Composite thermal insulation wall body and method for producing and mounting the same

A technology for composite walls and thermal insulation decorative panels, applied to walls, building components, ceramic molding machines, etc., can solve problems that cannot meet the needs of the industrialization of steel structure houses, achieve good fire protection, safe and reliable construction, and excellent The effect of fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings and different embodiments.

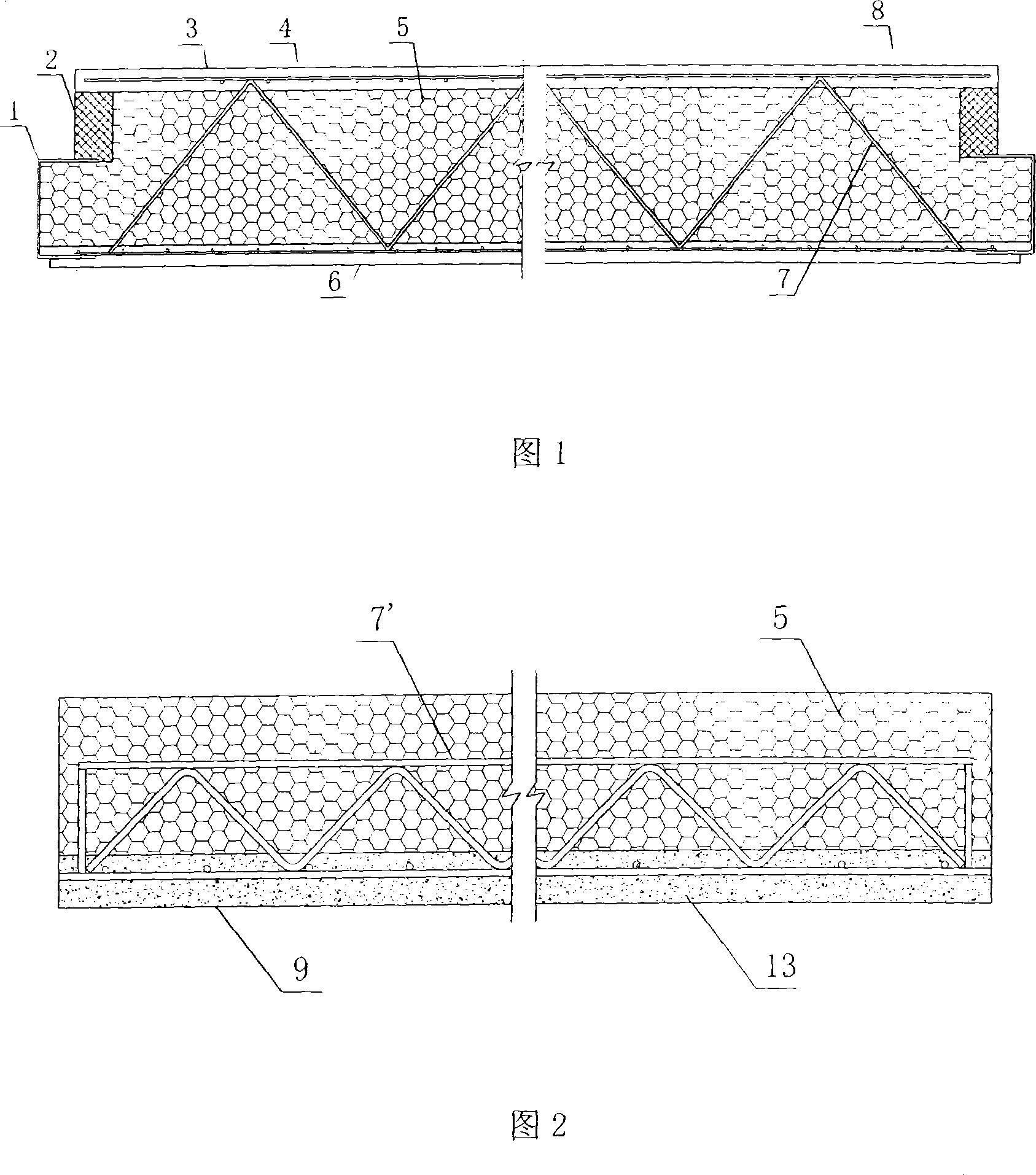

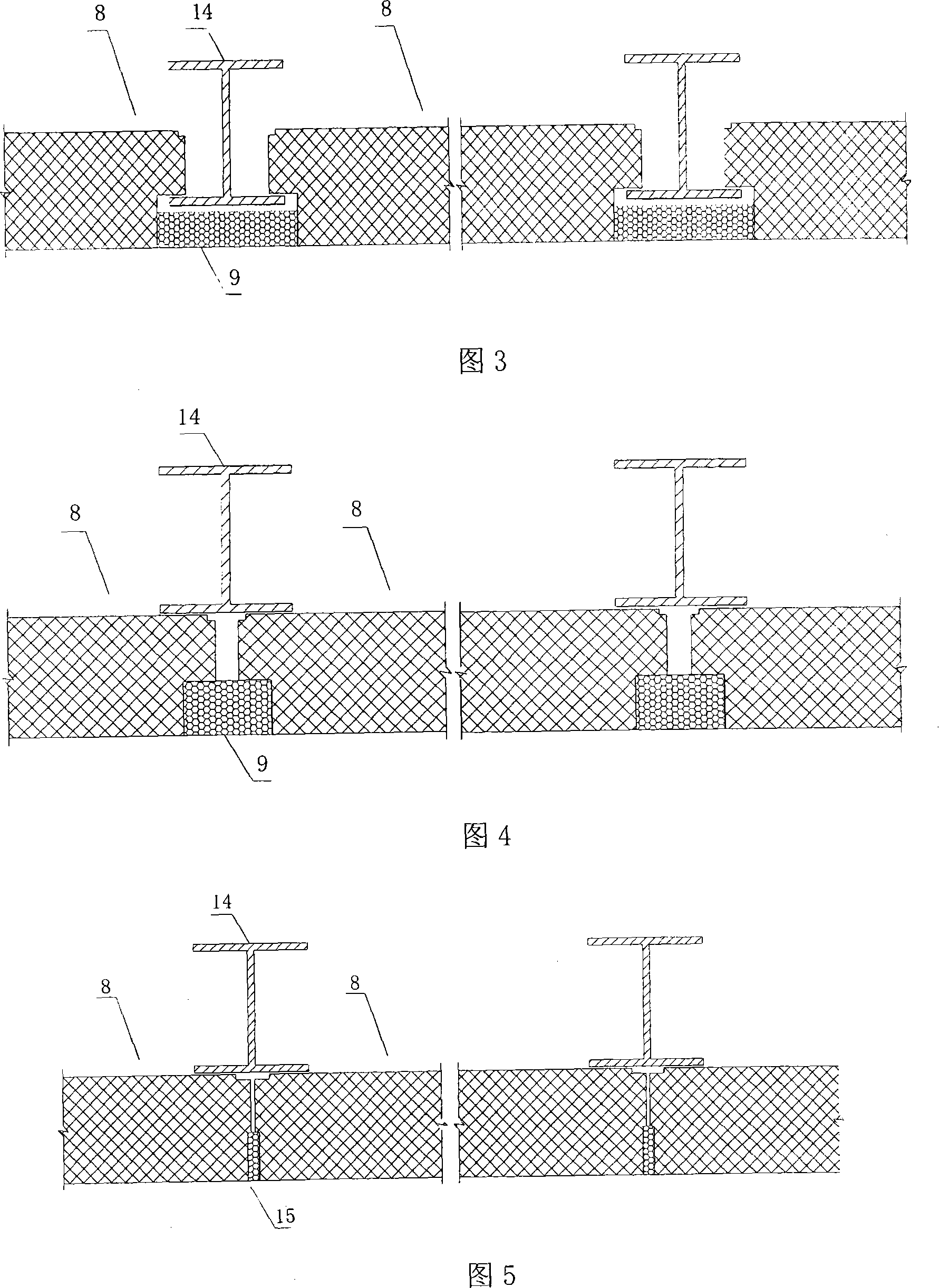

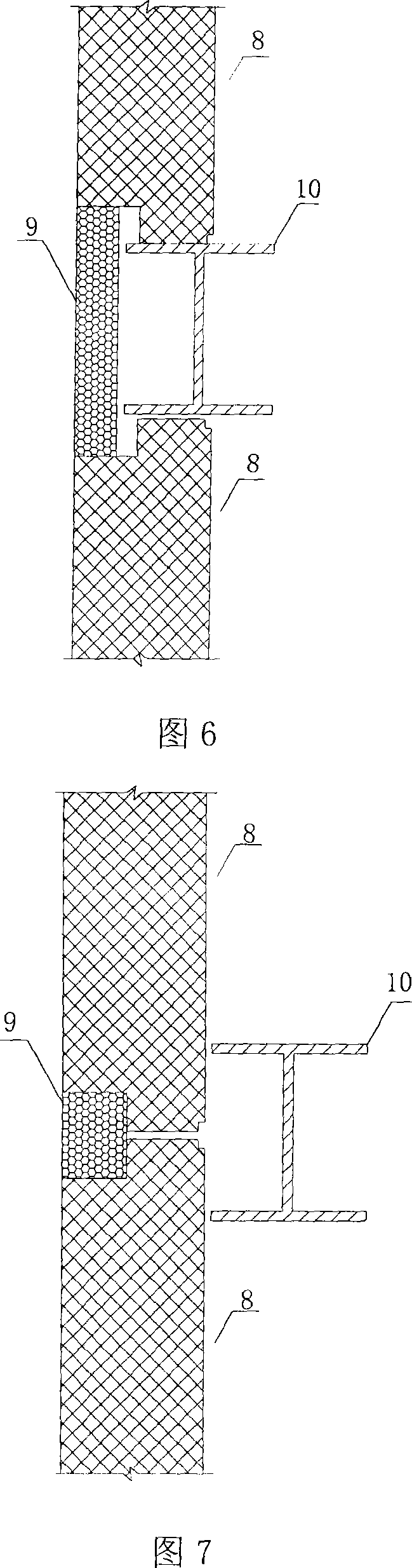

[0062] As shown in Figure 1, the single wall panel 8 of the present invention is mainly composed of a steel frame 1, a protective frame 2, an inner surface layer 6, an outer layer 3, a foamed cement insulation core layer 5 and a steel truss 71. Wherein, a steel frame 1 and a protective frame 2 are provided on the edge of the single wall panel; a steel truss 71 and a three-dimensional steel wire mesh 41 are arranged in the single wall panel; The inner surface layer 6 of anti-cracking material; the insulation core layer 5 made of foam cement is arranged in the middle; the outer surface layer 3 of material with anti-cracking performance is arranged on the outer surface of a single wallboard. The crack-resistant material is steel wire mesh.

[0063] As shown in Figure 2, the thermal insulation decorative panel 9 of the present invention is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com