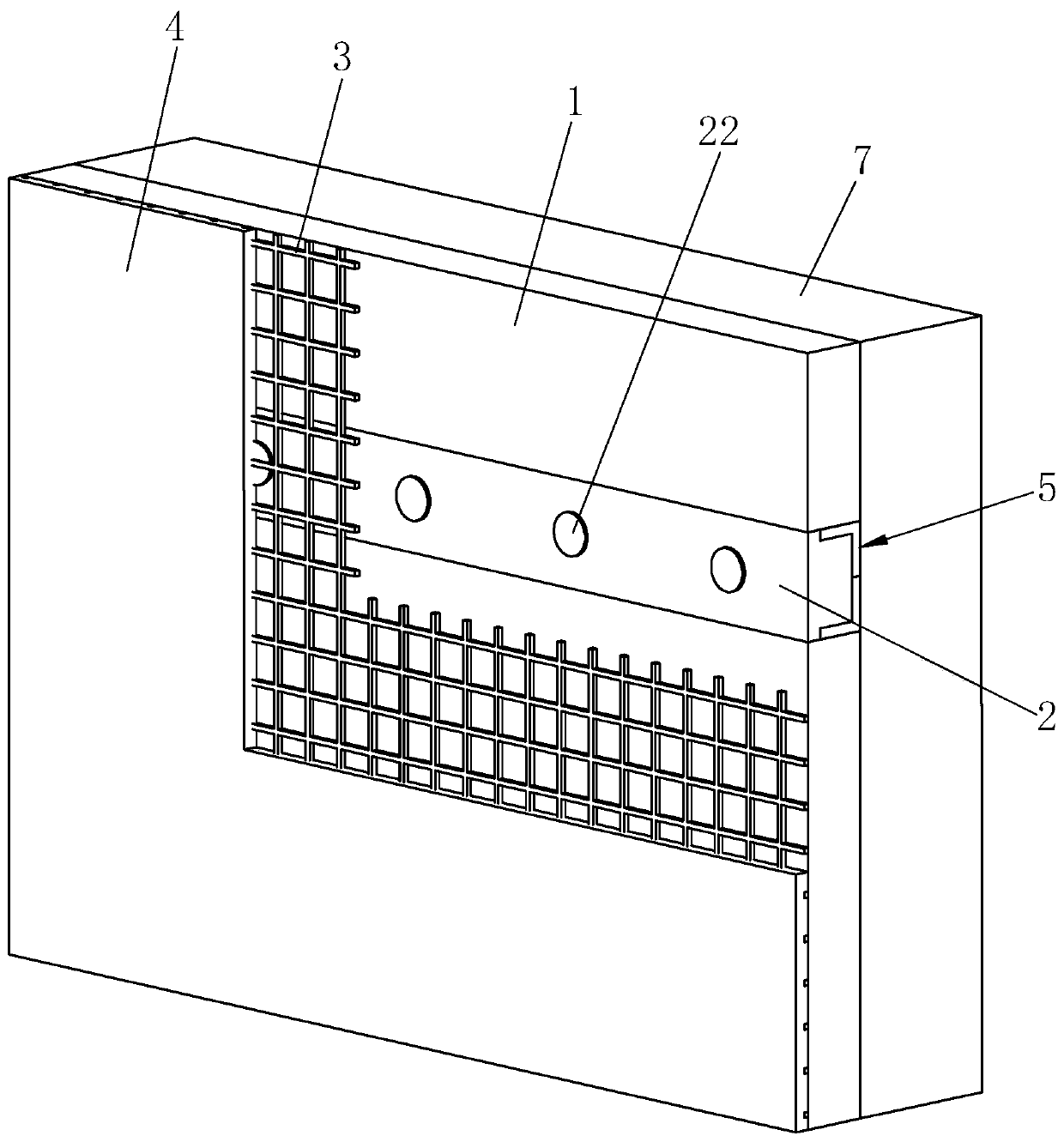

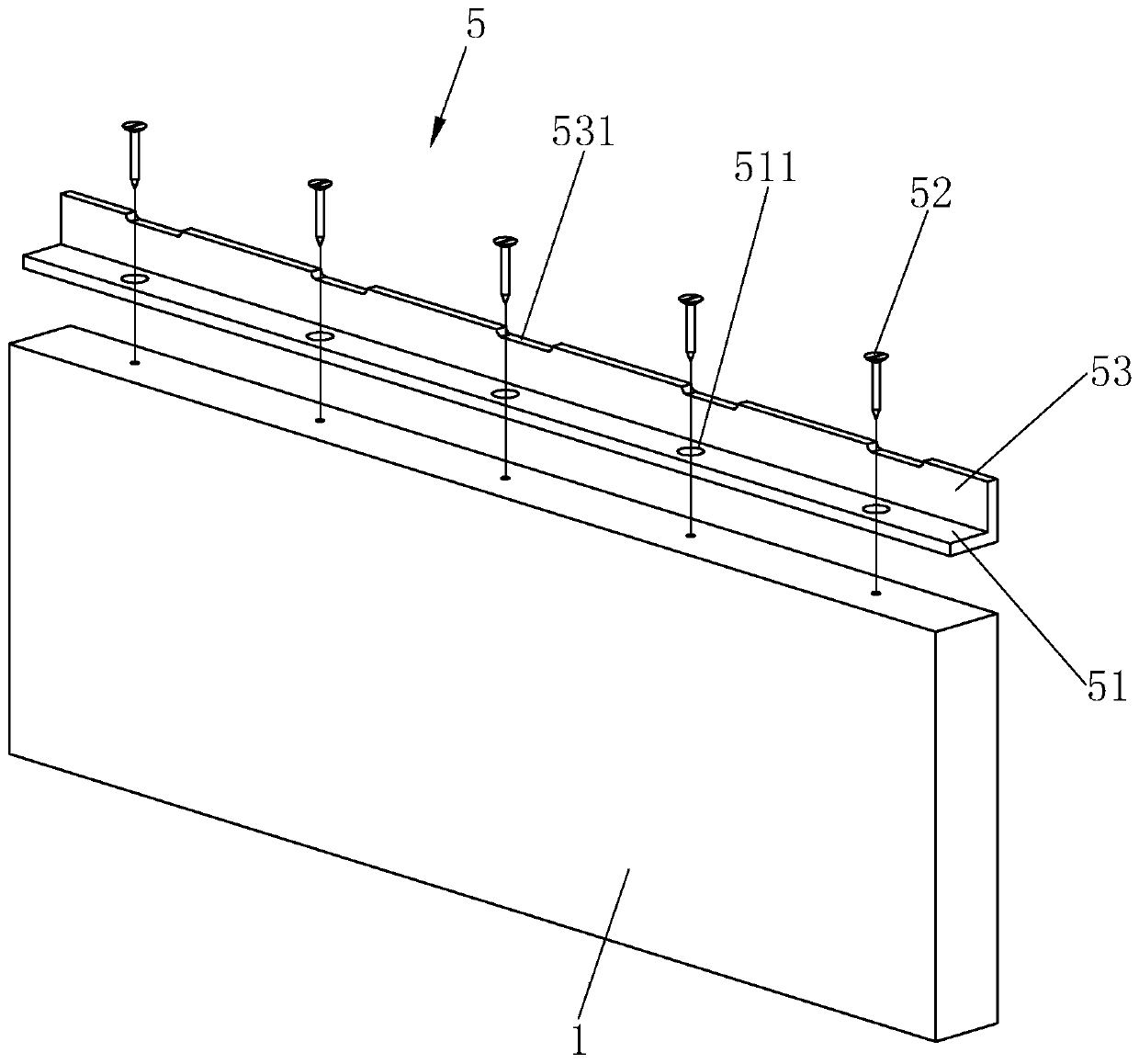

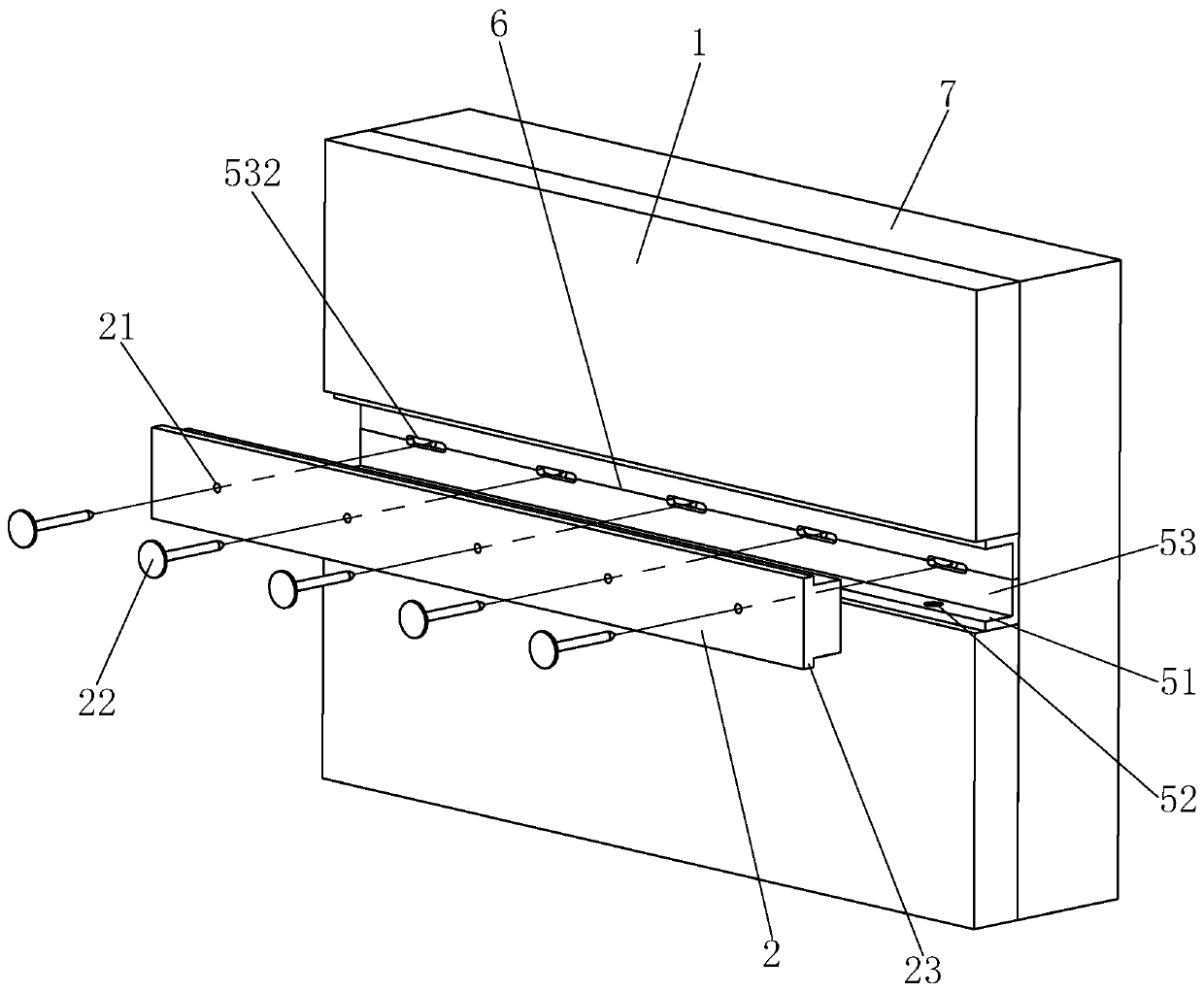

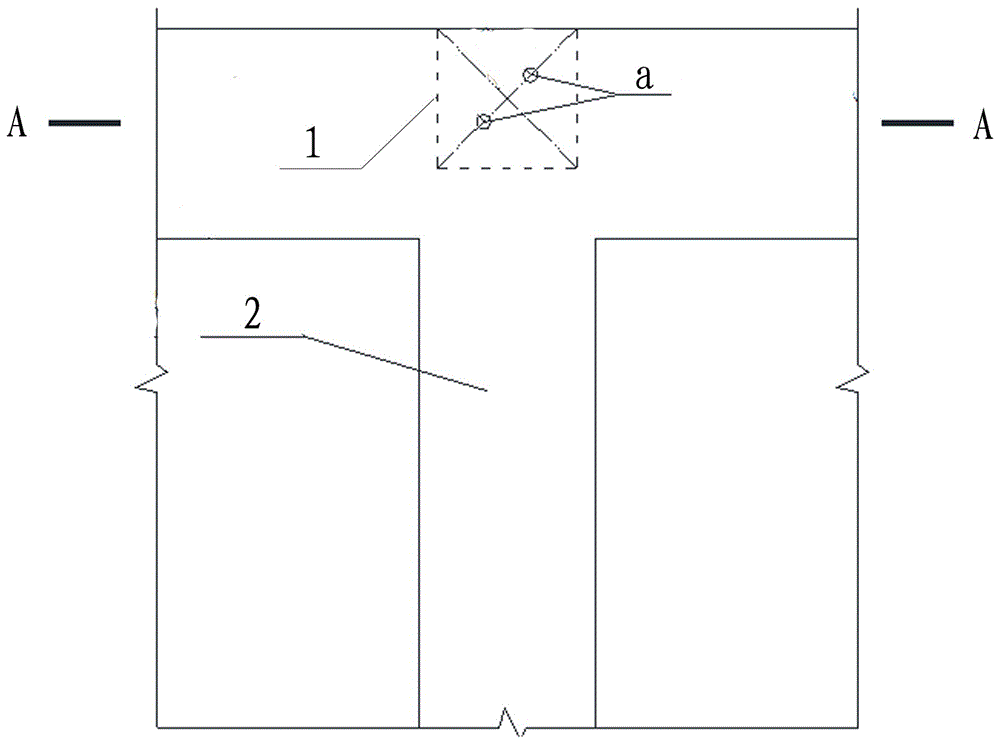

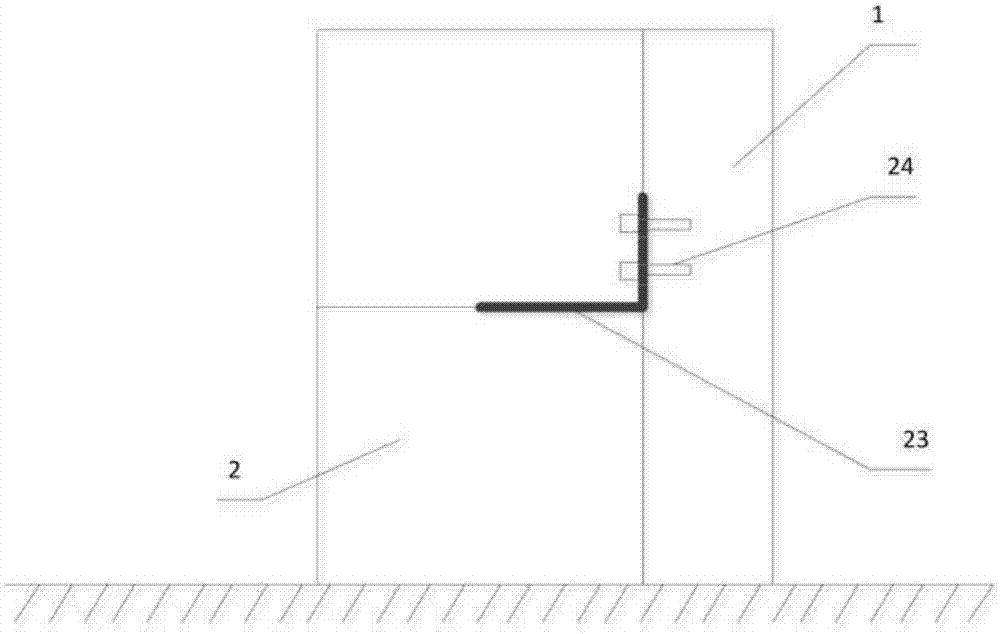

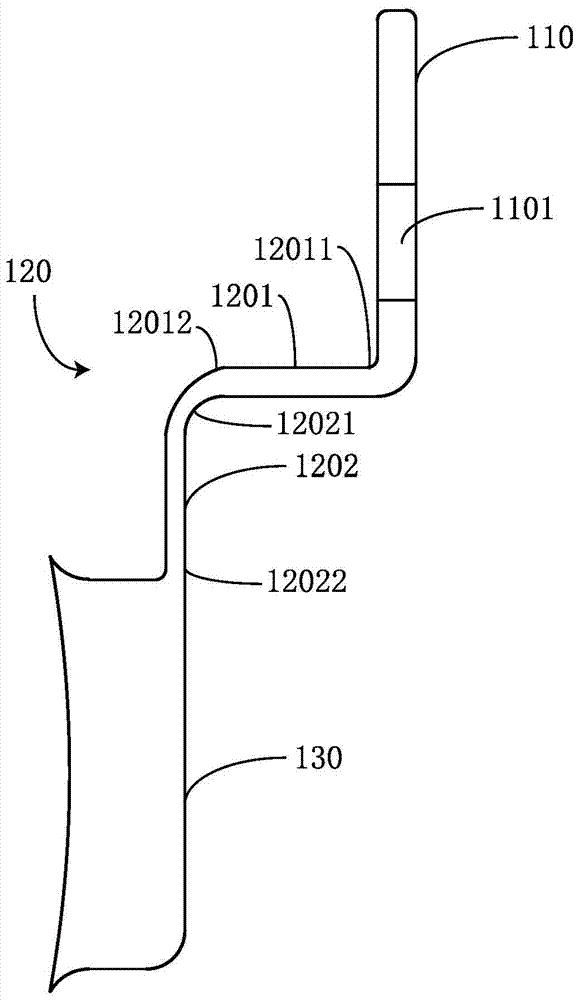

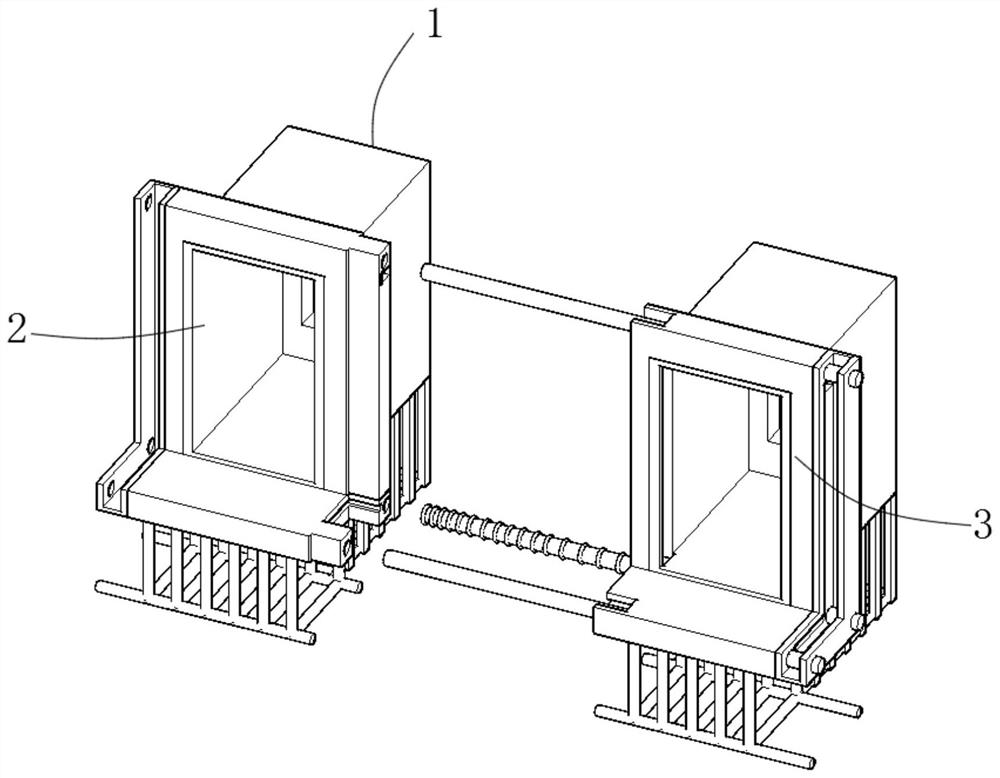

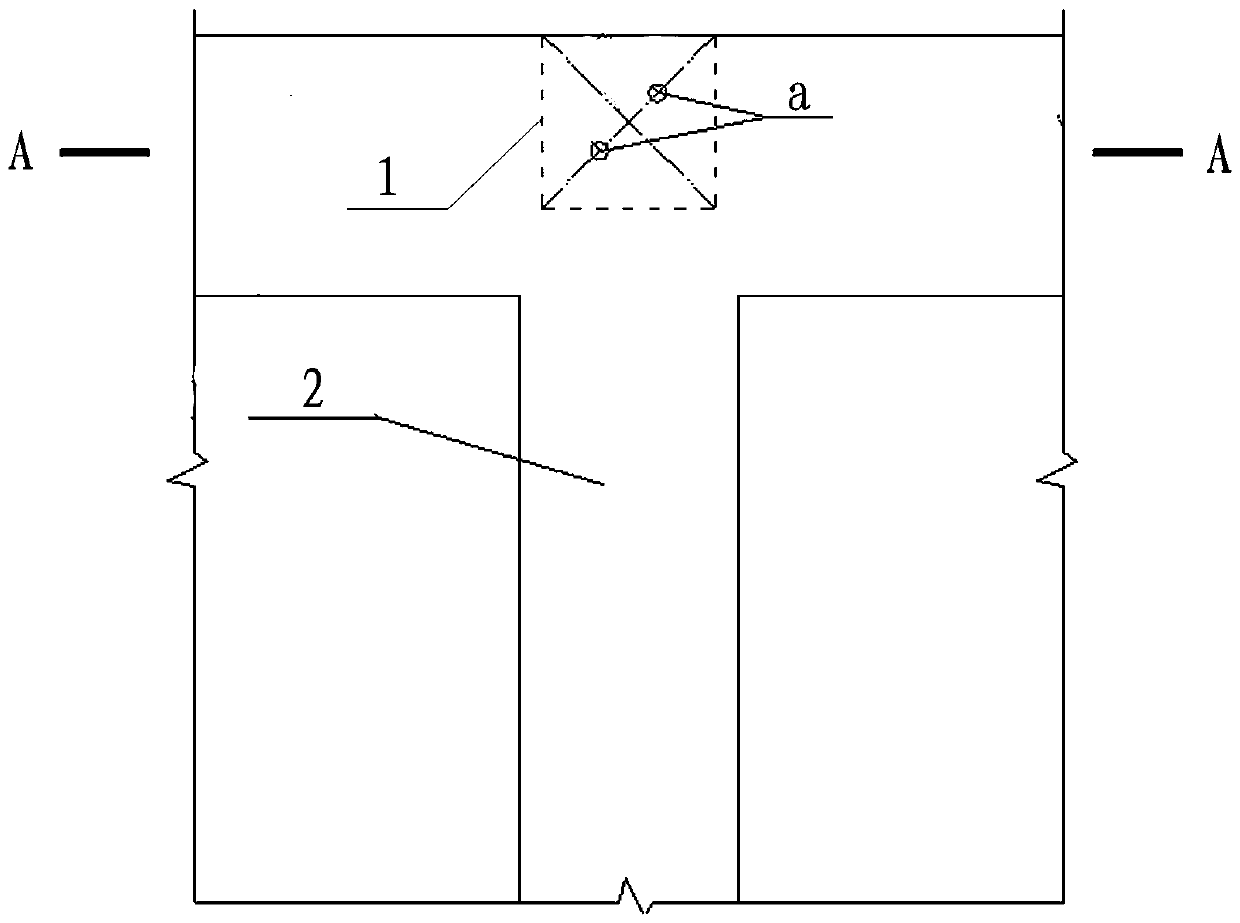

Foldable house and assembling and disassembling method thereof

ActiveCN105735480AReasonable structural designIncrease the usable areaBuilding constructionsEngineeringWall plate

The invention relates to a foldable house and an assembling and disassembling method thereof, and belongs to the technical field of moveable house structures. The foldable house comprises a first unit and a second unit, wherein the first unit and the second unit are structurally symmetric and can be integrally assembled with each other to form the foldable house; the first unit and the second unit both comprise bottom plates and mountain wall plates which are hinged to two opposite sides of the bottom plates; side wall plates are arranged between the two mountain wall plates; the bottoms of the