Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Consistent movement speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

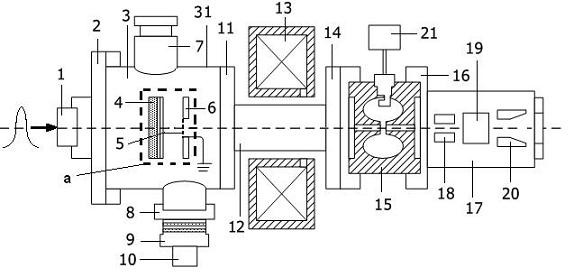

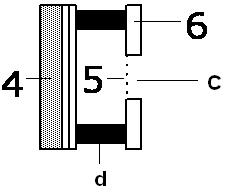

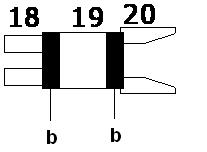

Electron gun device for generating high-brightness femtosecond electronic pulse

InactiveCN102592929AIncrease brightnessHigh spatio-temporal resolutionElectric discharge tubesPhotocathodeRadio frequency

The invention provides an electron gun device for generating a high-brightness femtosecond electronic impulse. The electron gun device comprises an incident window, a sealing component, a vacuum cavity, a photocathode, a grid, an anode, an observation window, a molecular pump, a pre-stage dry pump, an electronic focusing magnetic lens, an RF (Radio Frequency) electronic compression cavity, an RF signal generating device, an x-direction electronic deflector, a y-direction electronic deflector and an electronic scanning plate. Through the invention, the broadening function of the space charge effect on longitudinal pulse duration of an electronic beam impulse is effectively suppressed; the problem that the divergence of the electronic beam is increased due to electric field distortion at a small hole of the anode is solved; and the horizontal and longitudinal electronic impulses have super-high resolution factors, and the real-time detection on super-high time resolution and space resolution of ultrafast processes such as molecular reaction dynamics can be performed.

Owner:EAST CHINA NORMAL UNIV

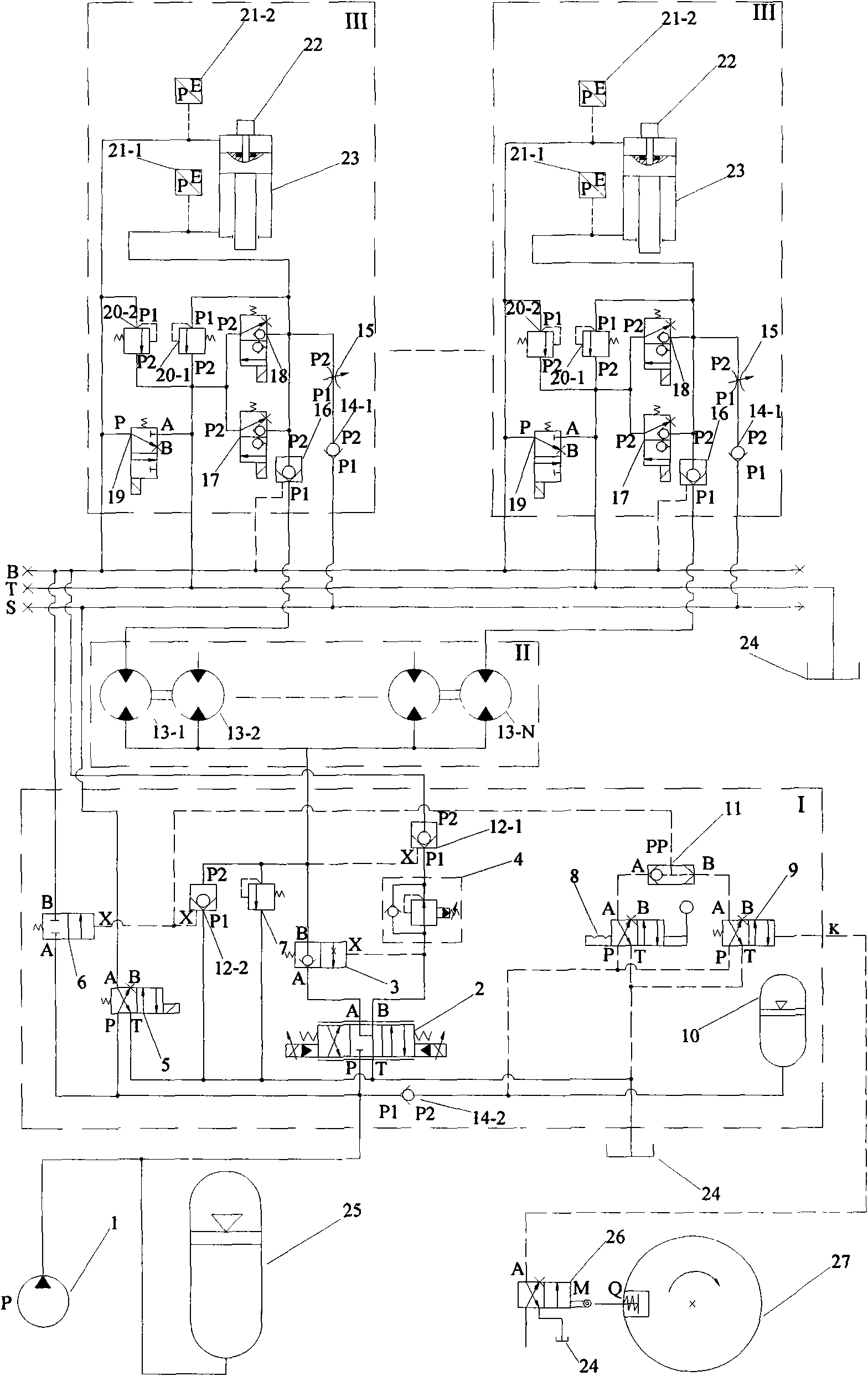

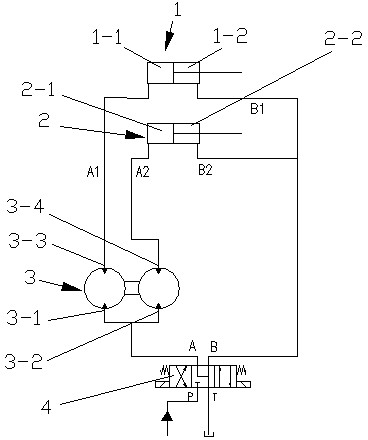

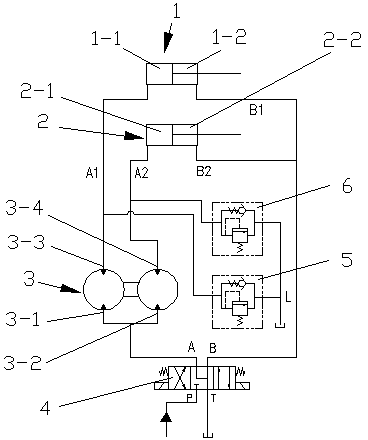

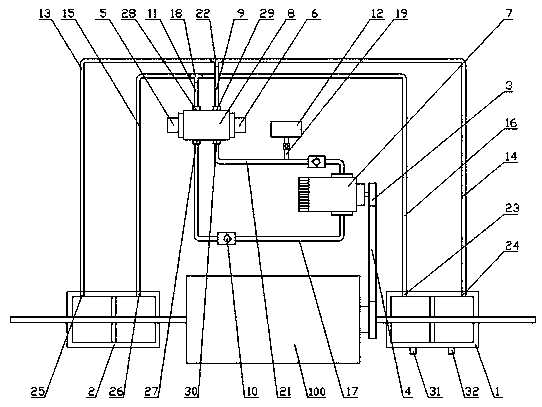

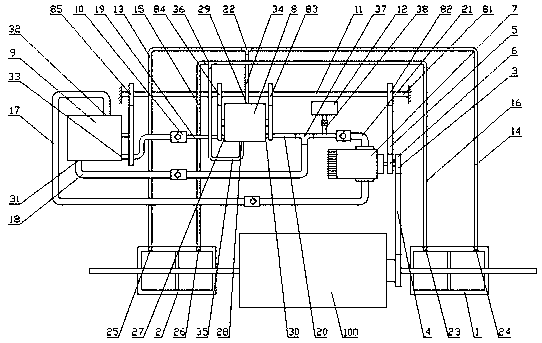

Water turbine cylinder valve machine electrohydraulic control system with function of runaway turnoff

InactiveCN101624961ASlow ascentIncrease ascent speedHydro energy generationMachines/enginesWater turbineServomotor

The invention discloses a water turbine cylinder valve machine electrohydraulic control system with a function of runaway turnoff, which consists of a control valve assembly, flow-dividing motors and oil distributing modules; wherein, the output of the control valve assembly is respectively connected with N synchronous flow-dividing motors and corresponding N oil distributing modules; a servomotor is respectively connected on the tail end of each oil distributing module as an executive device of a hydraulic system; the flow-dividing motor is radial plunger type and carries out flow dividing on hydraulic oil to ensure that the input and output oil amount of each servomotor hydraulic cylinder are equal, meanwhile, the oil distributing module is provided with two fine adjustment and rough adjustment electromagnetism ball valves to ensure that the synchronous control of corresponding servomotor meets the requirement of designing through accurately controlling flow entering into the servomotor by PLC. The invention can control the speed of the servomotor by controlling the flow of an electro-hydraulic proportional direction valve to realize hydraulic-electric synchronous and speed control with high precision, and a machine unit can be turned off immediately under the combined action of an over-speed protection device and a control system with the function of runaway when the machine unit is over speed.

Owner:TIANJIN UNIV

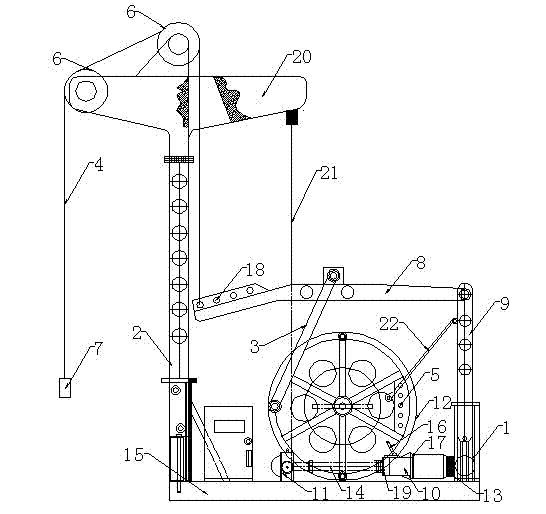

Pumping unit with wide swing angle

The invention discloses a pumping unit with a wide swing angle, which comprises a motor, a bracket, a connecting rod, a speed change mechanism, a lifting rope, a fixed pulley, a wellhead oil pumping device, a rocker arm, a rocker arm pillar and two crankshaft wheels, wherein one end of the rocker arm is movably connected on the rocker arm pillar, the other end of the rocker arm is connected with the lifting rope, the lifting rope is connected with the wellhead oil pumping device by the fixed pulley which is arranged on the bracket, the two crankshaft wheels are connected with the speed change mechanism, one end of the connecting rod is movably connected with the rocker arm, and the other end of the connecting rod is movably connected with the crankshaft wheels. According to the pumping unit disclosed by the invention, the speed change mechanism is matched with the crankshaft wheels to pump oil, so that a pumping unit can be started and the working of the pumping unit can be maintained by a motor with relatively small power, and the pumping speed and the stroke of the pumping unit can be conveniently regulated.

Owner:德阳振华机械设备制造有限公司

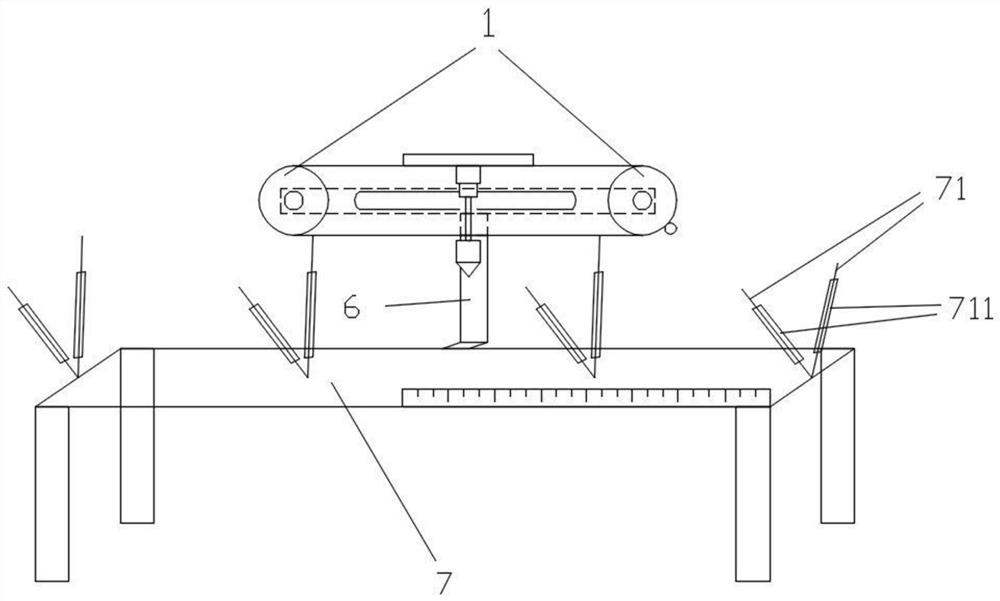

Tailoring and conveying separated spinning device

The invention discloses a tailoring and conveying separated spinning device. The tailoring and conveying separated spinning device comprises conveying rollers, the outer sides of the conveying rollersare sleeved with conveying belts, shaft end bearings of the conveying rollers are connected to a supporting frame, extrusion rollers are connected to the supporting frame through bearings, the extrusion rollers are arranged on the conveying rollers, the conveying rollers and the extrusion rollers are tightly attached to the inner sides and the outer sides of the conveying belts correspondingly, the outer sides of the shaft ends of the conveying rollers are in key connection with chain gears, the outer sides of the chain gears on the same side are in engaged connection with chains, shifting sleeves are fixed to the chains, and transmission blocks are arranged at the upper ends of the shifting sleeves. According to the tailoring and conveying separated spinning device, tailoring and conveying of cloth do not affected, the cloth is cut in a continuous conveying process of the cloth, then the working efficiency can be improved conveniently, the two sides of the tailoring part can be pressed in the cloth cutting process, then the cloth can be advantageously cut stably, and the problem that the cloth is cut to be damaged due to deviation of the cloth when the cloth is cut in the past isavoided.

Owner:尹宝珍

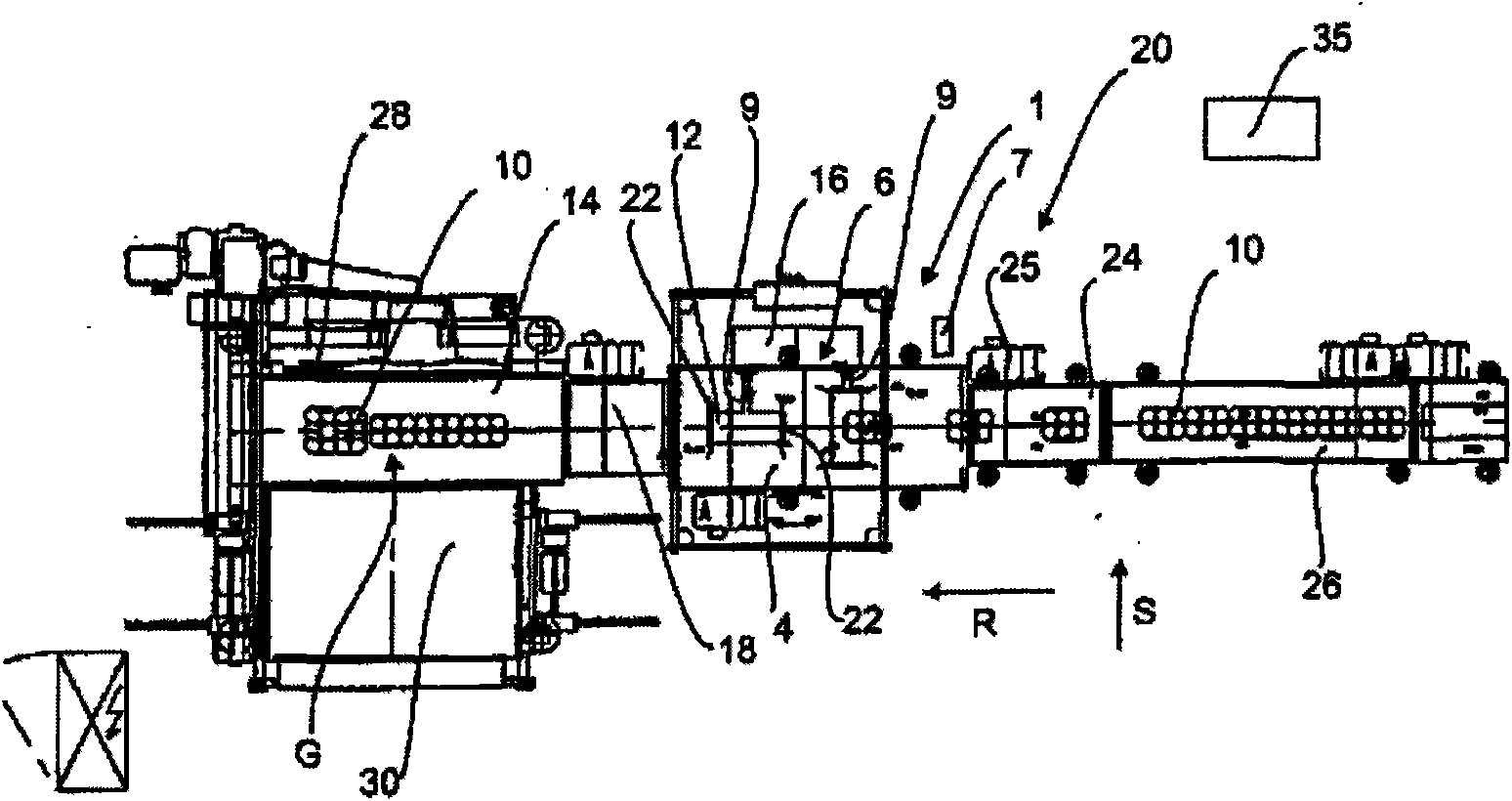

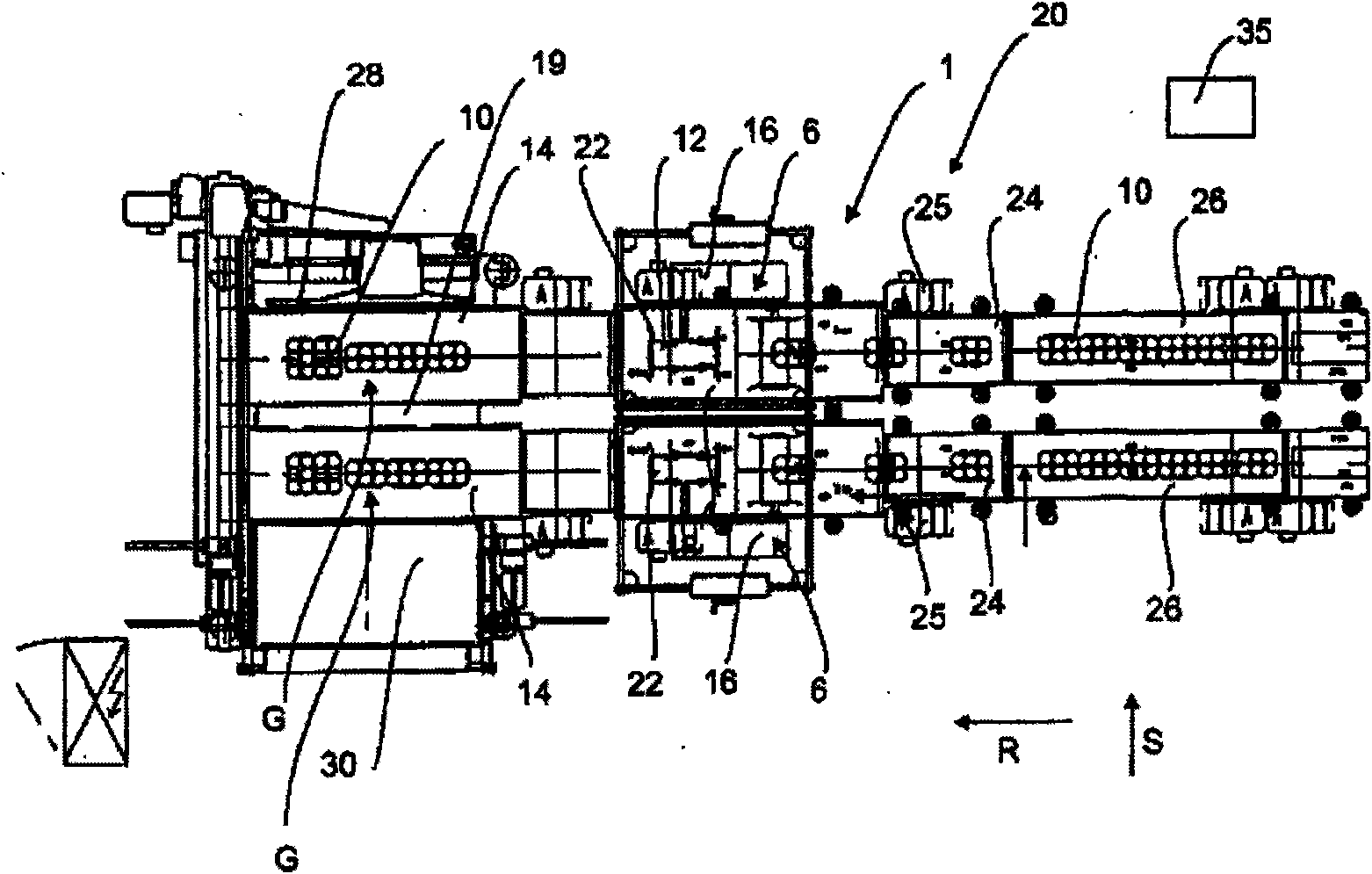

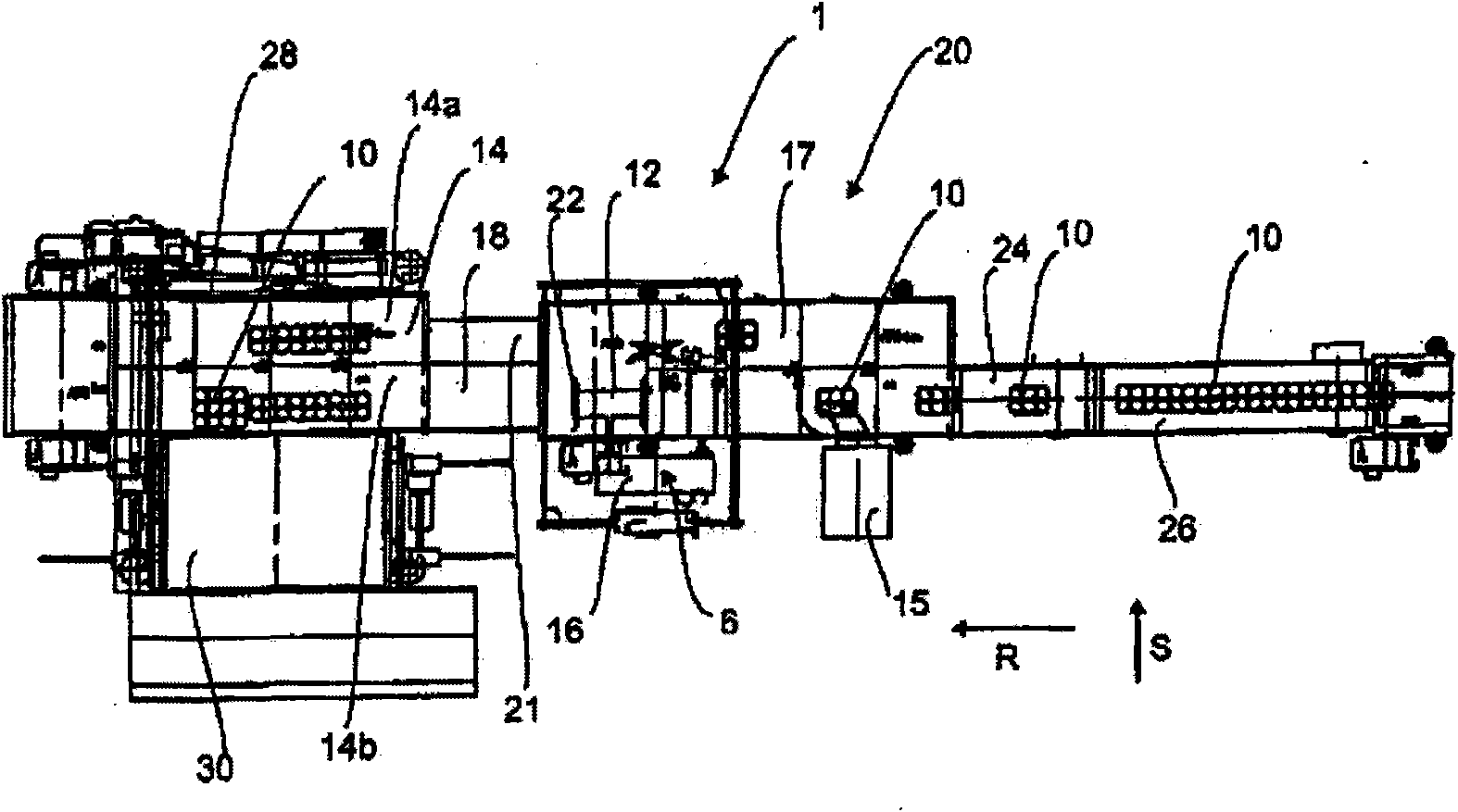

Apparatus for conveying packages

Disclosed is an apparatus (1) for conveying packages (10), comprising a first conveying device (4) that conveys the packages (10) in a predefined direction of travel (R) and a rotating device (6) which rotates at least some of the packages (10) by a predefined angle of rotation relative to a predefined axis of rotation. The rotating device (6) is equipped with at least one gripping mechanism (12)that grips the packages (10) for the rotating process. According to the invention, the conveying speed of the first conveying device (4) is synchronized with a moving speed of the gripping mechanism (12).

