A kind of reinforced concrete artificial mine pillar construction method

A technology of reinforced concrete and artificial pillars, which is applied in the direction of earth drilling, mining equipment, pillars/brackets, etc., and can solve problems such as the suspension of the top and the small working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

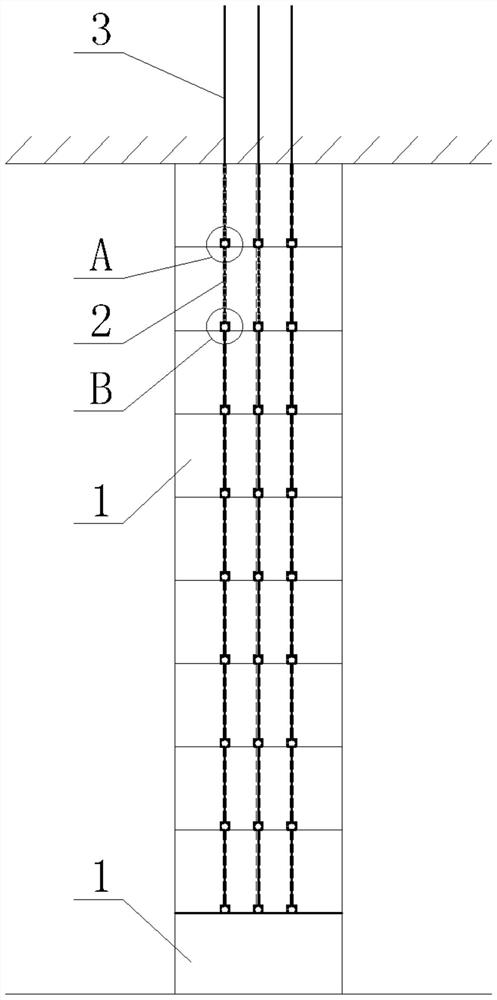

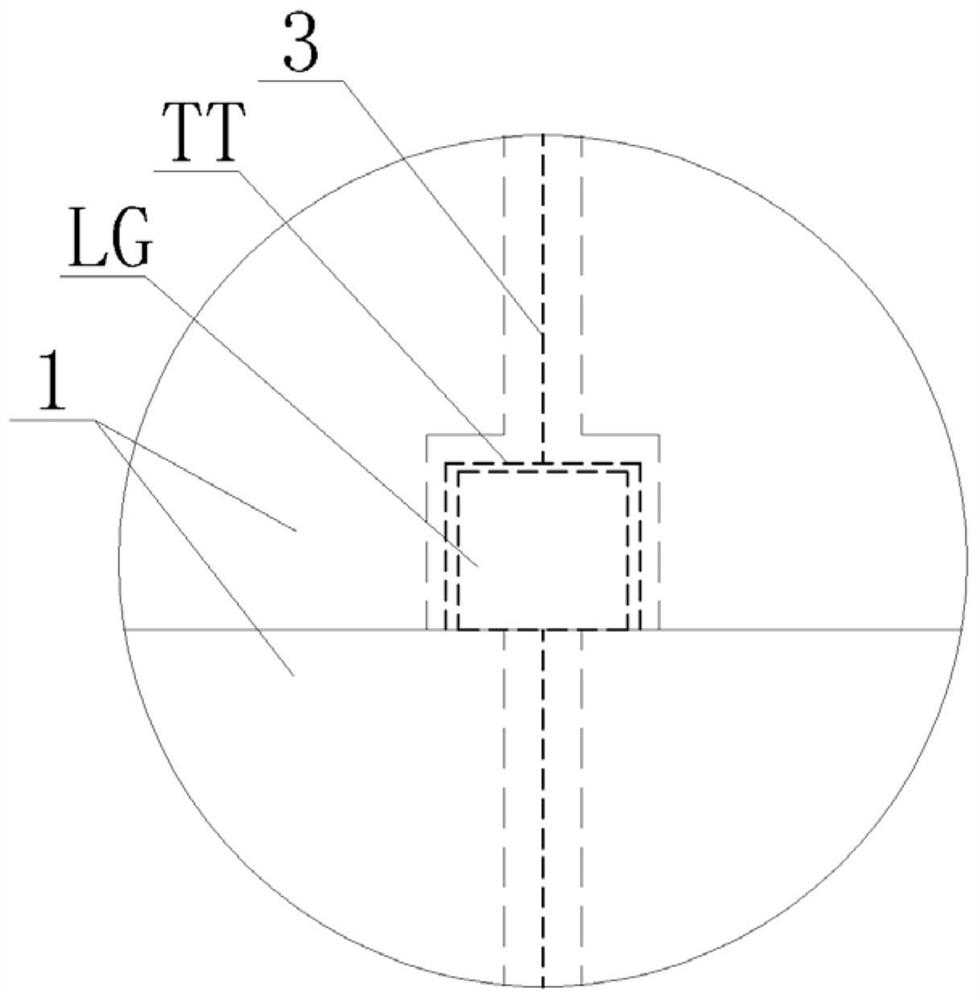

[0029] combine Figure 1 to Figure 4 It can be seen that the reinforced concrete artificial mine column disclosed in this embodiment includes several prefabricated unit bodies 1 , connecting rods 2 , and anchor cables 3 .