side wall plates are hinged to the bottom plates; a top plate is hinged to the tops of the side wall plates; side surface connecting parts and top connecting parts of both the first unit and the second unit are respectively assembled integrally through detachable side connecting members and top connecting members. The foldable house is smart in structural design, small in space, light in weight, rapid in assembly and disassembly, and convenient and rapid in transport, and can be repeatedly assembled and disassembled for use.

Owner:WANHUA MODULAR PROJECTS

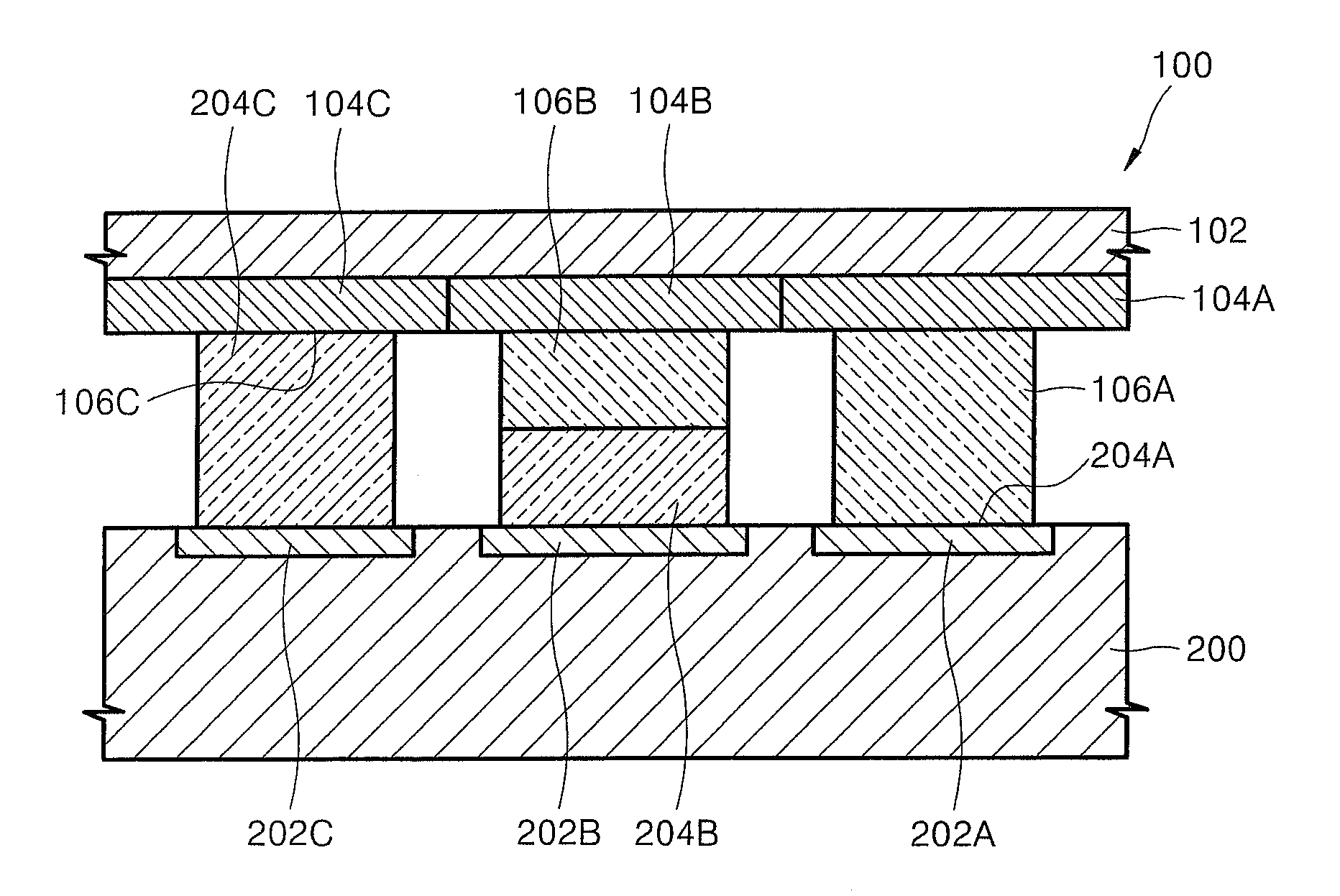

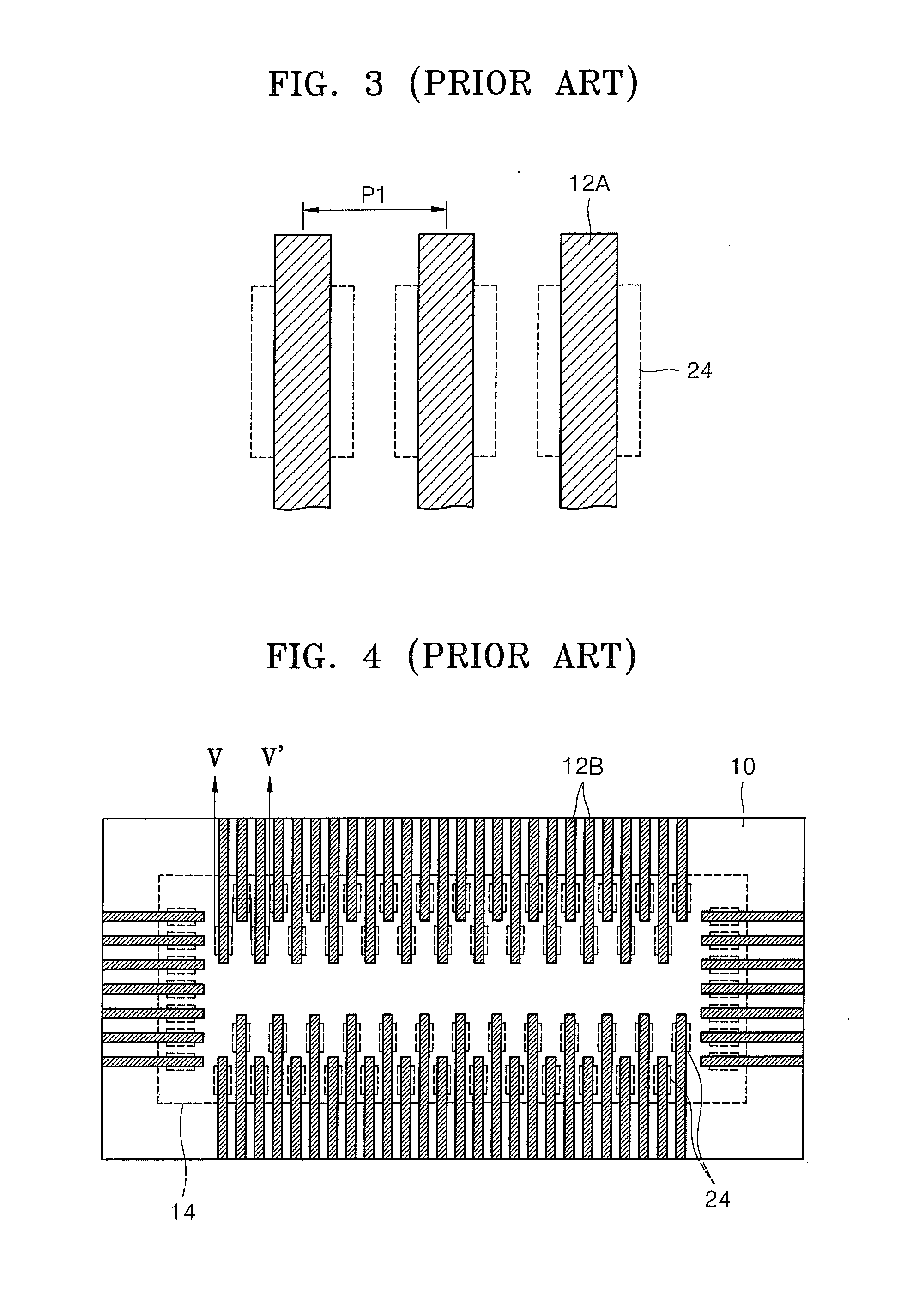

Semiconductor chip having bumps of different heights and semiconductor package including the same

InactiveUS20080119061A1Dense connectionDense connection arrangementsFinal product manufactureSemiconductor/solid-state device detailsSemiconductor chipSemiconductor package

A semiconductor chip is disclosed and includes a plurality of bond pads disposed on a semiconductor chip, and a plurality of chip bumps of different heights disposed on a corresponding bond pad.