Owner:KRONES AG

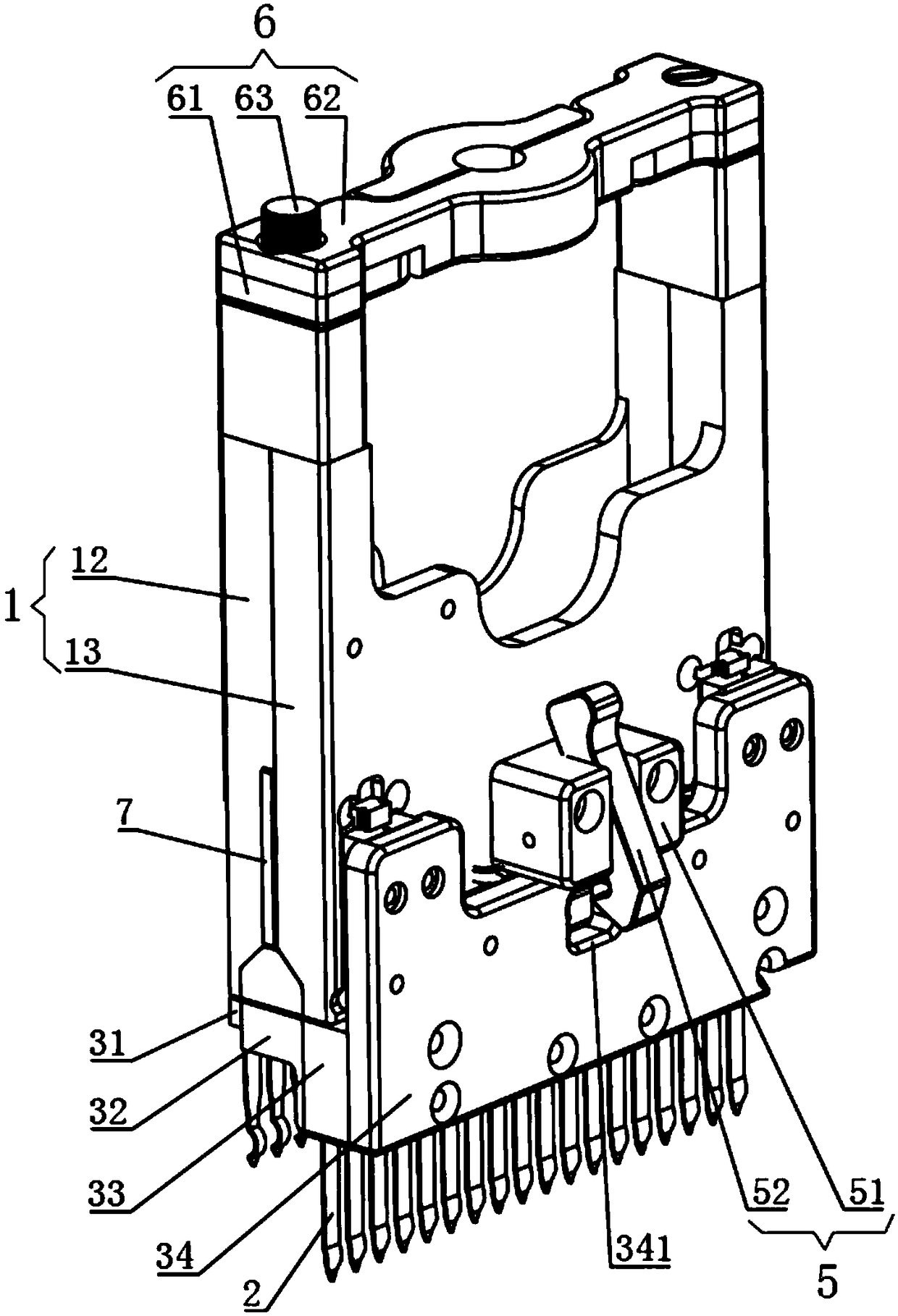

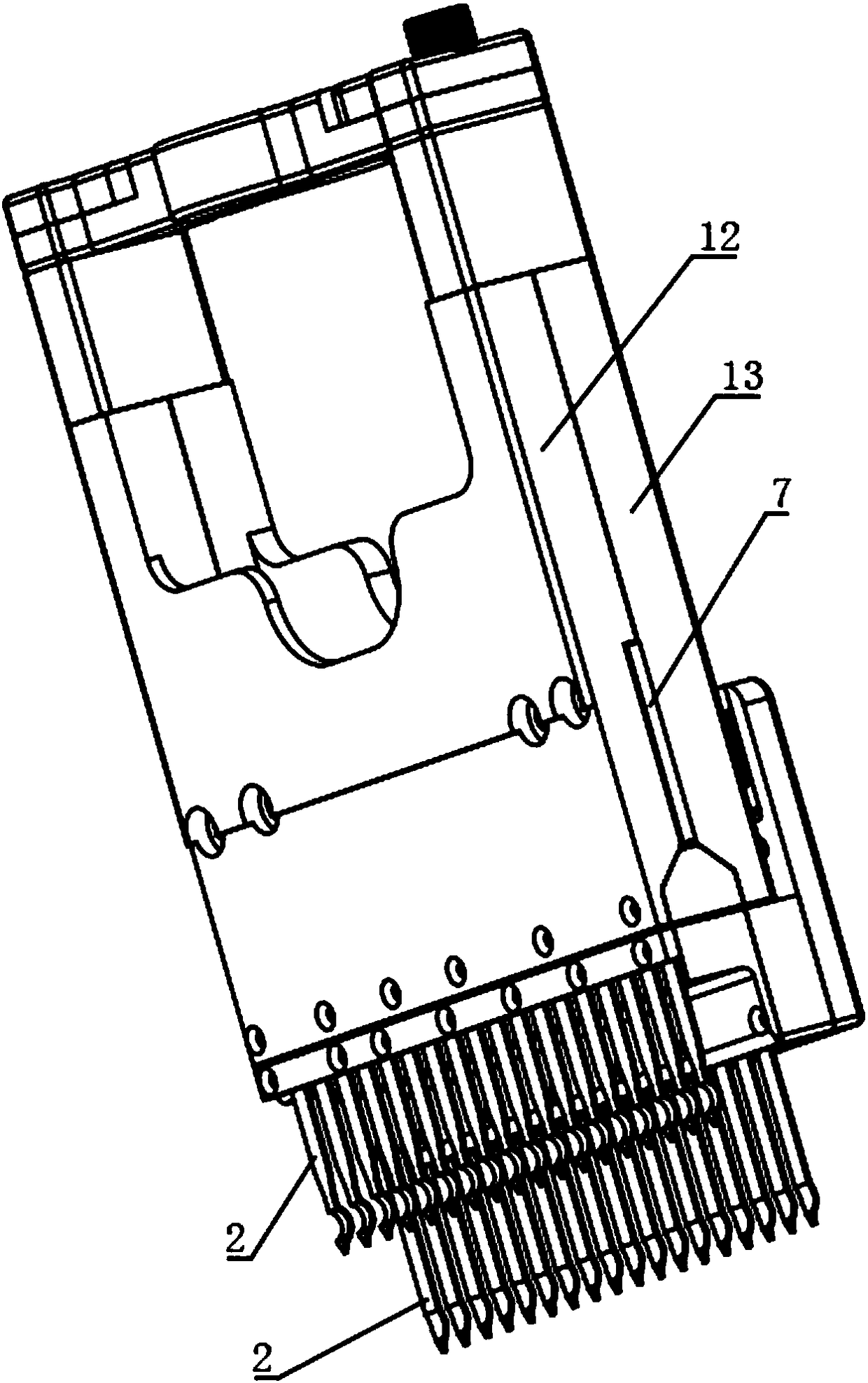

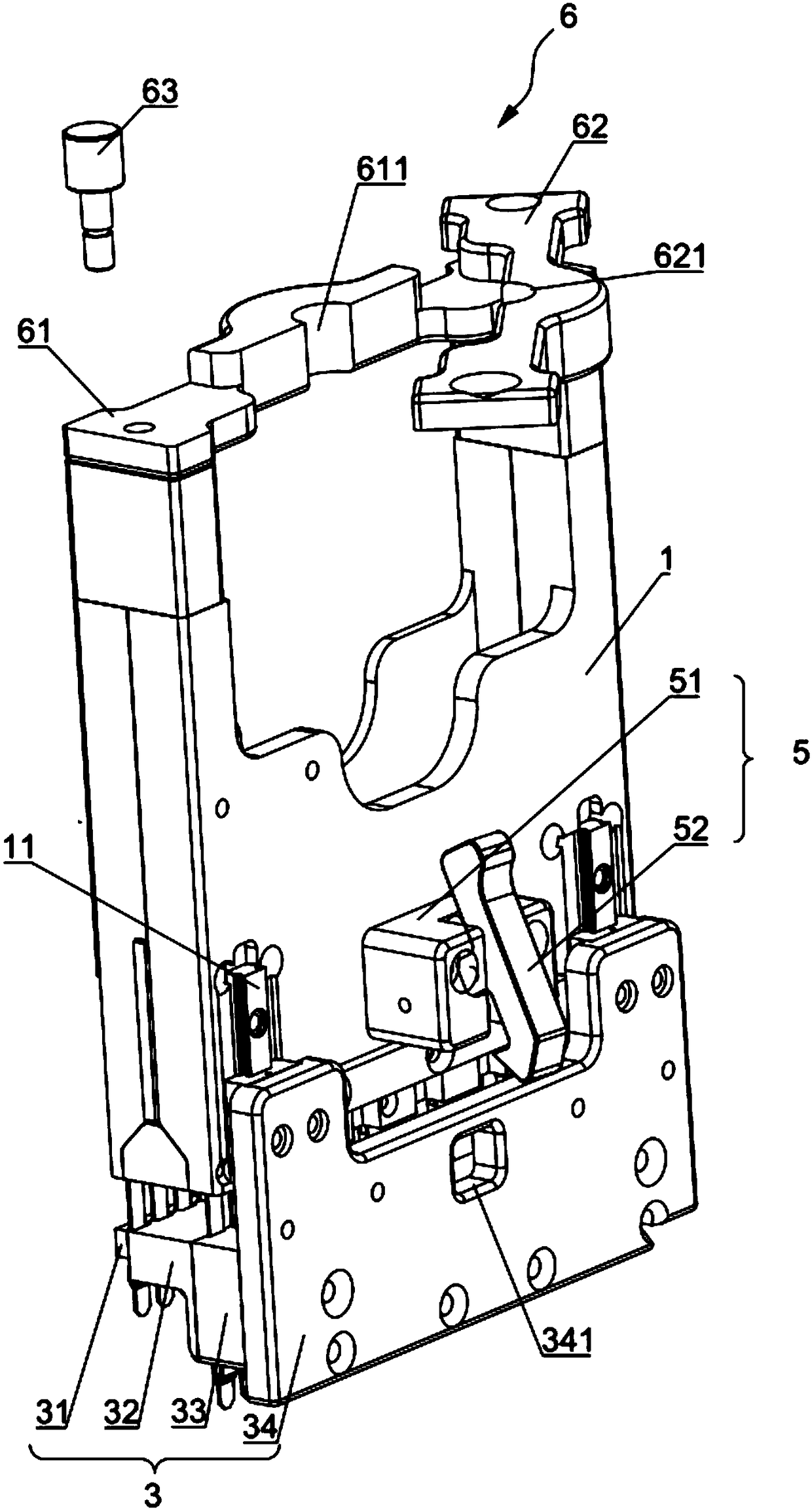

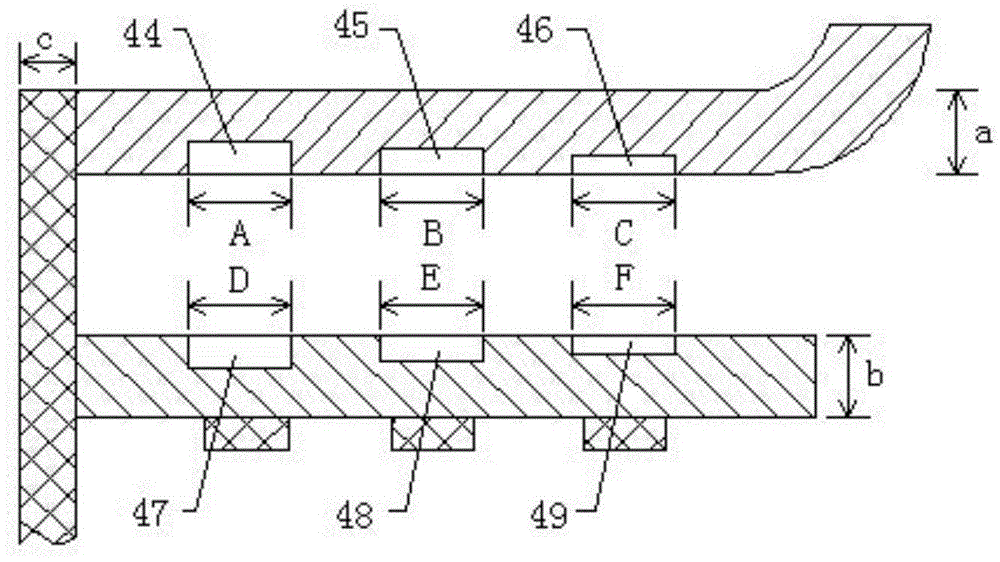

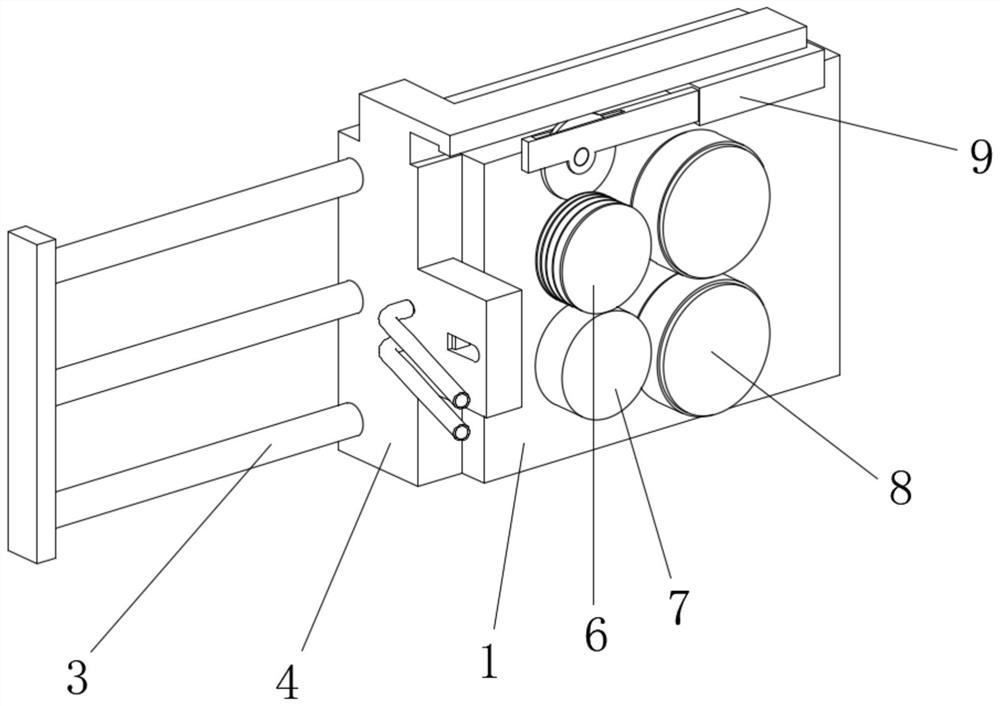

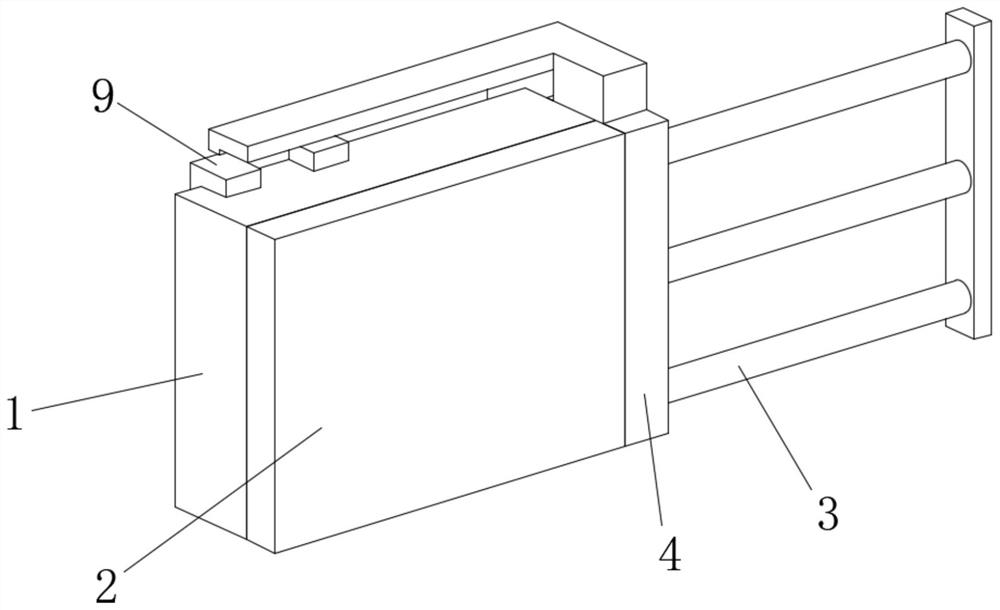

Test clamp

PendingCN108132366ASimple structureLow manufacturing costMeasurement instrument housingTest efficiencySoftware engineering

The present invention relates to the technical field of wiring terminal tests, and especially discloses a test clamp. The test clamp comprises a support seat, an installation rack, a plurality of testneedles and an elastic component. One end of the support seat is configured to abut against a product to be tested; the installation rack can slide close to or far away from the product to be testedalong the support seat, and is located at one end, far away from the product to be tested, of the support seat; one ends of the test needles are connected with one end, close to the product to be tested, of the installation rack, and the other ends of the test needles are configured to be inserted into the product to be tested; and one end of the elastic component is connected with the support seat, the other end of the elastic component is connected with the installation rack, and the elastic component can drive the installation rack to be far away from the product to be tested so as to allowthe test needles to be far away from the product to be tested. After the test of the product to be tested is finished, an external force is only removed, the elastic component drives the installationrack to move upwards, the test needles are pulled out from the product to be tested at the same time, the product to be tested cannot be damaged or damaging of the test needles themselves cannot happen, and therefore, the test clamp is simple in structure, low in manufacturing cost and high in test efficiency.

Owner:昆山威典电子有限公司

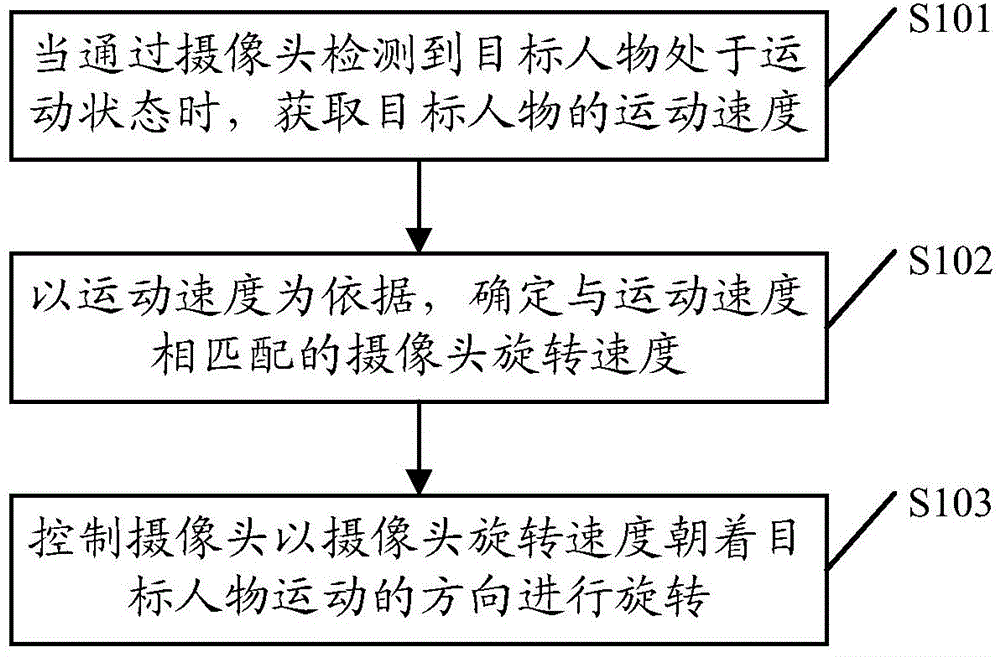

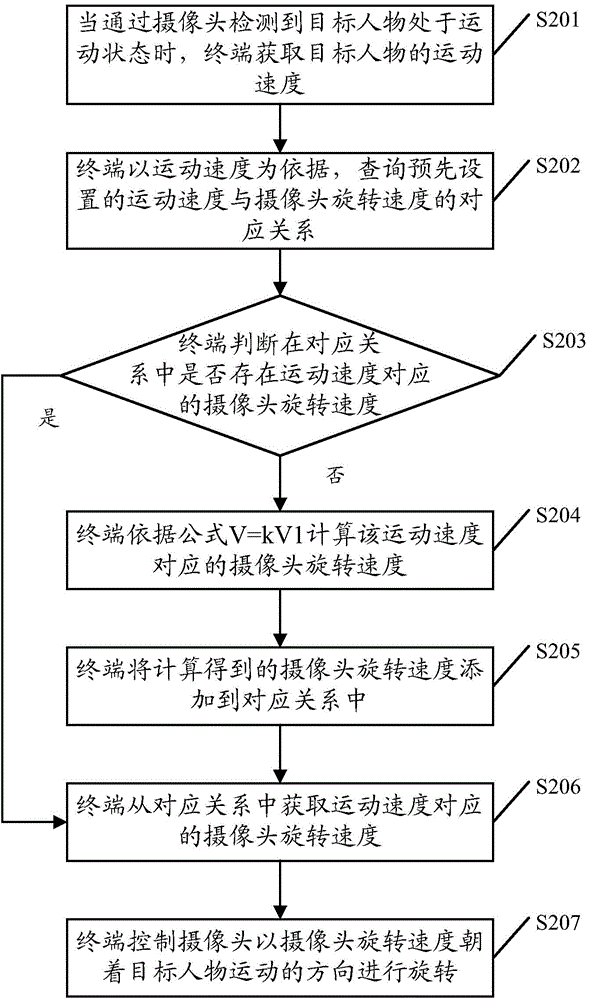

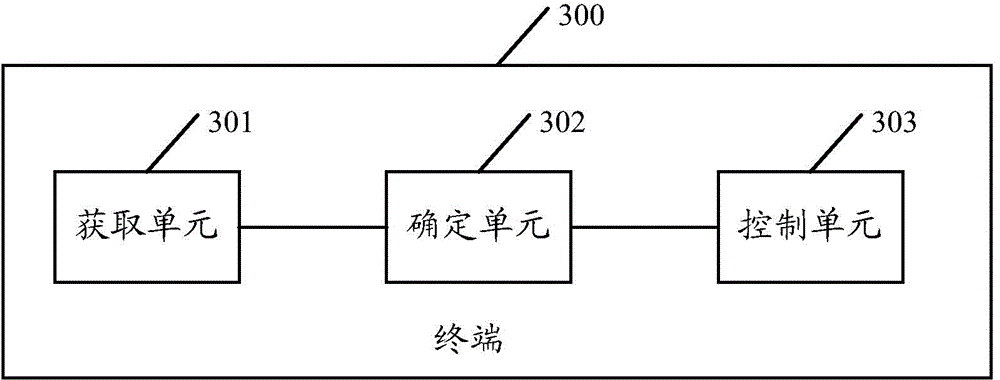

Rotary camera control method and terminal

ActiveCN104902169AImprove the shooting effectConsistent rotation speedTelevision system detailsColor television detailsCamera controlRotation velocity

The embodiment of the invention discloses a rotary camera control method and a terminal. The method comprises the following steps: acquiring a movement velocity of a target person when detecting that the target person is in a movement status through the camera; determining the rotary velocity of the camera matched with the movement velocity on the basis of the movement velocity; controlling the camera to rotate in the movement direction of the target person at the rotary velocity of the camera. A shooting effect of a movement target can be improved through the adoption of the method disclosed by the embodiment of the invention.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Large-sized hydraulic speed change floating box flap valve

InactiveCN102095004AReduce noiseAvoid damageBarrages/weirsOperating means/releasing devices for valvesEngineeringFlap valve

The invention discloses a large-sized hydraulic speed change floating box flap valve. The flap valve comprises a hinged support (1), a valve seat (3), an upper valve leaf (5) and a lower valve leaf (8), wherein both the valve seat (3) and the hinged support (1) are fixed on a pump station base; the upper valve leaf (5) is hinged with the hinged support (1) through a pin shaft (2); the lower valveleaf (8) is hinged with the upper valve leaf (5); the upper valve leaf (5) and the lower valve leaf (8) are hermetically contacted and matched with the valve seat (3) through a sealing structure, andthe upper valve leaf (5) is connected with the lower valve leaf (8) through at least one hydraulic mechanism (7); and one end of the hydraulic mechanism (7) is hinged with the upper valve leaf (5), and the other end of the hydraulic mechanism (7) is hinged with the lower valve leaf (8). After the structure is adopted, since the upper valve leaf and the lower valve leaf are provided with the hydraulic mechanism, the collision force of the valve leaves and the valve seat can be buffered by the hydraulic mechanism; thus water sealing rubber for sealing the valve leaves and the valve seat is prevented from being damaged so as to reduce the cost; meanwhile, the noise produced during collision is also reduced.

