Preparation method and application of gel electrolyte cell

A gel electrolyte and gel electrolyte technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of blocked lithium ion transmission channels, insufficient dispersion of copolymers, and lithium precipitation, etc. Chip interface, small impedance, slow rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

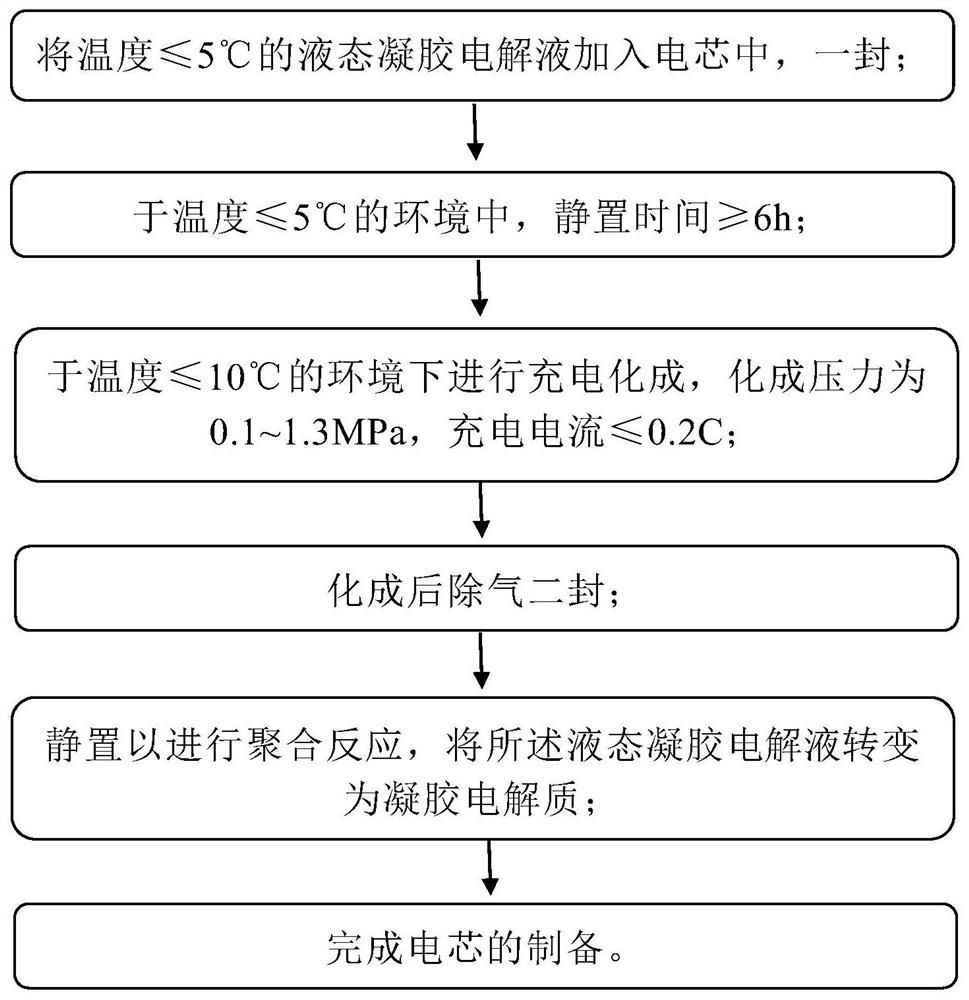

[0034] The first aspect of the present invention provides a method for preparing a gel electrolyte cell, such as figure 1 shown, including the following steps:

[0035] S1. Add liquid gel electrolyte with a temperature ≤ 5°C into the battery cell, one packet;

[0036] S2. Place the sealed battery in an environment with a temperature ≤ 5°C for a standing time ≥ 6h;

[0037] S3. Carry out charging and forming in an environment with a temperature of ≤10°C, the forming pressure is 0.1-1.3MPa, and the charging current is ≤0.2C;

[0038] S4, degassing and sealing twice after the formation, standing still to carry out the polymerization reaction, converting the liquid gel electrolyte into a gel electrolyte, and completing the preparation of the battery cell.

[0039] Wherein, the above-mentioned liquid gel electrolyte includes a liquid electrolyte mother solution, at least two monomers and an initiator. The liquid electrolyte mother liquor is a conventional lithium-ion battery ele...

Embodiment 1

[0056] A preparation method of a gel electrolyte cell, comprising the following steps:

[0057] S1. Remove water from the cell to make the water content of the cell pass the test, then place the cell and the liquid gel electrolyte in an environment of -30-5°C for a standing time of ≥1 hour; then put the liquid gel electrolyte Add the gel electrolyte into the cell, one packet;

[0058] S2. After one letter, place the battery core in an environment of -30~5℃, and the standing time is ≥6h;

[0059] S3. Carry out charging and formation under the environment of -30~10℃, the formation pressure is 0.1~1.3MPa, and the charging current≤0.2C;

[0060] S4, degassing and sealing twice after the formation, standing still to carry out the polymerization reaction, the ambient temperature of the polymerization reaction is 20-90°C, the pressure is 0.15-1.5MPa, and the time is 0.5-100h, so as to transform the liquid gel electrolyte For the gel electrolyte, the preparation of the cell is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com