Owner:SAMSUNG ELECTRONICS CO LTD

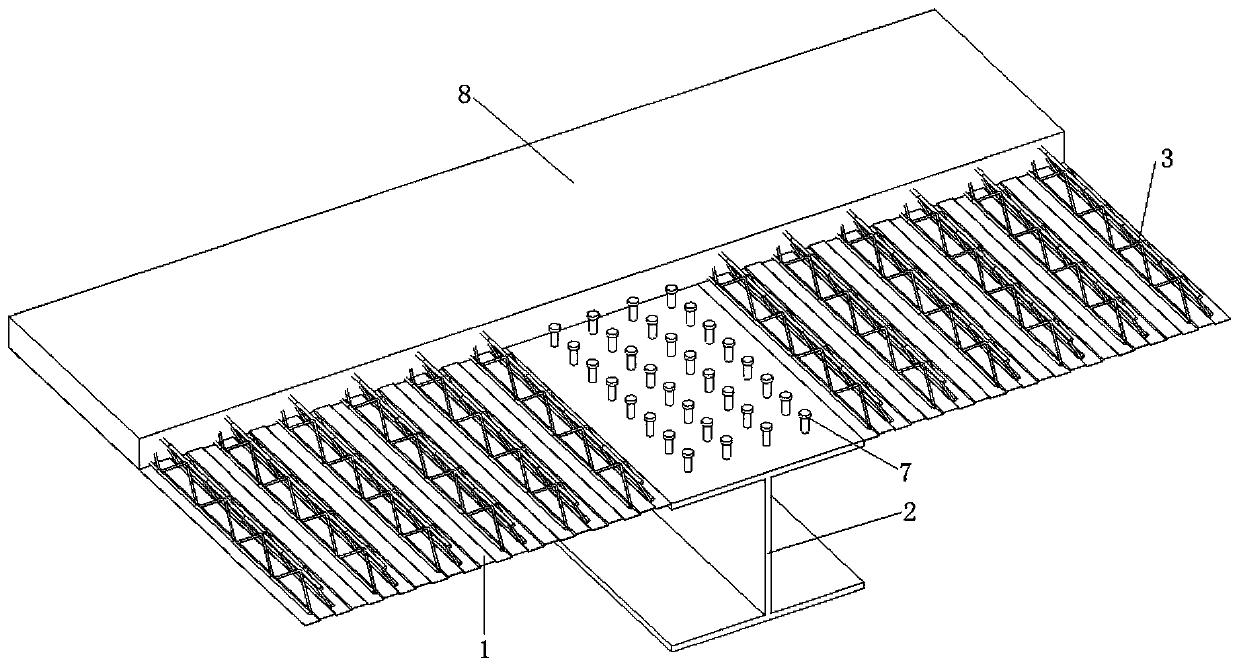

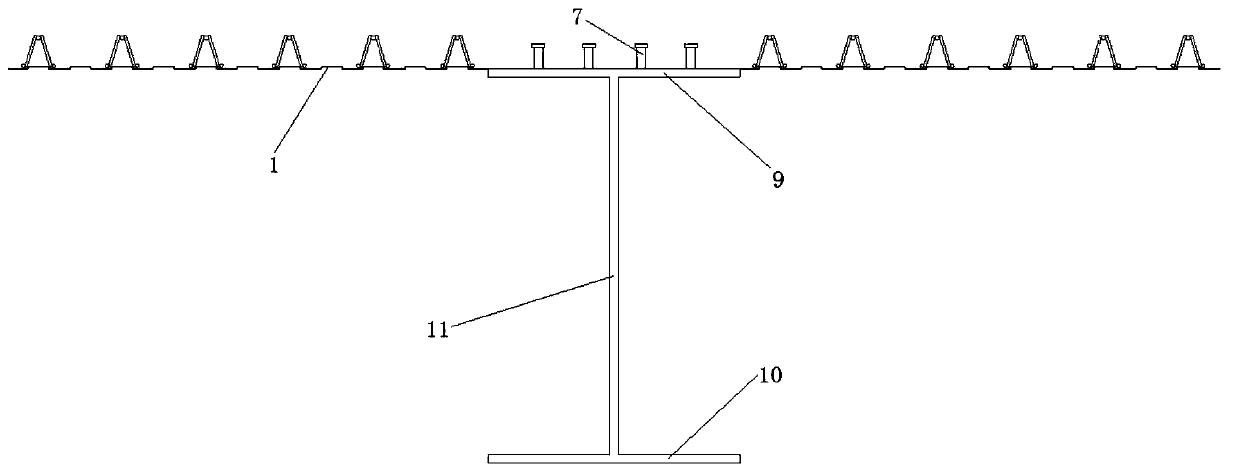

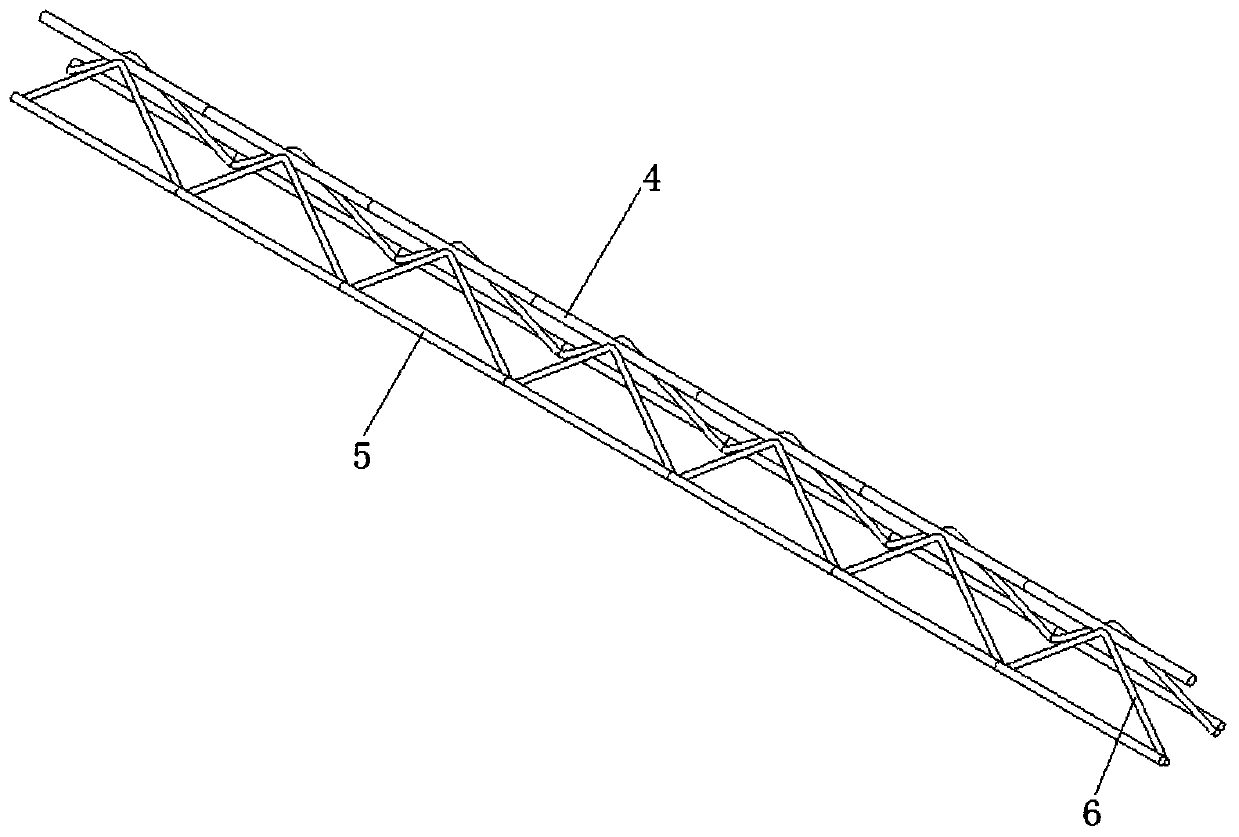

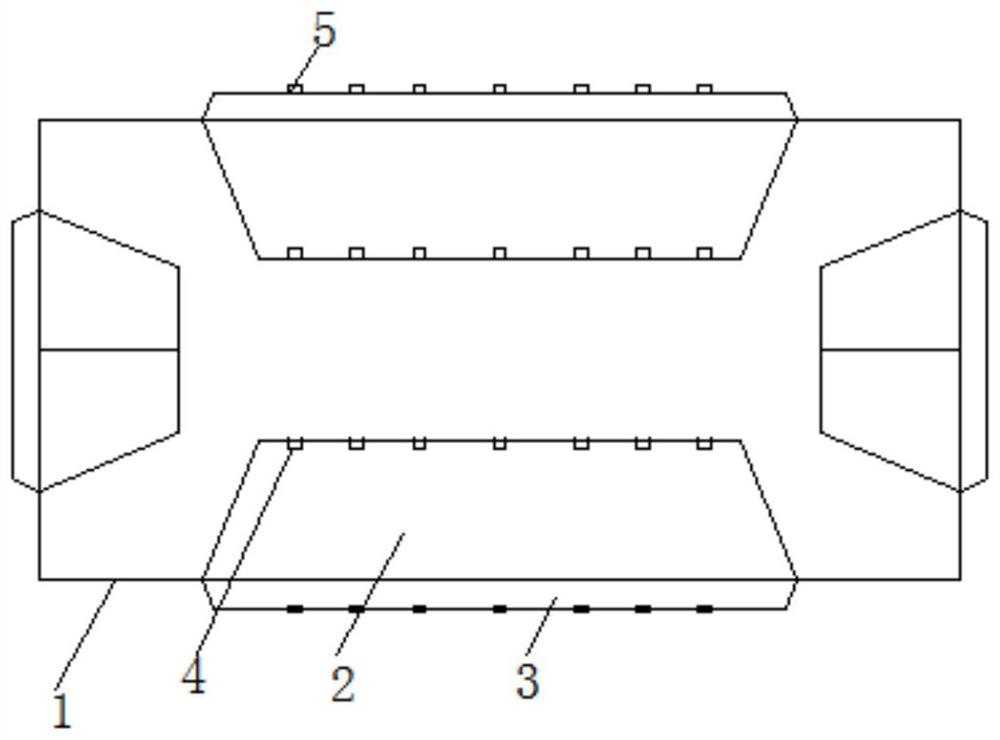

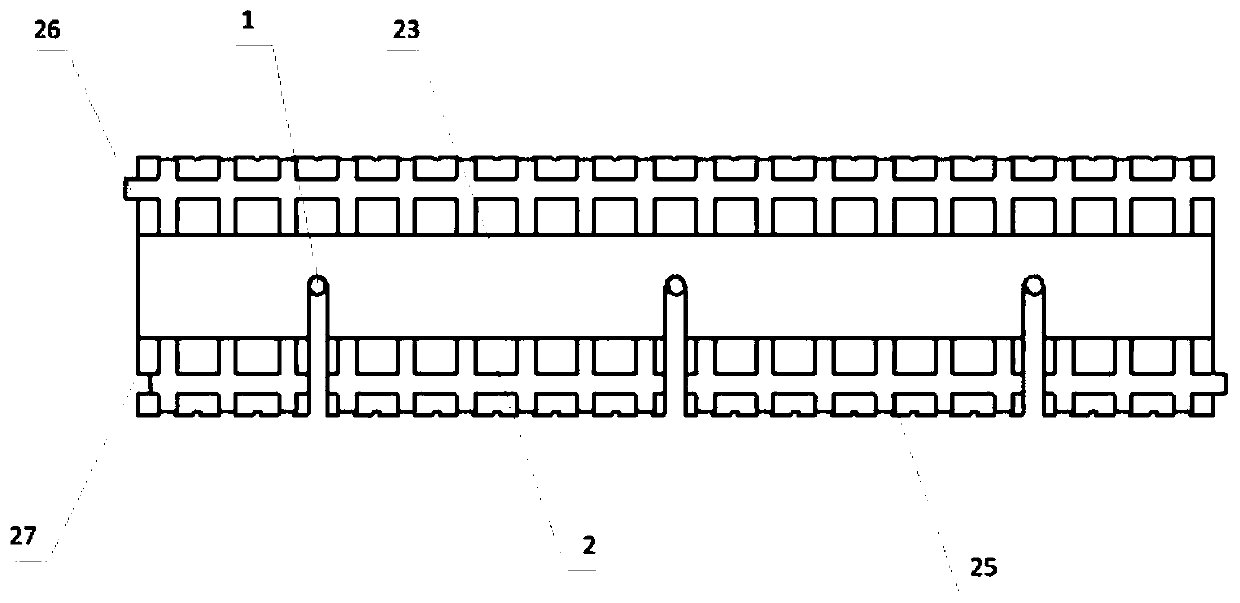

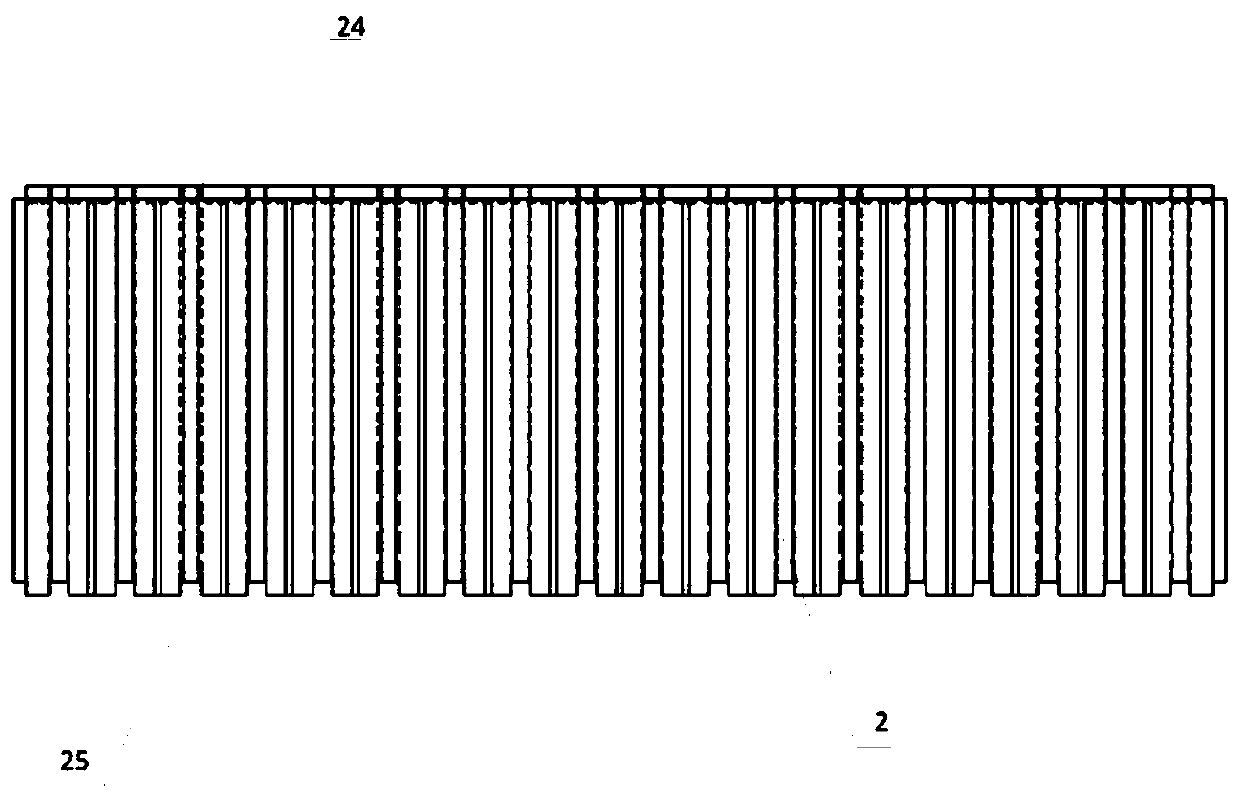

Steel plate composite beam bridge support-free cast-in-place concrete device and construction method

PendingCN110952457AEnhanced stiffeningAvoid intensityBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a steel plate composite beam bridge support-free cast-in-place concrete device and a construction method. The steel plate composite beam bridge support-free cast-in-place concrete device comprises profiled steel sheets, steel beams, steel reinforcement frameworks and shear connectors. The shear connectors are arranged on the upper flanges of the steel beams, the two sides of the upper flanges of the steel beams are each connected with a profiled steel sheet, and a plurality of steel bar frameworks are arranged on each profiled steel sheet. When the device is used for cast-in-place construction of the concrete bridge deck slab, a bracket is not required to be erected; the bearing capacity of the bridge deck slab is improved by the upper steel reinforcement frameworks; the profiled steel sheets at the bottom are used as a formwork, the bottom concrete is prevented from being subjected to slurry leakage, pitted surfaces, falling and other diseases, threats to pedestrians or vehicles passing under the bridge are avoided, meanwhile, the economical efficiency is good, construction is convenient and fast, the construction efficiency is remarkably improved, the construction cost is saved, and civilized construction and safe construction are convenient to achieve.

Owner:CHANGAN UNIV

A foldable house and its disassembly method

ActiveCN105735480BIncrease the usable areaReduce weightBuilding constructionsMechanical engineeringIndustrial engineering

Owner:WANHUA MODULAR PROJECTS

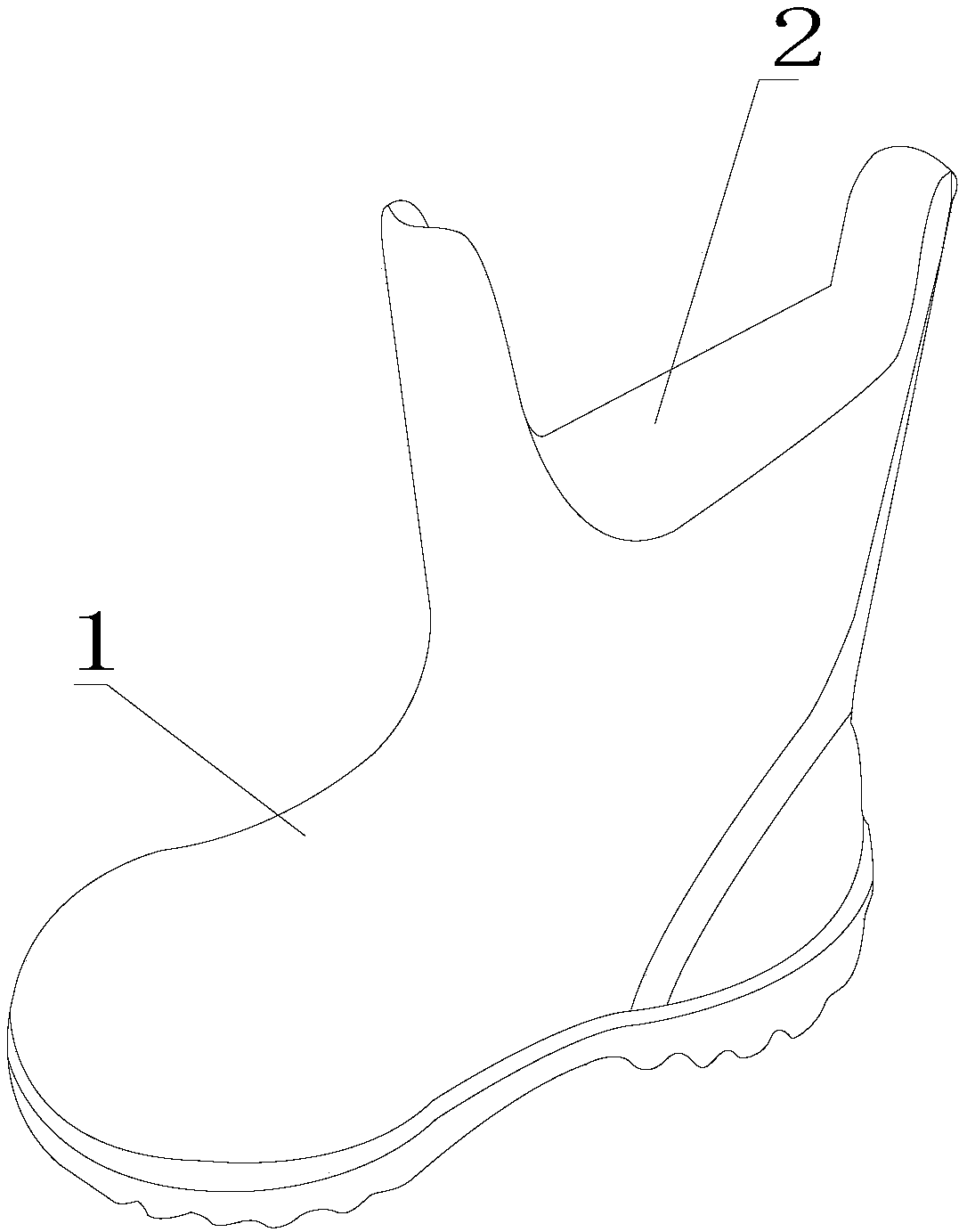

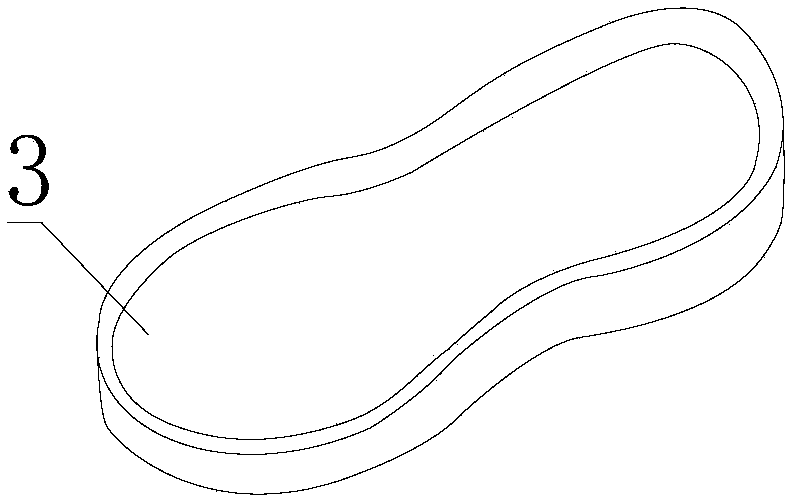

Manufacturing method of waterproof shoes capable of protecting toes

The invention discloses a manufacturing method of waterproof shoes capable of protecting the toes. The manufacturing method comprises the steps of manufacturing shoe shells, wherein the shoe shells are subjected to first drying treatment after the inner surfaces of the shoe shells are coated with cold adhesive; manufacturing sock bottoms and the sock body parts, and splicing the sock bottoms and the sock body parts into socks; conducting second drying treatment on the socks; blindly stitching the junctions of the sock bottoms and all the sock body parts; inserting shoe trees into lining of thesocks; conducting third drying treatment on the socks after the outer surfaces of the socks are coated with cold adhesive; conducting fourth drying treatment on insoles after the surfaces of the prepared insoles are coated with cold adhesive; placing the insoles in the shoe shells and above shoe soles, and inserting the socks with the shoe trees into the shoe shells to make the insoles located between the shoe soles and the sock bottoms; heating the shoe shells, the insoles and the socks with the shoe trees which are placed together in a set heating environment and afterwards, taking out theshoe shells, the insoles and the socks, pressurizing the surfaces of the shoe shells, and taking out the shoe trees. By means of the manufacturing method of the waterproof shoes, the waterproof shoeswhich have good waterproof performance and are stable in structure and comfortable to wear can be manufactured.