Owner:NINGBO JUSHEN PUMPS IND

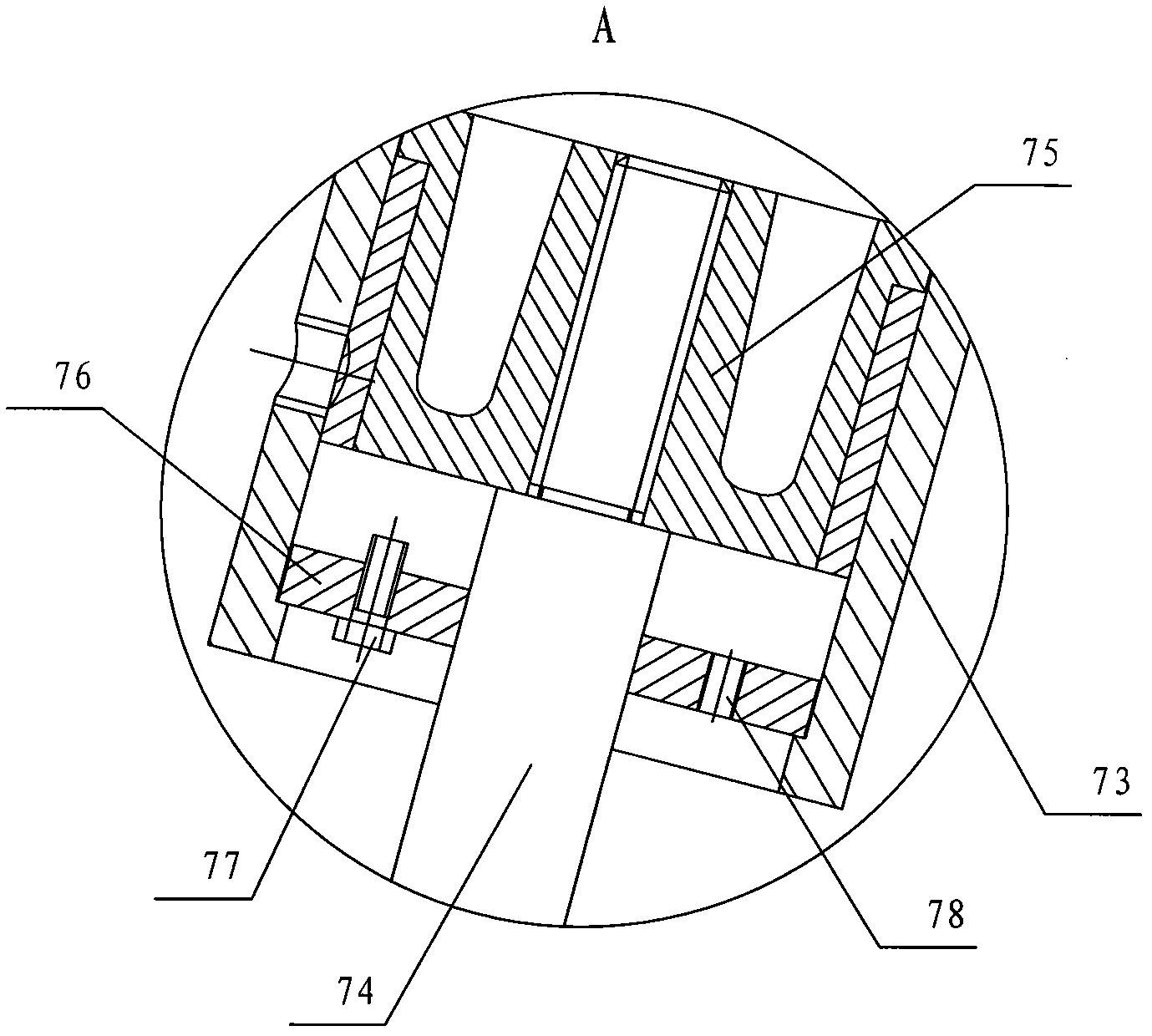

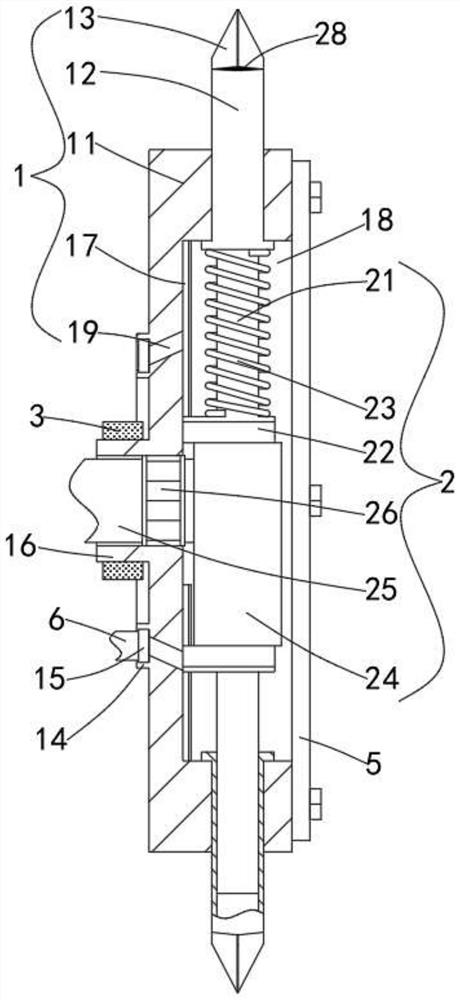

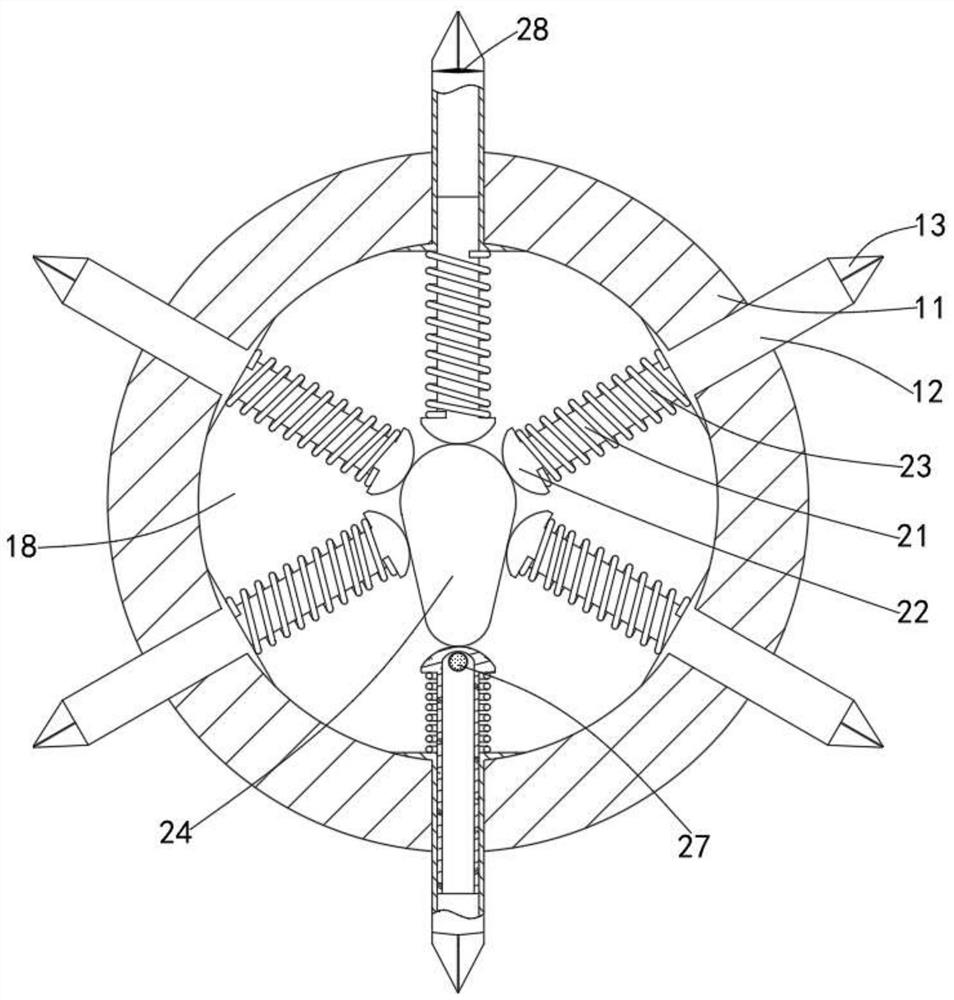

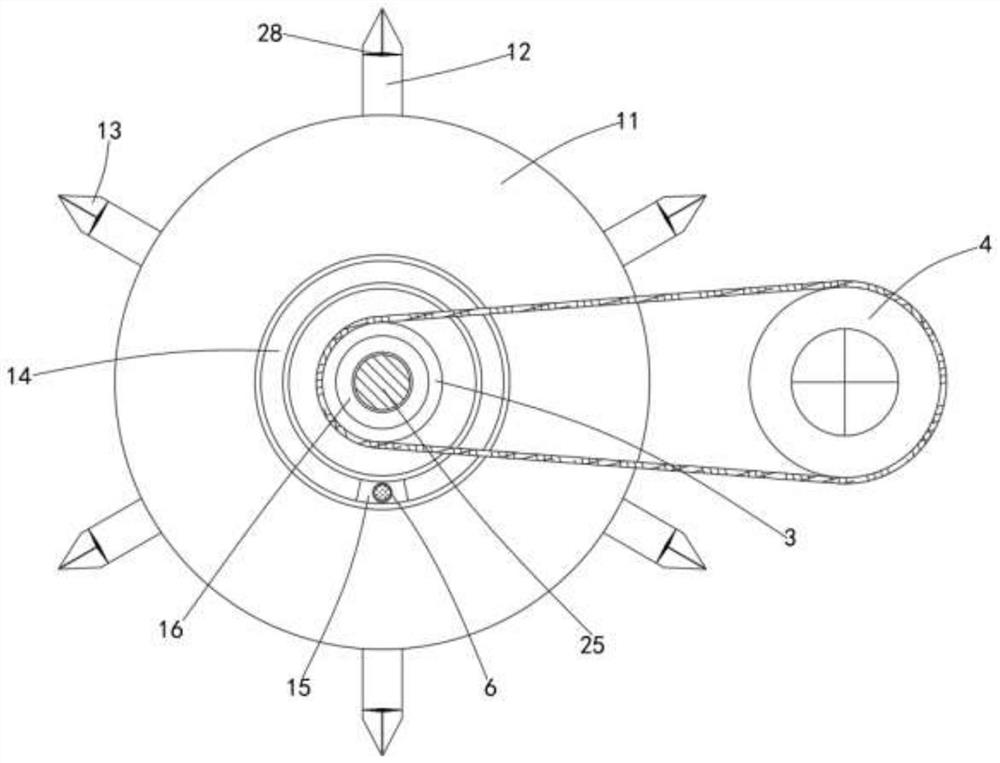

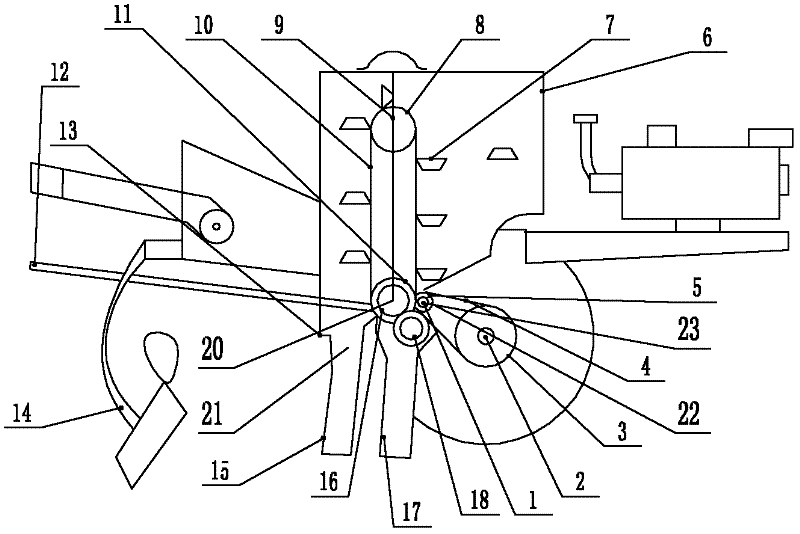

Film mulching and opening mechanism of full-automatic peanut sowing and film mulching all-in-one machine

InactiveCN111869374AConsistent positionConsistent frequencyPlantingDibble seedersAgricultural engineeringStructural engineering

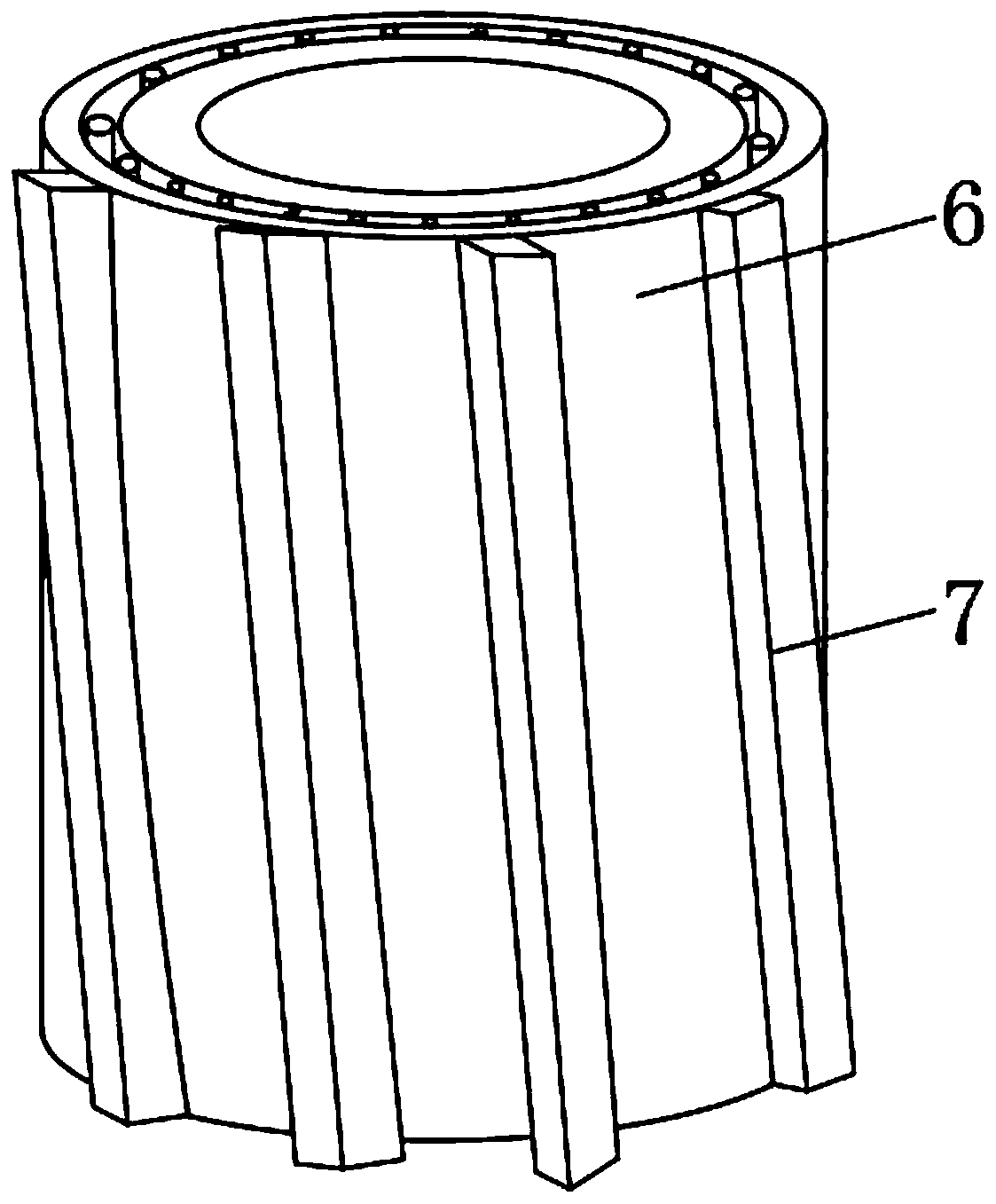

The invention provides a film mulching and opening mechanism of a full-automatic peanut sowing and film mulching all-in-one machine. The mechanism comprises an opening assembly and a sowing assembly,the opening assembly comprises a turntable, opening pipes and opening teeth, a plurality of seed guide cavities are circumferentially formed in the surface of one side of the turntable, the pluralityof opening pipes are circumferentially and fixedly connected to the side wall of the turntable, and the opening teeth are fixedly connected to one ends of outlets of the opening pipes. The sowing assembly comprises seed guide pipes, limiting blocks, a compression spring, a cam and a positioning shaft, the other end of the positioning shaft is slidably connected to the center of the turntable, thecam is fixedly connected to the other end of the positioning shaft, one ends of the seed guide pipes are slidably connected into the opening pipes, and the limiting blocks are fixedly connected to theother ends of the seed guide pipes; inlets are formed in the side surfaces of the limiting blocks and are flush with cavity openings at one ends of the seed guide cavities; and the turntable is arranged to rotate to enable the seed guide pipes to be regularly pushed by the cam and slide in the opening pipes, so that a material conveying pipe, the seed guide pipes and the opening pipes are communicated with one another at a certain frequency, and the opening and sowing positions and the operation frequency are always kept consistent.

