Plate laser cleaning process and laser cleaning equipment

A technology for laser cleaning and cleaning equipment, applied in the direction of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

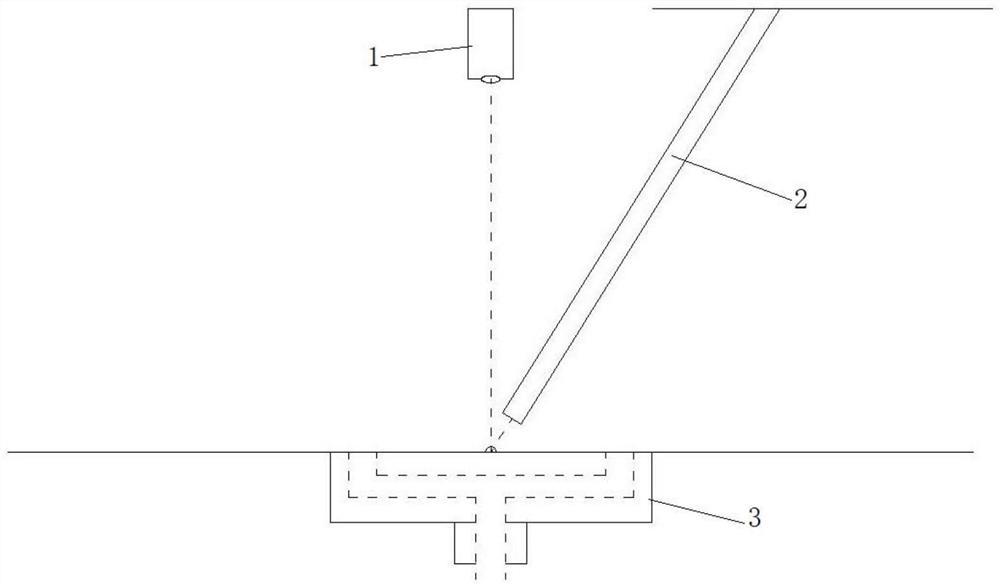

[0033] A plate laser cleaning equipment is composed of a plate table 3, a laser head 1 and a dust suction pipe 2.

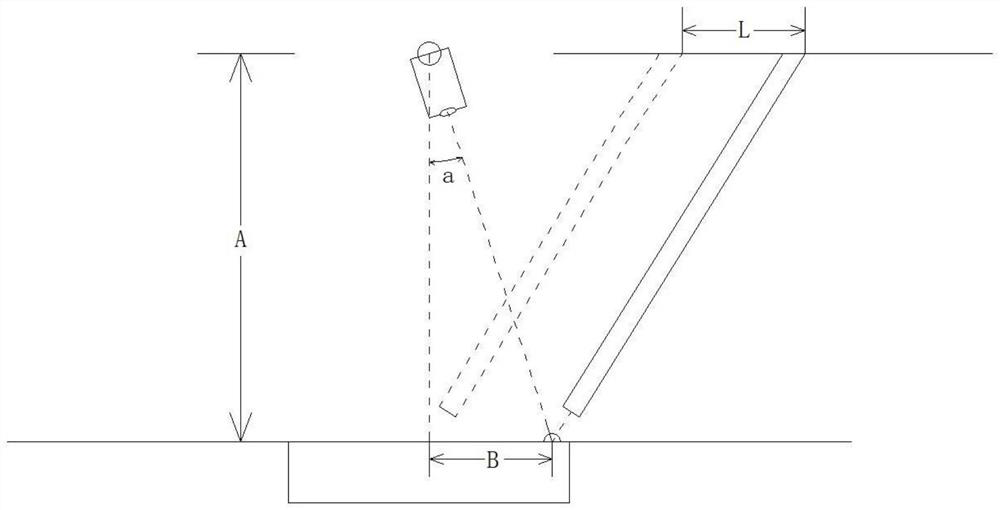

[0034] The top surface of the plate table is used for shelving the plate, and the plate table is coaxially driven and rotated by the second motor at the bottom.

[0035] The laser head and the dust suction pipe are suspended on the top of the board table through the rotating device and the moving device respectively. When the laser head is vertical, the focus of the laser is focused on the central axis of the plate table.

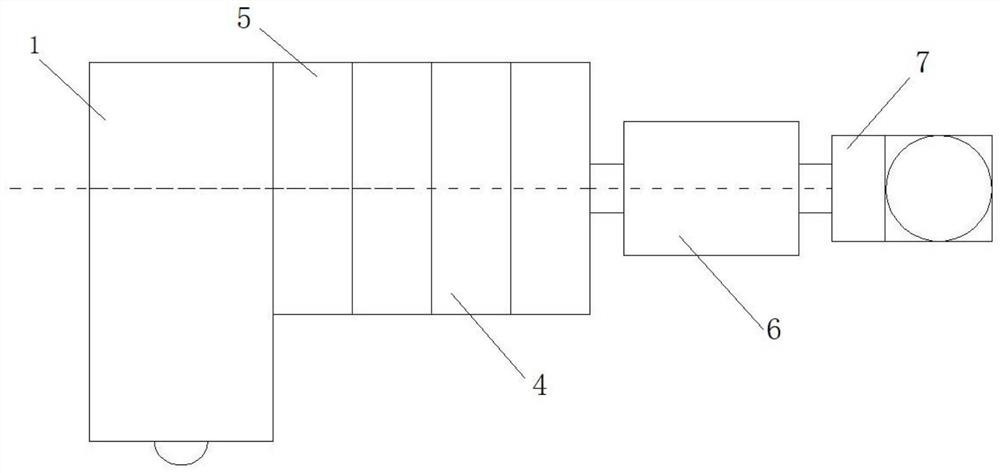

[0036] Both the rotating device 7 and the moving device are driven by a biaxial first motor.

[0037] The rotating device is composed of a rotating disc 5 and a peristaltic toothed disc 4. The peristaltic toothed disc 4 is composed of several toothed discs with different gear ratios, and the number of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com