A foldable house and its disassembly method

A folding and house technology, applied in the direction of construction and building structure, can solve the problems of complex installation process, cumbersome installation process, complex structure, etc., and achieve the effect of increasing the usable area, reasonable structure design and reducing weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

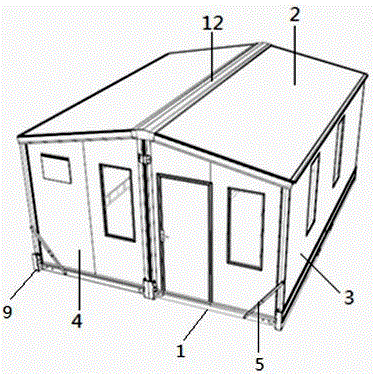

[0062] Foldable houses in this embodiment, refer to the attached Figure 1-17 , including a first unit and a second unit that are structurally symmetrical and can be assembled with each other to form a foldable house. The first unit and the second unit both include a bottom plate 1 and gable panels 4 hinged on opposite sides of the bottom plate 1. Two A side wall panel 3 is arranged between the gable panels 4, the bottom of the side wall panel 3 is hinged on the base plate 1, the top of the side wall panel 3 is hinged with a top plate 2, and the same side of the side wall panel 3 and the top panel 2 is provided with a The limit hole of the limit pin 15 is inserted, and the side joints and top joints of the first unit and the second unit are assembled into one body through detachable side joints and top joints respectively; bottom plate 1, side wall plate 3 The gable panels 4 are made of lightweight energy-saving panels surrounded by aluminum alloy frames. The lightweight energ...

Embodiment 2

[0064] For a foldable house in this embodiment, refer to the attached Figure 17 The difference between this embodiment and Embodiment 1 is that a plurality of assembled foldable houses can be assembled sequentially through connectors to form a house cluster.

Embodiment 3

[0066] A method for disassembling a foldable house in this embodiment includes the following steps:

[0067] The house assembly process is as follows:

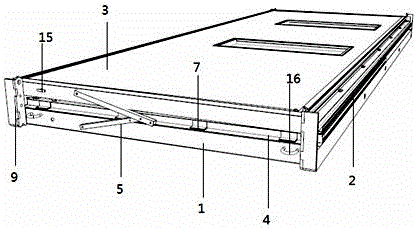

[0068] 1. Put the folded house unit in place (refer to the attached figure 2 );

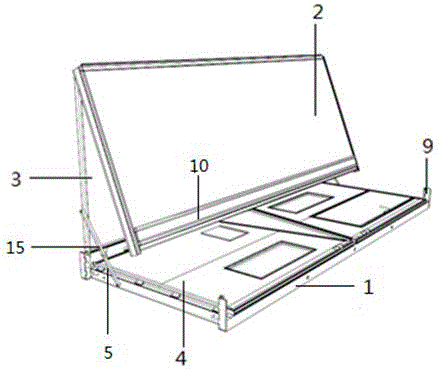

[0069] 2. First unfold the side wall panel 3 of the first unit or the second unit, and the folding rods 5 at both ends of the unit will be opened with the rotation of the side wall panel 3 until the side wall panel 3 stands upright (refer to the attached image 3 ), remove the limit pin on the side of the house, and install the limit pin to the socket of the folding rod 5 to fix the side wall panel 3 . The function of the limit pin is to limit the mutual movement of the top plate 2 and the side wall panel 3 when folding, and after the side wall panel 3 is unfolded, fix the folding rod 5 to keep it unfolded, thereby keeping the side wall panel stable;

[0070] 3. Unfold the top panel 2 (refer to the attached Figure 4 ), keep the top plate 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com