Owner:广州市步坤实业有限公司

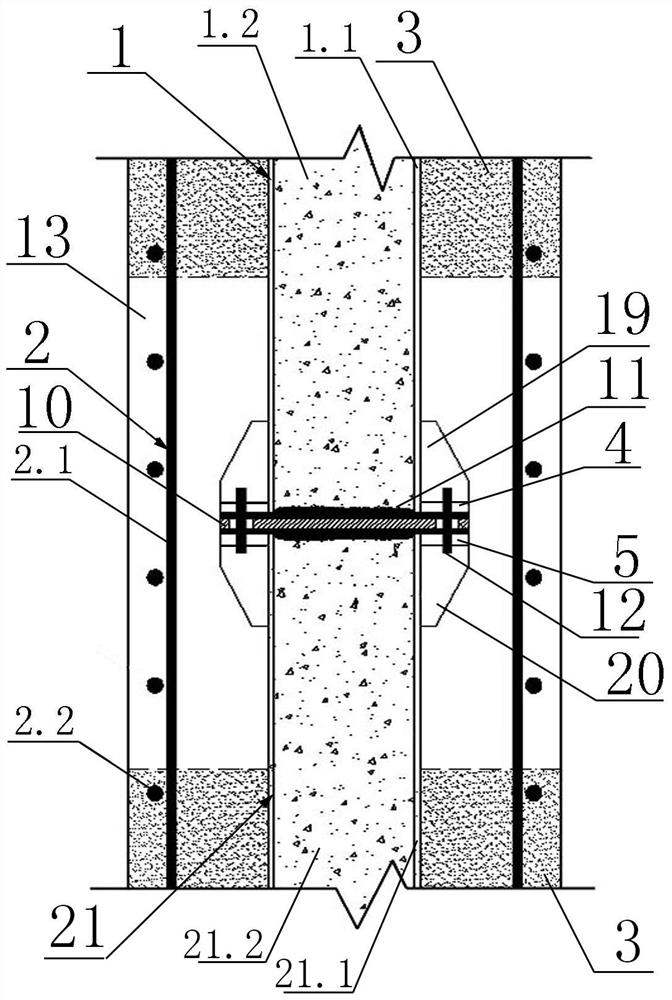

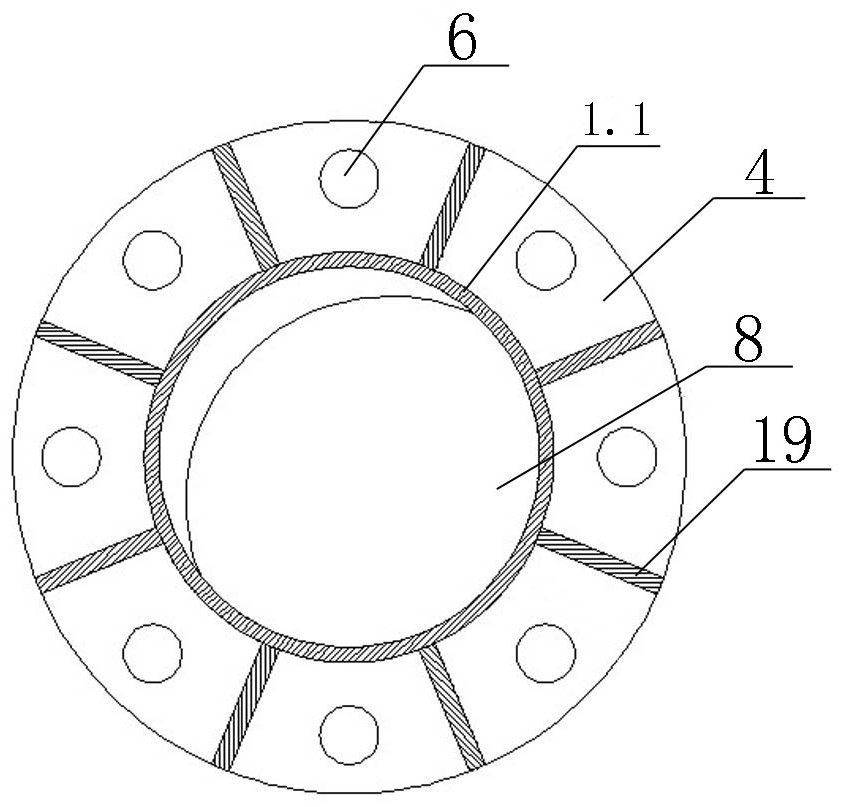

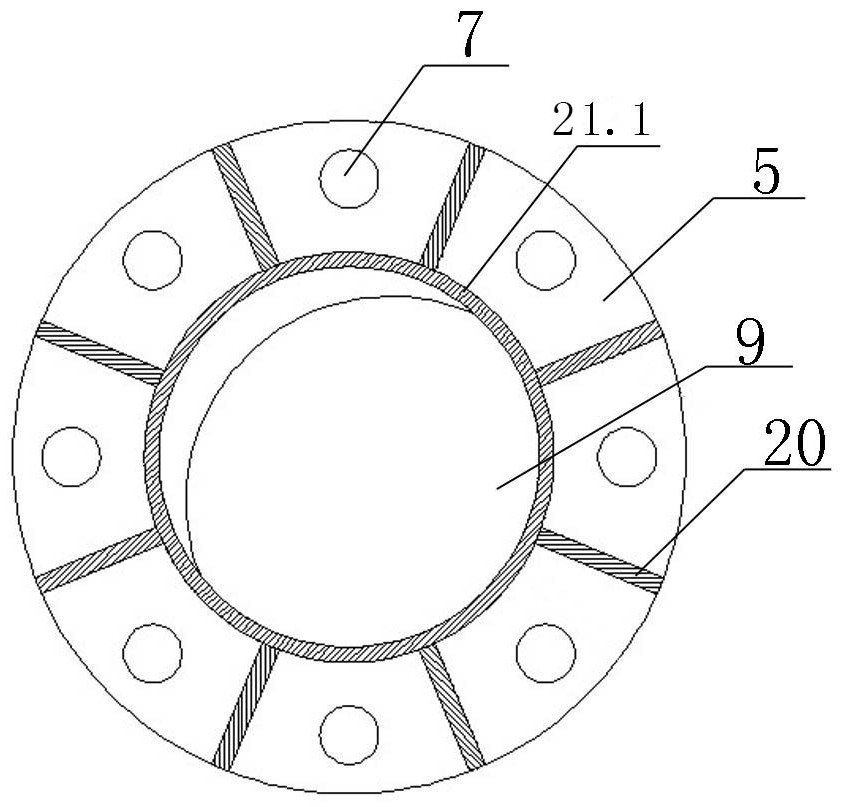

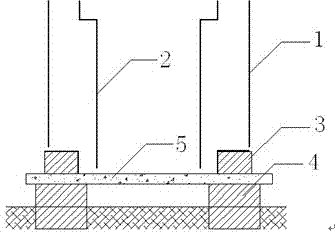

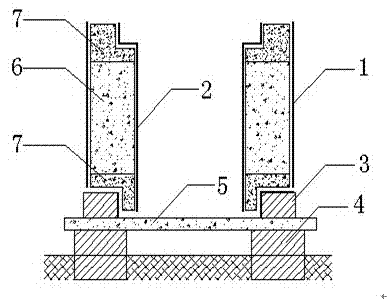

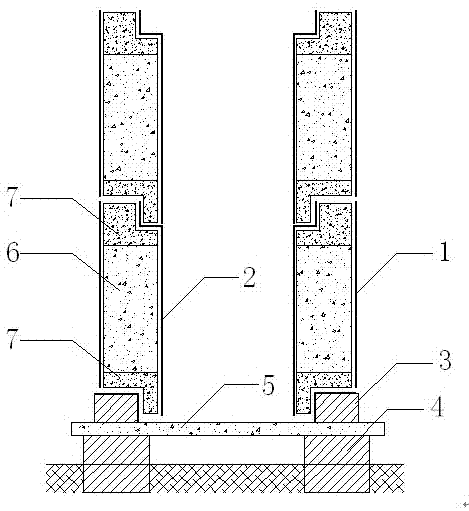

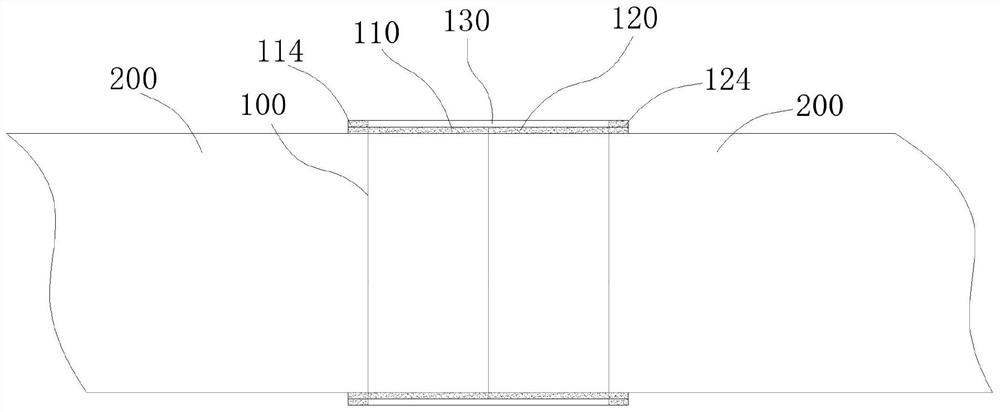

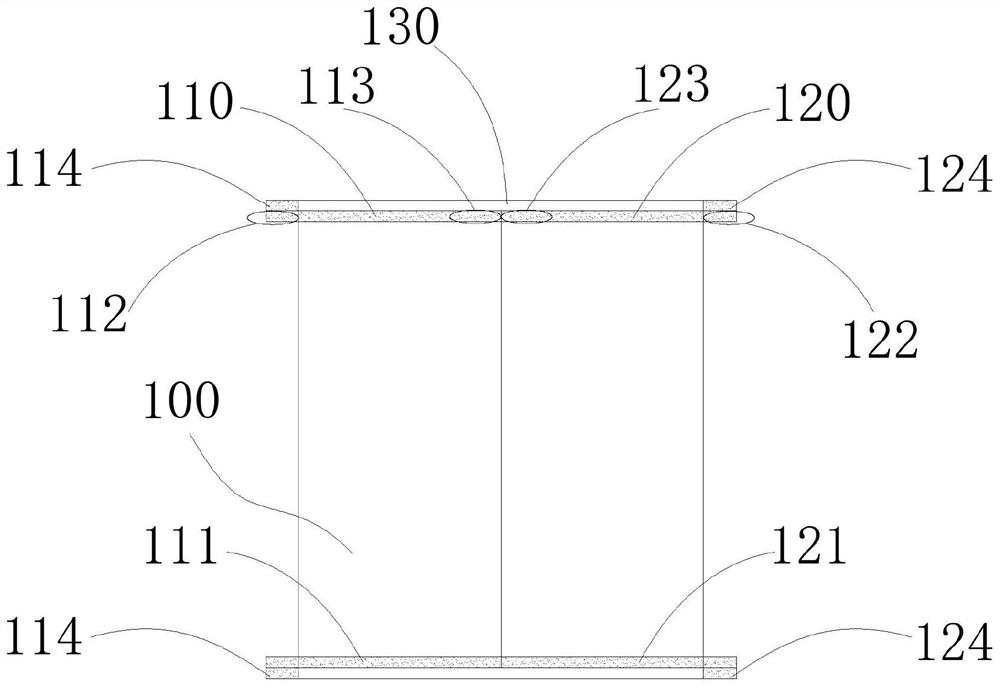

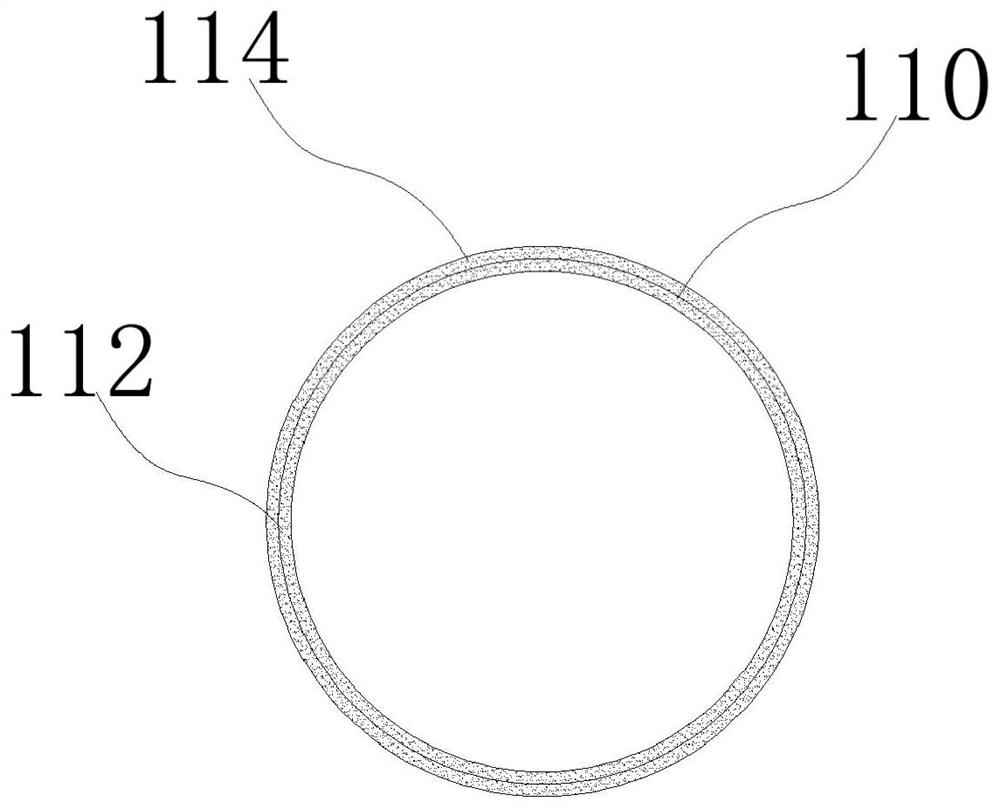

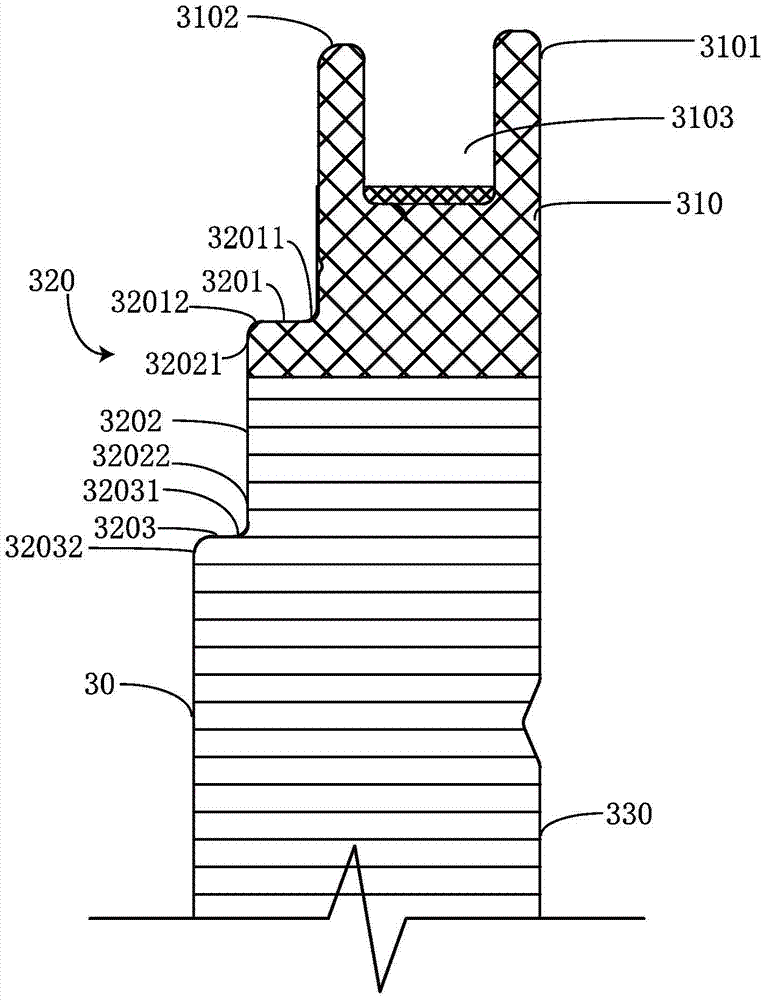

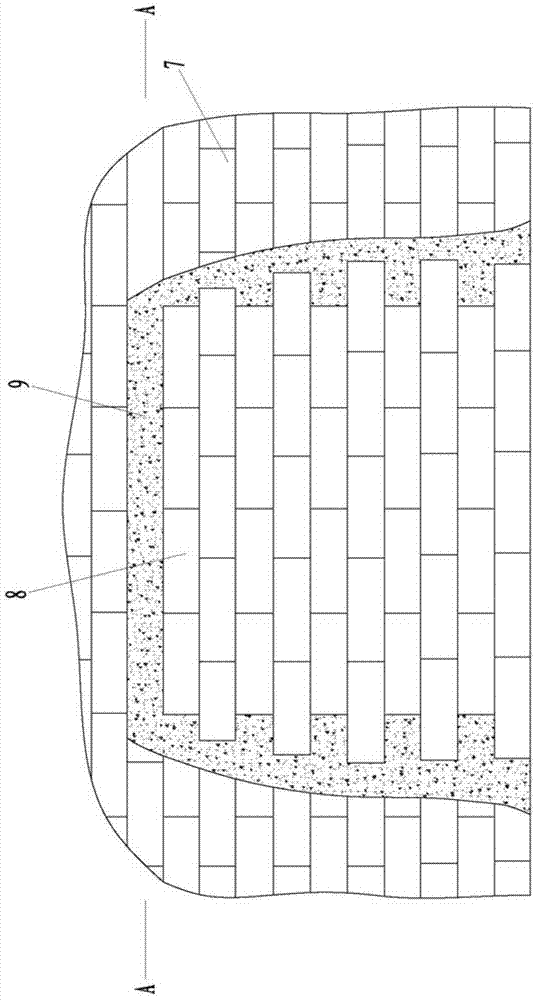

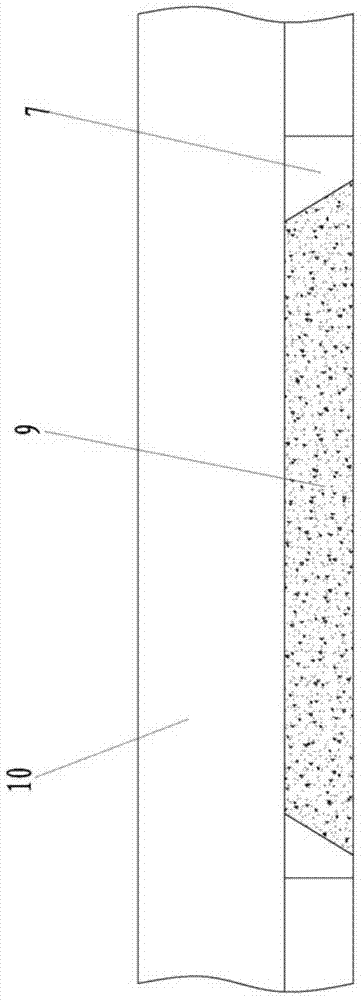

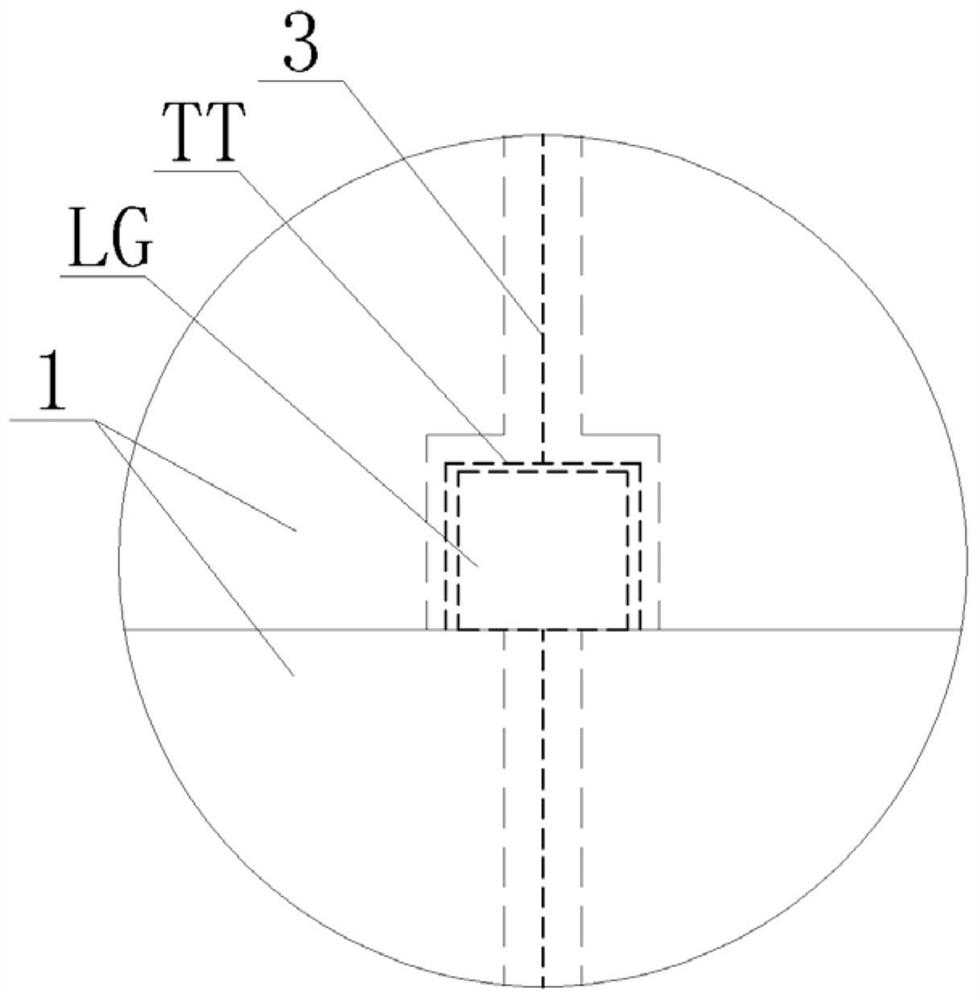

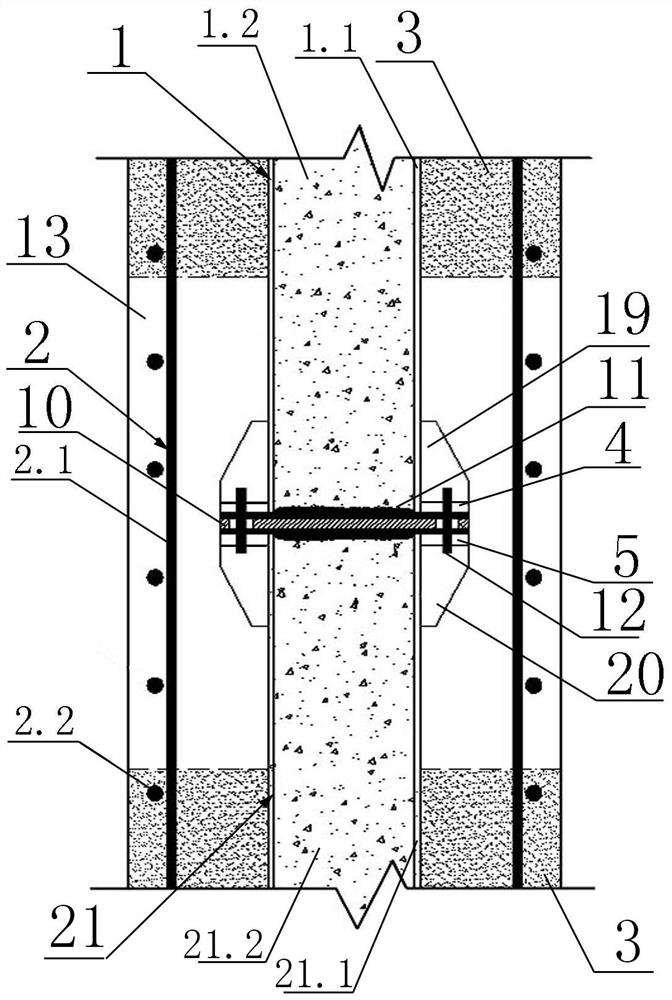

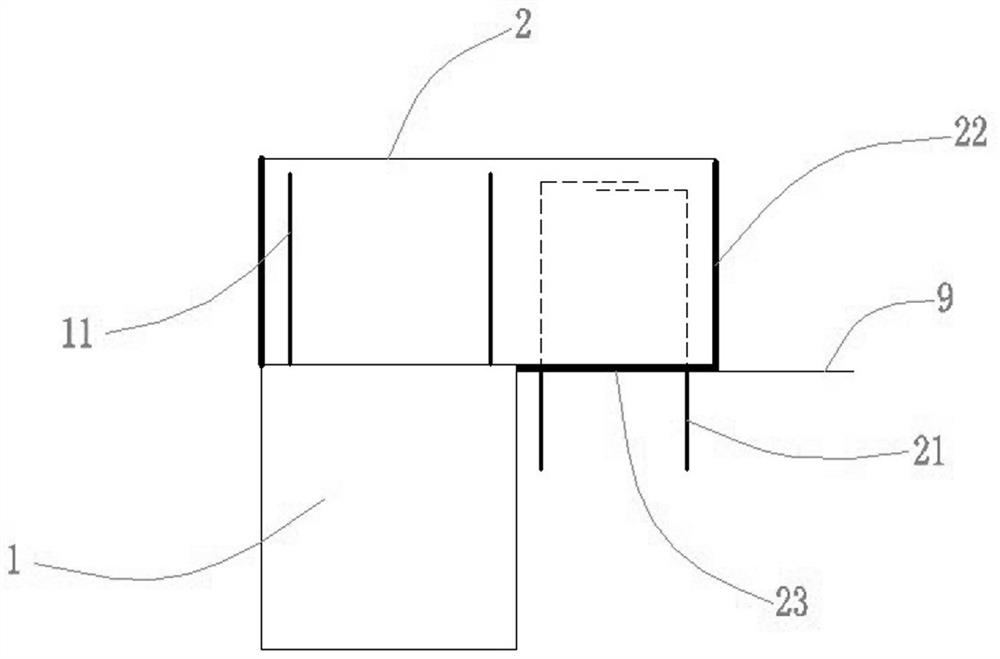

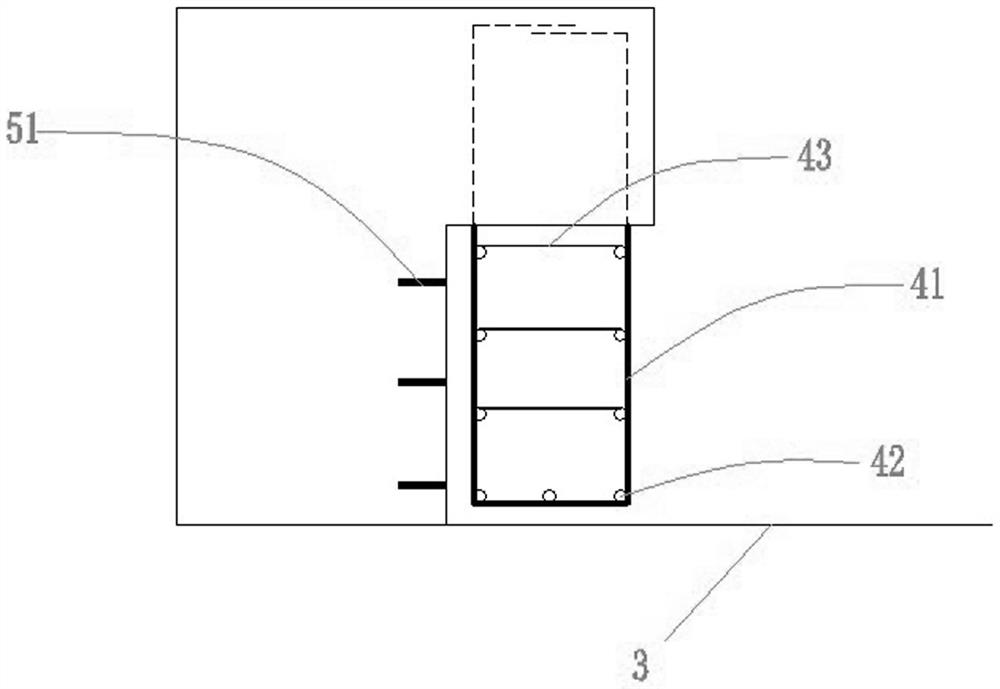

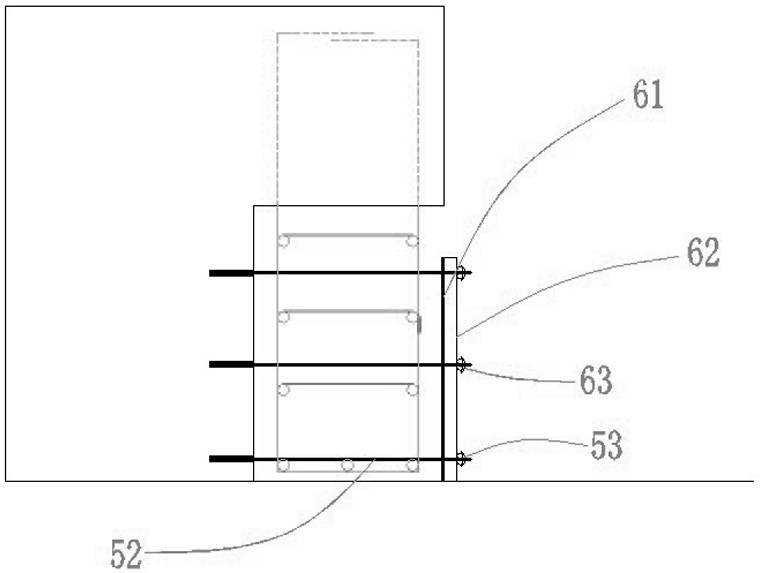

Lengthening joint containing prefabricated concrete-filled steel tube core column component and construction method of lengthening joint

ActiveCN111749346ASmall sectionIncrease the usable areaStrutsProtective buildings/sheltersArchitectural engineeringRebar

The invention discloses a lengthening joint containing a prefabricated concrete-filled steel tube core column component and a construction method of the lengthening joint. The lengthening joint comprises an upper-section core column, a lower-section core column, a steel reinforcement framework, a joint concrete layer and out-of-tube concrete layers. The bottom end of the upper-section core columnis connected with an upper flange plate, the top end of the lower-section core column is connected with a lower flange plate, a connecting assembly comprises a connecting plate, bonding glue layers and high-strength bolts, the connecting plate is arranged between the upper flange plate and the lower flange plate, air holes are formed in the middle of the plate face of the connecting plate at intervals, the bonding glue layers are arranged between the connecting plate and the upper flange plate and between the connecting plate and the lower flange plate, and the upper-section core column and the lower-section core