Owner:HUBEI JINLIFENG AGRI SCI & TECHCO LTD

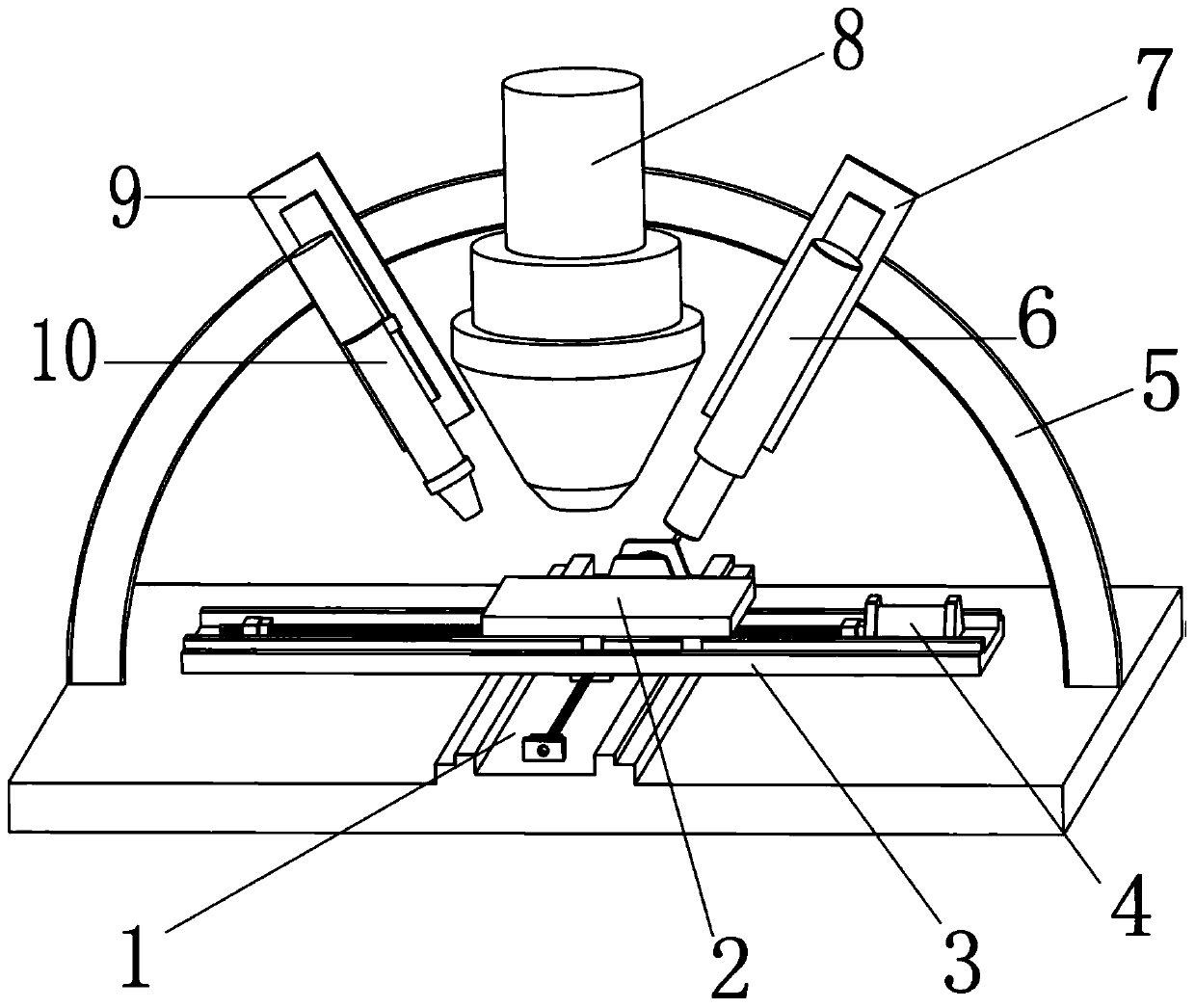

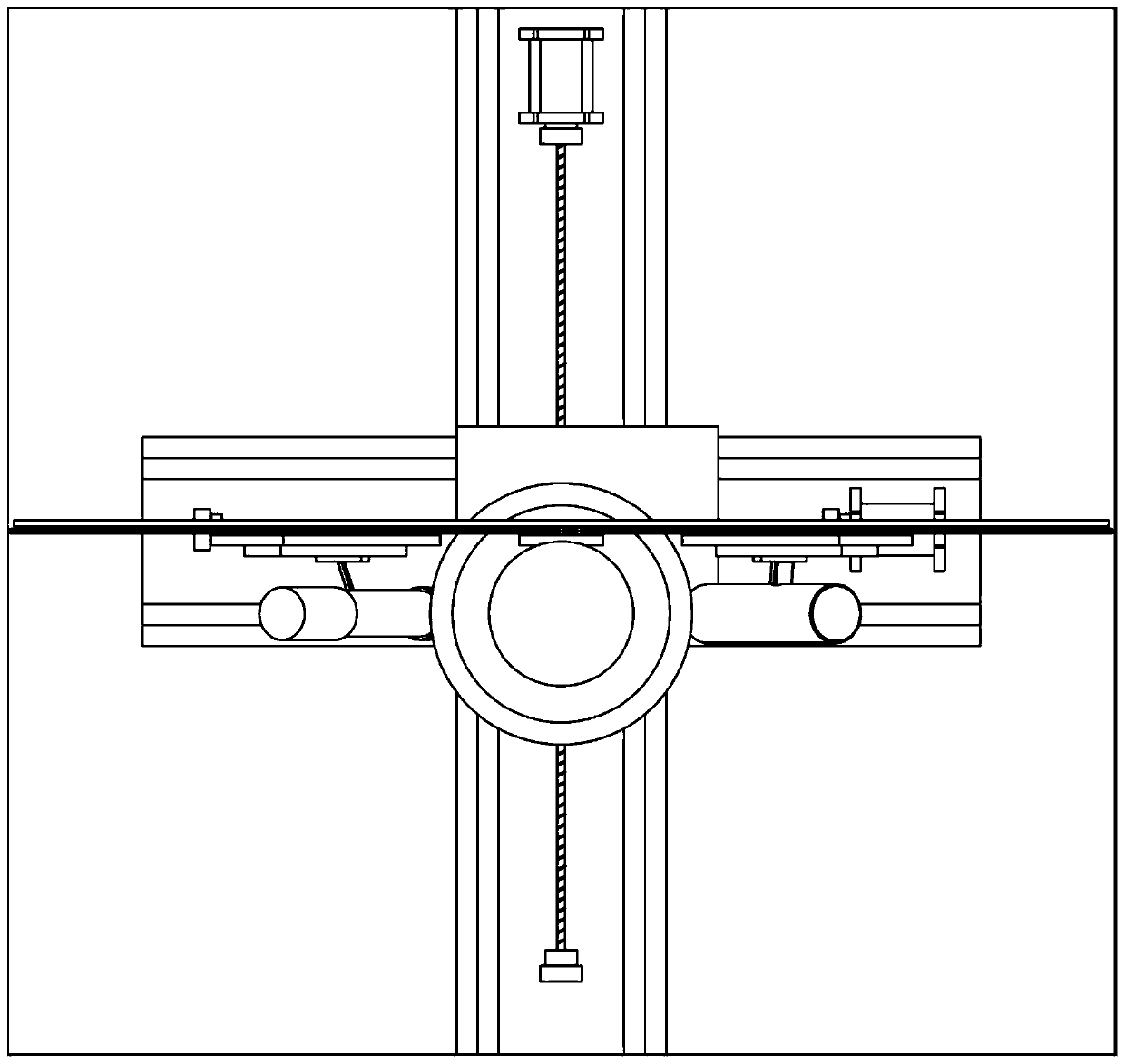

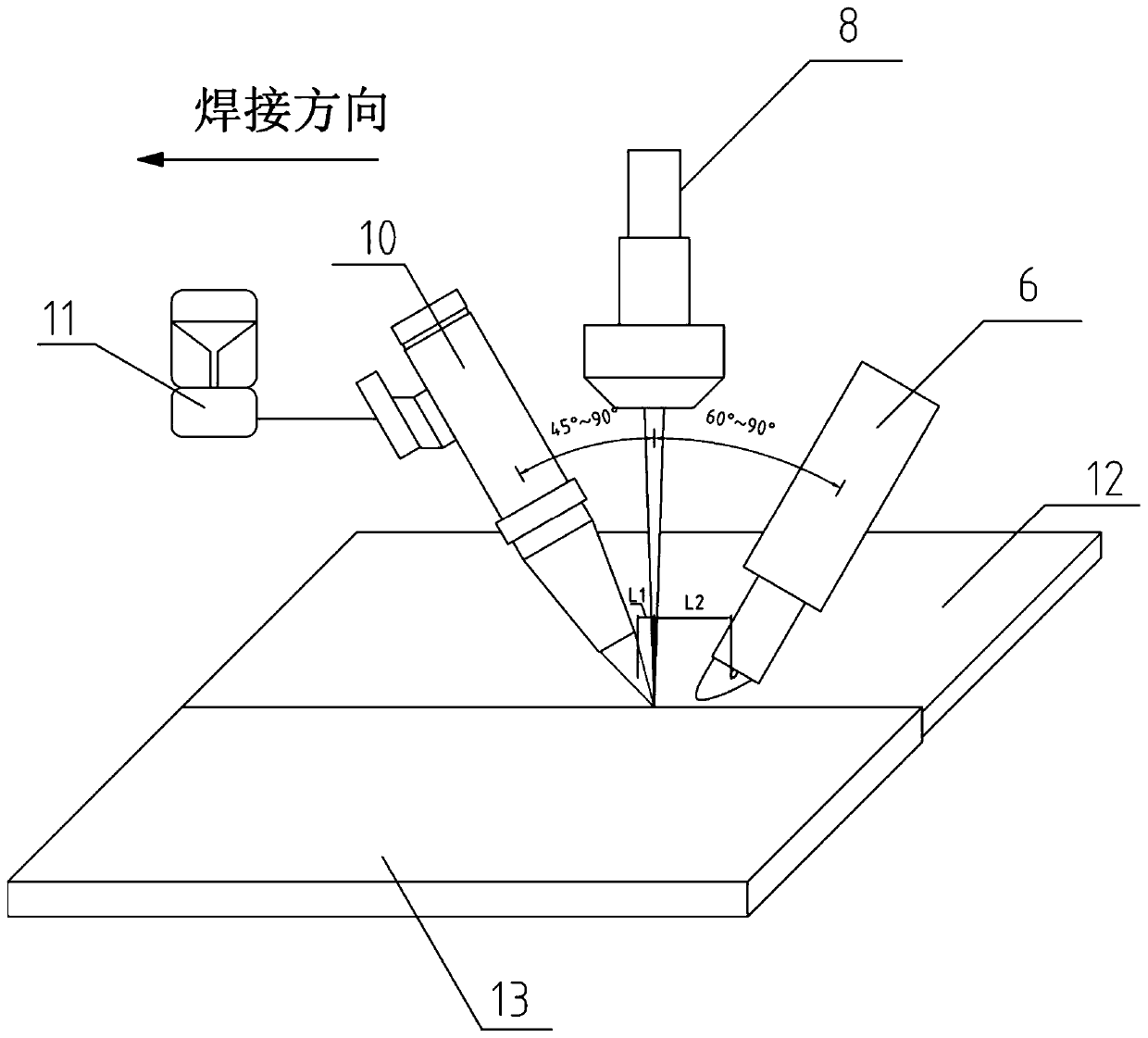

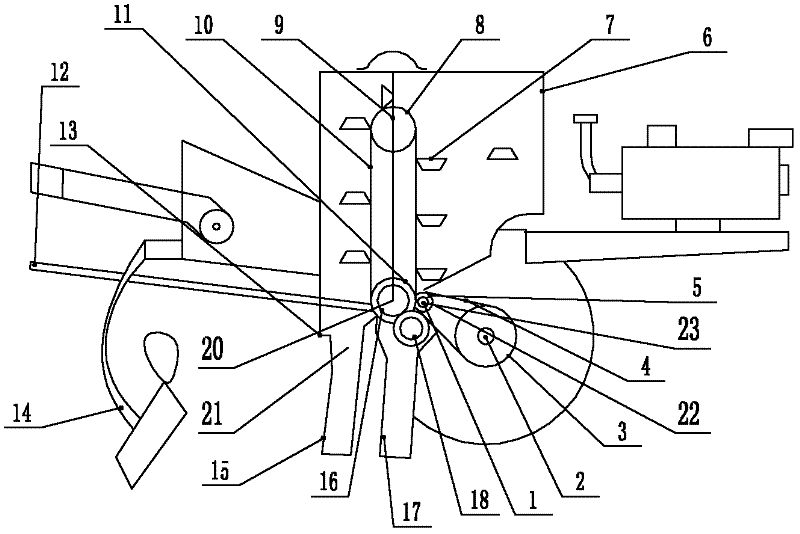

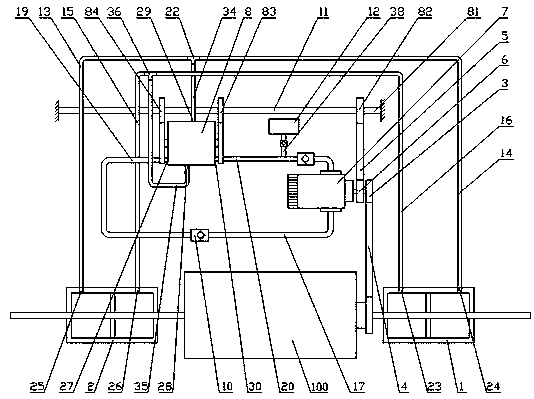

Double-arc auxiliary laser welding device and method

InactiveCN110732775AFast welding speedImprove weld qualityLaser beam welding apparatusPhysicsLaser soldering

The invention discloses a double-arc auxiliary laser welding device and method. The device comprises a welding worktable, a horizontal plane moving device, a base, a ring-shaped sliding rail, a TIG welding sliding guide rail, a laser guide rail, a plasma arc welding gun guide rail, a coaxial powder sending device, a TIG welding device, a laser device and a plasma arc welding device, wherein the TIG welding device, the laser device and the plasma arc welding device are located on the same plane. The horizontal plane moving device adjusts the welding worktable to move in the horizontal plane. The ring-shaped sliding guide rail is fixedly arranged on the base. The TIG welding device, the laser device and the plasma arc welding device are connected with the TIG welding sliding guide rail, thelaser guide rail and the plasma arc welding gun guide rail correspondingly. The TIG welding sliding guide rail and the plasma arc welding gun guide rail are arranged on the ring-shaped sliding guide rail. The laser guide rail is fixedly arranged on the ring-shaped sliding guide rail, and the coaxial powder sending device is connected with the plasma arc welding device. By means of the double-arc auxiliary laser welding device, penetration of the back face of a connector can be ensured while the welding speed is increased, the forming attractiveness of a weld joint is achieved while the cleanliness of the weld joint is ensured, and the quality of the weld joint is high.

