Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Avoid the risk of bursting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beverage making method of horizontal type rotation beverage making machine

The invention discloses a beverage making method of a horizontal type rotation beverage making machine. The beverage making machine comprises a machine base with a brewing cavity, a brewing head, a water inlet pricking needle arranged at the brewing head, a leading-out pricking needle arranged at the brewing head, a liquid supply mechanism for supplying liquid to the brewing head and a brewing cup for containing a material bag; and one end of the brewing head is connected with the liquid supply mechanism, and the other end of the brewing head supplies the liquid to the interior of the material bag. The beverage making method includes the water inlet step, the making step and the beverage discharging step; a driving device is additionally used in the making step to drive the water inlet pricking needle to rotate, so that a jet flow area is formed by the water inlet pricking needle, beverage powder is flushed by liquid flow in the jet flow area so as to be mixed and dissolved, and therefore mixing dissolution of the liquid and the beverage powder is quickened; in addition, the beverage powder is sufficiently dissolved, residues are avoided, and the taste and the nutritive value of a beverage are improved; meanwhile, the rotation jet flow motion is formed by the water inlet pricking needle in the rotation process, dissolution of the beverage powder is better promoted, and the making efficiency and the taste of the beverage are improved.

Owner:JOYOUNG CO LTD

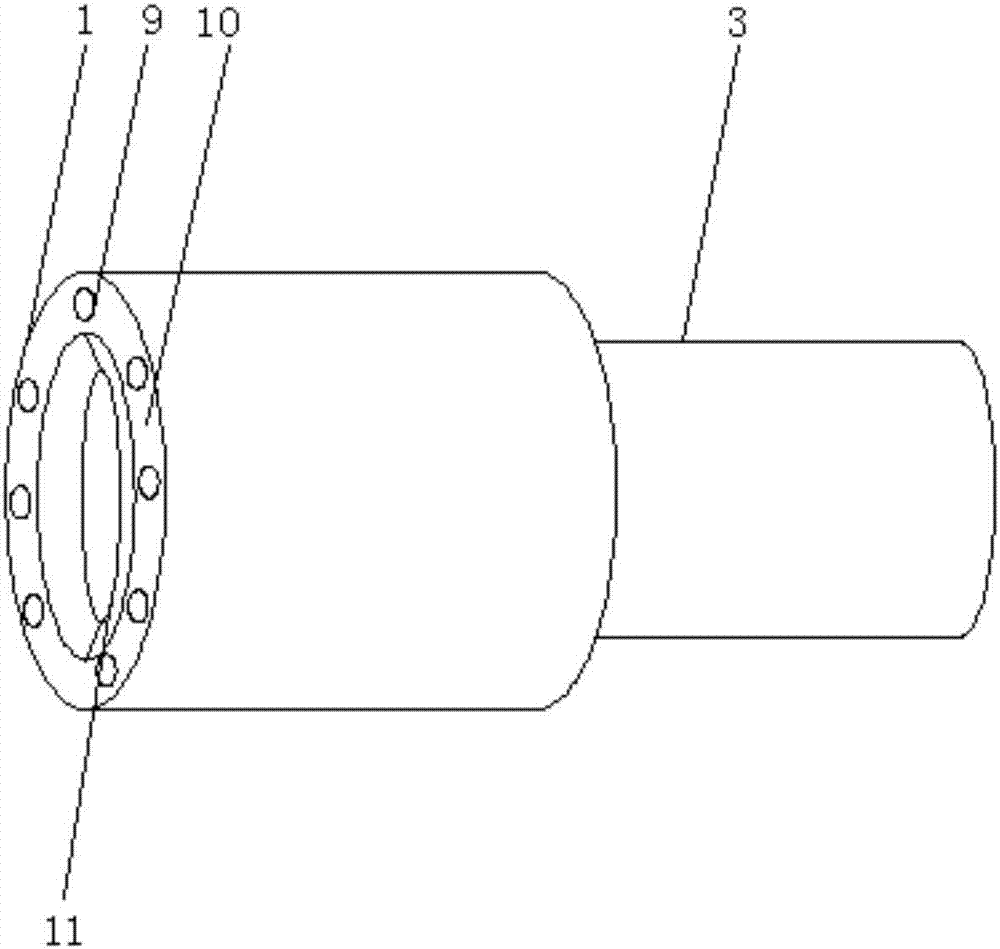

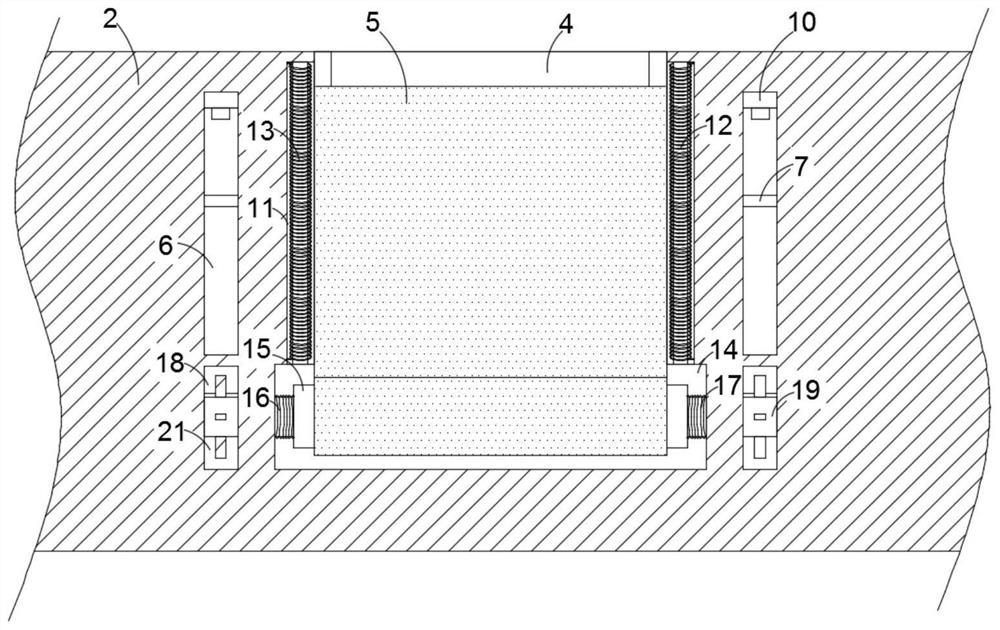

Mould apparatus and method for manufacturing multicomponent glass optical fiber prefabricating stick