column are connected through the high-strength bolts; and the steel reinforcement framework is arranged around joints of the upper-section core column and the lower-section core column, and the joint concrete layer is poured between the out-of-pipe concrete layer on the outer side of the upper-section core column and the out-of-pipe concrete layer on the outer side of the lower-section core column. The technical problems that the thickness of an existing joint cannot be adjusted, inclination deviation exists, compression deformation is large, force transmission is not reliable, construction efficiency is low, and concrete in a steel pipe is difficult to pour are solved.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

Preparation method of assembly type precast concrete member

ActiveCN103406990BPrevent and reduce crackingDense connectionCeramic shaping apparatusFiberEngineering

The invention discloses a preparation method of an assembly type precast concrete culvert. The method comprises the steps as follows: when casting is performed in a vertical direction, the top (a contact surface) of a former precast concrete section is used as a bottom template of an assembly type precast concrete culvert section; when the strength of a precast concrete member reaches 70% of the design strength, two precast concrete sections are hoisted by a hoisting machine, the former section is shifted from the bottom and stored, the later section is transferred to an original position of the former section at the same time, the casting of a next section proceeds, and the circulation is continued; concrete of each section is cast in layers; and fiber concrete are arranged on both the bottom layer and the top layer. According to the method, the prepared precast concrete member can enable connection surfaces between every two adjacent sections to be closely contacted, so that cracking of concrete of contact surfaces among sections of the assembly type precast concrete culvert is prevented and reduced.