Owner:清远市世辰科技有限公司 +1

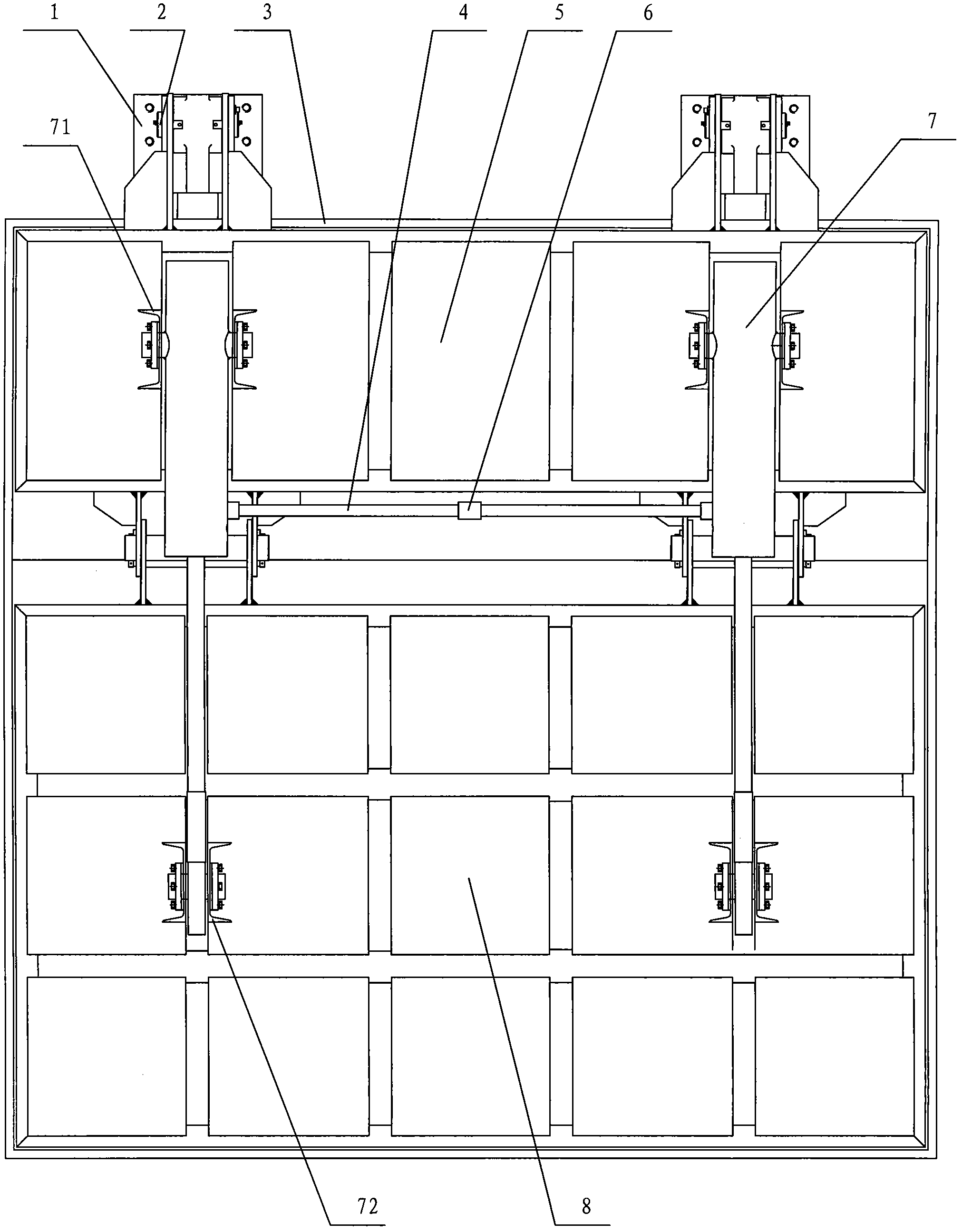

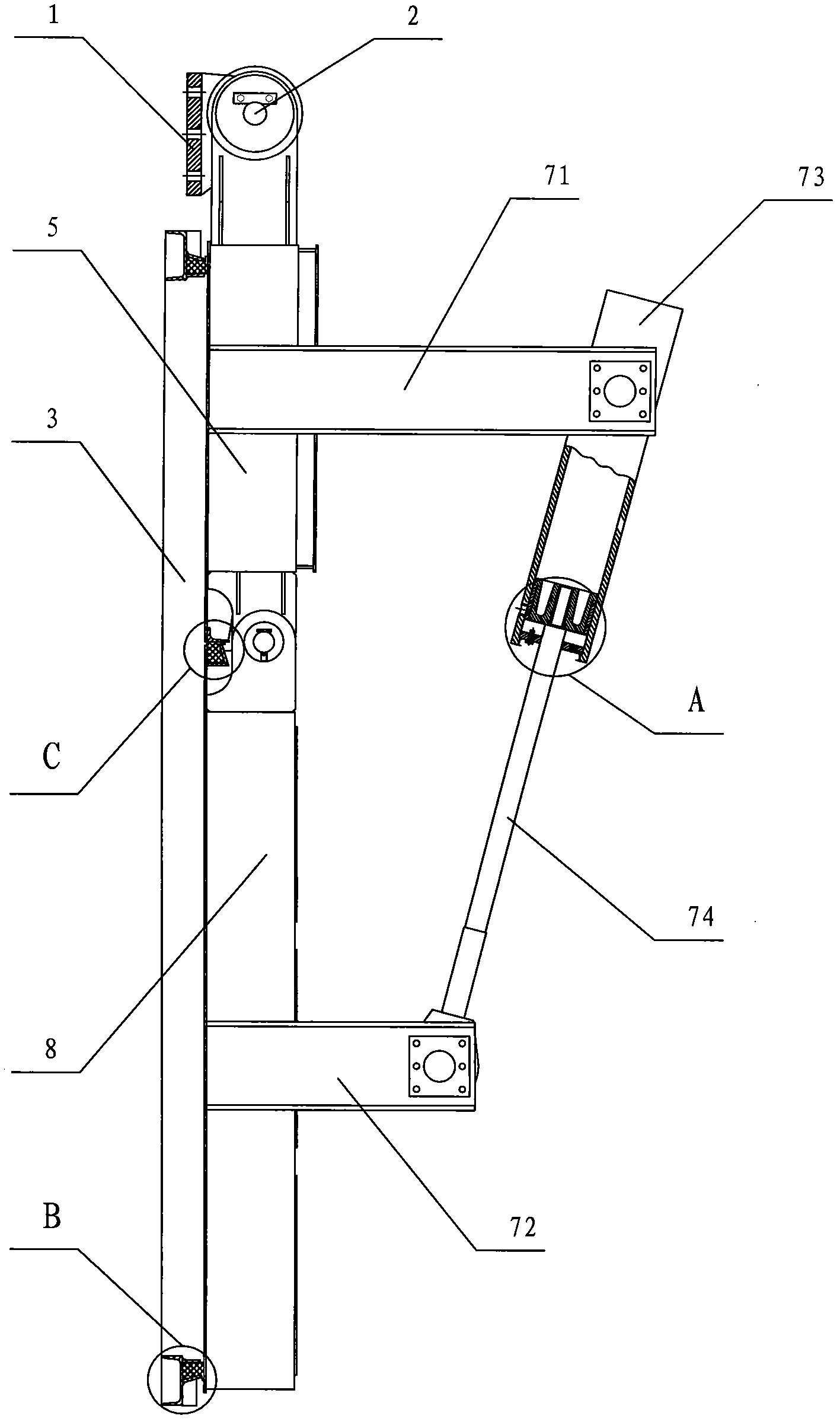

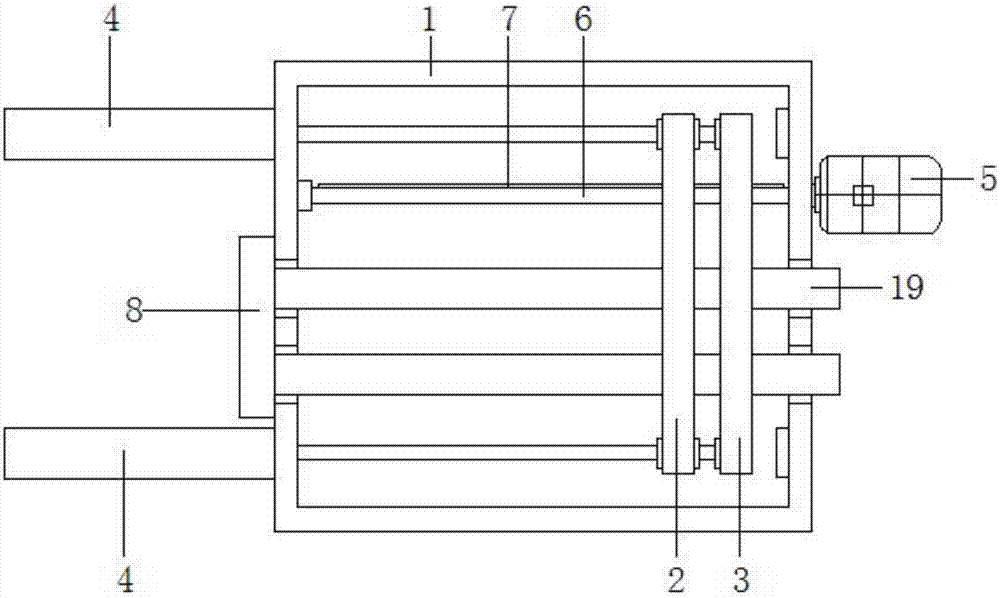

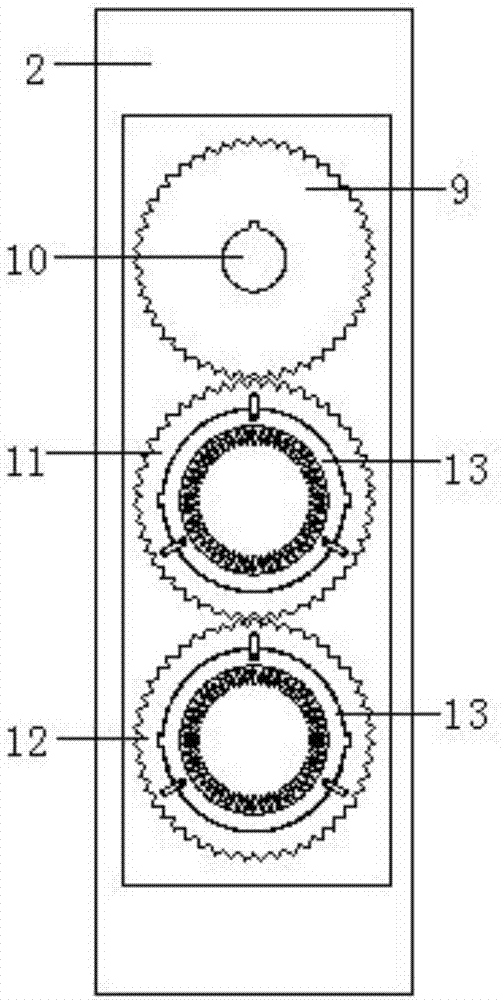

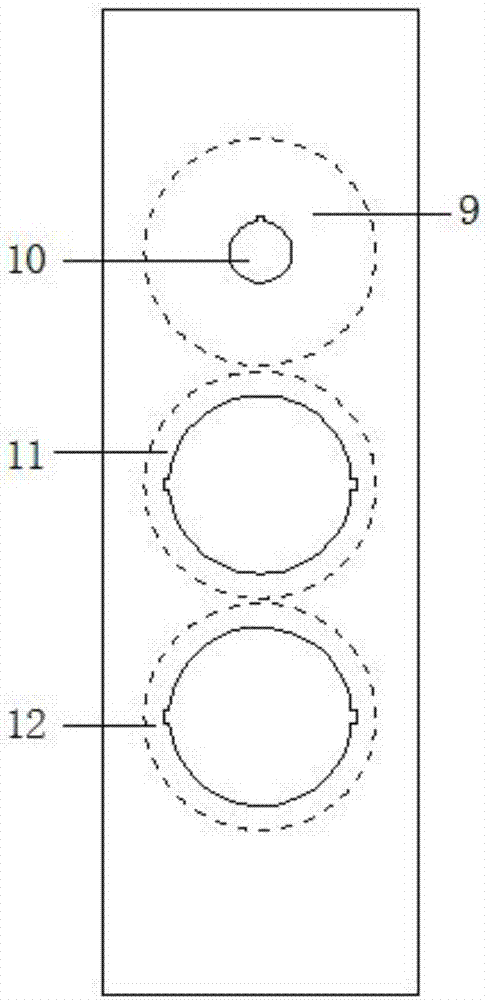

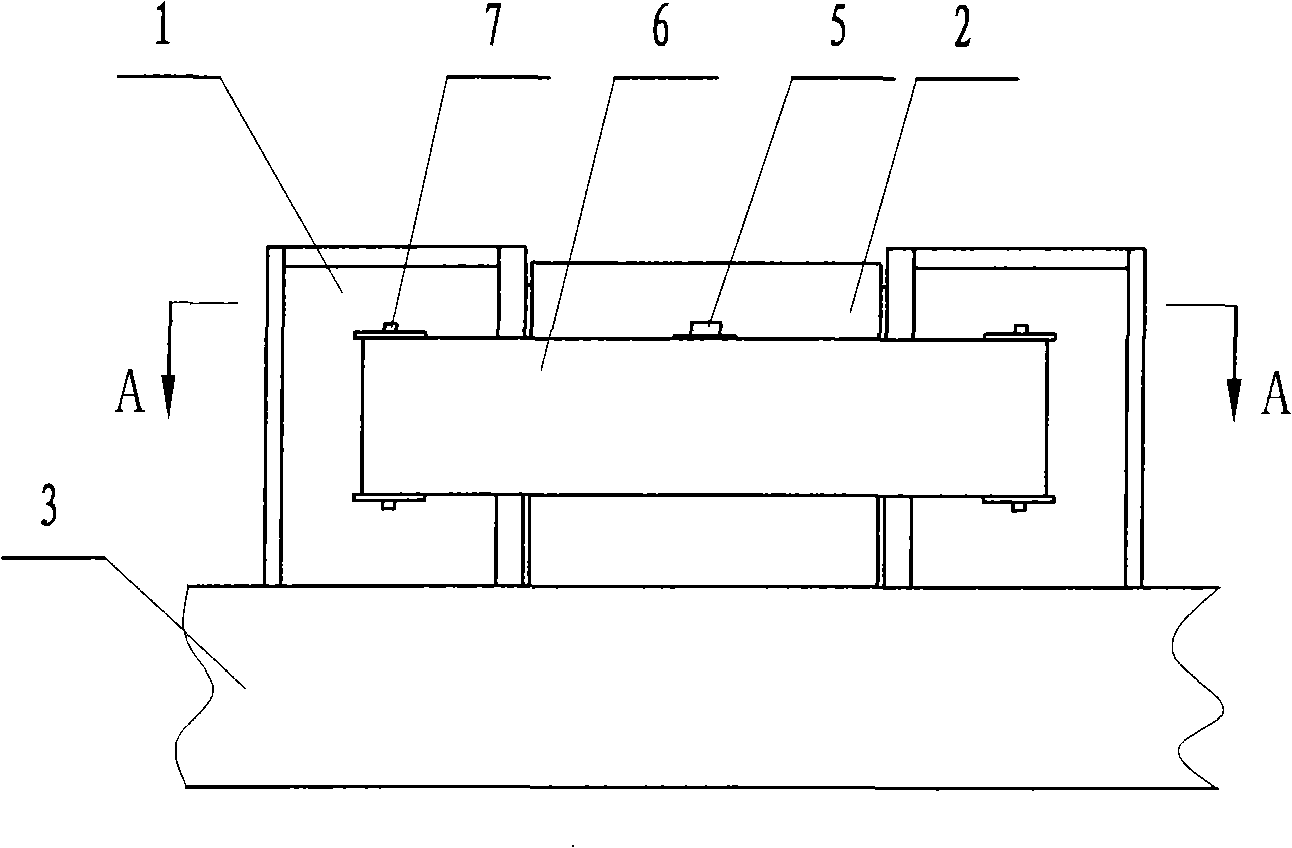

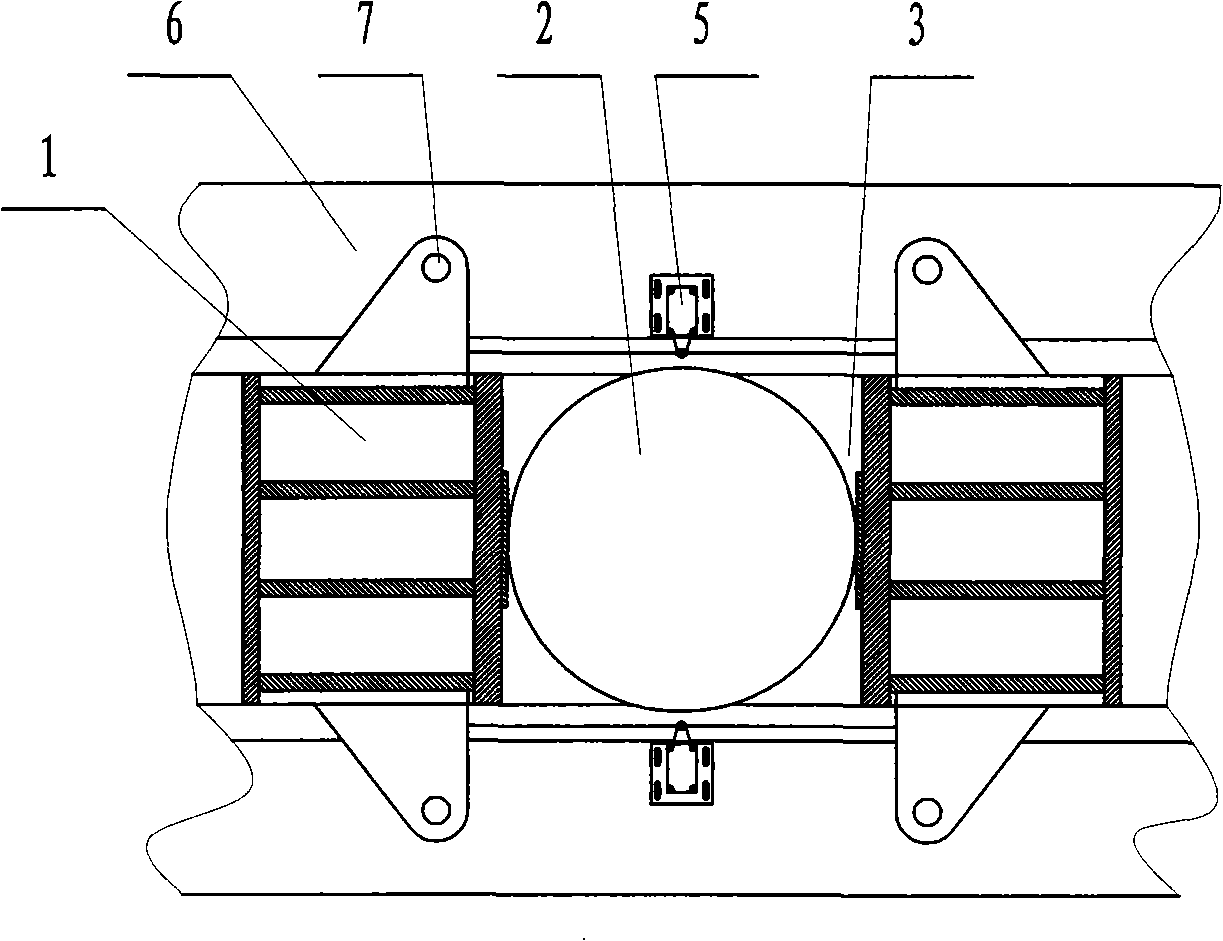

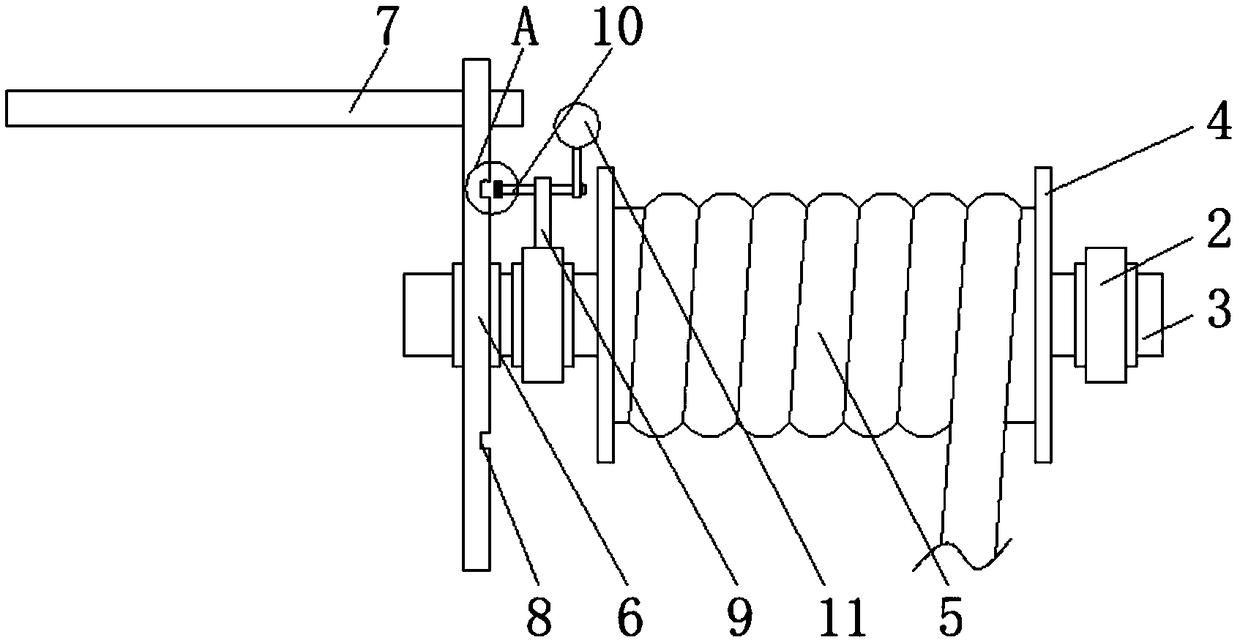

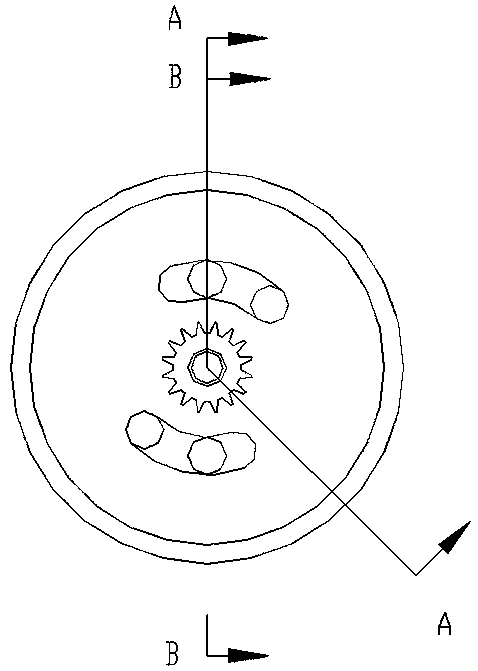

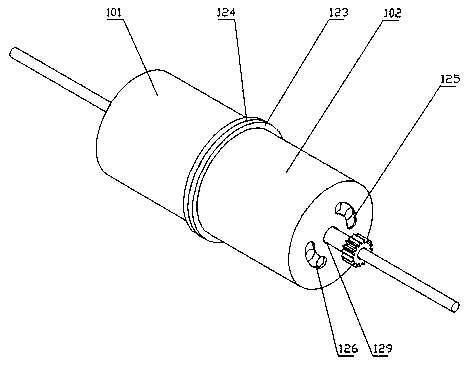

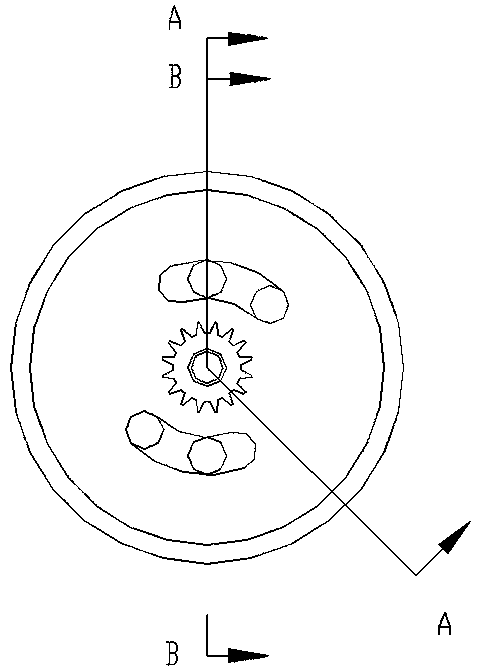

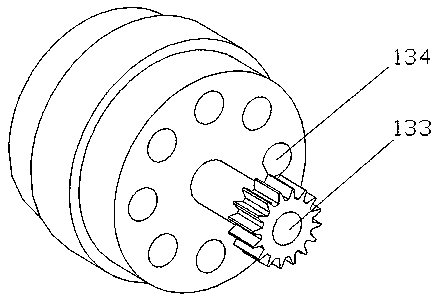

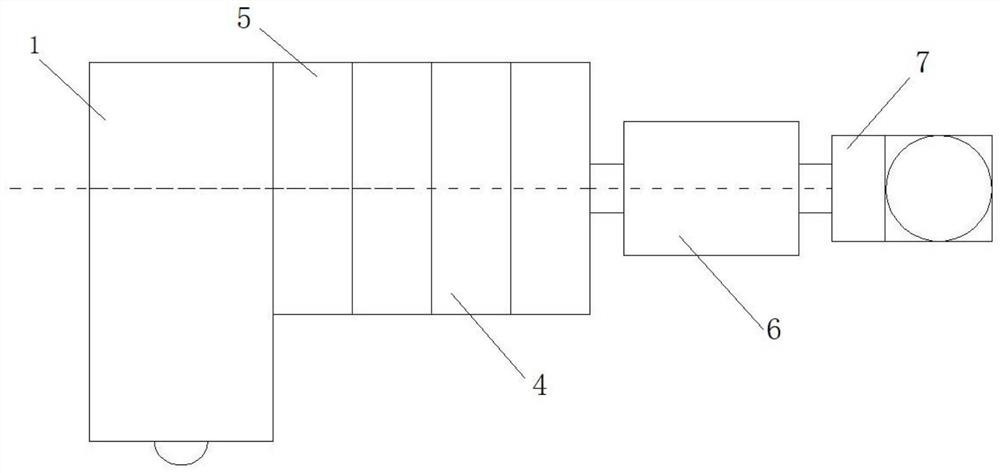

Burr and scrap chip grinding equipment used for aluminum bar surface layers

ActiveCN107443193AConsistent movement speedImprove work efficiencyEdge grinding machinesGear wheelElectric machinery

The invention discloses burr and scrap chip grinding equipment used for aluminum bar surface layers. The burr and scrap chip grinding equipment comprises a first-stage transmission gear, a second-stage transmission gear, a first grinding device and a second grinding device. Electric cylinders are connected to a first grinding plate through telescopic rods at the front ends of the electric cylinders. A connecting key is welded to a rotary shaft. A connecting hole is formed in the middle of a transmission gear. The first grinding device is mounted between the first-stage transmission gear and the second-stage transmission gear. Rotary gear levers are connected with the two sides of the first grinding device. A wire brush is connected with the middle of the inner side of the first grinding device. A cloth wheel is mounted in the middle of the inner side of the second grinding device. A grinding motor drives the first grinding device and the second grinding device to rotate, the electric cylinders drive the grinding plate to move, grinding can be completed without pausing, and by arranging a second grinding plate, aluminum bars are subjected to secondary grinding through the cloth wheel; and by arranging the two transmission gears, the two sets of aluminum bars can be subjected to grinding treatment simultaneously, and the working efficiency is improved.

Owner:元泰高导材料(山西)有限公司

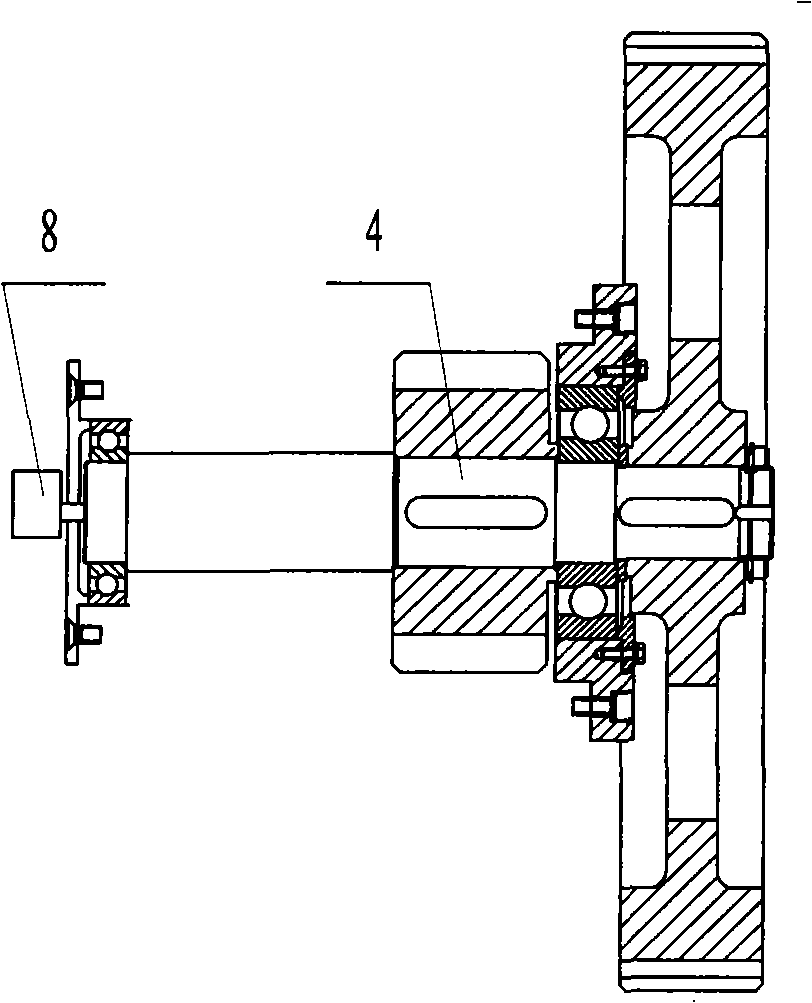

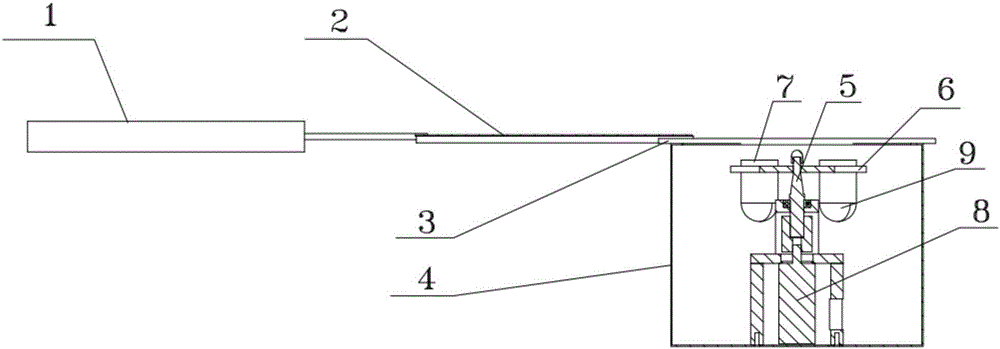

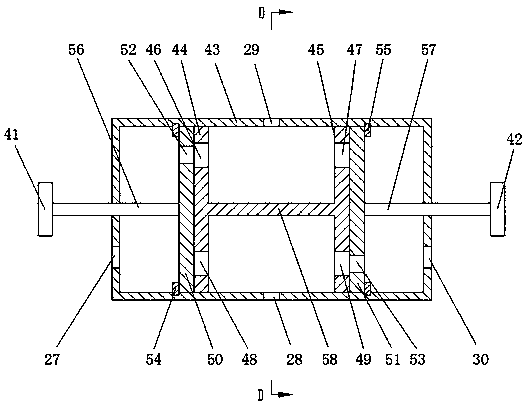

Box-girder moving trolley

The invention discloses a box beam moving trolley which solves the serious consequences possibly caused by the inconformity of the running speeds of a rigid car and a soft car at the two sides of a guide rail existing in the prior art. The invention comprises large support saddles, an oil jack, a bearing beam and a driving shaft component. The oil jack is arranged on the bearing beam and the front part and the rear part of the oil jack are respectively provided with a large support saddle; the large support saddles are arranged on the bearing beam; the box beam moving trolley also comprises three sets of protection devices which are respectively a travel switch and a stop crossbeam arranged at the two sides of the large support saddles and an encoder arranged at one side of the driving shaft component. Compared with the prior art, the box beam moving trolley of the invention has the advantages of adopting redundant protection, ensuring the conformity of the running speeds of the rigid car and the soft car and having simple and easy implementation.

Owner:WUHAN KATTOR IND

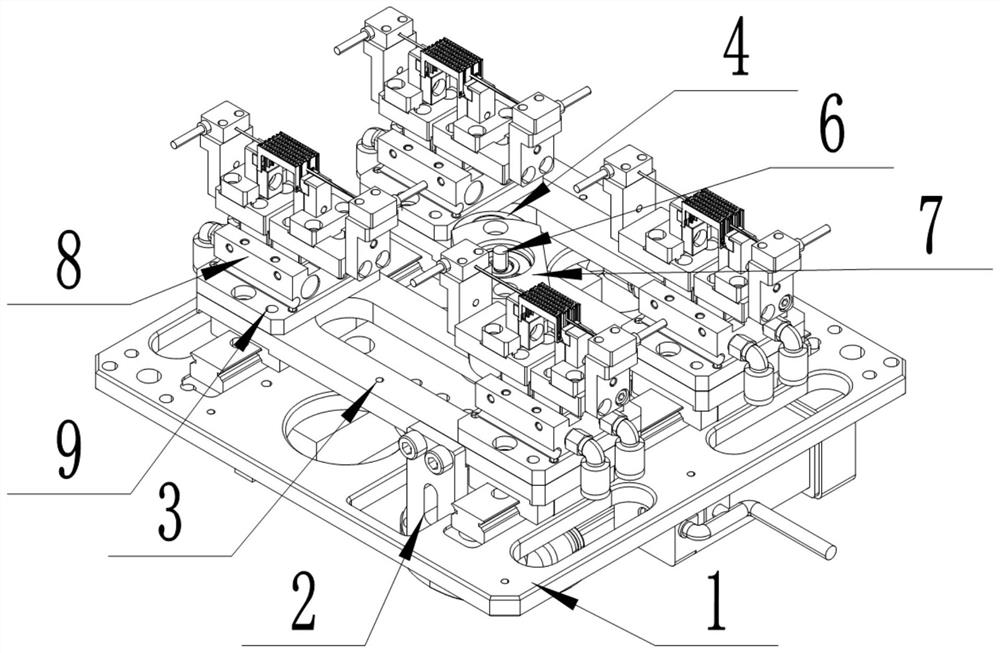

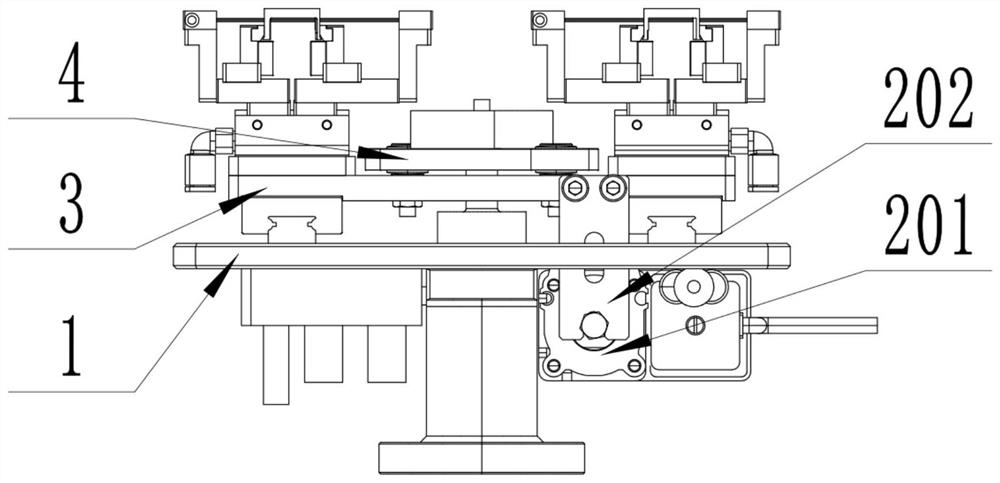

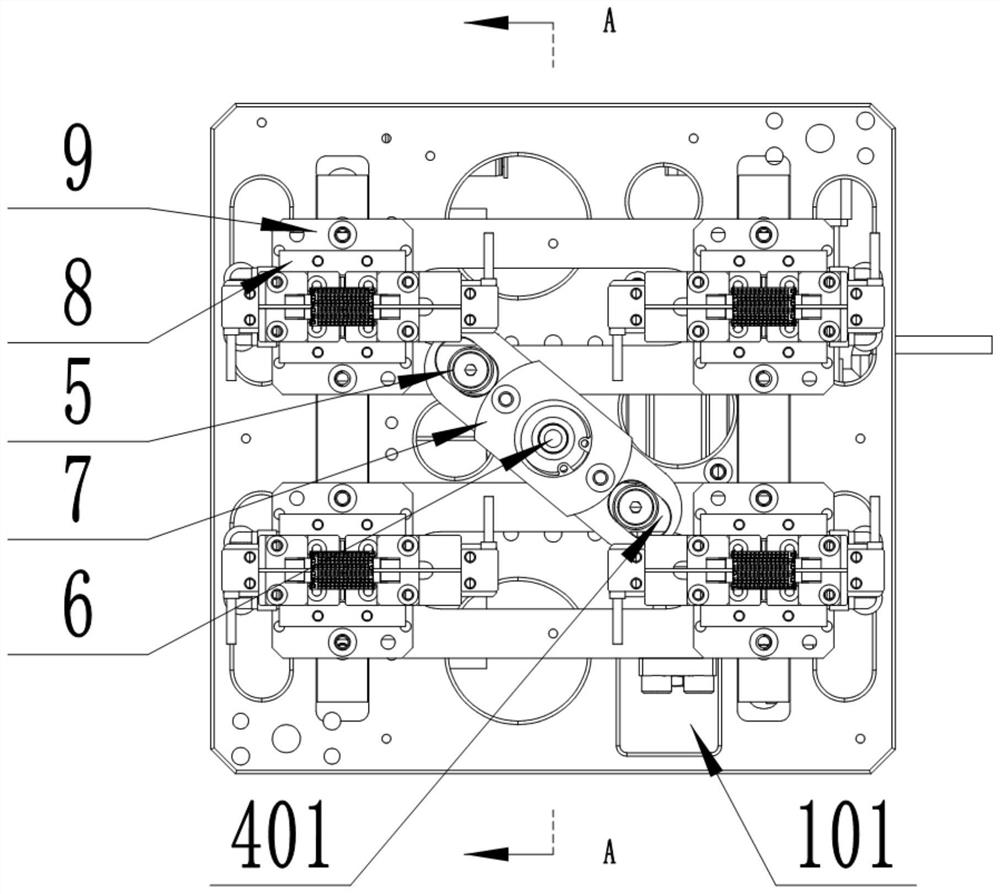

Full-automatic multi-point variable-pitch clamp

InactiveCN112158595AImprove debugging efficiencyReduce inventory costsPackagingConveyor partsControl engineeringSlide plate

The invention provides a full-automatic multi-point variable-pitch clamp. The full-automatic multi-point variable-pitch clamp comprises a driving element arranged on a clamp base and a plurality of sliding plates slidably connected to the top surface of the clamp base, wherein the driving element is connected to any one sliding plate; the center lines of all the sliding plates coincide; any two adjacent sliding plates are connected through a linkage assembly; the linkage assembly comprises a linkage plate rotatably connected to the clamp base; the two ends of the linkage plate are connected tothe sliding plates through followers; and the rotation center line of the linkage plate and the clamp base is located in the middle of the linkage plate. According to the scheme, one power source isadopted, and every two adjacent sliding plates are connected through the corresponding linkage assembly, so that the distance between pneumatic claws can be automatically switched without being adjusted by personnel, the model changing efficiency is improved, related quality risks and the like are avoided, and then the equipment debugging efficiency after mold changing is improved. In addition, the inventory and maintenance cost of the clamp are reduced.