The invention relates to a die device for manufacturing a multi-component glass optical fiber preformed rod and a method thereof. The die device is formed by screwed connection of both ends of a stainless steel column cylinder and two stainless steel end covers, wherein the two stainless steel end covers are provided with same small holes for fiber core glass rods to pass through; the side wall on the top end of the stainless steel column cylinder is provided with a through opening which is lower than the top end; and the through opening forms a groove of the stainless steel column cylinder, wherein the inside and the outside of the groove are communicated and the groove is intilted. The die device solves the problems of large interface consumption, large difficulty in manufacture of glass optical fibers with special end face structures, complex manufacturing technique and so on, and has the advantages of capability of precise control of the end face structures of the optical fibers, simple technology, good maneuverability, high production efficiency and so on.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

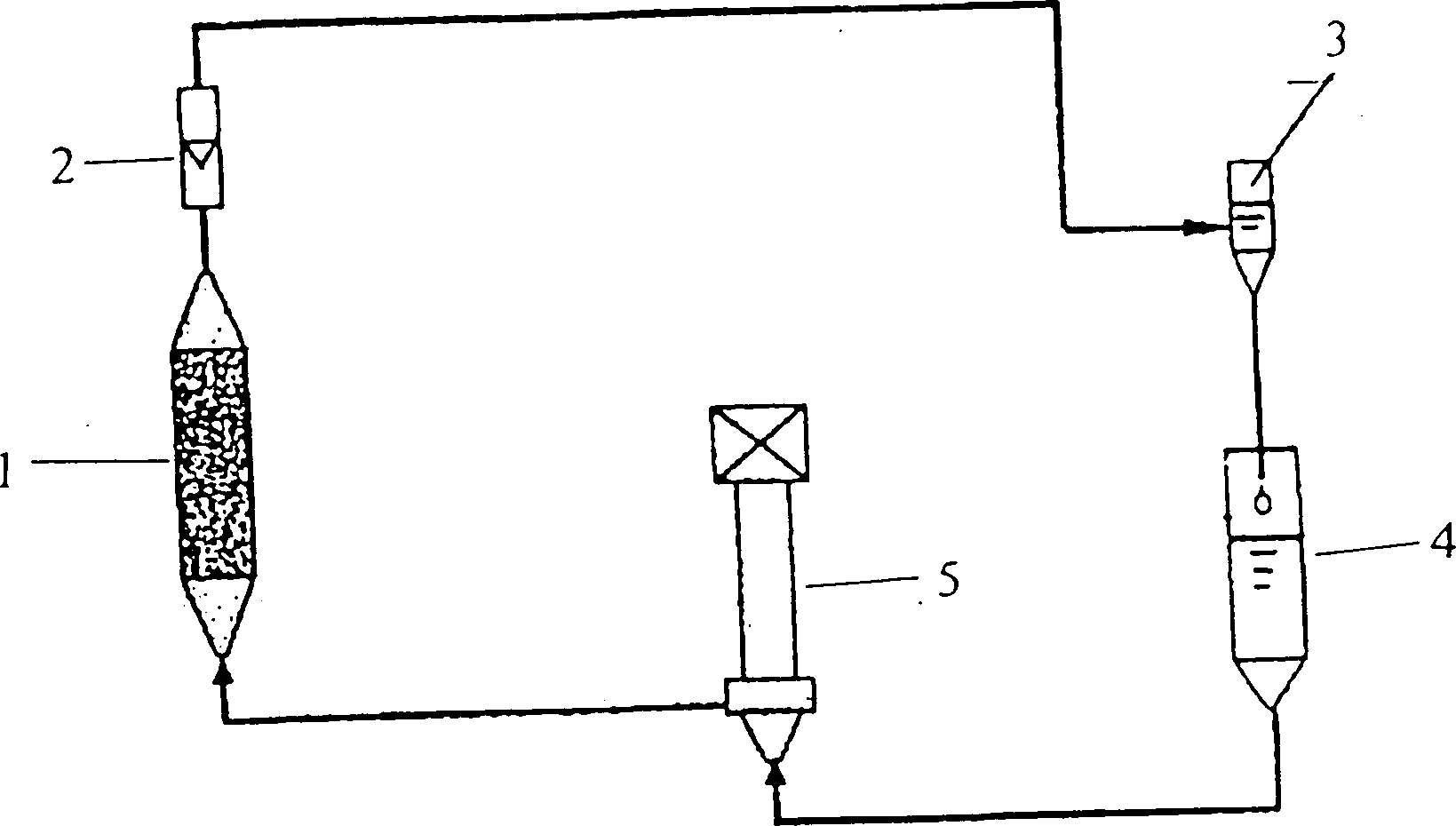

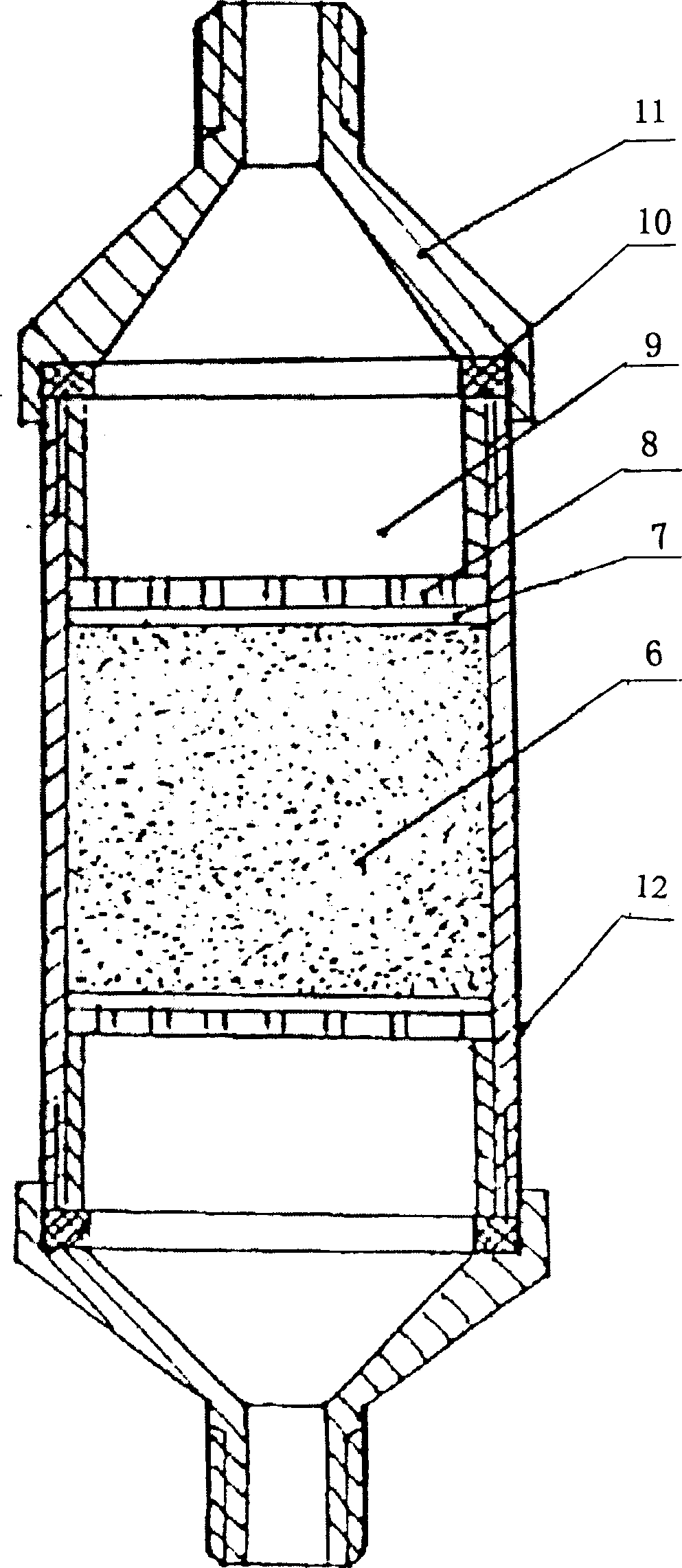

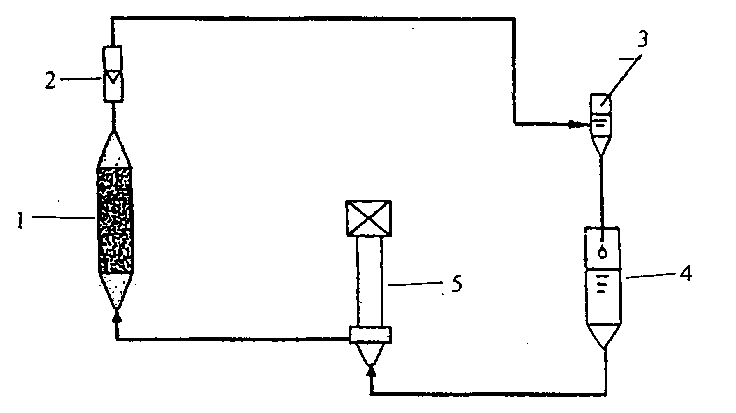

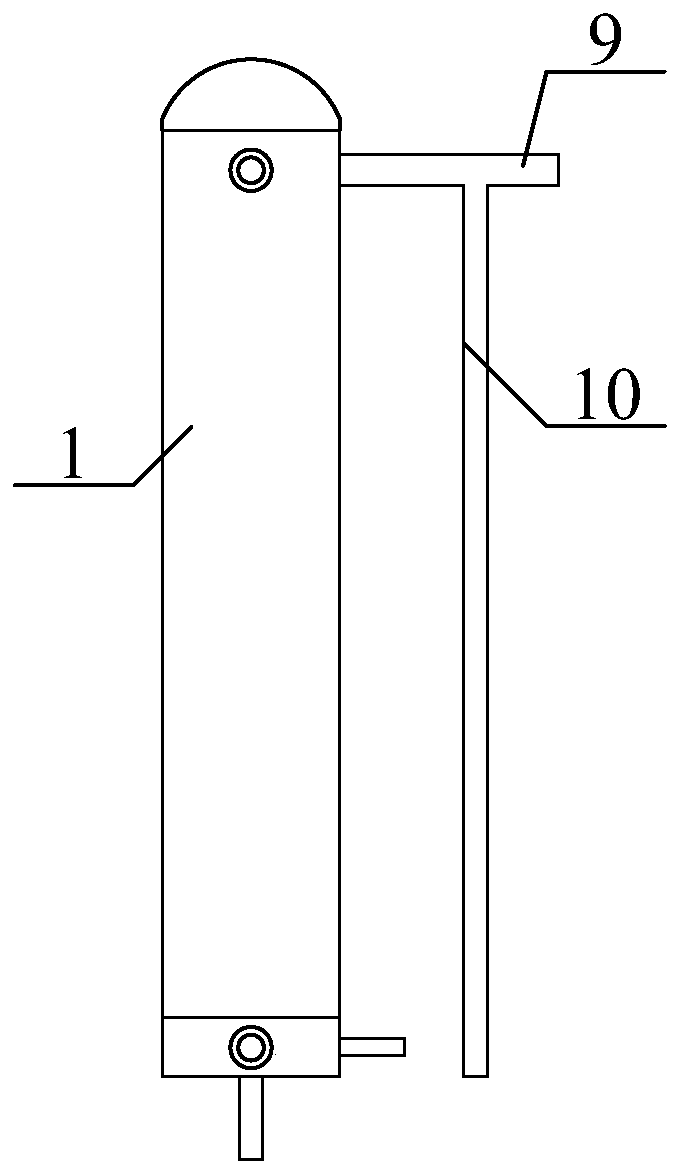

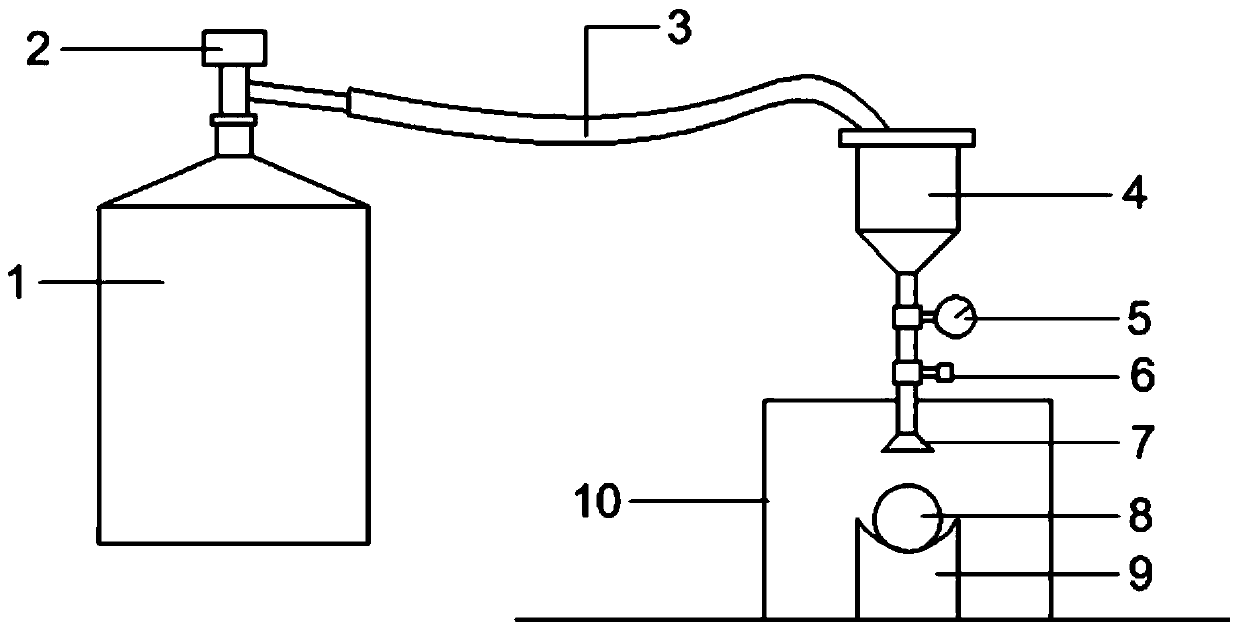

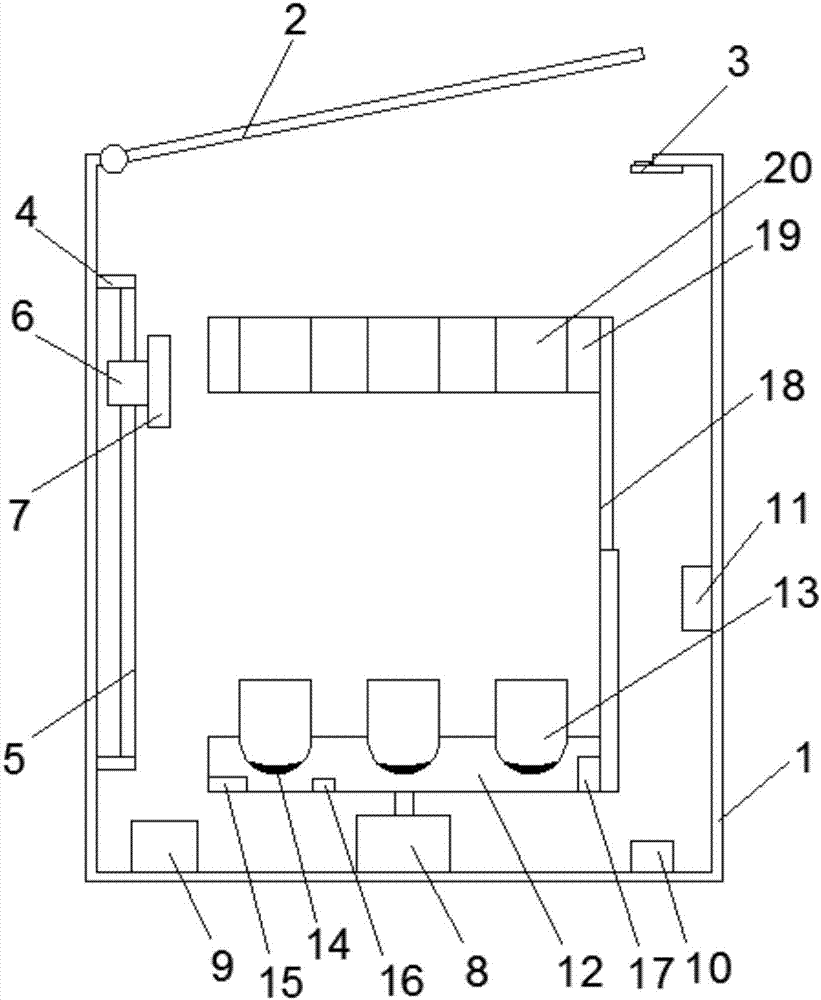

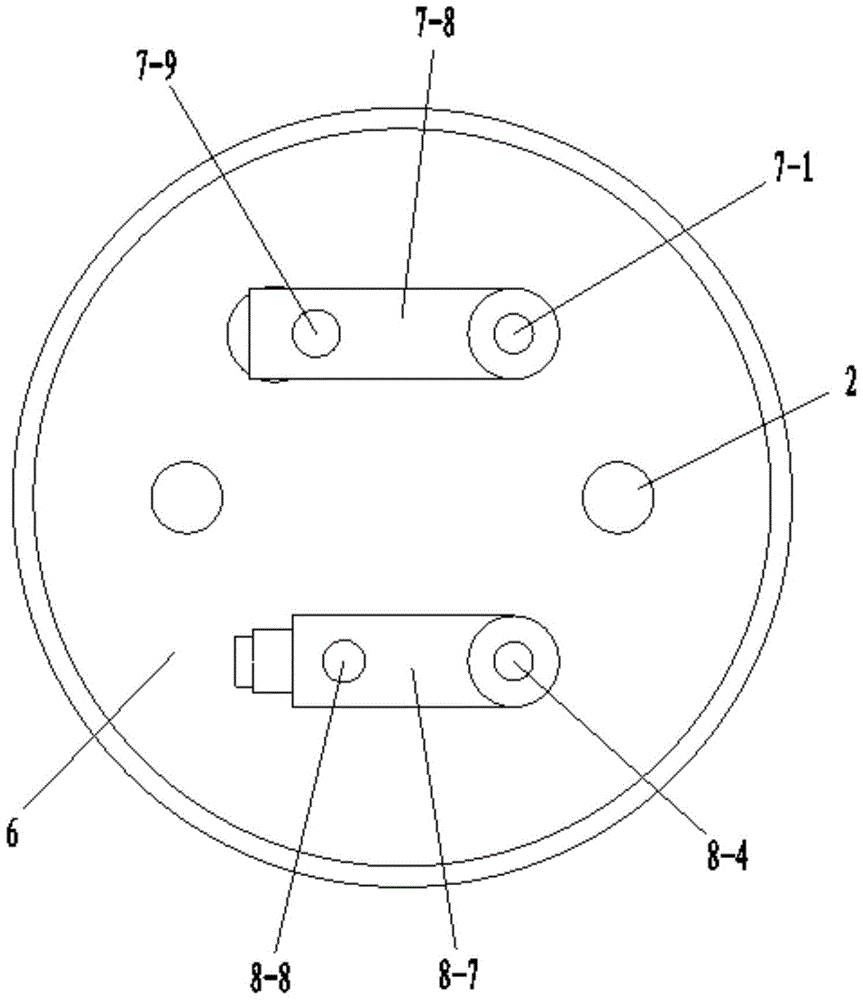

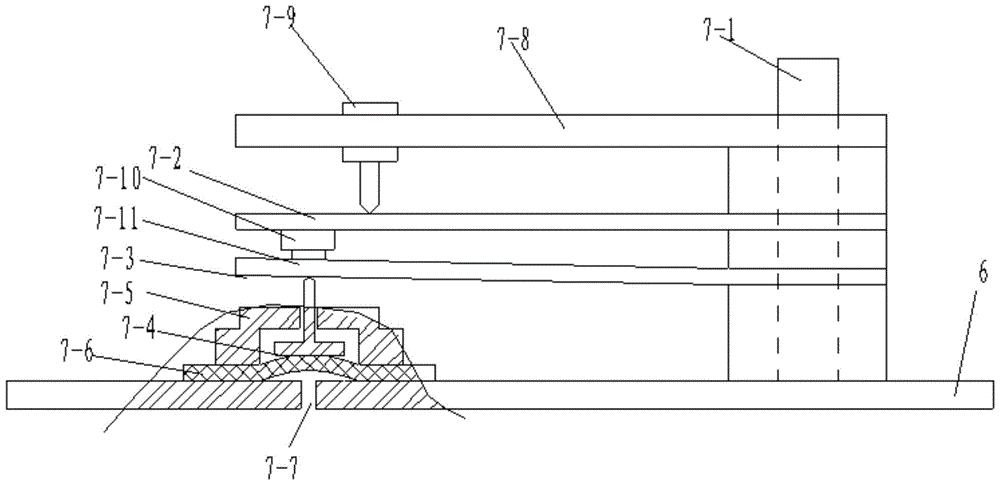

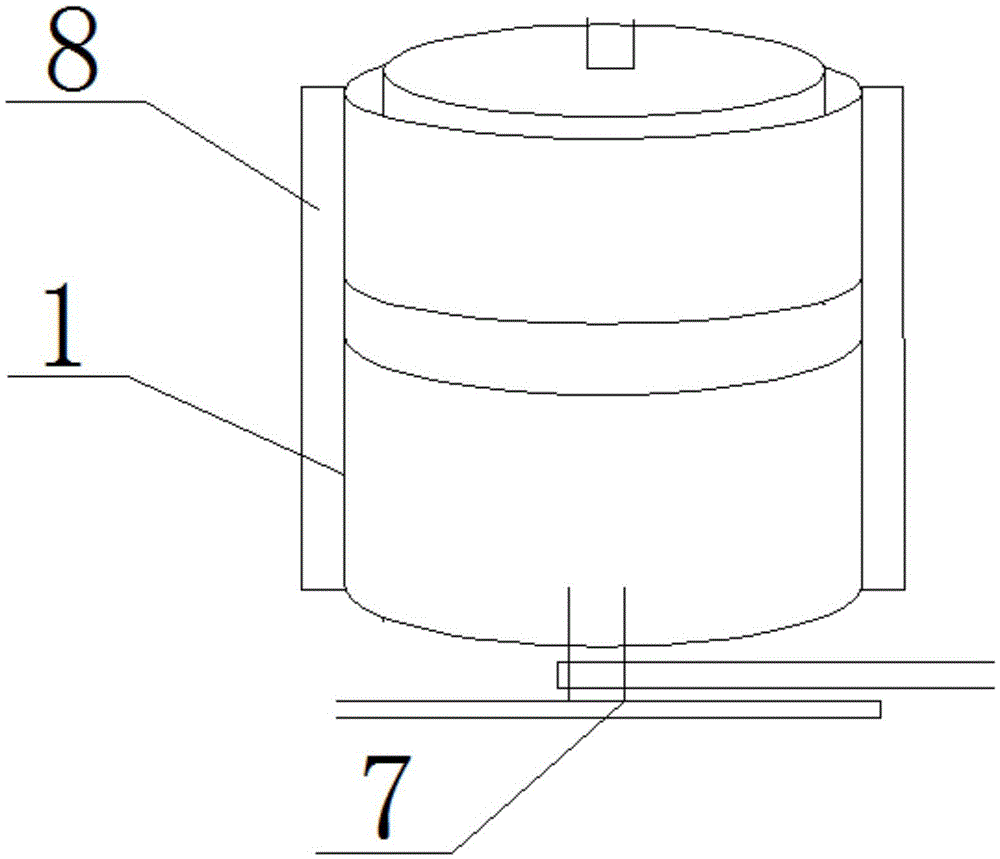

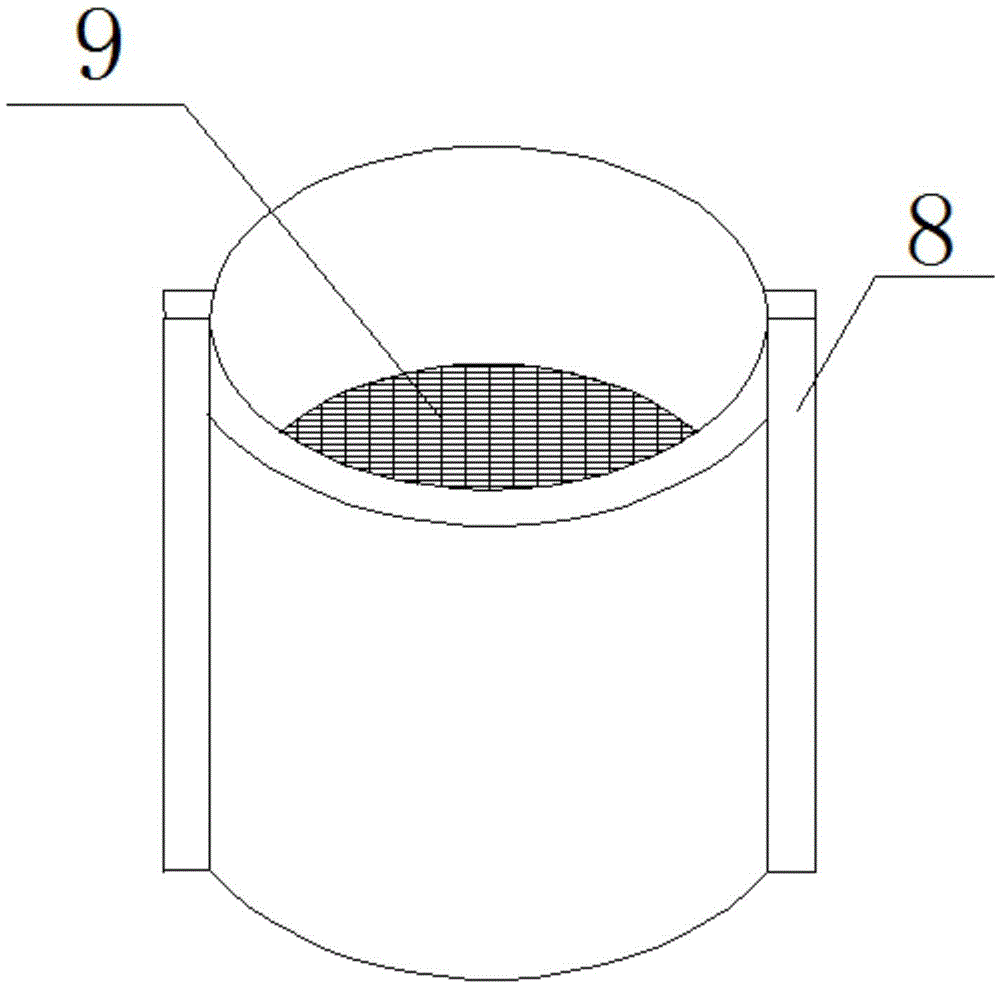

Circulating column experiment device for researching nuclein migration

InactiveCN1396449AAvoid the risk of burstingAvoid risk of leakageComponent separationSolid sorbent liquid separationEngineeringCirculating pump

A circulating column experiment equipment for researching the nuclein migration is composed of experiment column, flowmeter, sampler, liquid container and circulating pump. It features that the experiments with different liquid-solid ratios can be conducted by regulating the height of filled adsorption medium and equipping the assembly with corresponding height. Its advantage is high correctness.

