The repair method of hot blast stove burner rush repair

A repair method and burner technology are applied in the field of hot blast stove burners to achieve the effects of ensuring sealing, enhancing sealing, improving strength and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

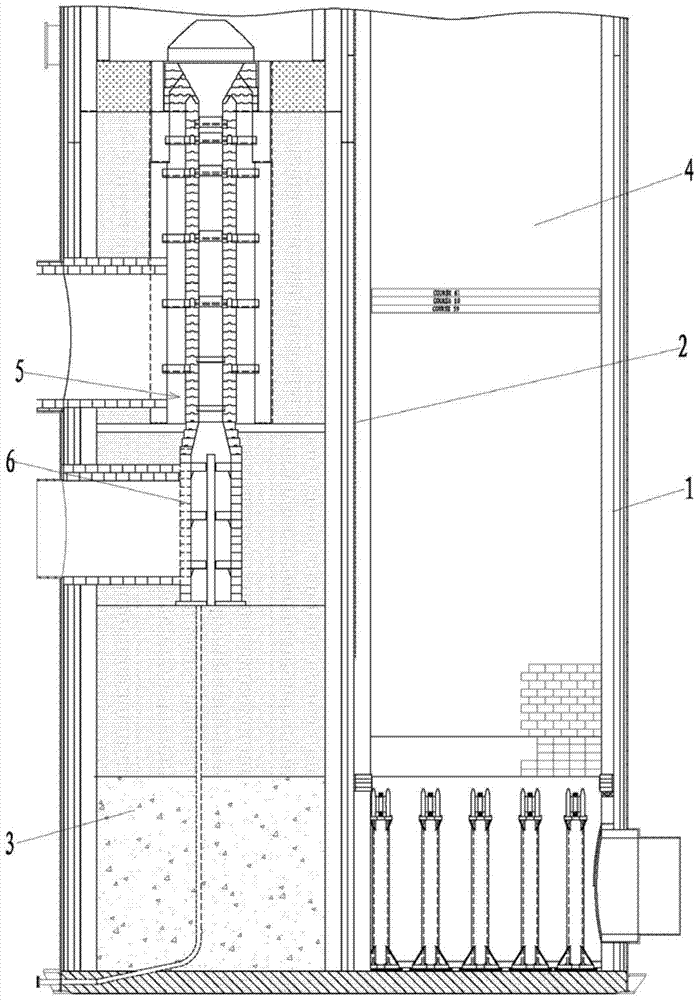

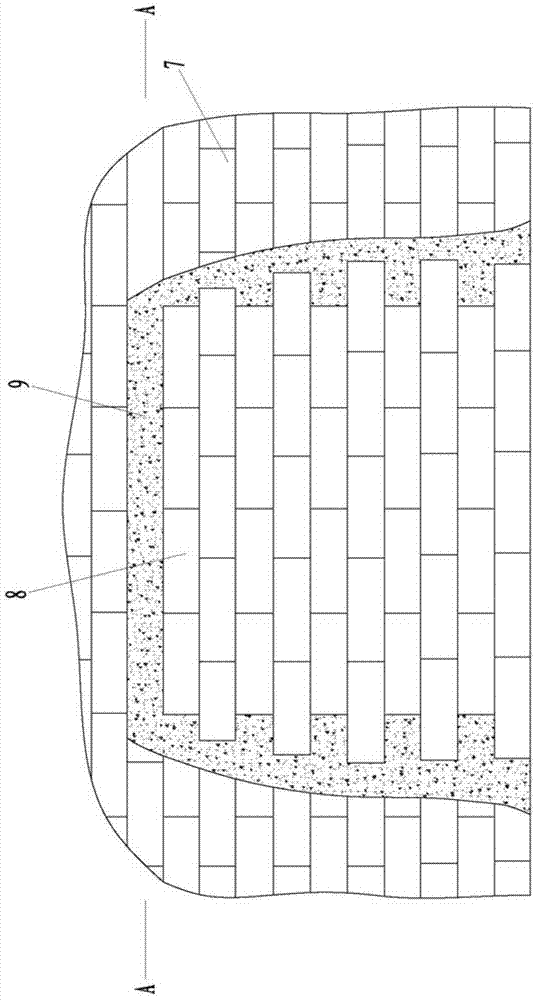

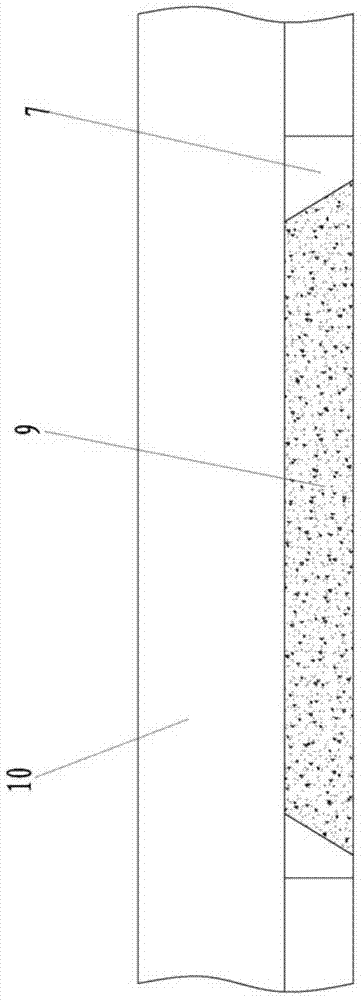

[0028] Such as figure 1 The shown hot blast stove structure diagram of the present invention includes a cylindrical housing 1, the inner cavity of the housing 1 is divided into a combustion chamber 3 and a regenerator 4 by a partition wall 2, and a burner 5 is arranged in the combustion chamber 3. The burner 5 includes a cylindrical gas channel protection wall 6 with a rectangular cross section. combine figure 2 , image 3 As shown in the present invention, the repair method embodiment of the hot blast stove burner is a schematic diagram of the front view and a schematic diagram of the top view. When a failure occurs on a certain old wall 7 of the gas channel protection wall 6, the repair method includes the following steps:

[0029] (1) the old body of wall 7 areas where the gas duct protection wall 6 fails is removed;

[0030] (2) lay new body of wall 8 (i.e. mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com