Owner:宝利根(成都)精密工业有限公司

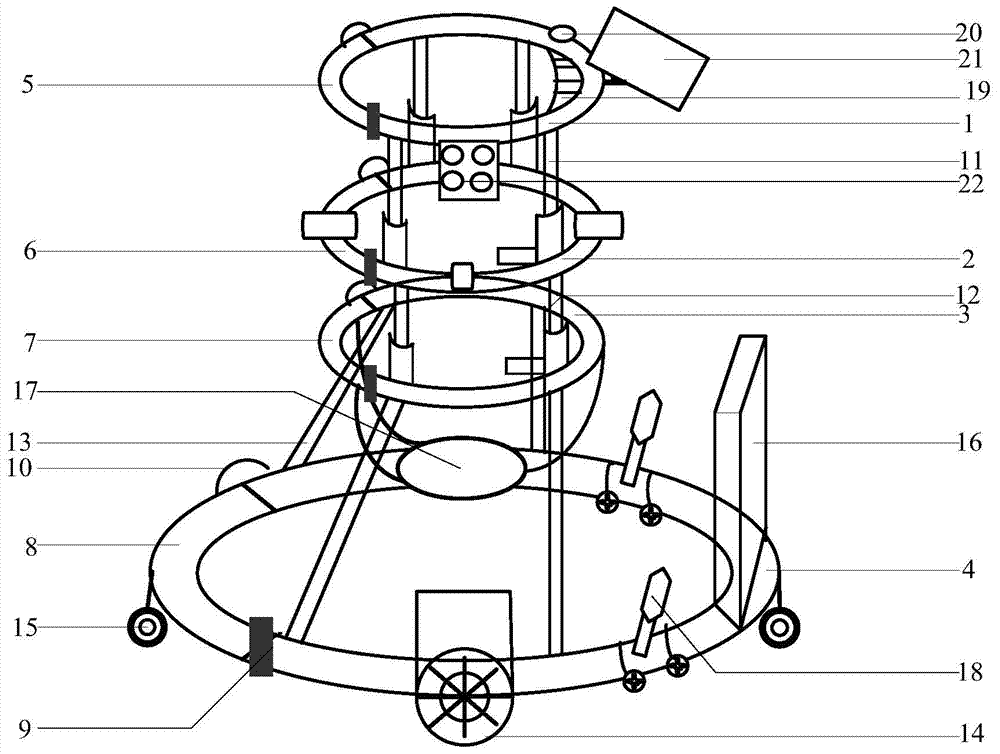

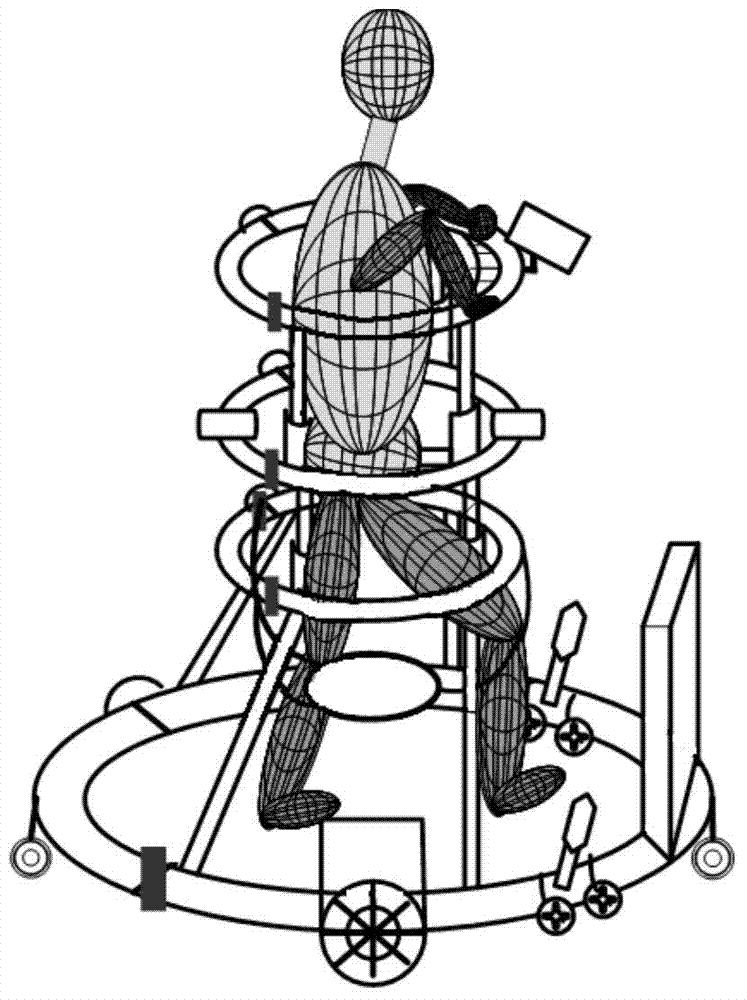

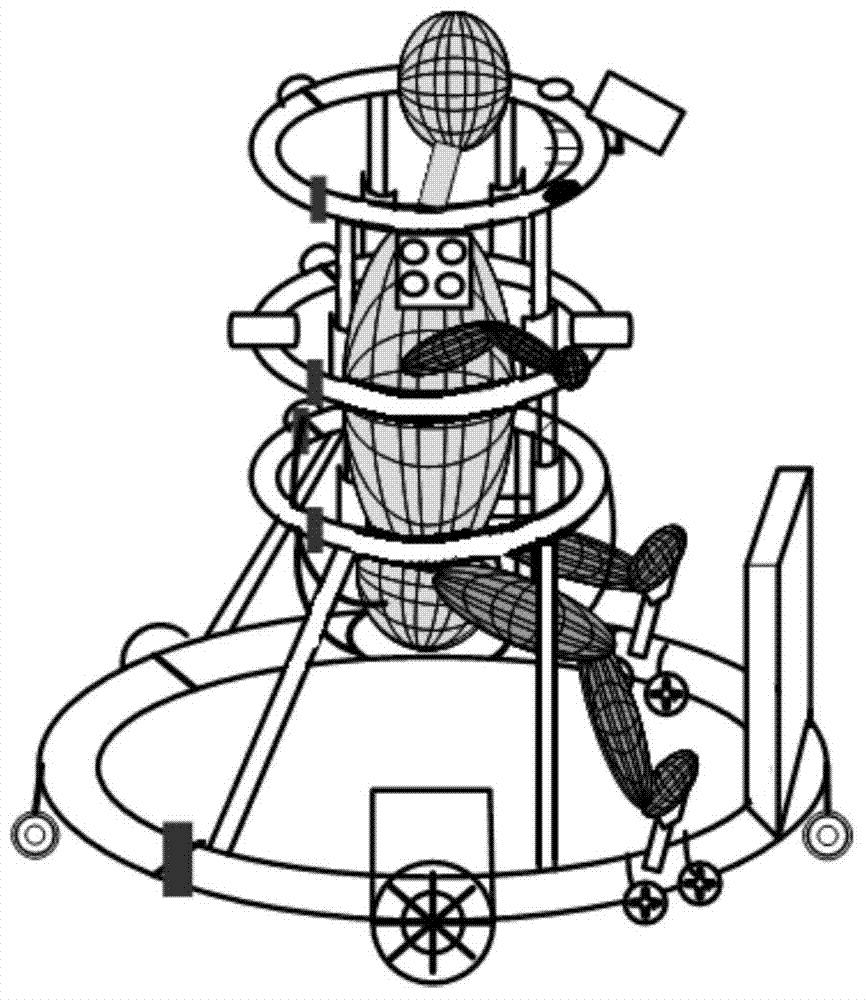

Assistive rehabilitation training robot for stroke hemiplegic patients

InactiveCN103610567BEffective protectionAdapt to different heights of lower limbsChiropractic devicesWheelchairs/patient conveyanceDrive wheelEngineering

The invention provides an assistive rehabilitation training robot for stroke hemiplegic patients. The assistive rehabilitation training robot comprises an upper-layer armrest frame, a middle-layer detection frame, a lower-layer support frame and a movable base plate which are parallelly arranged in the vertical direction. Each adjacent two of the upper-layer armrest frame, the middle-layer detection frame and the lower-layer support frame are fixedly connected with each other by three telescopic rods and an electric push rod, and the lower-layer support frame is fixedly connected with the movable base plate by lower-layer support rods; an emergency stop switch, a display screen and a control panel are respectively mounted on the outer surface of a U-shaped frame of the upper-layer armrest frame, four tension sensors are peripherally uniformly distributed at the upper edge of the middle-layer detection frame, and a detachable chair is mounted on the lower-layer support frame; two driving wheels and two driven wheels are peripherally symmetrically mounted at the upper edge of the movable base plate, a control box is mounted on the outer surface of a U-shaped frame of the movable base plate, and pedals are further arranged on the U-shaped frame of the movable base plate; the control box is respectively connected with the four tension sensors, motors, the emergency stop switch, the display screen and the control panel. The assistive rehabilitation training robot has the advantage that rehabilitation training requirements of the stroke hemiplegic patients can be met.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Potato seeder

InactiveCN102388708AEasy to useReduce the effect of slippagePotato plantersClutchAgricultural engineering

The invention relates to a seeder, especially to a potato seeder, which is characterized by comprising a frame assembled by a supporting base, and a seed storage box fixed on the upper part of the supporting base and composed of a fixed vertical pillar inside and a lower seed discharging duct connected at the bottom. The pillar is mated with an upper seed discharging chain wheel and a lower seed discharging chain wheel respectively at the top and bottom, and a seed discharging chain is mated between the upper seed discharging chain wheel and the lower seed discharging chain wheel. And seed extraction bowls are uniformly distributed on the outer circumference of the seed discharging chain. A clutch handle and a furrower opener are fixed at the rear of seed storage box. The seed discharging chain is in cooperation with a transmission device, and the frame is in cooperation with the right half shaft of a hand tractor. The potato seeder of the invention has the advantages of unique structure, convenient use and operation, high seeding rate, small resistance and no damage to seeds, and can be matched with a hand tractor.

Owner:赵润良

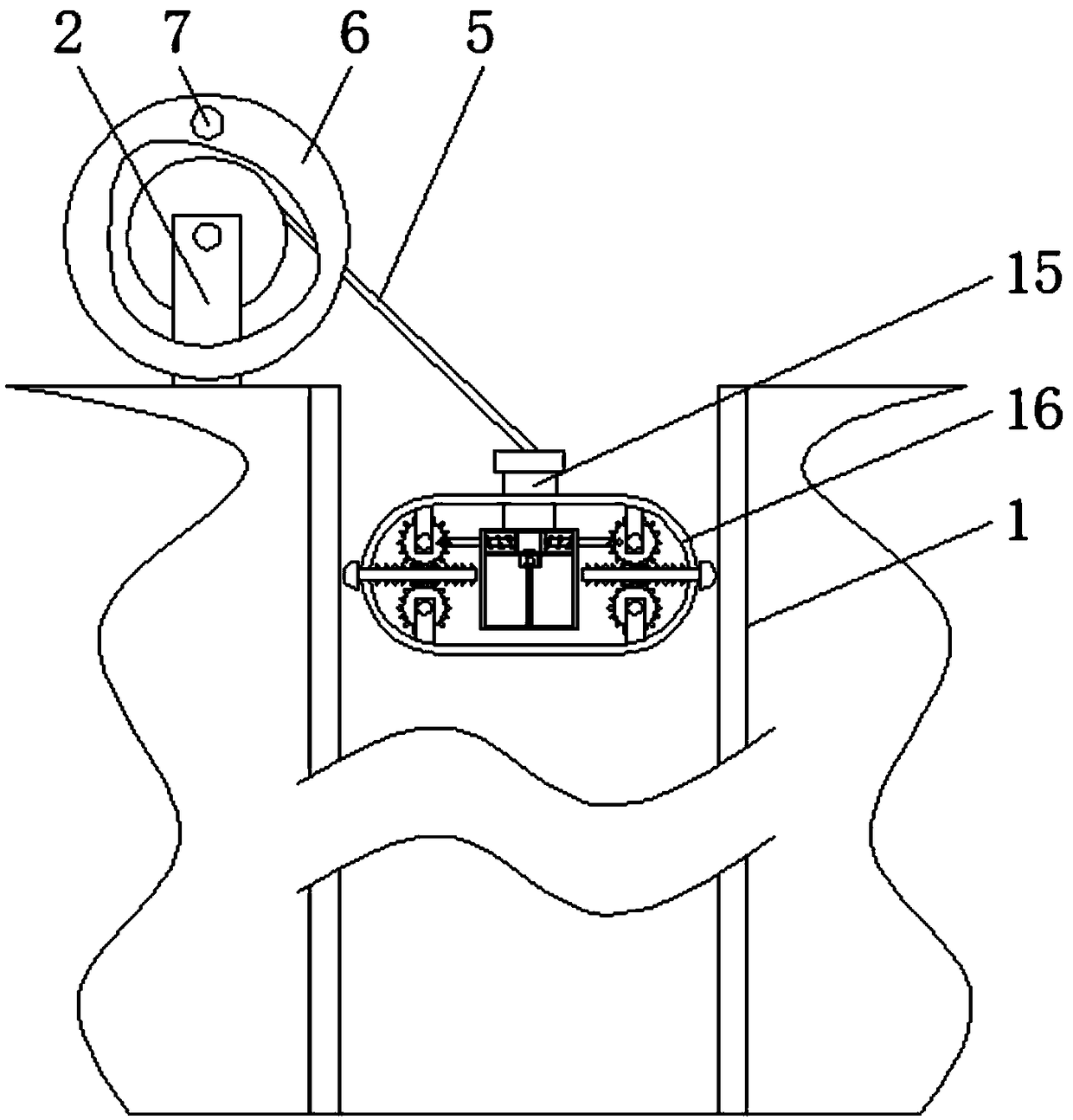

Balancing weight well civil structure deviation measuring device

InactiveCN108955473APlay a restrictive roleAvoid measurement effectsMechanical measuring arrangementsDrinking water installationStationary stateRestoring force

The invention relates to the technical field of building measuring equipment, and discloses a balancing weight well civil structure deviation measuring device. The balancing weight well civil structure deviation measuring device includes a deep well; a fixing bracket is fixedly mounted on one side of the top of the deep well, and a rotating shaft I is movably sleeved in the center of the fixing bracket; an outer wall of the rotating shaft I is fixedly sleeved with a reel on one side of the fixing bracket; an outer wall of the reel is wound with a steel rope; a round plate located on the outerwall of the rotating shaft I fixedly sleeves one side of the reel; a handle is fixedly sleeved with the top at one side of the round plate; a clamping groove is formed in one side of the round plate;and a fixing rod is fixedly arranged on a top end of the fixing bracket. According to the balancing weight well civil structure deviation measuring device, the clamping groove is formed in the round plate, an installation box can limit motion of the round plate, the influence of the restoring force of the steel rope on the measurement can be prevented during the measurement process, it is ensuredthat a measuring box is in a stationary state during measurement, and measurement errors are reduced.

Owner:李梦平

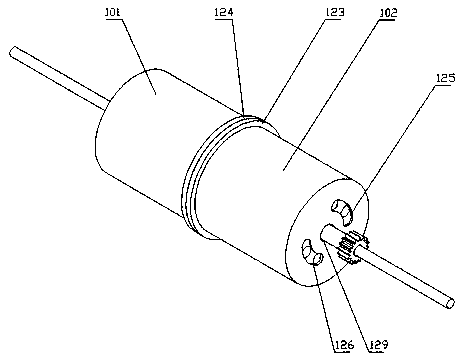

Intelligent centrifuge control method and device in full-automatic cell cultivation system

The invention relates to an intelligent centrifuge control method and a device in a full-automatic cell cultivation system. A controller controls a relay in a centrifuge; a servo motor drives a push rod to pull a cover plate; the cover plate moves to the left side so as to open the cover plate of the centrifuge; a mechanical gripper grabs a centrifugal pipe; the grabbed centrifugal pipe is put in an initial object carrying frame corresponding to an initial point; a sensor sends a detecting signal to detect if the object carrying frame in the initial point position loads the centrifugal pipe; if the centrifugal pipe is put in, a rotating frame rotates by an angle until all centrifugal pipes are put on the rotating frame; when all the centrifugal pipes are placed, the angle rotation is finished, the push rod pushes the cover plate, the cover plate of the centrifuge is closed, and the rotating frame slowly accelerates to rotate for centrifugal work; labors are reduced to participate in a cell cultivation environment in the whole process; and the working efficiency of the centrifuge for centrifugating cells can be improved.

Owner:NINGBO JIANYI ELECTRONICS INFORMATION TECH CO LTD

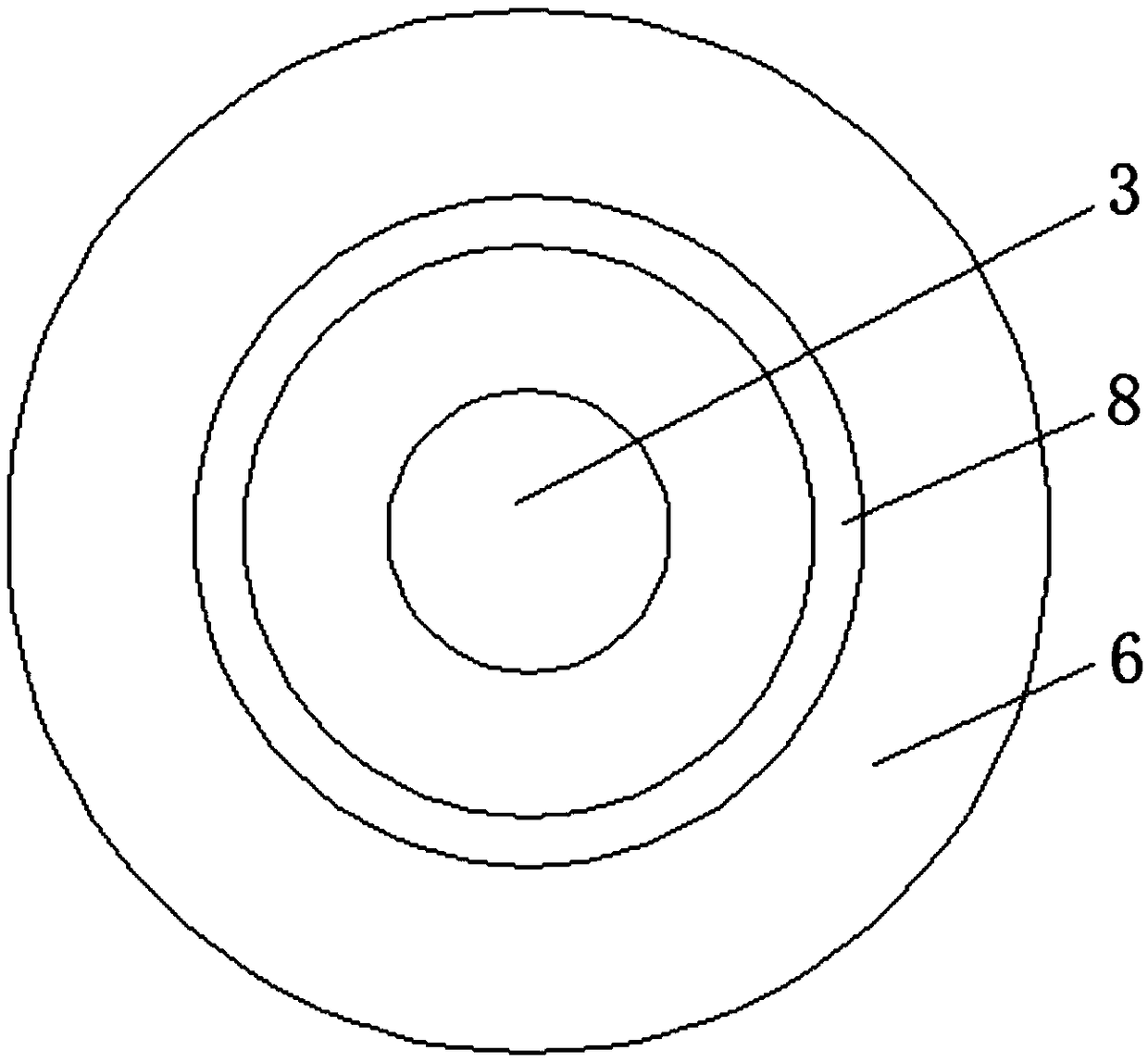

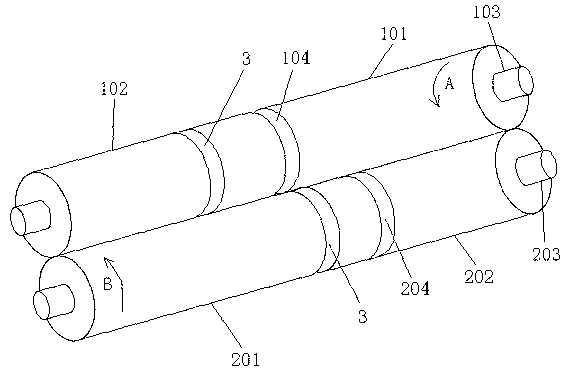

Segmental roller of textile machinery

InactiveCN103103647AMitigates inconsistent wearExtended service lifeDrafting machinesPulp and paper industryPressure sensor

The invention discloses a segmental roller of textile machinery. The segmental roller comprises an upper roller and a lower roller, wherein the upper roller comprises a first drive roller and a first transmission roller. The first drive roller is fixedly connected with an upper transmission shaft, and the first transmission roller is movably connected with the upper transmission shaft. The lower roller comprises a second drive roller and a second transmission roller. The second drive roller is fixedly connected with a lower transmission shaft, and the second transmission roller is movably connected with the lower transmission shaft. Pressure sensors are respectively arranged on the first transmission roller and the second transmission roller. The segmental roller can detect moving speed of slivers, prolongs service life, and improves production efficiency.

Owner:SUZHOU ZUNYUAN TEXTILE

Engine capable of achieving constant volume combustion and working method of engine

InactiveCN109798186AStable compression ratioSolve technical problems that are difficult to controlMachines/enginesAutomotive engineeringEngineering

The invention provides an engine capable of achieving constant volume combustion and a working method of the engine. The engine mainly comprises an engine body; the right side of the engine body is connected with an oil cylinder A, and the left side of the engine body is connected with an oil cylinder B; a connecting wheel A is arranged on the engine body and connected with a hydraulic pump; an oil inlet and an oil outlet of the hydraulic pump are connected with a valve plate through pipelines; a connecting wheel B and a connecting wheel C are arranged on the valve plate; and a transmission wheel B is arranged on the hydraulic pump, and the transmission wheel B, the connecting wheel B and the connecting wheel C are all connected with a transmission assembly. The hydraulic pump drives a cylinder body in the engine body to rotate, hydraulic oil operates to drive an extension rod in the engine body to slide in a reciprocating mode in the axial direction, and thus the engine completes thework applying process; and through design, the engine can apply work bidirectionally, the engine can achieve constant volume combustion by using the valve plate, and thus the problems that an existingengine wastes energy and is short in life, small in displacement and the like are solved.