Owner:CHINA INST FOR RADIATION PROTECTION

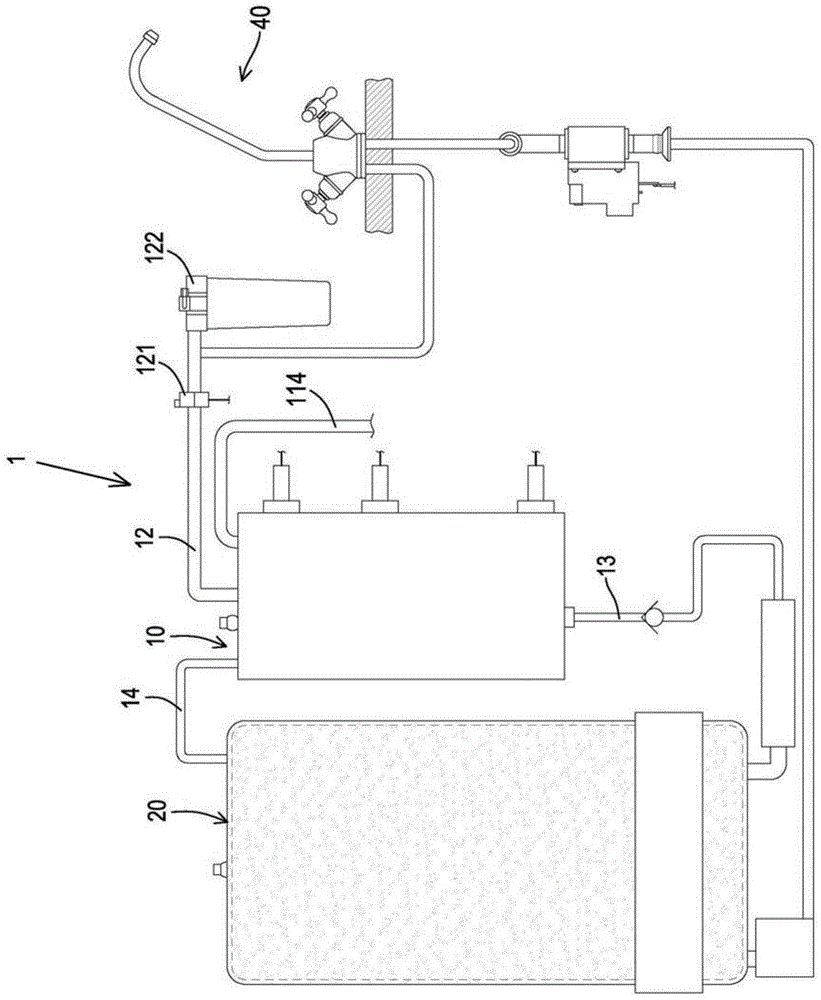

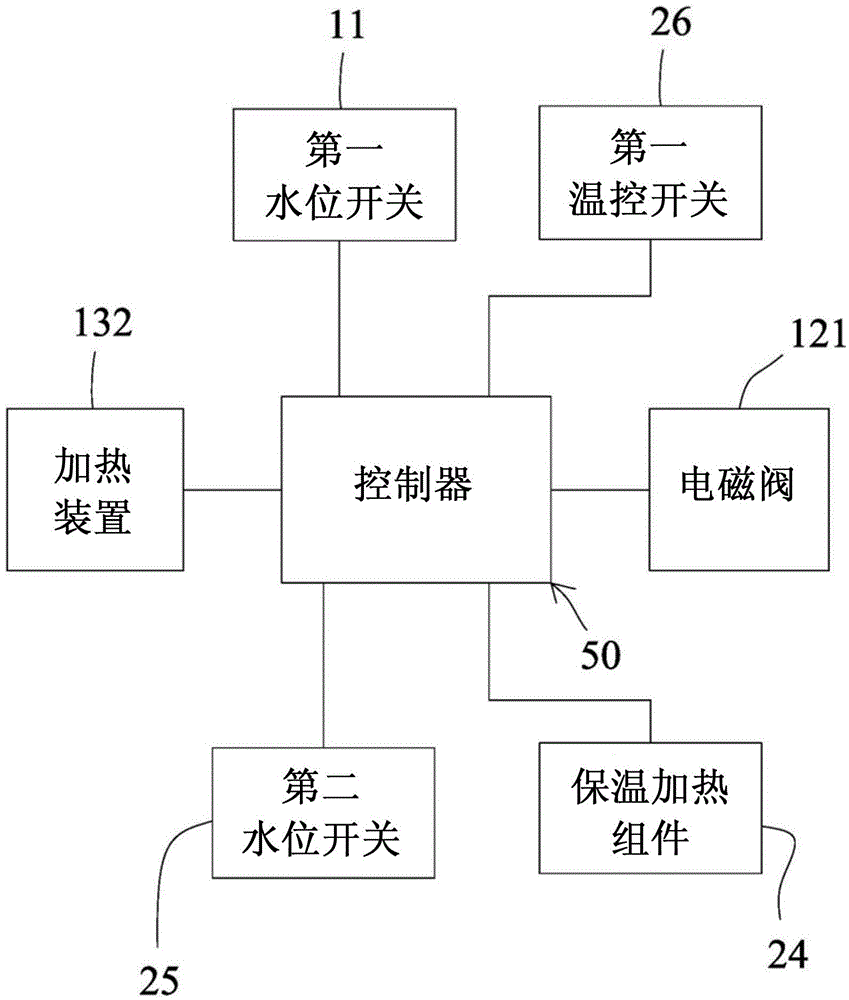

Drinking water system with automatic water adding function and safety control method thereof

The invention relates to a drinking water system with an automatic water adding function and a safety control method thereof. A water inlet pipeline and a drainage pipe are connected to one side of an unboiled water barrel, a heating pipeline and a condensation pipe are connected between the unboiled water barrel and a hot water barrel, and a plurality of sections of first water level switches and second water level switches for detecting the water level are arranged inside the unboiled water barrel and the hot water barrel, so that the heating pipeline is controlled to add boiled water into the hot water barrel automatically. When the second water level switches fail efficacy, the condensation pipe leads overflowing boiled water into the unboiled water barrel, for the reason that the first water level switches are provided with multiple security mechanisms such as a dry burning-resistant mechanism and a full water level emergency outage mechanism, when the first water level switches also fail efficacy, water in the unboiled water barrel can be led out by the drainage pipe due to overflowing, and accordingly the safety drinking water system with a non-pressure non-vapor service environment can be created. According to the invention, boiled water can be automatically added, the multiple security mechanisms such as the dry burning-resistant mechanism and the full water level emergency outage mechanism are achieved, and therefore the explosive danger of the drinking water system is avoided.