Owner:JSTI GRP CO LTD

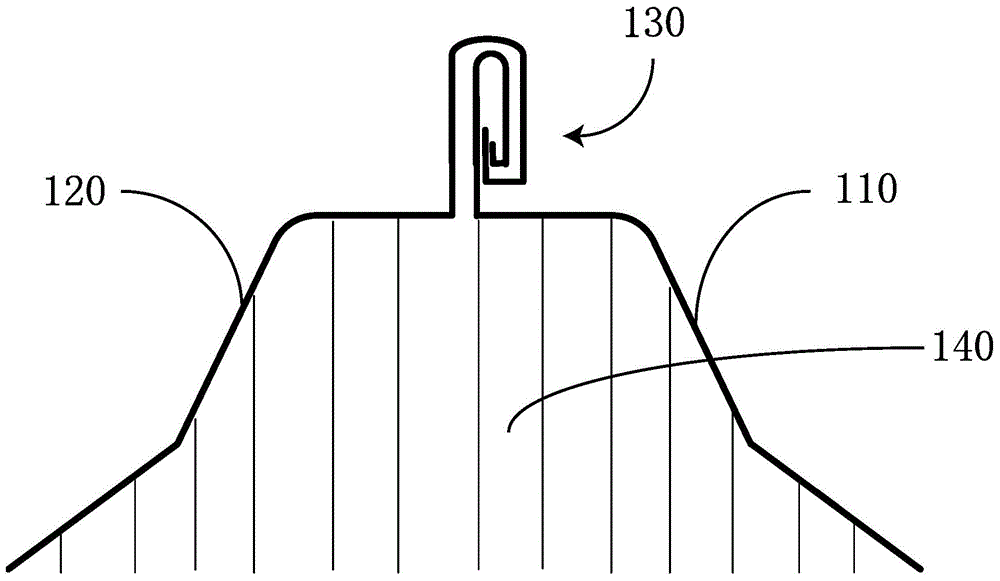

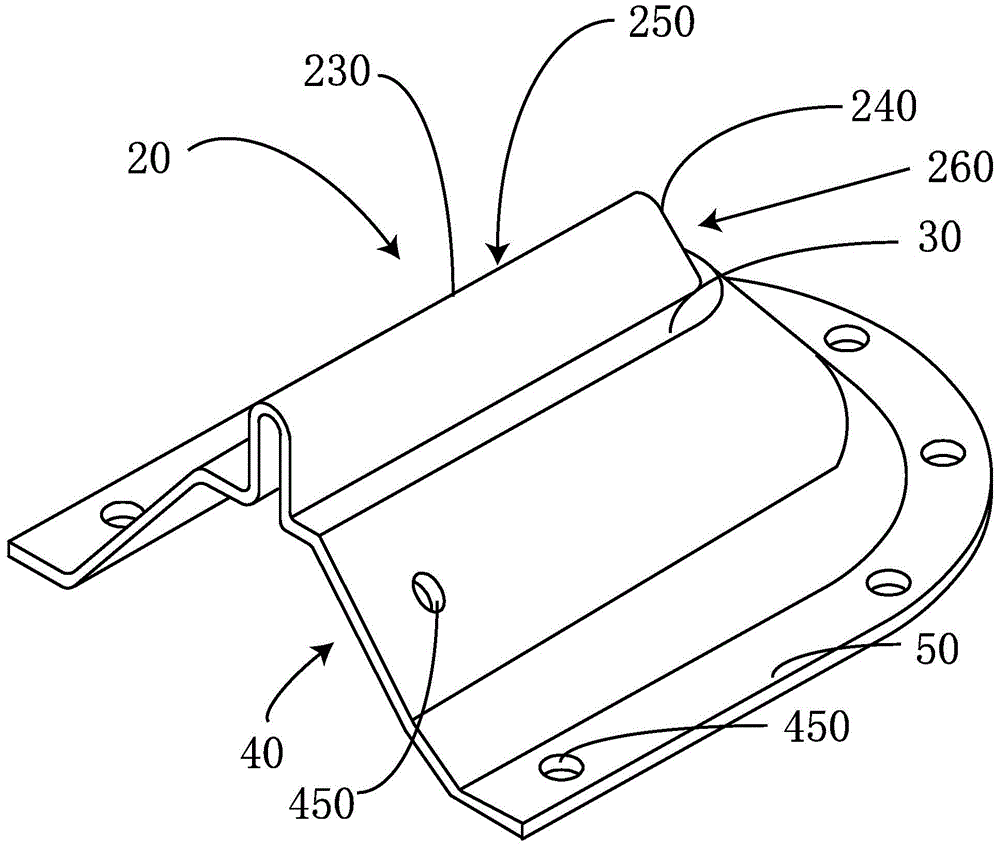

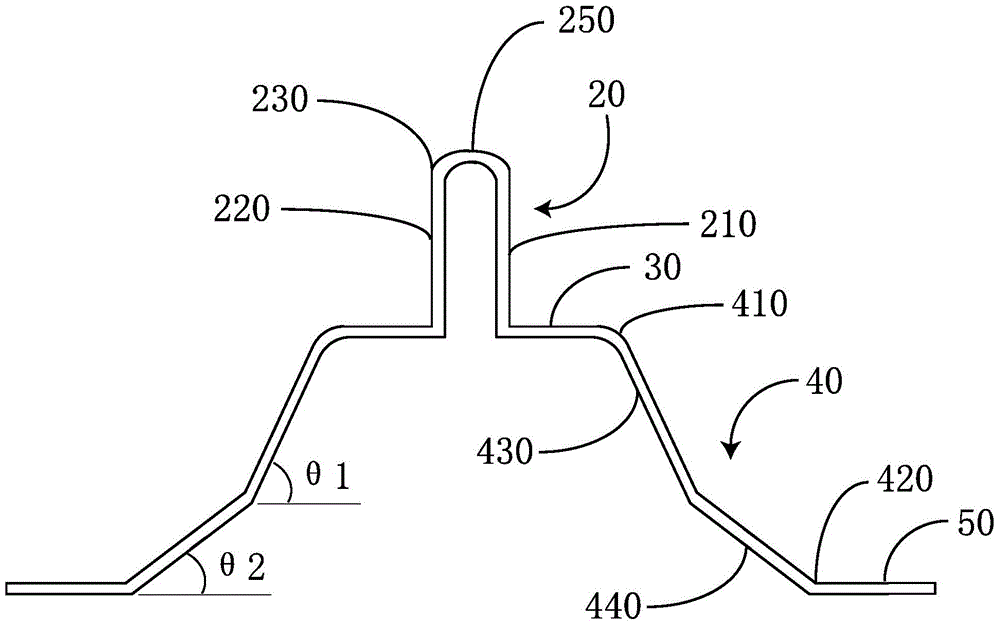

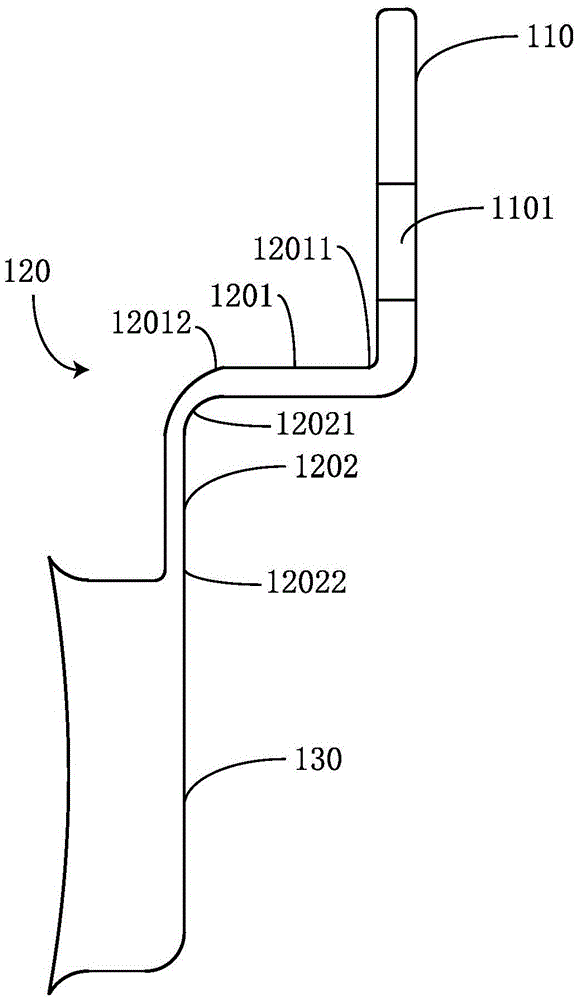

Vertical seam choke plug

InactiveCN104912260AReduce the risk of water leakageImprove smoothnessRoof covering using slabs/sheetsWater leakageMechanical engineering

A vertical seam choke plug comprises a raised top part, an extended part, a skirt part and a skirt edge, wherein the raised top part comprises a first side face and a second side face which are disposed vertically and mutually at an interval, and opposite top edges of the first side face and the second side face and one side edge are mutually connected in order to let the top end of the raised top part and one side end form sealing space; the extended part is extended to a direction remote from and perpendicular to the raised top part along bottom edges of the first side face and the second side face and the bottom edge of a sealed side end of the raised top part; the top part of the skirt part is connected to the edge of the extended part remote from the raised to part and is extended for a distance in a direction remote from the raised top part to reach the bottom part of the skirt part, and perimeter of the bottom part of the skirt part exceeds the perimeter of the top part of the skirt part; and the skirt edge is connected to the bottom part of the skirt part and is lengthened in a direction parallel to the extended part and remote from the raised top part. The vertical seam choke plug provided by the invention solves the problem that a hidden danger of water leakage exists at an intersection part between a metal roofing board opened base and a metal roofing board slab rib on an upstream face and a downstream face when a traditional structure is used.

Owner:DUOWEI UNION GRP

Shear wall structure and method

PendingCN114837326AThe connection process is simpleReliable connectionConstruction materialWallsRebarWall plate

The shear wall structure comprises a prefabricated wall panel and a steel bar connecting structure, wedge-shaped grooves and wedge-shaped connecting blocks are alternately arranged on the upper end face, the lower end face, the left side face and the right side face of the prefabricated wall panel correspondingly, and the wedge-shaped grooves and the wedge-shaped connecting blocks are sequentially arranged in the thickness direction of the prefabricated wall panel; a plurality of first connecting steel bars are further arranged in each wedge-shaped groove, and second connecting steel bars are further arranged on the wedge-shaped connecting blocks; the steel bar connecting structures are used for connecting the first steel bars and the second connecting steel bars of the two adjacent prefabricated wall plates in the transverse direction and the vertical direction of the prefabricated wall plates. The invention further discloses a construction method of the shear wall plate. The problems of water leakage and water seepage of straight seams formed during connection of existing prefabricated shear walls are solved.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

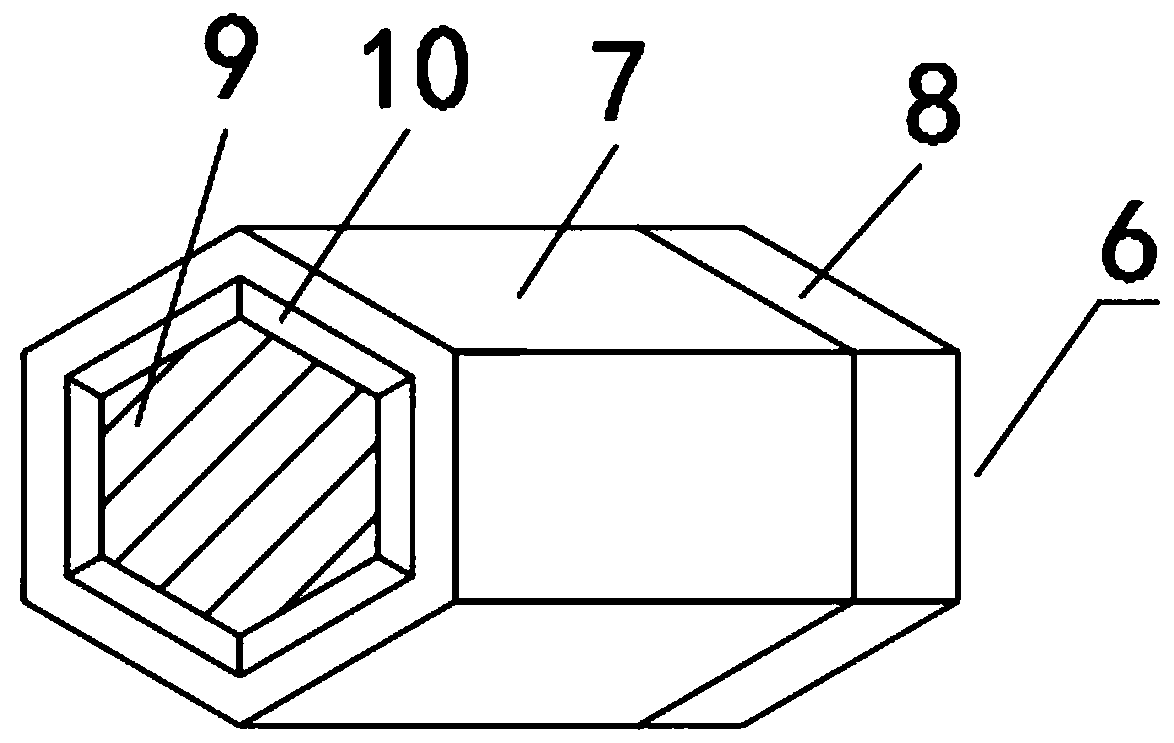

Pipeline connector

PendingCN112594458AAvoid enteringInhibit sheddingFluid pressure sealed jointsStructural engineeringMechanical engineering

The invention relates to a pipeline connector which comprises a connecting pipe and a connecting pipe lining part, the connecting pipe is a pipe body, the connecting pipe lining part is arranged on the inner wall of the connecting pipe, and the connecting pipe lining part comprises a connecting pipe lining part first part and a connecting pipe lining part second part. The connecting pipe lining part first part and the connecting pipe lining part second part are arranged on the inner wall of the connecting pipe. The pipeline connector has the advantages of being convenient to operate and tightin connection.

Owner:深圳鑫宝通材料科技有限公司

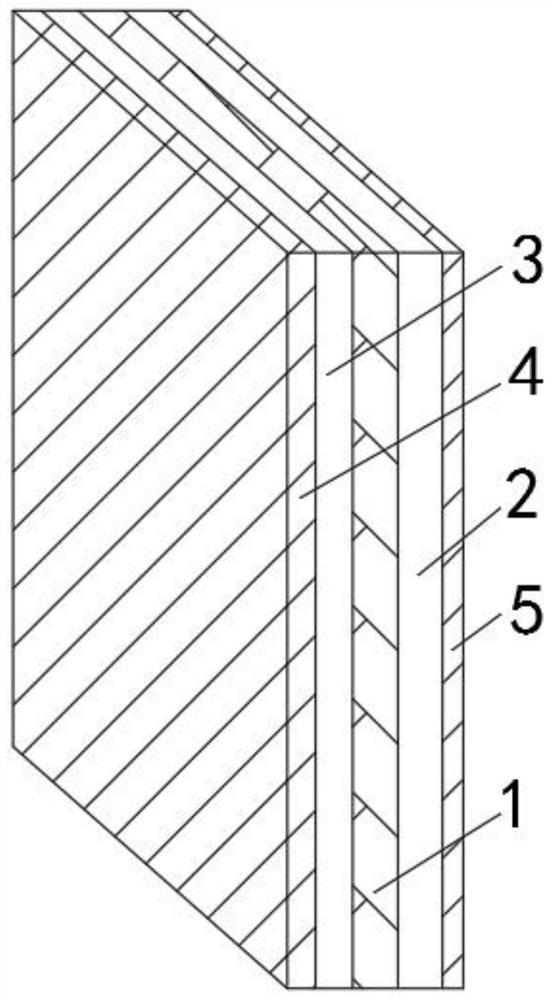

Environmental-protection multi-functional composite plate material and processing equipment for composite plate material

ActiveCN110629952AImprove adsorption capacityReduce weightCovering/liningsNon-rotating vibration suppressionAgricultural engineeringHardness

The invention discloses an environmental-protection multi-functional composite plate material and processing equipment for the composite plate material. The environmental-protection multi-functional composite plate material comprises a polythene base layer plate, the two side walls of the polythene base layer plate are provided with a first bamboo charcoal plate and a second bamboo charcoal platecorrespondingly, the outer side walls of the first bamboo charcoal plate and the second bamboo charcoal plate are provided with a second log base plate and a first log base plate correspondingly, andthe side walls of the first bamboo charcoal plate and the second bamboo charcoal plate are both provided with a plurality of sets of insert grooves in clamping connection with clamping connection columns. The environmental-protection multi-functional composite plate material is environmentally friendly and has good anti-collision and noise reduction effects, the composite plate material is high inoverall hardness, and the processing equipment is adopted to process the plate material, plate material cut mouths are made to keep smooth, the fit rate of multiple sets of the plate materials in later-period coordination use is effectively increased, gaps between the plate materials are reduced, furthermore, damage caused to the composite plate material in plate material processing positioning is effectively avoided, and the quality of the composite plate material is guaranteed.

Owner:安徽群升建筑工程有限公司

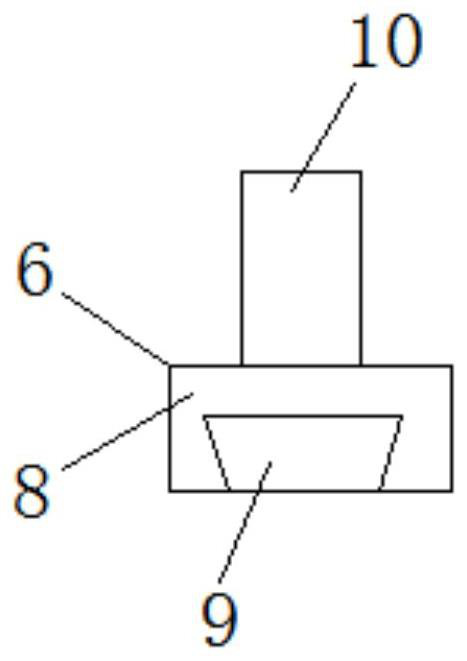

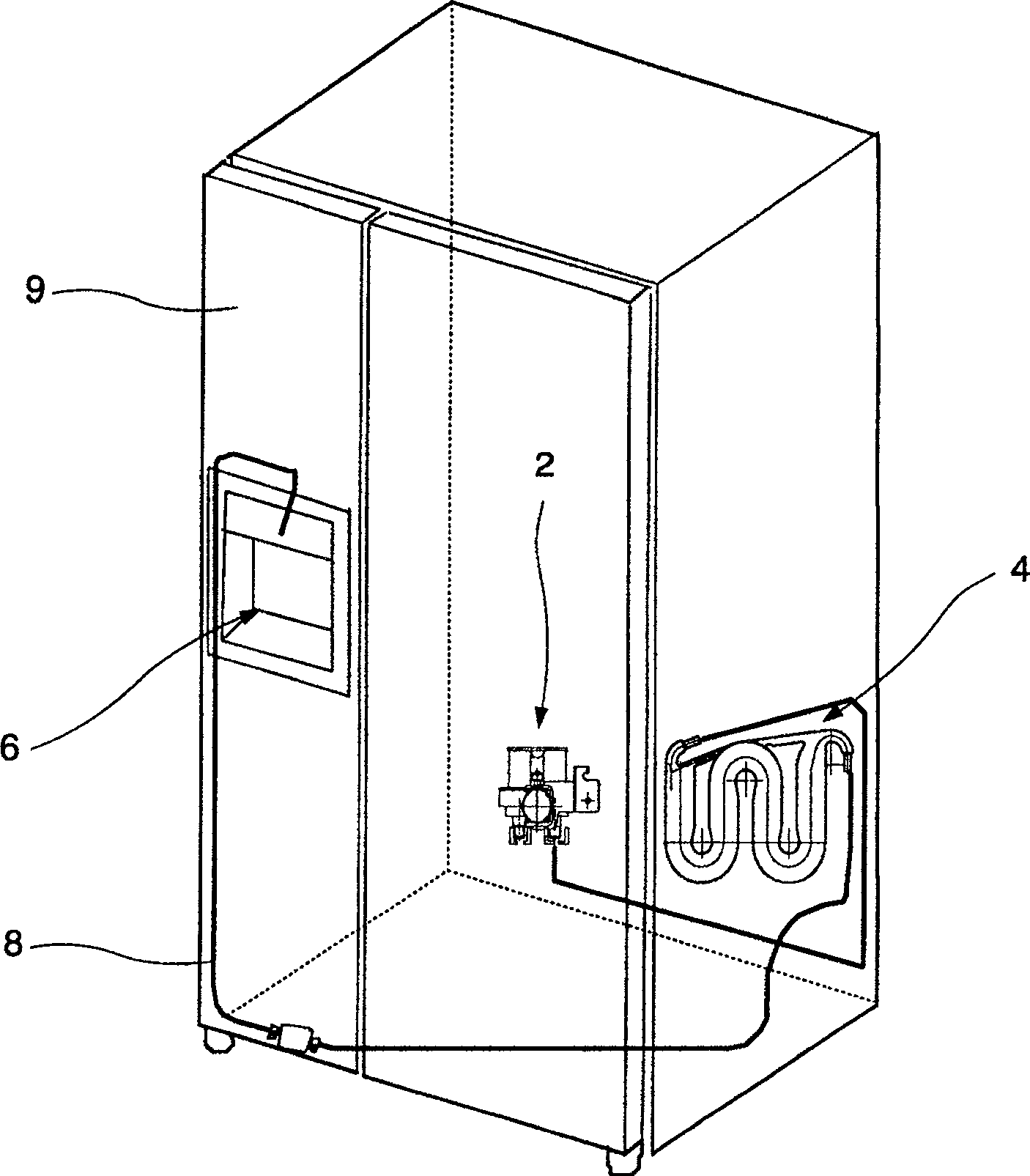

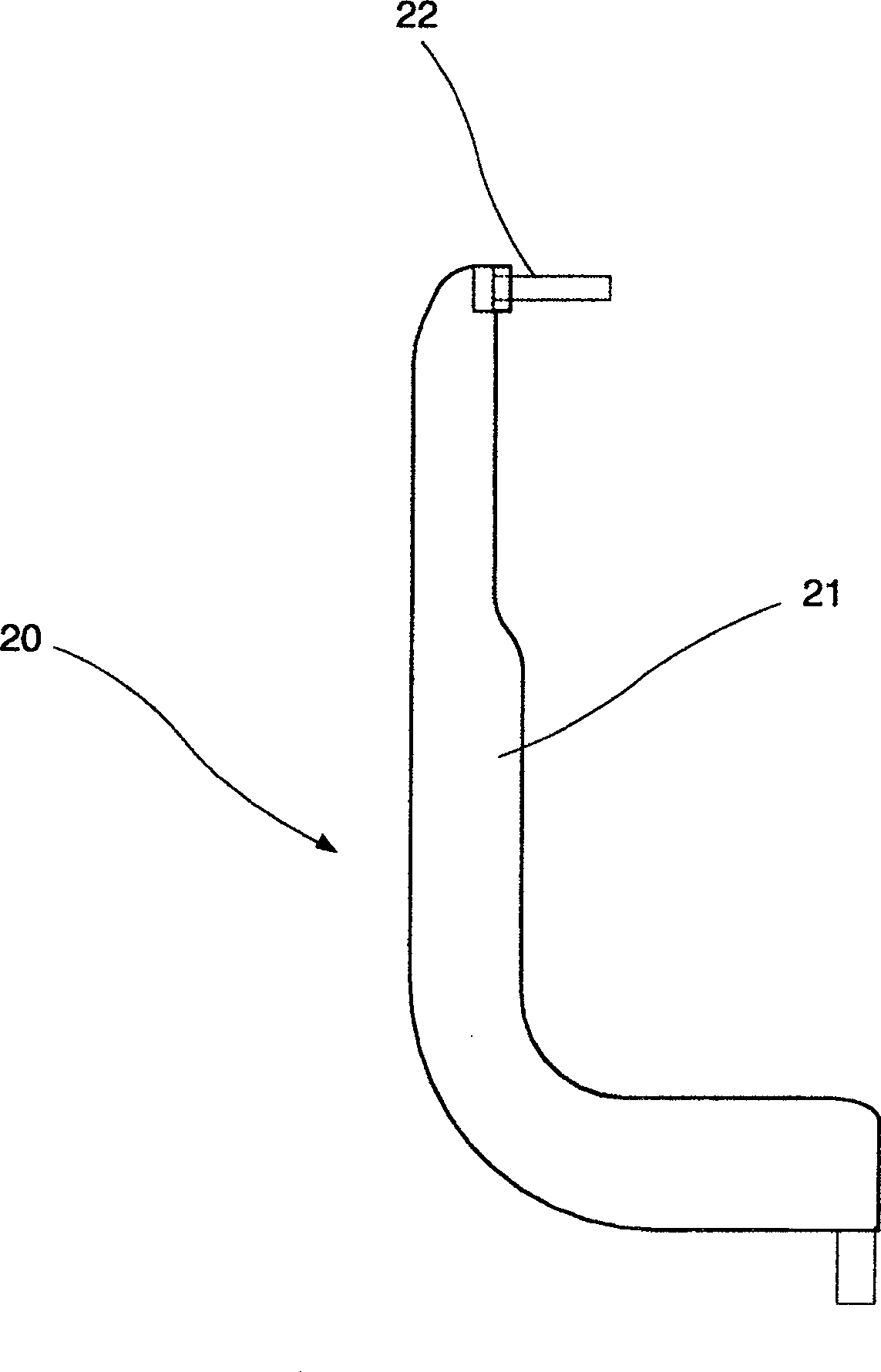

Water tank for refrigerator

InactiveCN100520243CSmall sizeDense connectionLighting and heating apparatusDomestic refrigeratorsBlow moldingEngineering