Owner:烟台小米机械技术有限公司

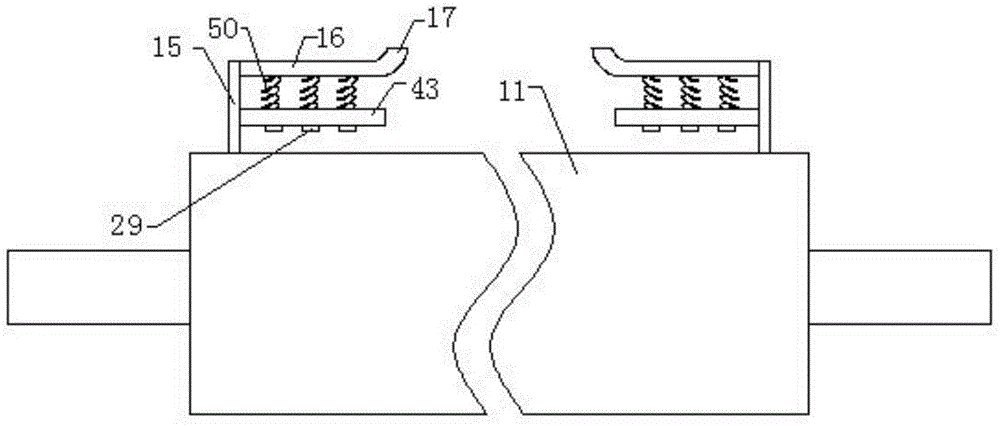

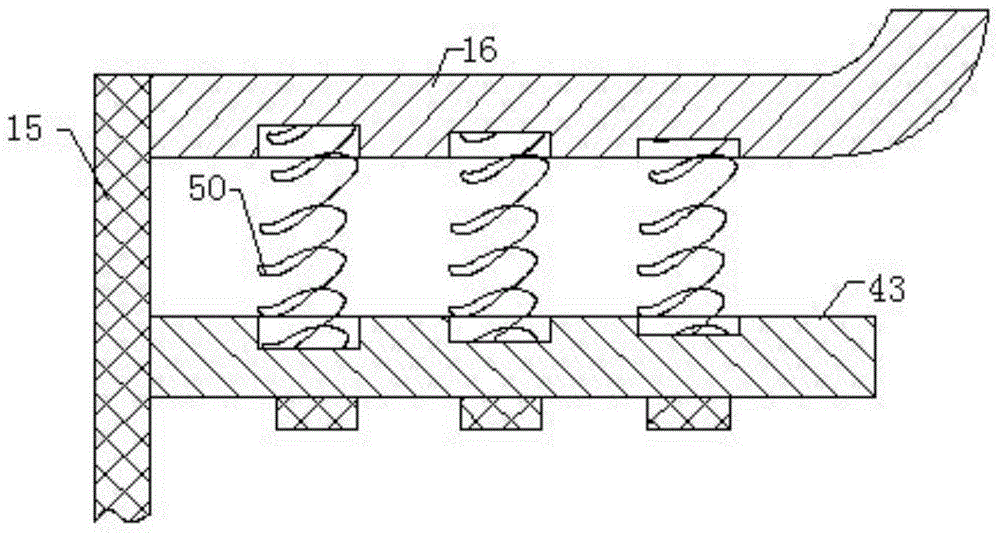

Textile machine

ActiveCN104562417AGood technical effectStrong pressing forceWeft knittingPulp and paper industryTextile

The invention relates to the field of textiles, and discloses a textile machine, which comprises a textile machine body and a roller, wherein elastic press sheets are arranged on the roller, a first spring is arranged between every two of the elastic press sheets, a first mounting groove, a second mounting groove and a third mounting groove are formed in the first elastic press sheet, a fourth mounting groove, a fifth mounting groove and a sixth mounting groove are formed in the second elastic press sheet, the depth A of the first mounting groove is greater than the depth B of the second mounting groove, the depth B is greater than the depth C of the third mounting groove, the depth A is equal to the depth D of the fourth mounting groove, the depth B is equal to the depth E of the fifth mounting groove, and the depth C is equal to the depth F of the sixth mounting groove. The textile machine has the advantages that when a cloth is wound, the two sides of the cloth are fixedly arranged at the surface of the roller by the elastic press sheets, the winding for several circles by workers is not needed, and the cloth can be automatically wound; by arranging the layers of elastic press sheets, the pressure between each elastic press sheet and the cloth can be adjusted; when the different first spring is selected, the different pressing force can be adjusted.

Owner:ZHEJIANG HEXIN TEXTILE

Shearing synchronous oil circuit for flash welding machine

ActiveCN102606553BReduce volumeReduce weightServomotorsResistance welding apparatusSynchronous motorFlash welding

The invention discloses a shearing synchronous oil circuit for a flash welding machine, which comprises a first shearing cylinder, a second shearing cylinder, a three-position four-way reversing valve and a synchronous motor. The first shearing cylinder and the second shearing cylinder are respectively provided with a first cavity and a second cavity, the three-position four-way reversing valve is provided with a first oil port, a second oil port, a third oil port and a fourth oil port, the first oil port of the three-position four-way reversing valve is connected with an oil inlet circuit, the third oil port of the three-position four-way reversing valve is connected with an oil return circuit, both a first inlet and a second inlet at one end of the synchronous motor are communicated with the second oil port of the three-position four-way reversing valve, a first outlet and a second outlet at the other end of the synchronous motor are correspondingly communicated with the first cavities of the first shearing cylinder and the second shearing cylinder respectively, and both the second cavities of the first shearing cylinder and the second shearing cylinder are communicated with the fourth oil port of the three-position four-way reversing valve. By the aid of the shearing synchronous oil circuit, the volume of oil entering the two shearing cylinders can be equivalent during shearing, and the movement speeds of the two shearing cylinders can be uniform.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

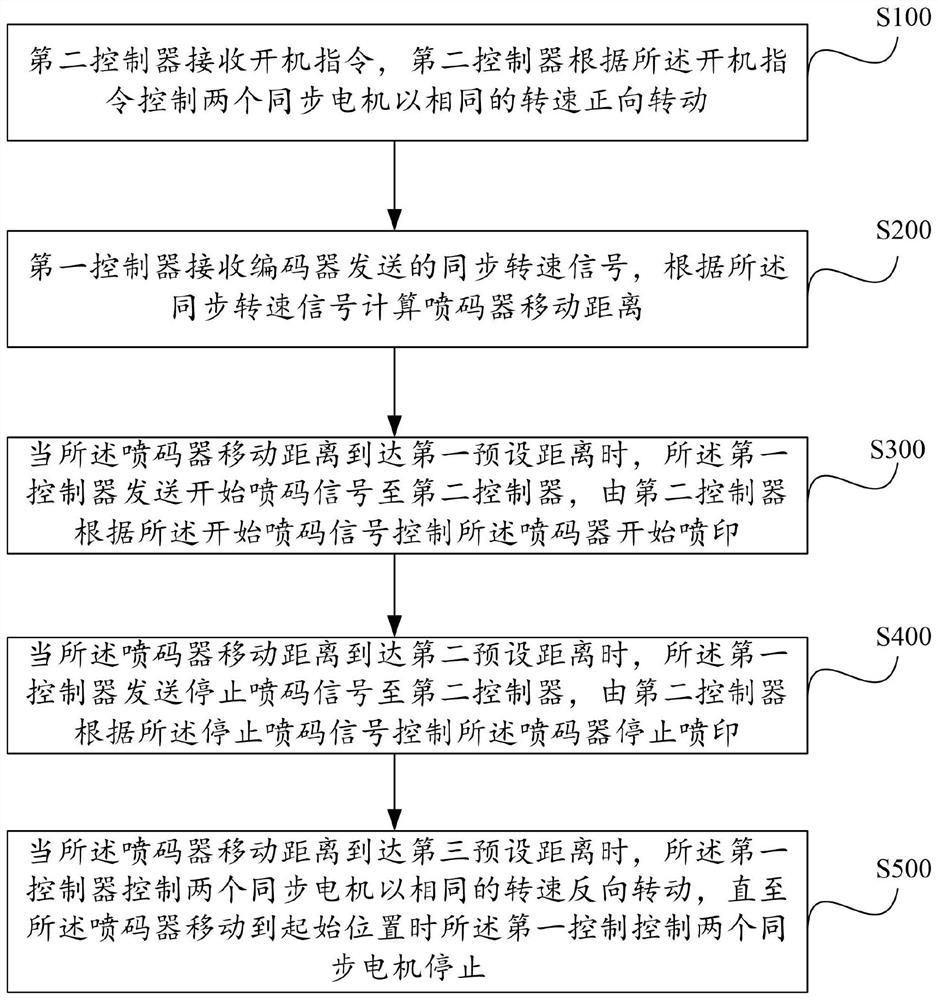

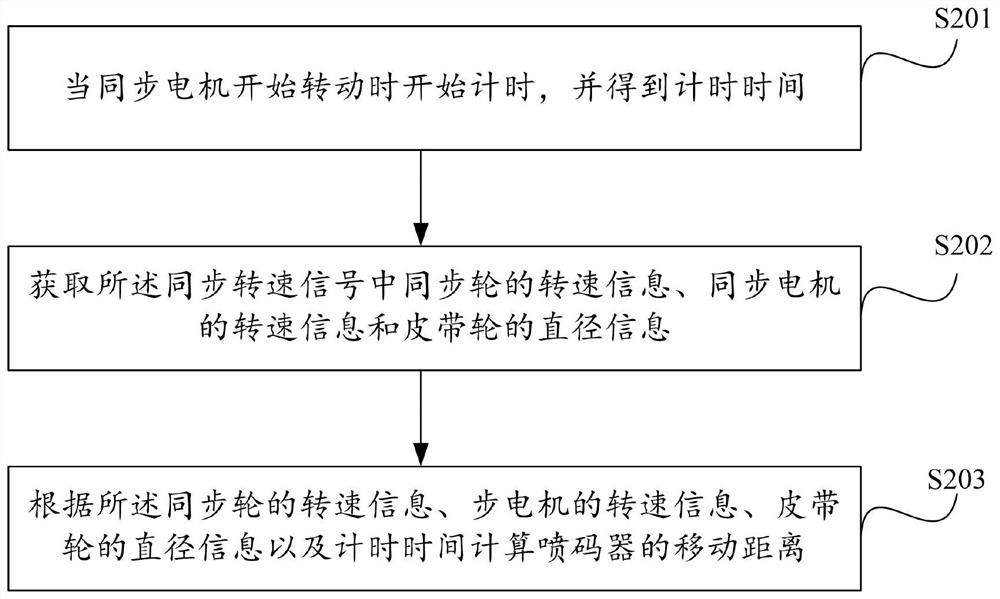

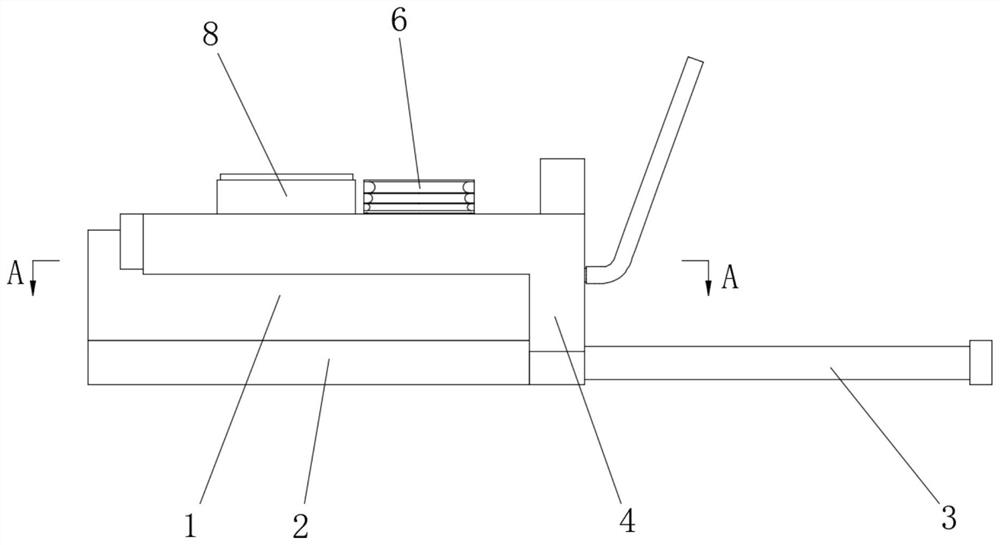

A printing control method for a printing system

ActiveCN110254058BConsistent movement speedAvoid inaccurate codingTypewritersOther printing apparatusSynchronous motorControl engineering

The present invention is applicable to the technical field of pipe material spray printing, and provides a spray printing control method of a spray printing system, comprising: the second controller controls two synchronous motors to rotate forward at the same speed according to the start-up command, and the belt drives the spray printing The encoder moves forward along the guide rail; the first controller calculates the moving distance of the inkjet printer according to the synchronous speed signal; when the moving distance of the inkjet printer reaches the first preset distance, the second controller starts The coding signal controls the inkjet printer to start printing; when the moving distance of the inkjet printer reaches the second preset distance, the second controller controls the inkjet printer to stop printing according to the stop coding signal ; When the moving distance of the inkjet printer reaches the third preset distance, the second controller controls the synchronous motor to rotate in reverse according to the signal, so that accurate inkjet can be realized, and the inkjet is highly controllable.

Owner:DENG QUAN PLASTIC TECH HUNAN CO LTD

Cutting device for steel bar straightening machine

ActiveCN113182461AAvoid the problem of not being fully straightenedImprove straightening effectCleaning using toolsRubber ringStraight tube

The invention relates to the technical field of building material machinery, and discloses a cutting device for a steel bar straightening machine. The cutting device comprises a shell, one side of the shell is fixedly provided with a sealing cover, one side of the sealing cover is fixedly sleeved with three stroke rods, and the positions, close to one end of the shell, of the outer surfaces of the stroke rods are movably sleeved with the cutting device. A power machine is fixedly installed at the bottom of an inner cavity of the shell, the number of output shafts of the power machine is two, a compression roller device and an extrusion device are fixedly installed at one end of each output shaft, a straightening device is movably connected to the position, located on one side of the compression roller device, of the front face of the shell in a sleeving mode, and a switching device is fixedly installed at the top of the shell. A rubber ring is made of wear-resistant rubber, so that the rubber ring can remove rust which is not cleaned away when the steel bar passes through a straight pipe in the rotating process, the problem that the quality of a final product is poor due to the fact that a large amount of rust still exists after the steel bar is sheared is solved, and the quality of the final product produced by the device is improved.

Owner:天津德工建设工程有限公司

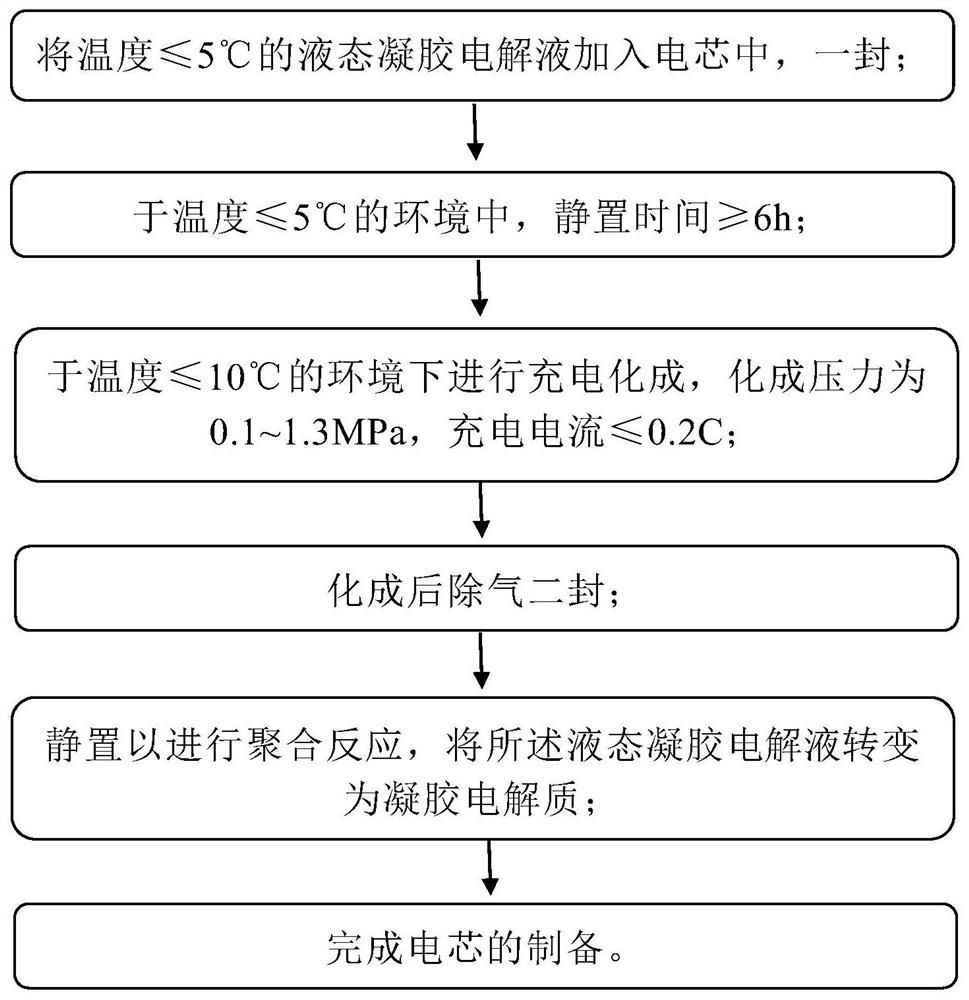

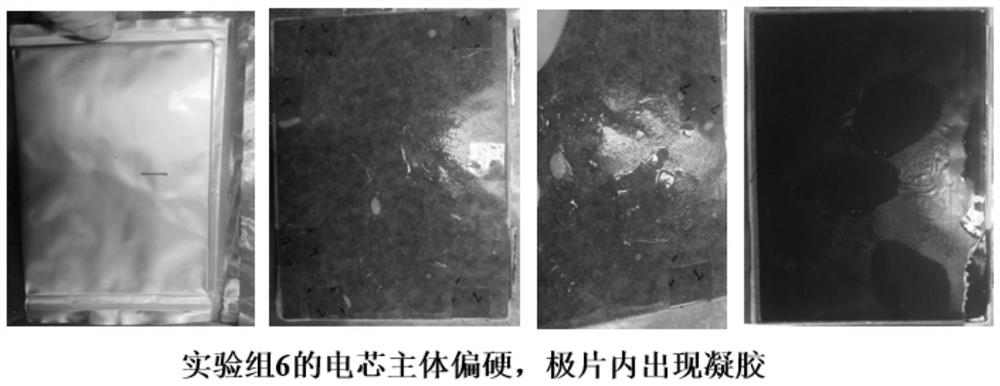

Preparation method and application of gel electrolyte cell

ActiveCN113871706AAchieve dispersionTo achieve the purpose of dispersing gel state electrolyteFinal product manufactureLi-accumulatorsElectrolytic agentCharge current

The invention provides a preparation method and application of a gel electrolyte cell, and the preparation method comprises the following steps: S1, adding a liquid gel electrolyte with the temperature of less than or equal to 5 DEG C into the cell, and sealing primarily; S2, placing the primarily sealed battery cell in an environment with the temperature of less than or equal to 5 DEG C, and standing for more than or equal to 6 hours; S3, conducting charging formation in the environment with the temperature smaller than or equal to 10 DEG C, wherein the formation pressure ranges from 0.1 MPa to 1.3 MPa, and the charging current is smaller than or equal to 0.2 C; and S4, carrying out degassing and secondary sealing after formation, carrying out standing for a polymerization reaction, converting the liquid gel electrolyte into gel electrolyte, and completing preparation of the battery cell. Compared with the prior art, the rate of the copolymerization reaction is slowed down through low temperature, so that the liquid electrolyte fully infiltrates the pole piece and the diaphragm before being converted into gel, thereby solving the problems that the copolymer of the existing gel electrolyte cannot be fully dispersed into the battery cell before being polymerized, so that a lithium ion transmission channel is blocked, and local lithium precipitation of the negative electrode is caused.

Owner:HUNAN LIFANG NEW ENERGY SCI & TECH

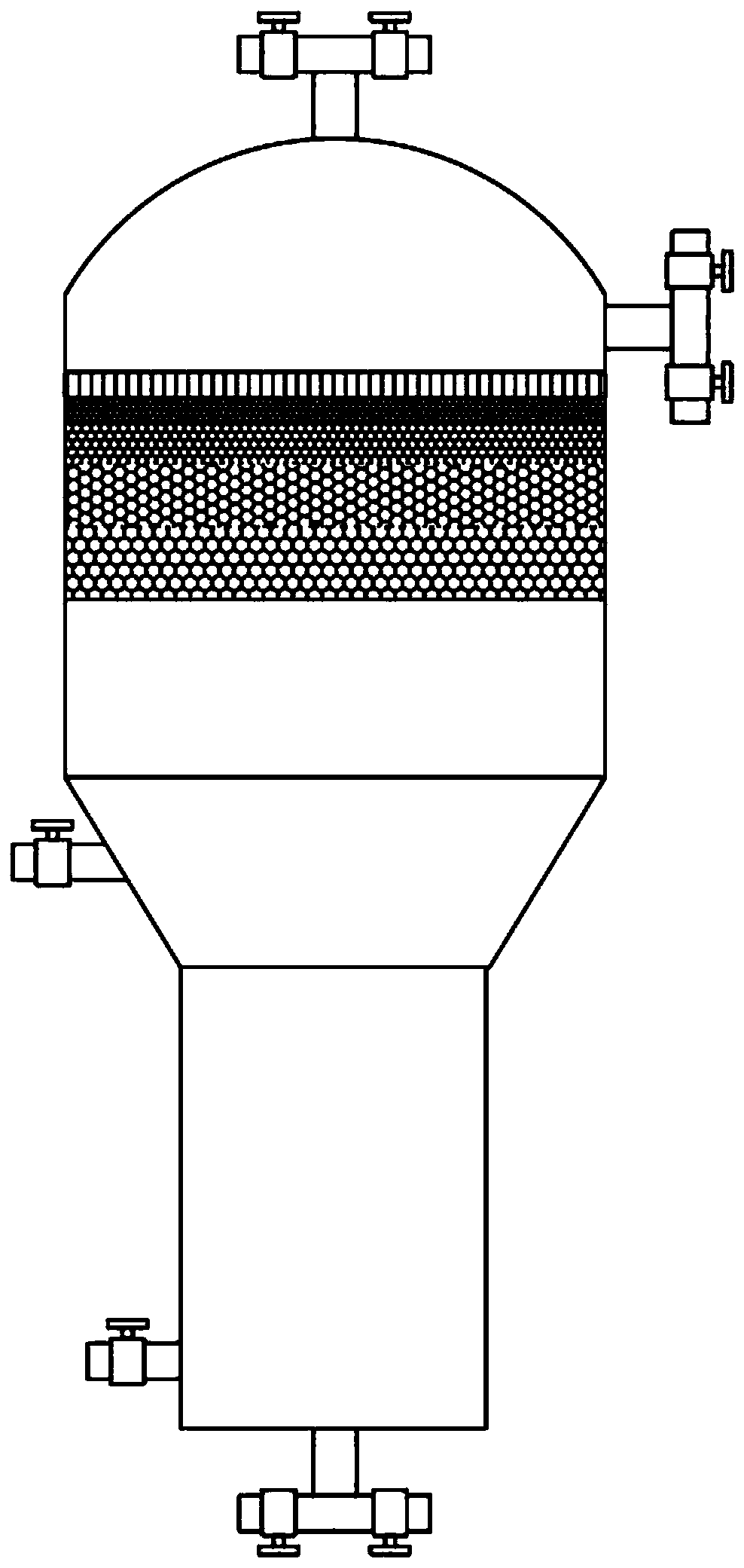

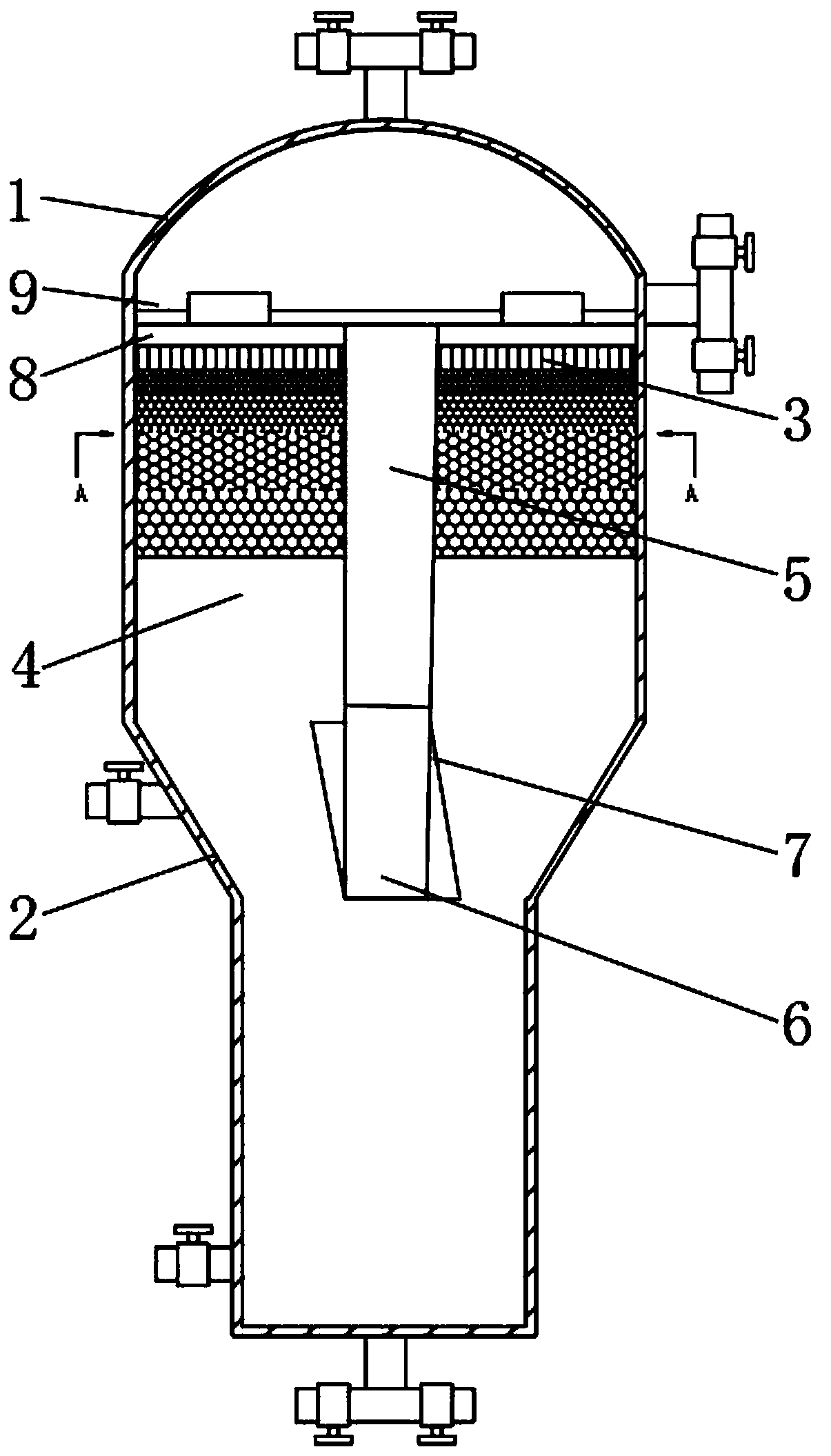

Floating bed biofilter with backwashing function

InactiveCN110577246AFacilitated DiffusionShorten speedSpecific water treatment objectivesTreatment involving filtrationParticle flowWhole body

The invention relates to the technical field of filtering equipment, and discloses a floating bed biofilter with a backwashing function, wherein the floating bed biofilter comprises a filter body, themiddle part of the filter body is provided with a diameter changing section, and the upper part of the filter body is provided with a perforated plate. According to the floating bed biofilter with the backwashing function, when filter material particles flow through the diameter changing section; particles in the middle move along an inclined push plate; the direction changes, diffusion of particles in the diameter changing section is accelerated, and at the same time, the speed of the particles in the middle is reduced; the movement speeds of internal and external particles are consistent; the bed forming quality is improved, and the bed forming time is shortened; meanwhile, when blockage occurs, gradual expansion is performed in one blocked isolation cavity, interference to filter materials in other isolation cavities is avoided, the time for blocking gaps of filter material parts is delayed, and the single-time service period is prolonged; and meanwhile, due to the fact that the filtering effect in the single isolation cavities is poor, interference to the whole body is small, and the output water quality during blockage is improved.