Owner:MAXTEC PLASTICS INC

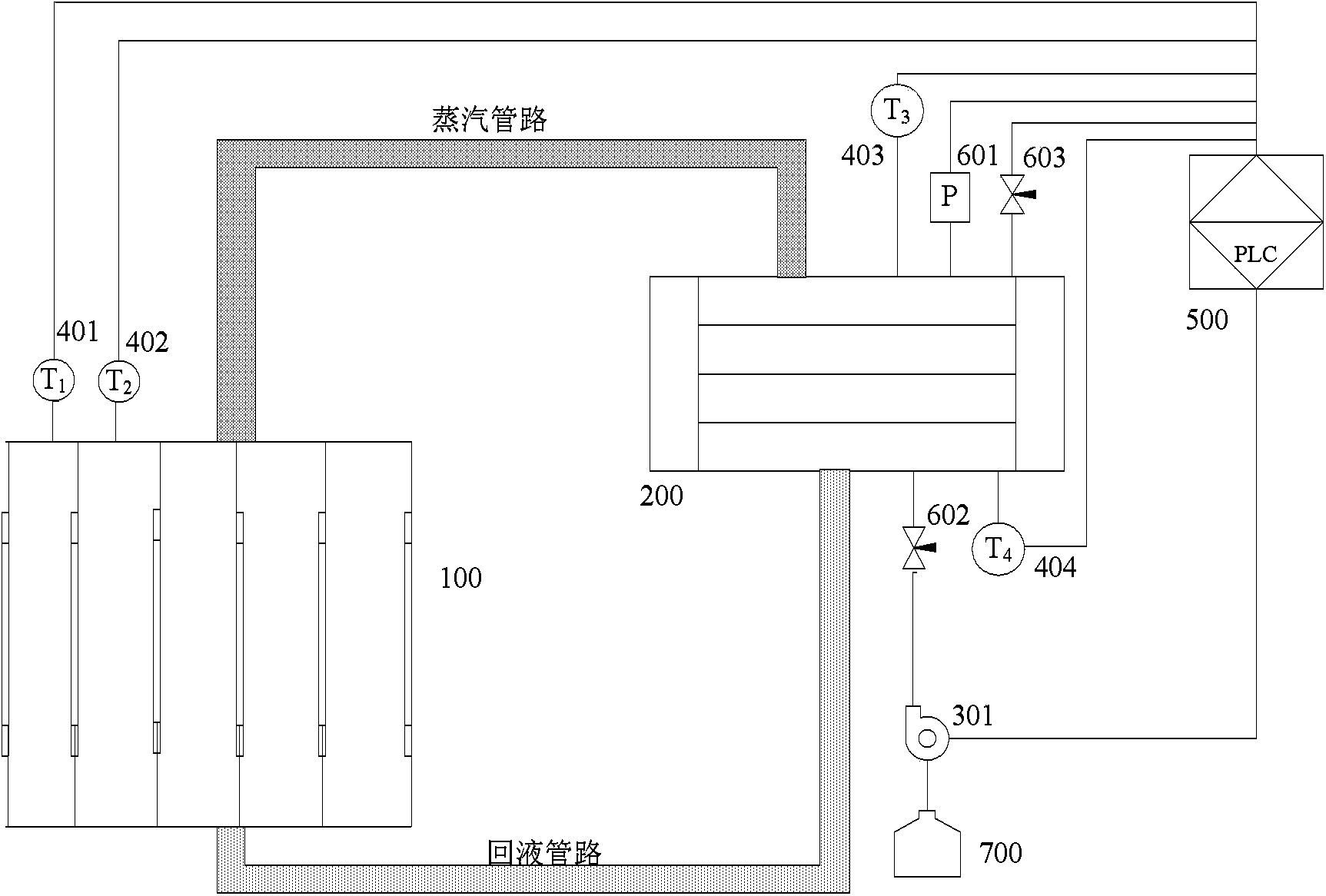

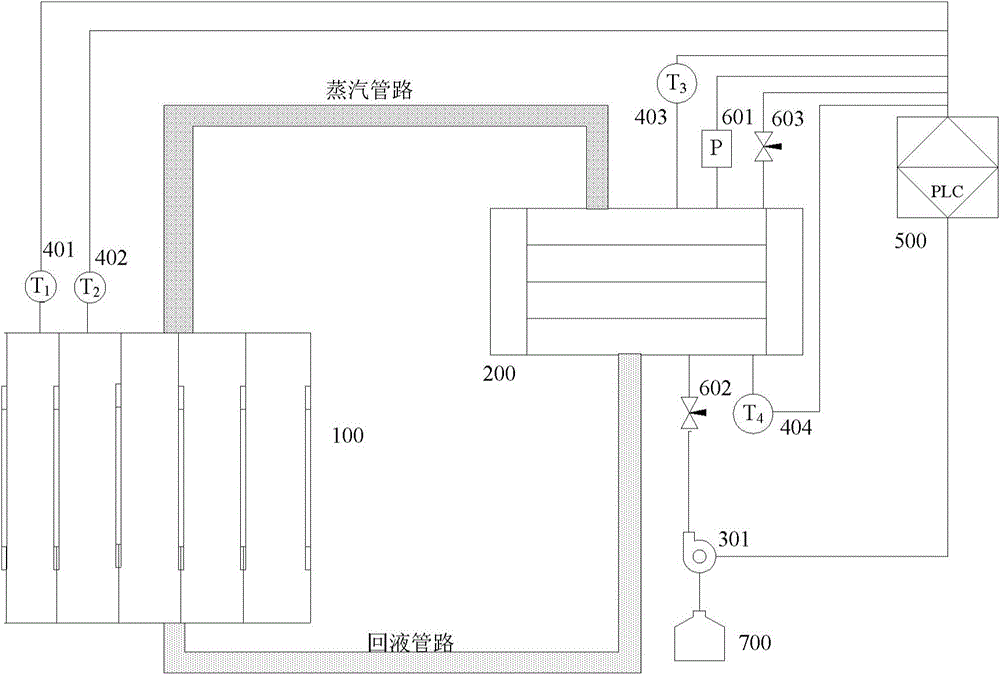

Automatic safe control device of industrial waste heat recovery system

ActiveCN103486898AAvoid the risk of burstingHigh pressureHeat exchange apparatusWorking fluidControl system

The invention provides an automatic safe control device of an industrial waste heat recovery system. The automatic safe control device is based on the industrial waste heat recovery system. Temperature sensors are mounted on a heat-pipe-type cooler and are used for measuring the temperature; the port of a condenser is provided with a temperature sensor for measuring the cooling amount of the entire system, and a pressure sensor is mounted on the condenser for measuring the pressure of working fluid inside the system; signals of the sensors are inputted into the control system, and safe and effective utilization of industrial waste can be realized by controlling the number of the working fluid inside the system.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Flushing device with pressure releasing function