A water tank for a refrigerator, the water tank is installed inside the door equipped with a dispenser, and is used to supply water to the dispenser, the water tank includes an outlet, which is made by injection molding, connected to the dispenser On the faucet; the main body is made by blow molding in the state where the above outlet is inserted. The present invention facilitates the connection between the water tank and the water nozzle of the distributor when the water tank is installed inside the door.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

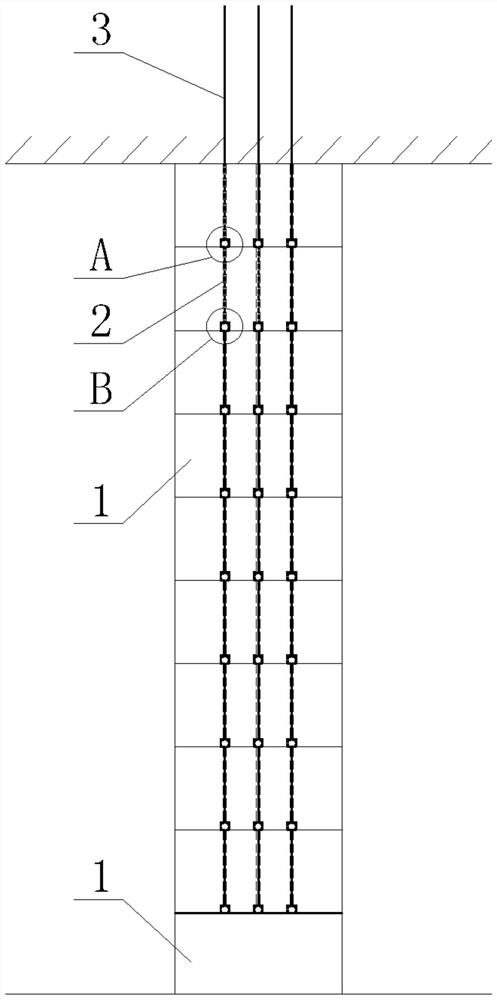

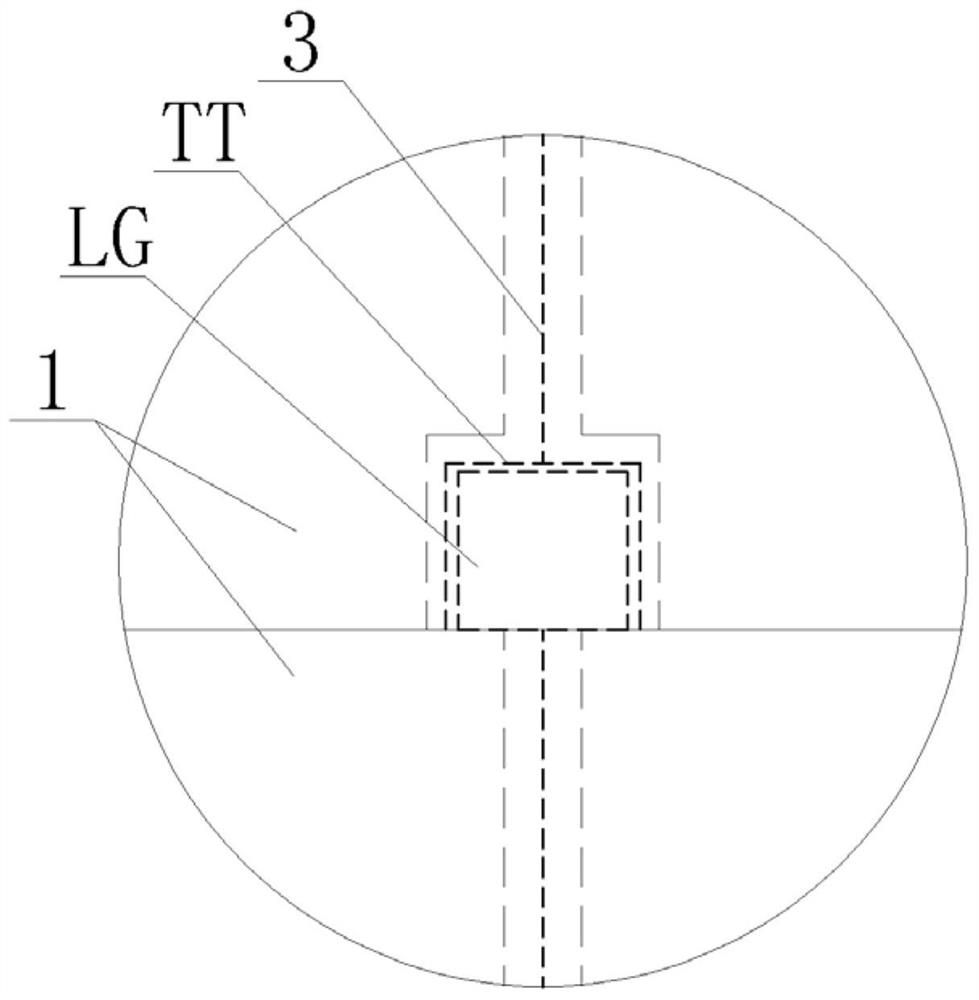

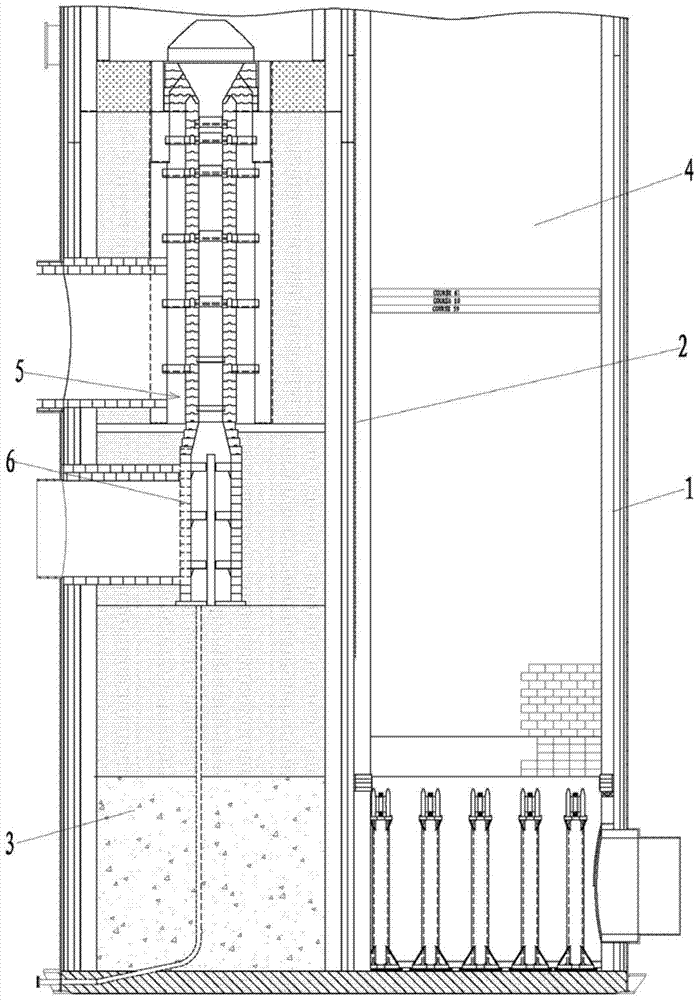

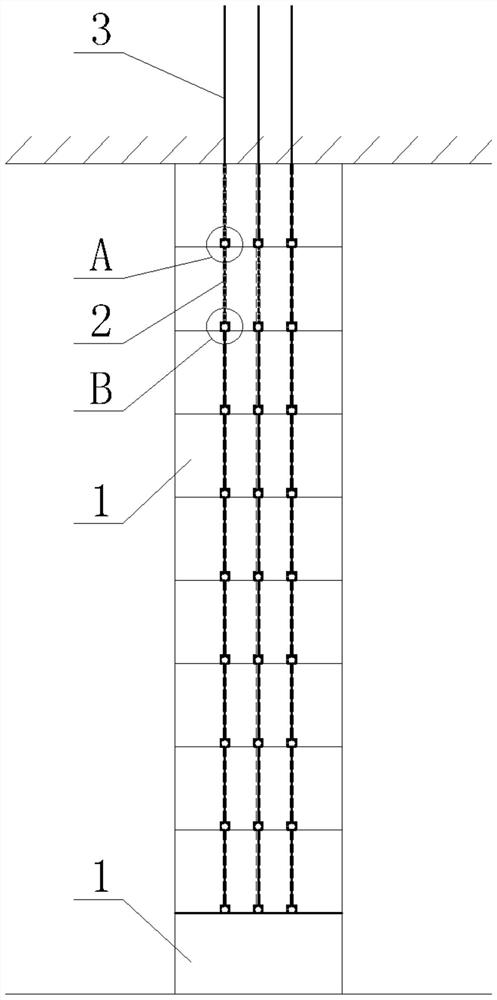

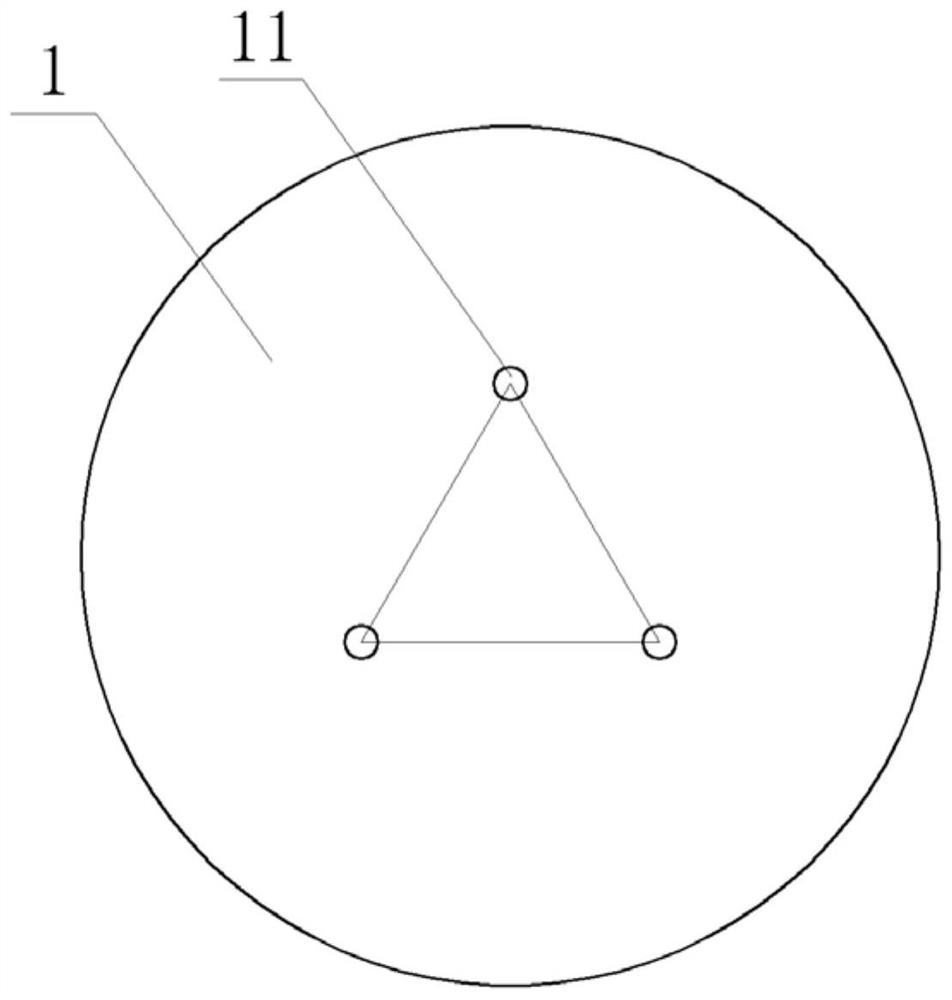

Reinforced concrete artificial pillar construction method

ActiveCN114109458AHighly precise controlPrecise control of construction heightProps/chocksReinforced concreteArchitectural engineering

The invention discloses a reinforced concrete artificial ore pillar construction method which comprises the following steps: accurately and equally dividing the height of a goaf, prefabricating unit bodies according to the equally-divided height, assembling the prefabricating unit bodies in a top-down inverted manner, and fixing the prefabricating unit bodies which are in top contact with a goaf top plate through anchor cable components. The next prefabricated unit body adjacent to the roof-contacted prefabricated unit body is detachably connected with the lower end of the anchor cable component through a connecting rod component, the subsequent prefabricated unit bodies are sequentially connected with the previous prefabricated unit body through connecting rod components, and the last prefabricated unit body is embedded between the prefabricated unit body above the last prefabricated unit body and a goaf bottom plate. The prefabricated unit bodies are firmly connected to the lower portion of the top plate through the anchor cables and the connecting rods, the top plate is forced to sink to a certain degree under the action of gravity and tension to compress installation gaps between the prefabricated unit bodies, and the artificial pillars are completely connected into a whole. The method is of great significance in improving the stability of the goaf, converting artificial pillars into original pillars to reduce resource loss and ensuring safe mining of mines.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST +1

Heat preserving and energy saving structure for outer wall of old house and modification construction technology thereof

InactiveCN111519930AGuaranteed firmnessGuaranteed corrosion resistanceBuilding repairsHeat proofingEngineeringHeat conservation

The invention relates to a heat preserving and energy saving structure for an outer wall of an old house and a modification construction technology thereof. The structure comprises multiple heat preserving plates, grid cloth and anti-crack mortar, wherein the heat preserving plates are bonded to the surface of the outer wall, the grid cloth is bonded to the sides, away from the outer wall, of theheat preserving plates, and the anti-crack mortar covering the grid cloth. Connecting parts are detachably connected to the peripheries of the heat preserving plates. A filling groove is formed between every two adjacent heat preserving plates through two connecting parts. Seam filling blocks made of the same material as that of the heat preserving plates are arranged in the filling grooves. The seam filling blocks are filled between every two adjacent heat preserving plates, the seam filling blocks are fully filled into gaps between every two heat preserving plates, the gaps between every twoadjacent heat preserving plates are reduced, and the heat preserving effect of the outer wall is improved.

Owner:新兴华北(北京)建设工程有限公司

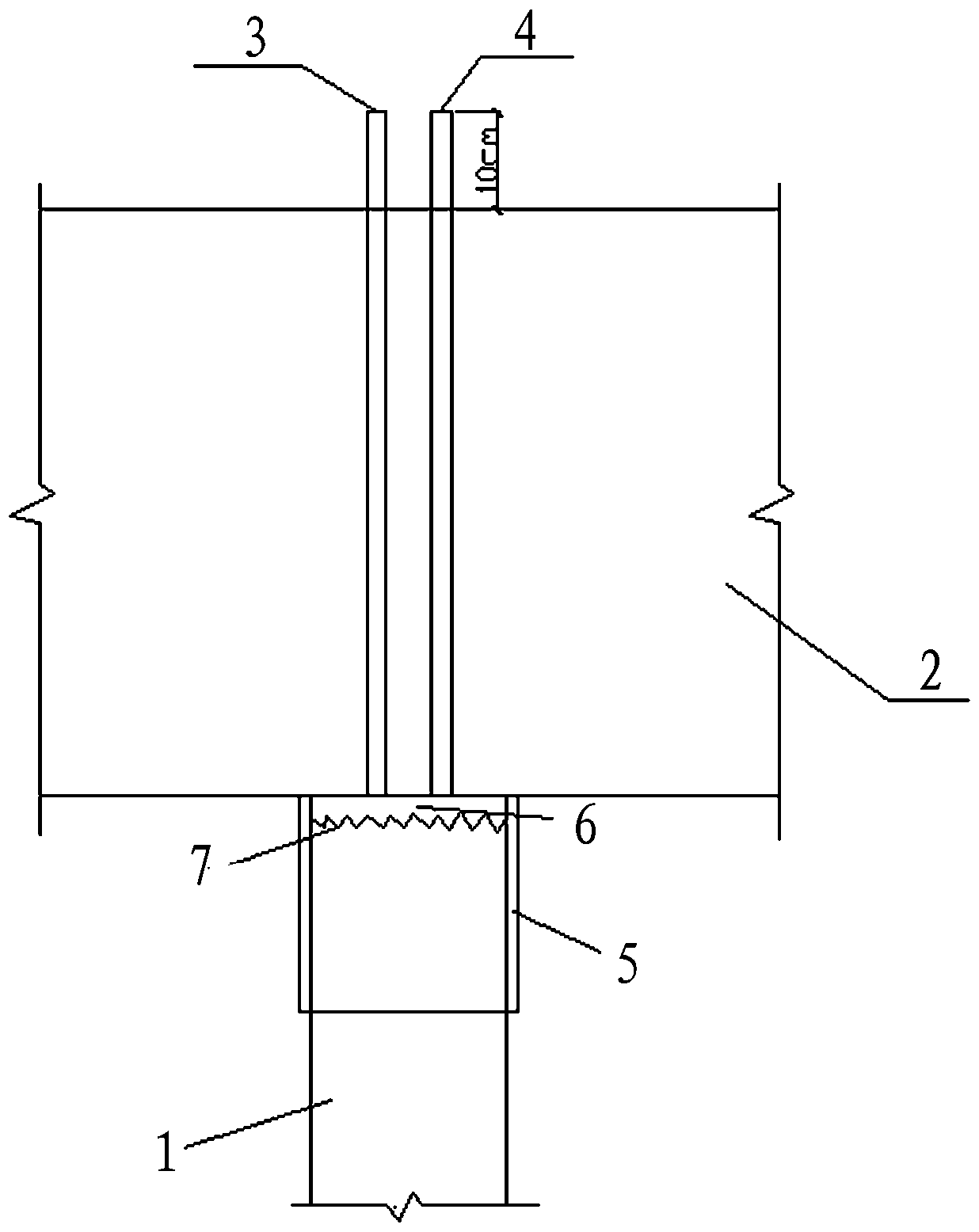

Constructional column top pouring construction method

ActiveCN106285005AWill not change the construction processDense connectionBuilding material handlingRebarConcrete beams

The invention belongs to the technical field of constructional column construction for buildings and particularly relates to a constructional column top pouring construction method. To make the top of a constructional column be tightly connected with the bottom of a beam and sufficiently play the aseismic effect of the constructional column, the constructional column top pouring construction method is provided. The construction method comprises the steps that after concrete beam and slab steel bars and formworks are installed and before concrete is poured, galvanized steel pipes communicating with the top end of the constructional column are embedded in a positioned mode, and when concrete of the constructional column is poured till the bottom of a concrete beam cannot be compactly filled, pouring is conducted through the embedded galvanized steel pipes. The effect that the top of the constructional column is tightly connected with the bottom of the beam is guaranteed, the construction quality of an infilled wall is improved, and original constructional column construction technique procedures are not changed. The number of the embedded galvanized steel pipes is no less than two, one embedded steel pipe can serve as an ichor pipe while pouring, and the effect that the top is sufficiently poured is guaranteed.

