Engine capable of achieving constant volume combustion and working method of engine

A constant-volume combustion and engine technology, which is applied in the direction of machines/engines, mechanical equipment, etc., can solve problems such as waste of energy, short life, and difficulty in constant-volume combustion of engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

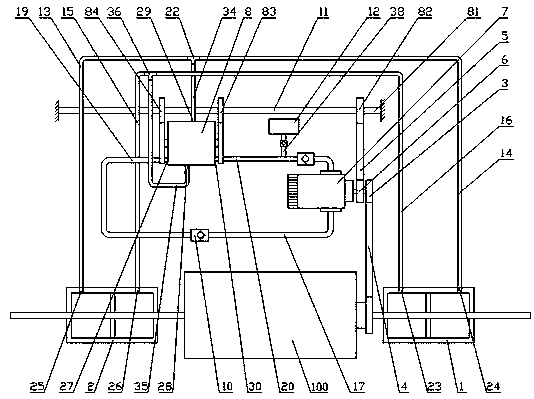

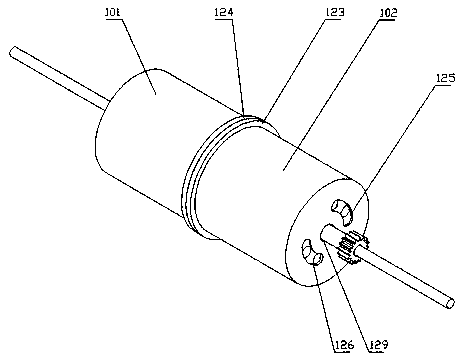

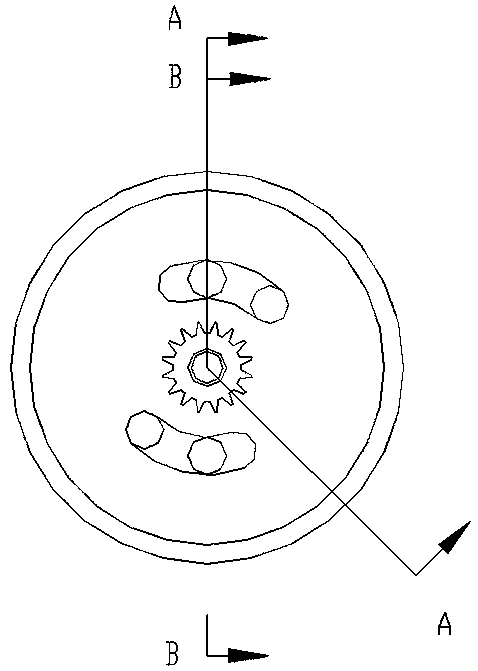

[0042] Embodiments of the present invention provide an engine capable of constant volume combustion and its working method, in which the hydraulic pump drives the cylinder in the engine body to rotate, and the operation of the hydraulic oil drives the extension rod in the engine body to reciprocate and slide axially , so that the engine completes the work process. At the same time, the work done by the engine also provides kinetic energy for the hydraulic pump. This design can make the engine realize two-way work, so that when the cylinder block of the engine rotates once, the pistons on both sides run two strokes respectively, and reduce the friction force in the engine. In addition, the engine can achieve constant volume combustion by using the valve plate, thereby solving the problems of energy waste, short life, and small displacement of the existing engine.

[0043] In order to better understand the technical solution of the present invention, the technical solution of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com