[0030] In this embodiment, each prefabricated unit body is installed in a flip-up manner. First, the uppermost prefabricated unit body is tightly fixed on the roof of the goaf through an anchor cable, and then each prefabricated unit body is successively and tightly fixed under the prefabricated unit body. , until the bottom penultimate prefabricated unit is installed.

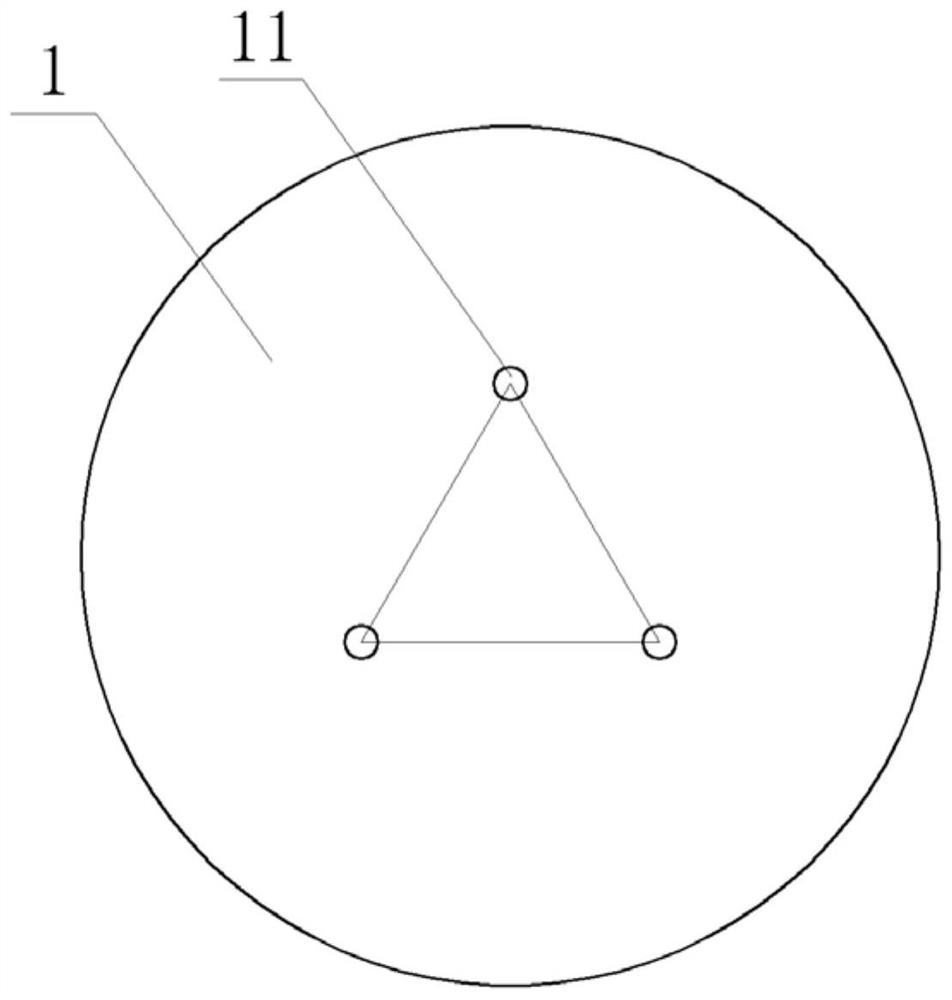

[0031] The prefabricated unit body 1 is a reinforced concrete cylinder, and a plurality of longitudinal through holes 11 with a diameter larger than the diameter of the anchor cable 3 are reserved in the prefabricated unit body. the bottom (on the gob floor).

[0032] The diameter of the lower end section of the longitudinal through hole 11 is larger than that of other positions, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com