Owner:CHINA SHANXI SIJIAN GRP

Solid EPS module wall body and construction method thereof

The invention discloses a solid EPS module wall body and a construction method thereof. The solid EPS module wall body comprises a reinforced concrete pile and an EPS wall surface. The EPS wall surface comprises a fixing vertical rib, EPS modules, a right angle clamping device and a fixing nail. The EPS modules sleeve the fixing vertical rib through U-shaped grooves, the opening directions of theU-shaped grooves of the two groups of the EPS modules assembled up and down are opposite, a positioning groove is formed in the middle of the top of each of the EPS modules, and a positioning bulge isarranged at the bottom; one right angle clamping arm of the right clamping device is located between the positioning groove of the EPS module under the right angle clamping arm and the positioning bulge of the EPS module above the right angle clamping arm and provided with a first U-shaped clamping groove, the other right angle clamping arm is located between the EPS module and the reinforced concrete pile and provided with a through fixing hole, and is fixed on the reinforced concrete pile through the fixing nail. The solid EPS module wall body has light weight, fast construction, good heatpreservation and thermal insulation performances, fireproof and dampproof functions and low construction cost.

Owner:李文升

A green and environmentally friendly multifunctional composite board and processing equipment for the composite board

ActiveCN110629952BImprove adsorption capacityReduce weightCovering/liningsNon-rotating vibration suppressionProcess engineeringComposite plate

The invention discloses a green and environment-friendly multifunctional composite board and processing equipment for the composite board, comprising a polyethylene base board, the two side walls of the polyethylene base board are respectively provided with a first bamboo charcoal board and a second bamboo charcoal board, The outer sidewalls of the first bamboo charcoal board and the second bamboo charcoal board are respectively provided with a second log substrate and a first log substrate, and the side walls of the first bamboo charcoal board and the second bamboo charcoal board are provided with several groups of clamping columns. The slots that are engaged with each other; the composite board in the present invention is green and environmentally friendly, and has good anti-collision and noise reduction effects. It is smooth, which effectively improves the lamination rate of multiple groups of plates when they are used together in the later stage, reduces the gap between the plates, and effectively avoids damage to the composite plates when the plates are processed and positioned, ensuring the composite plates. quality.

Owner:安徽群升建筑工程有限公司

Sandwich panel socket joint strip and its application node structure

Owner:DUOWEI UNION GRP

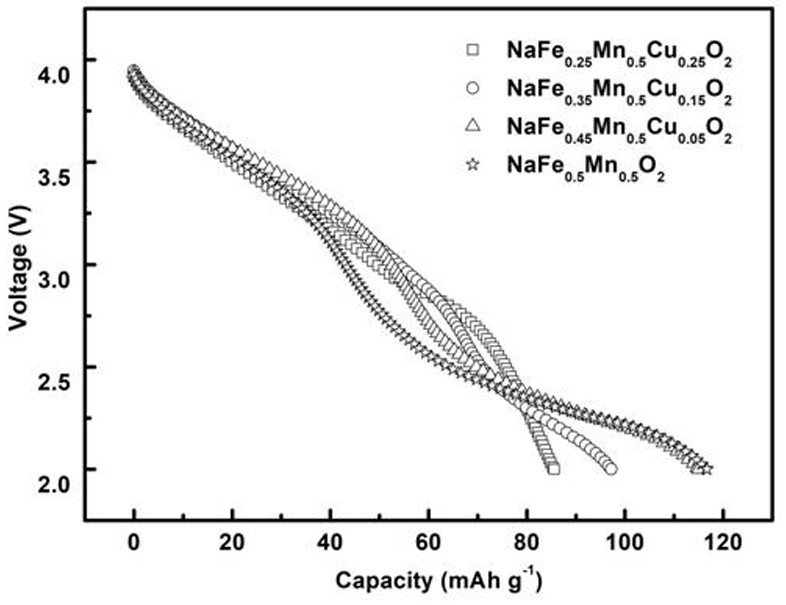

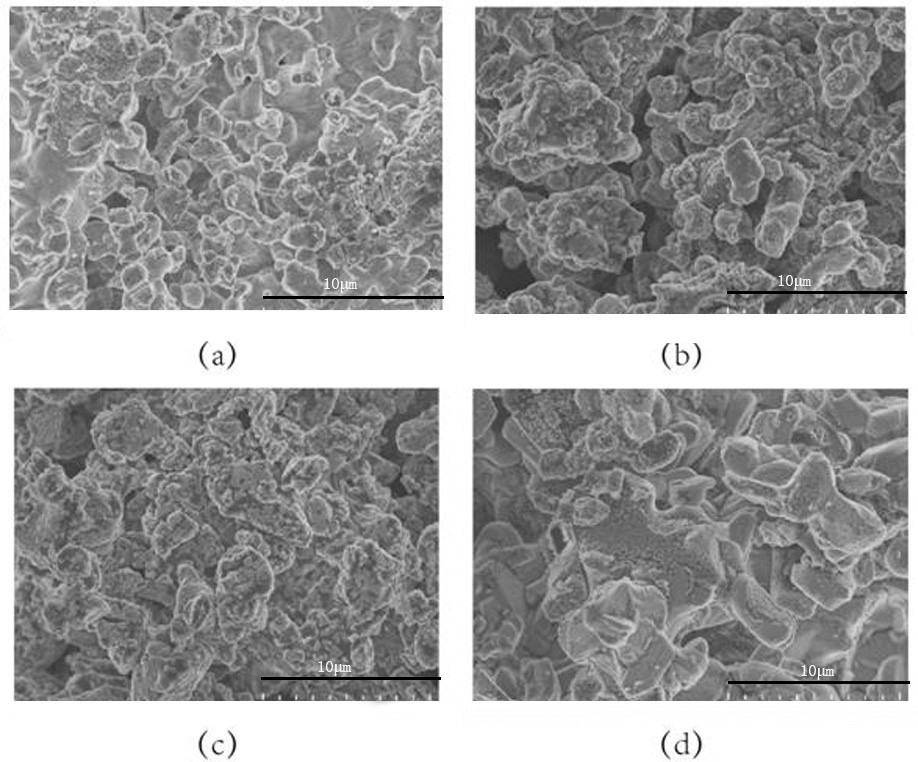

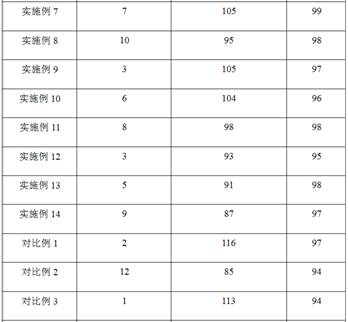

A class of large particle sodium ion battery positive electrode material and method for increasing material particle size

InactiveCN108735996BDense connectionIncrease volumetric energy densityFinal product manufactureNon-aqueous electrolyte accumulator electrodesElectrical batterySodium-ion battery

The invention discloses a class of large-grain sodium-ion battery cathode materials and a method for increasing the particle size of the materials, belonging to the technical field of energy materials. The large particle sodium ion battery positive electrode material (Na m A 1‑x B x o 2 , 0.05≤x≤0.25) It is prepared by pre-mixing, tableting, and high-temperature calcination. by Na m AO 2 The metal element B whose oxide melting point is close to the calcination temperature is added, and the melting of the material is used to make the material bond with a larger particle size, which improves the volumetric energy density and electrochemical performance of the material. The method is simple and easy to operate, has abundant raw materials and low price, and is easy to realize large-scale production. The anode material for a sodium ion battery provided by the present invention has a relatively large particle size and excellent electrochemical performance, so the anode material for a sodium ion battery of the present invention can be used as a novel high-volume energy density storage material with simple synthesis and suitable for large-scale production. energy materials with broad application prospects.

Owner:FUJIAN NORMAL UNIV

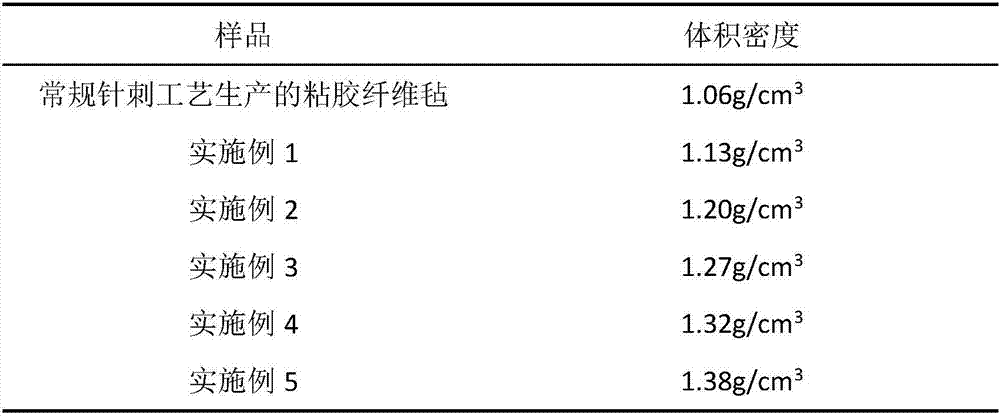

Method for improving volume density of viscose felt

The invention relates to a method for improving volume density of a viscose felt, and belongs to the technical field of a textile processing. The method includes steps of performing negative pressureabsorption on a fluffy viscose screen under a negative pressure condition when the viscose screen after loosening carding and lapping passes through the upper surface of a needling platform in a viscose felt needling technology; absorbing the viscose screen to contract towards the negative pressure running direction; when the viscose screen is contracted, needling the viscose screen after being contracted by a needle of an upper needle plate at the upper part of the needle platform. On the basis of the same needling density, conveying speed of the viscose and the needling frequency, the negative pressure makes the viscose screen realize the compact at first and then needle to make the connection of the viscose tight; the viscose volume in the unit volume is increased, and the volume density of the viscose felt after being needled is improved.

Owner:WUHAN TEXTILE UNIV

A prefabricated eps module wall and its construction method

The invention discloses an assembled EPS (expanded polystyrene) modular wall and a construction method thereof. The assembled EPS modular wall comprises vertical fixing ribs and EPS modules, wherein the vertical fixing ribs are perpendicular to the ground, and the bottoms of the vertical fixing ribs are fixed in a concrete foundation; a through U-shaped groove is formed in each of the EPS modules,the EPS modules are nested on the vertical fixing ribs through the U-shaped grooves, and the U-shaped grooves are matched with the vertical fixing ribs; the opening directions of the U-shaped groovesin two groups of EPS modules assembled up and down are opposite; a positioning groove is formed in the top of each EPS module, and a positioning bulge is arranged at the bottom of each EPS module. The assembled EPS modular wall is light in weight, rapid to construct, good in thermal insulation performance, fireproof, moisture-proof and low in construction cost.

Owner:李文升

A kind of assembly structure for modern building

ActiveCN111456253BStretchableDense connectionBuilding material handlingArchitectural engineeringAssembly structure

The invention discloses an assembly structure for modern buildings, comprising an assembly structure main body, a first assembly part is arranged on one side of the inner end of the assembly structure main body, and a second assembly part is fixedly connected to the other end of the first assembly part , the bottom of the inner end of the first assembly part is provided with a first frame, the front end of the first frame is fixedly connected with a first frame, and the side end of the first frame is connected with a first grouting frame, so The bottom end of the first frame is fixedly connected with a fourth steel bar, the transverse end of the fourth steel bar is fixedly connected with a third steel bar, and the front end of the third steel bar is fixedly connected with a second steel bar, The transverse position of the second reinforcing member is fixedly connected with the first reinforcing member, and the center of the inner end of the second fitting is provided with a second support column. The present invention is an assembly structure for modern buildings, through the arrangement of the first assembly part and the second assembly part, the purpose of grouting treatment of the inner end assembly is realized.

Owner:江西京丰建设工程有限公司

Construction Method of Grouting at the Top of Structural Column

ActiveCN106285005BWill not change the construction processDense connectionBuilding material handlingConcrete beamsArchitectural engineering

Owner:CHINA SHANXI SIJIAN GRP

The repair method of hot blast stove burner rush repair

ActiveCN105648129BGuaranteed tightnessImprove sealingBlast furnace detailsHeating stovesCombustorHot blast

Owner:BEIJING SHOUGANG CO LTD

A kind of reinforced concrete artificial mine pillar construction method

ActiveCN114109458BHighly precise controlPrecise control of construction heightProps/chocksReinforced concreteArchitectural engineering

The invention discloses a method for constructing a reinforced concrete artificial ore pillar. The height of the goaf is precisely divided into equal parts, the unit bodies are prefabricated according to the equal heights, and the prefabricated unit bodies are assembled in a top-down manner, and the gob is assembled with the gob height. The prefabricated unit body connected to the roof is fixed by the anchor cable member, the next prefabricated unit body adjacent to the top-connected prefabricated unit body is detachably connected to the lower end of the anchor cable member through the connecting rod member, and the subsequent prefabricated unit body is sequentially connected with the previous prefabricated unit body. The unit bodies are connected by connecting rod members, and the last prefabricated unit body is embedded between the prefabricated unit body above it and the bottom plate of the goaf. The prefabricated unit body is firmly connected to the bottom of the roof by using the anchor cable and the connecting rod, and the roof plate is forced to sink to a certain extent by the action of gravity and tension to compress the installation gap between the prefabricated unit bodies, so that the artificial ore pillars are completely connected as a whole. It is of great significance to improve the stability of the goaf, convert the primary ore pillar to the artificial ore pillar to reduce the loss of resources, and ensure the safe mining of the mine.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST +1

A kind of extension joint and construction method of prefabricated steel tube concrete core column member

ActiveCN111749346BSmall sectionIncrease the usable areaStrutsProtective buildings/sheltersArchitectural engineeringRebar

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

Laminboard socket rubber strip and application node structure thereof

ActiveCN105484398AGuaranteed service lifeGood waterproof performanceWallsBuilding insulationsStructural engineeringMechanical engineering

Owner:DUOWEI UNION GRP

Construction method for anti-floating beam of subway station

PendingCN114575391APrevent floatingStable structureArtificial islandsProtective foundationArchitectural engineeringSubway station

The invention belongs to the field of metro station structure construction, and particularly relates to a metro station anti-floating beam construction method which is used for pouring an anti-floating beam in a space below a top beam on a station top plate and preventing a station main body structure from integrally floating due to the influence of water floating, and comprises the following steps: pre-burying two reinforcing steel bars and installing anti-floating beam reinforcing steel bars when the top beam is constructed; the method comprises the following steps: embedding three expansion bolts into a ground wall surface, mounting an anti-floating beam straight wall section formwork system, fixing a formwork by adopting an inner tie bar, erecting a vertical formwork system, mounting and fixing an over-irrigation area formwork, fixing an outer formwork system by adopting an inclined steel pipe and a steel bar, pouring anti-floating beam concrete in a layered manner, shoveling the over-irrigation area concrete, and dismounting the formwork system. The formwork structure is firm, the supporting structure is stable, and concrete pouring construction is facilitated. The method is reasonable in design and convenient to operate, the roof waterproof layer structure is not damaged, the anti-floating beam and the top beam bottom are tightly connected, and the effect is remarkable.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Integral molding process of a light carbon fiber carrying case

The invention relates to an integral molding process for a light portable carbon fiber box. The integral molding process comprises the following steps: (1) combining and assembling a mould; (2), laying up; (3) arranging a guide net and a spiral net; (4) sealing the mould; and (5) performing a guide process. Compared with the prior art, the integral molding process has the advantages that aramid fibers and carbon fibers are mixed and laid up, so that the mechanical performances including toughness, impact performance, strength, rigidity and the like are comprehensively improved when the box body is kept light; through grooves and small through holes in a buried plate, resin ribs can be dispersed more quickly; the guide net and the spiral tube are arranged, and the guide process is set, so that the resin penetrates layer by layer in a transverse direction and a longitudinal direction of lay-up layers, and the porosity is reduced by connecting the lay-up layers more tightly through the resin; high-strength and low-temperature curing epoxy resin can be quickly cured at low temperature, so that the molding time is shortened, the operation environment is improved, the process flow is simplified, and the operation environment is improved.

Owner:SYST EQUIP CO LTD OF THE 28TH RES INST LI YANG

Water tank for refrigerator

InactiveCN1766482ASmall sizeDense connectionLighting and heating apparatusDomestic refrigeratorsRefrigerator carEngineering

The invention discloses a refrigerator water pot, which consists of outlet and body part, wherein the outlet is made of injection molding method, which connects on the water-cock of distributor; the body part is made of injection molding method when the outlet plugs in the body part; the water pot is set in the door within distributor, which supplies water to the distributor. The invention is more convenient to connect the water pot with water-cock of distributor.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com