Owner:桐乡市常新农机专业合作社

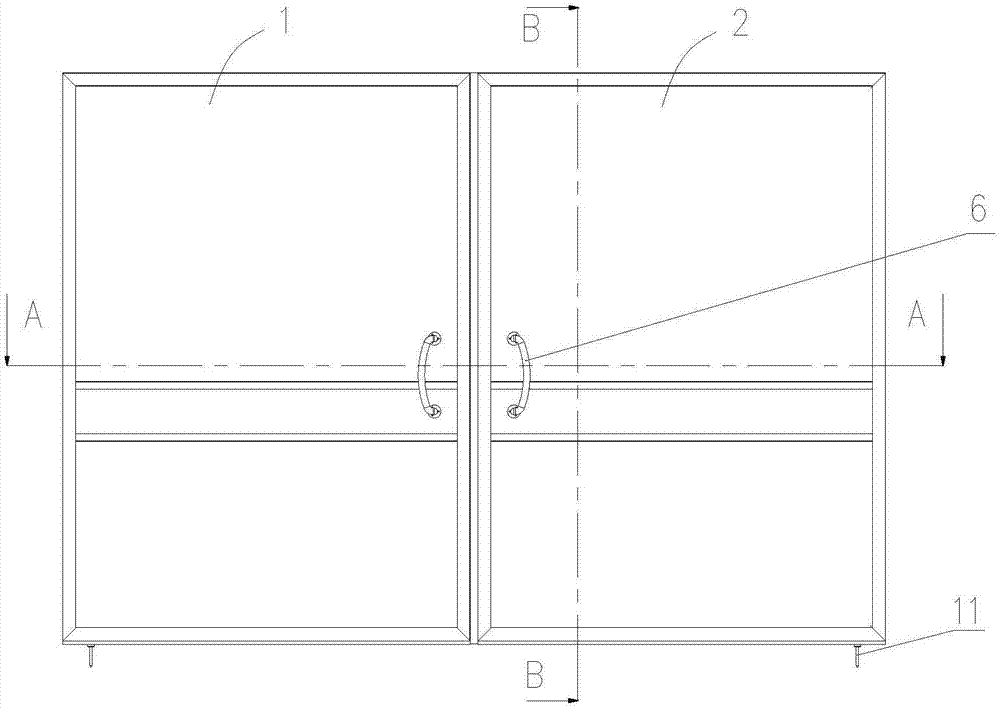

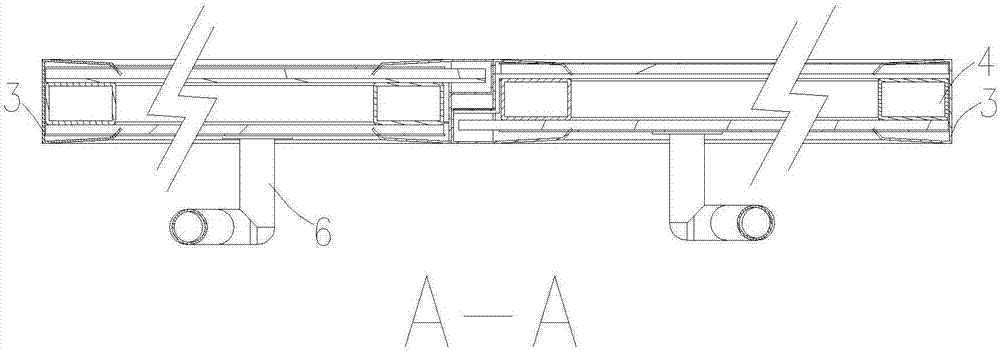

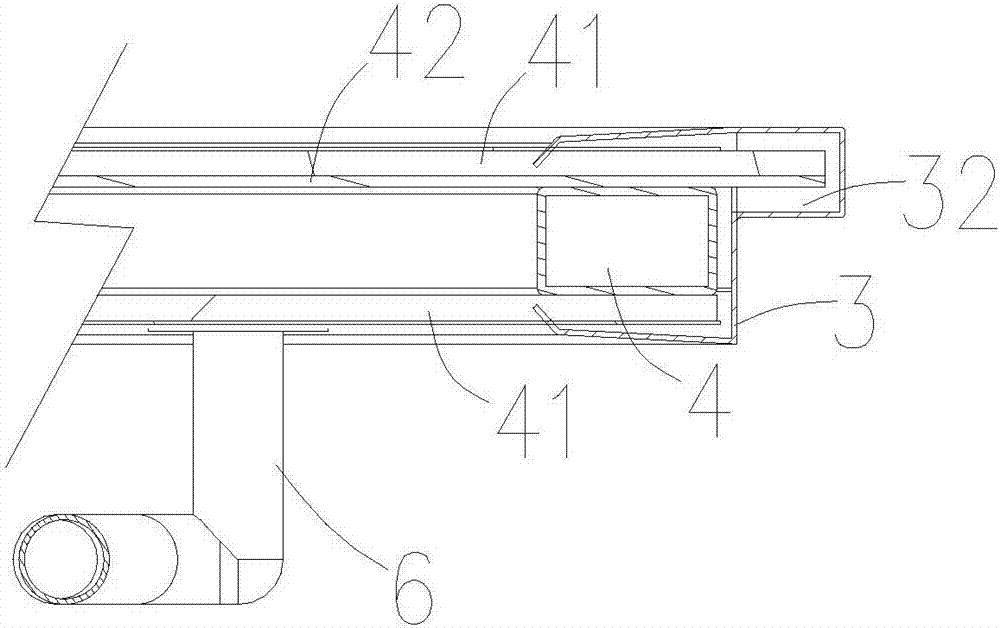

A protective double door

ActiveCN106121422BConsistent movement speedSimple structurePower-operated mechanismWing suspension devicesEngineeringOpening - action

The invention relates to the technical field of protective doors and discloses a protective double-leaf door. The protective double-leaf door comprises a first door leaf, a second door leaf and a drive device. The peripheral side faces of the first door leaf and the peripheral side faces of the second door leaf are all provided with covering edges covering and sealing the peripheral side faces of the door leaves. The covering edges of the inner side faces, located at the joint of the first door leaf and the second door leaf, of the door leaves are each provided with a boss portion, and the boss portions are matched with each other. The width of each boss portion is smaller than a half of the width of the inner side face of each door leaf. The drive device comprises a guide rail, rail wheel assemblies, an installation plate, a motor, a belt, belt pulleys and a controller, wherein the motor, the belt, the belt pulleys and the controller are arranged on the installation plate. The distance between the belt pulleys located at the two ends of the belt is larger than the width of the protective double-leaf door. The rail wheel assemblies connected with the first door leaf and the rail wheel assemblies connected with the second door leaf are connected to two segments, located in different movement directions, of the belt correspondingly. The two door leaves are synchronously driven to conduct the opening action or the closing action through the motor and the belt device, and therefore the movement speeds of the door leaves are equal. The drive device is simple in structure and reliable in strength.

Owner:ZHUZHOU HELI ELECTROMAGNETIC TECH

Double-acting hydraulic engine and working method thereof

InactiveCN109736943AWide range of usesLarge displacementMachines/enginesAutomotive engineeringCylinder block

The invention provides a double-acting hydraulic engine and a working method thereof. The double-acting hydraulic engine mainly comprises an engine main body, an oil cylinder A is connected to the right side of the engine main body, an oil cylinder B is connected to the left side of the engine main body, a connecting wheel A is arranged on the engine main body, the connecting wheel A is connectedwith a hydraulic pump, the oil inlet and the oil outlet of the hydraulic pump are connected with a reversing valve through pipelines, and the other ports of the reversing valve are connected with theoil cylinder A and the oil cylinder B through pipelines. According to the double-acting hydraulic engine and the working method thereof, the cylinder body in the engine body is driven to rotate through the hydraulic pump, an extending rod in the engine main body is driven to slide in the axial direction through the operation of the hydraulic oil, so that the engine finishes the working process, meanwhile, the engine works to provide the kinetic energy for the hydraulic pump, the design can enable the engine to achieve bidirectional work and enable the cylinder body of the engine to rotate forone circle, pistons on the two sides run two strokes respectively, so that the problems that an existing engine is short in service life, large in size, small in displacement and the like are solved.

Owner:烟台小米机械技术有限公司

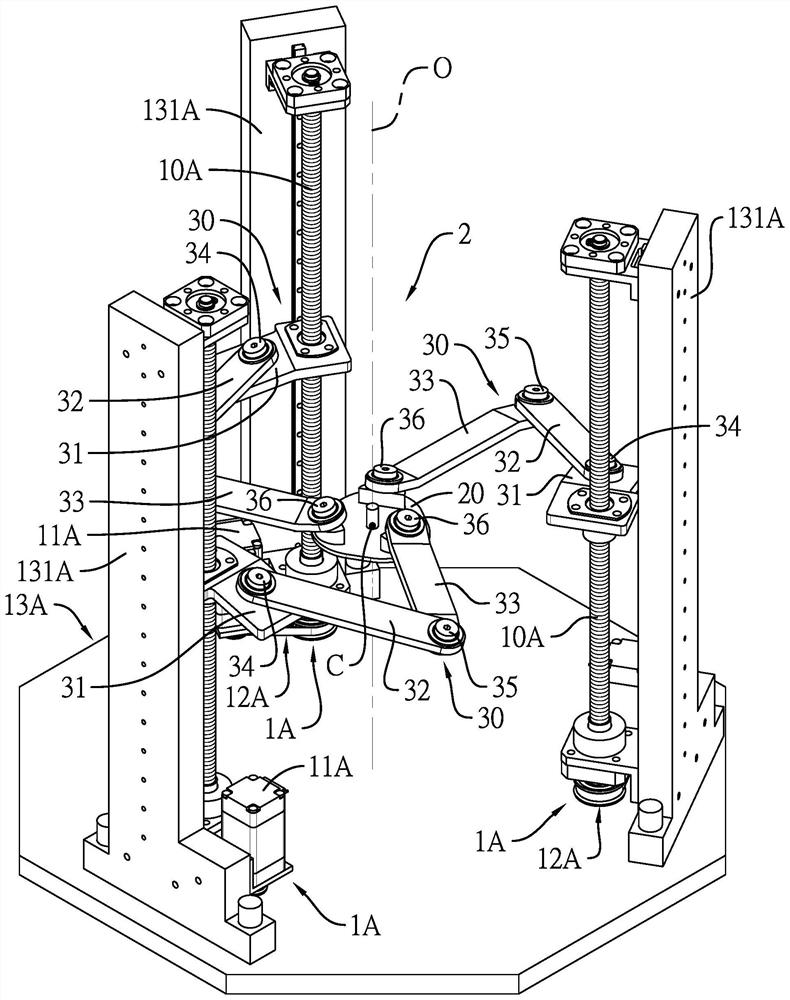

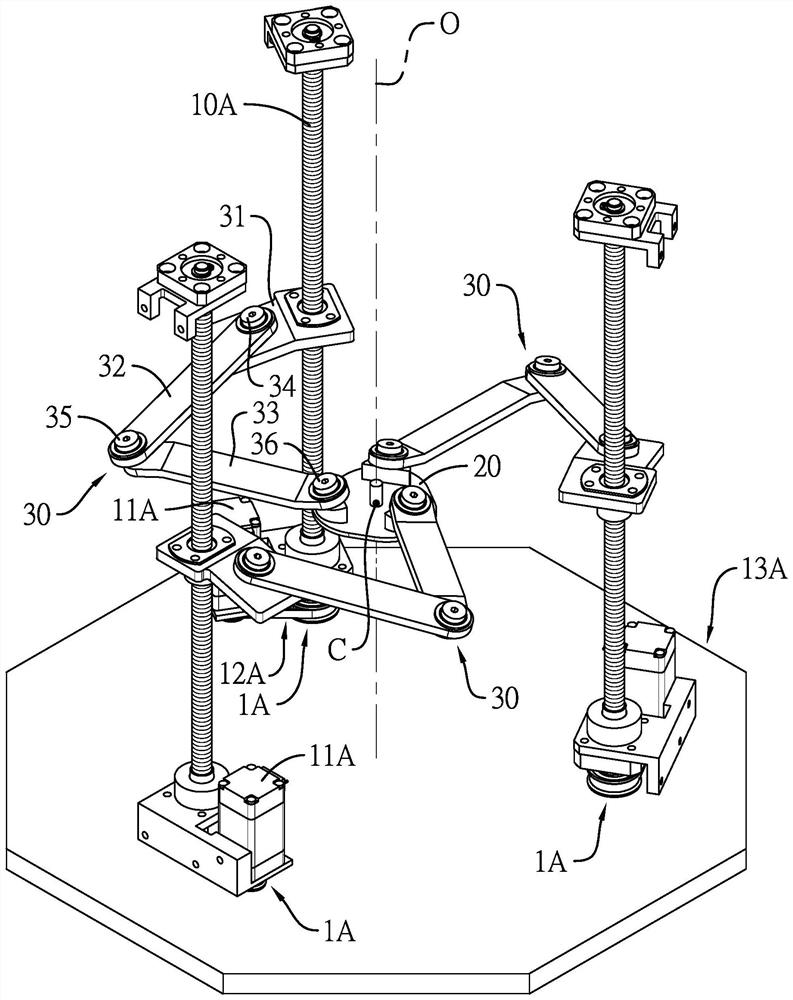

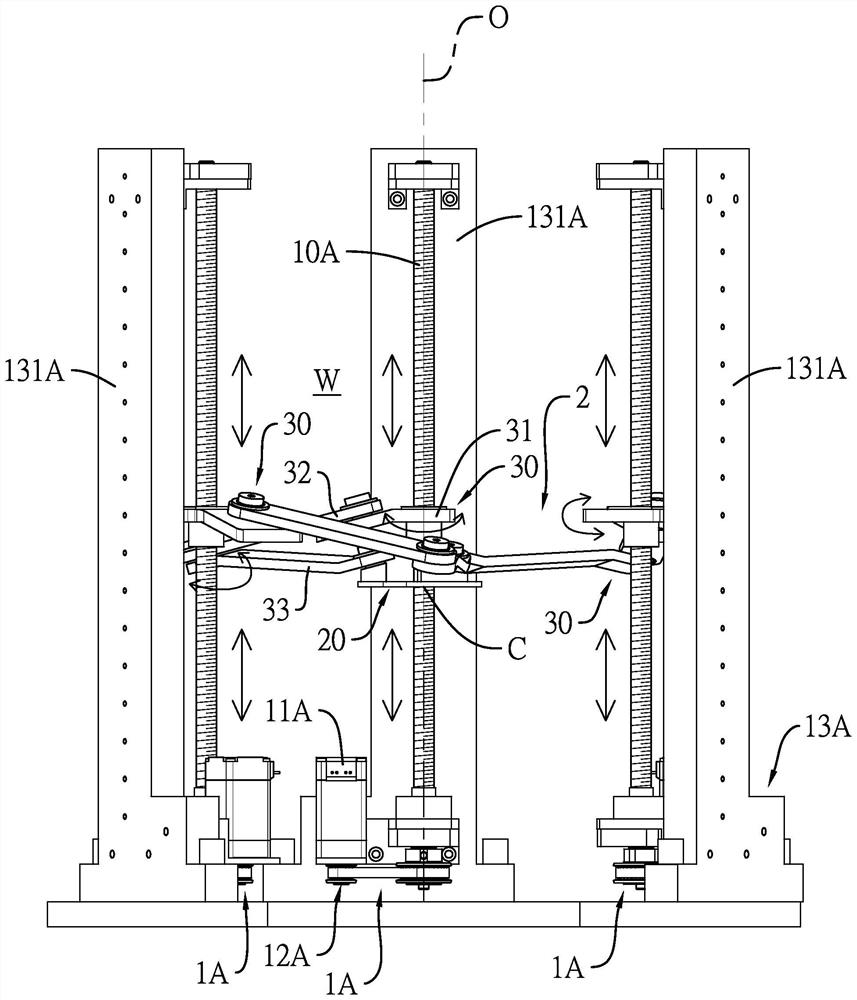

A parallel type three-axis linear robot

PendingCN113442112AReduce the overall heightIncrease heightProgramme-controlled manipulatorJointsAcute angleClassical mechanics

The invention relates to a parallel type three-axis linear robot. The parallel type three-axis linear robot comprises three drivers located on the periphery of a central axis and a movement mechanism. The movement mechanism comprises a three-connecting-rod set which is rotationally symmetrical relative to the central axis and an end effector which is connected with the three-connecting-rod set in parallel. Each connecting rod set is driven by a driver in a linear or rotating manner, so that the end effector can linearly move in a three-dimensional space; each connecting rod set comprises a first connecting rod, a second connecting rod and a third connecting rod which are sequentially connected in series, wherein the third connecting rod is pivoted to the end effector; the first rotating joint, the second rotating joint and the third rotating joint are respectively pivoted among the first connecting rod, the second connecting rod, and the third connecting rod; included angles between the first to third rotary joints and an imaginary plane perpendicular to the central axis are acute angles; the first center distance between the first rotating joint and the second rotating joint is equal to the second center distance between the second rotating joint and the third rotating joint, so that the overall height of the movement mechanism can be reduced, the working stroke is increased, and the movement stability is improved.

Owner:蓝兆杰

Hydraulic engine and working method thereof

InactiveCN109681321AStable compression ratioSolve technical problems that are difficult to controlEngine controllersMachines/enginesCombustionHydraulic pump

The invention discloses a hydraulic engine and a working method thereof. The hydraulic engine mainly comprises an engine main body, wherein the right side of the engine main body is connected with anoil cylinder A; the left side of the engine main body is connected with an oil cylinder B; a connecting wheel A is arranged on the engine main body and is connected with a hydraulic pump; an oil outlet of the hydraulic pump is connected with a rotating valve through a pipeline; an oil inlet of the hydraulic pump is connected with a flow distributing disc; a connecting wheel D is arranged on the rotating valve; a connecting wheel B and a connecting wheel C are arranged on the flow distributing disc; a transmission wheel B is arranged on the hydraulic pump; and the transmission wheel B, the connecting wheel B, the connecting wheel C and the connecting wheel D are connected with transmission assemblies. The hydraulic engine and the working method thereof disclosed by the invention have the advantages that the engine having the special structure is combined with a hydraulic system, so that the problems that a compression ratio of an existing engine is easily changed and constant-volume combustion is difficult to realize are solved.

Owner:烟台小米机械技术有限公司

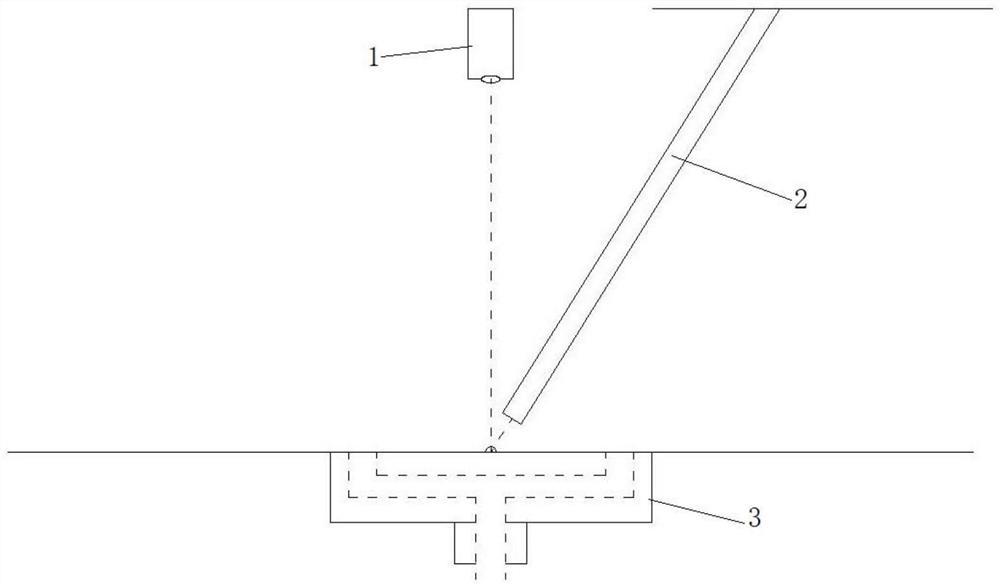

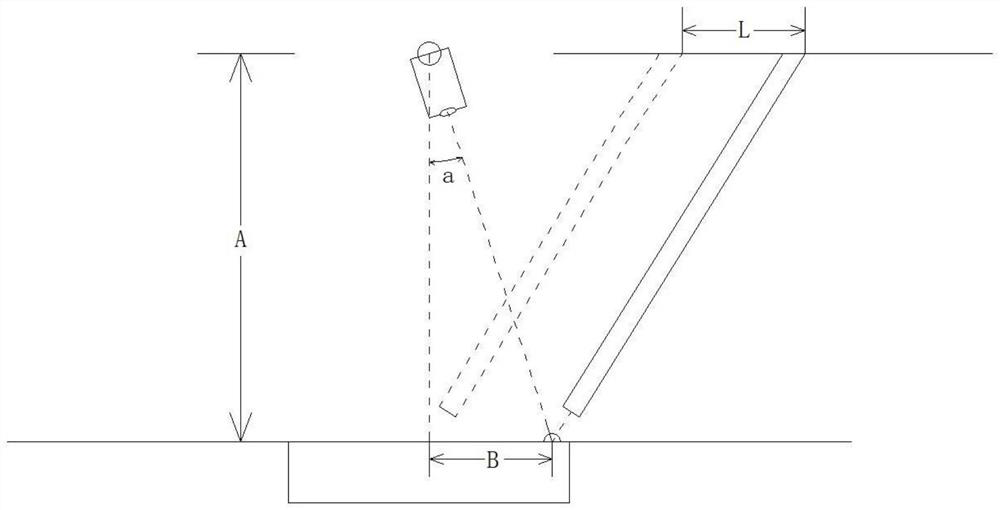

Plate laser cleaning process and laser cleaning equipment

ActiveCN113182281AGuaranteed uniformityGuaranteed adsorption efficiencyDirt cleaningElectric machineryEngineering

The invention discloses a plate laser cleaning process and laser cleaning equipment. The center of the top face of a plate serves as a base point, and cleaning is conducted in the edge direction of the plate in a diffusion circle mode; and the diffusion circle is formed by unidirectionally changing the inclination angle of a laser head and rotating the plate by taking the center as the axis point. The same motor is used as a power source, the uniformity of the rotating frequency of a power shaft is guaranteed, the angular rate of the laser head and the moving rate of a dust suction pipe are consistent by adjusting a wriggling rotating disc and threads, and the adsorption efficiency of the dust suction pipe is guaranteed; the inclination angle of the laser head is changed unidirectionally, the forward diffusion circle is formed in combination with a plate axis point rotation mode, and reverse diffusion is formed through reverse change of the inclination angle of the laser head; when forward diffusion is combined, the laser removes dirt at high frequency; and the cleaning effect is strengthened through low frequency by reverse diffusion and laser. The equipment is simple in structure, convenient to use, integrated in the cleaning process, high in the automation degree, good in the cleaning effect, low in the dust splashing rate, environmentally friendly, high in practicability and wide in applicability.

Owner:苏州思萃声光微纳技术研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com