The invention discloses a flushing device with a pressure releasing function. The flushing device comprises a tank body, a water inlet / outlet mechanism and a pressure mechanism, wherein the pressure mechanism comprises a piston component, an elastic part and a water injection switch, wherein the piston component partitions the tank body into an upper cavity and a lower cavity in a sealing manner; a pressure releasing switch is arranged in the piston component; and the pressure releasing switch is used for controlling unsealing and sealing between the upper cavity and the lower cavity. By adopting the technical scheme, the flushing device has the advantages that: if water feeding control does not work, continuous water feeding makes elastic potential energy of the elastic part increase continuously, and the pressure of the lower cavity is very high; a pressure releasing cavity and the pressure releasing switch are arranged in the piston component, and water flow enters the upper cavity through the pressure releasing cavity, so that the pressure of the lower cavity can be released, and the pressure of the upper cavity and the pressure of the lower cavity can be effectively balanced; therefore, a danger that the tank body bursts can be prevented.

Owner:XIAMEN AXENT

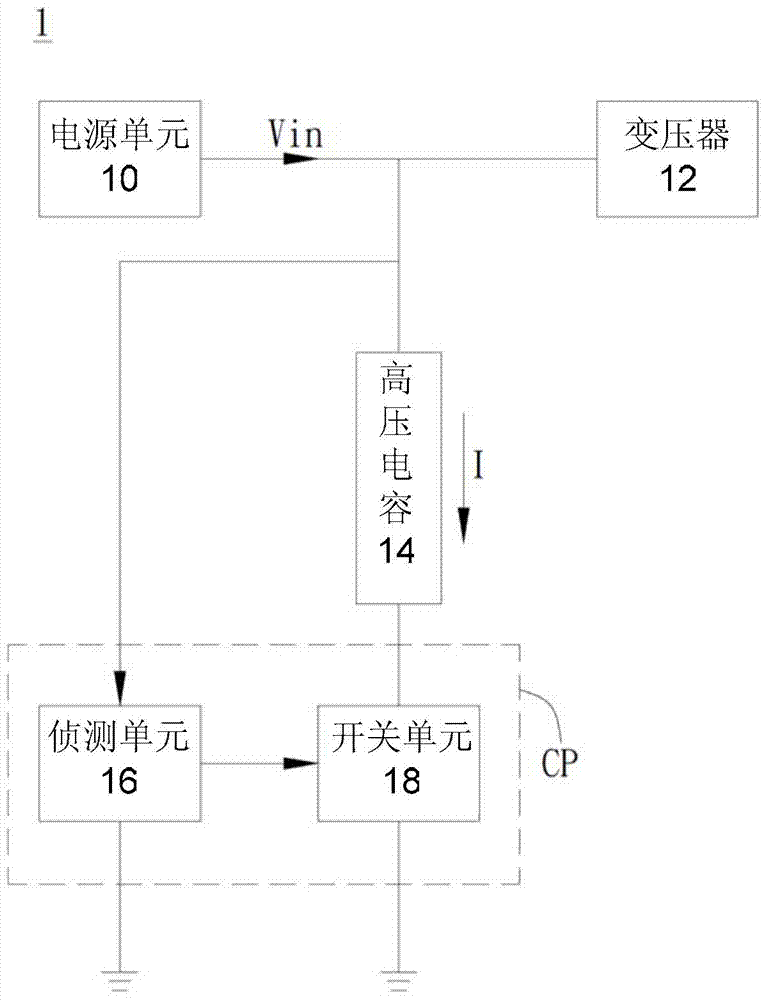

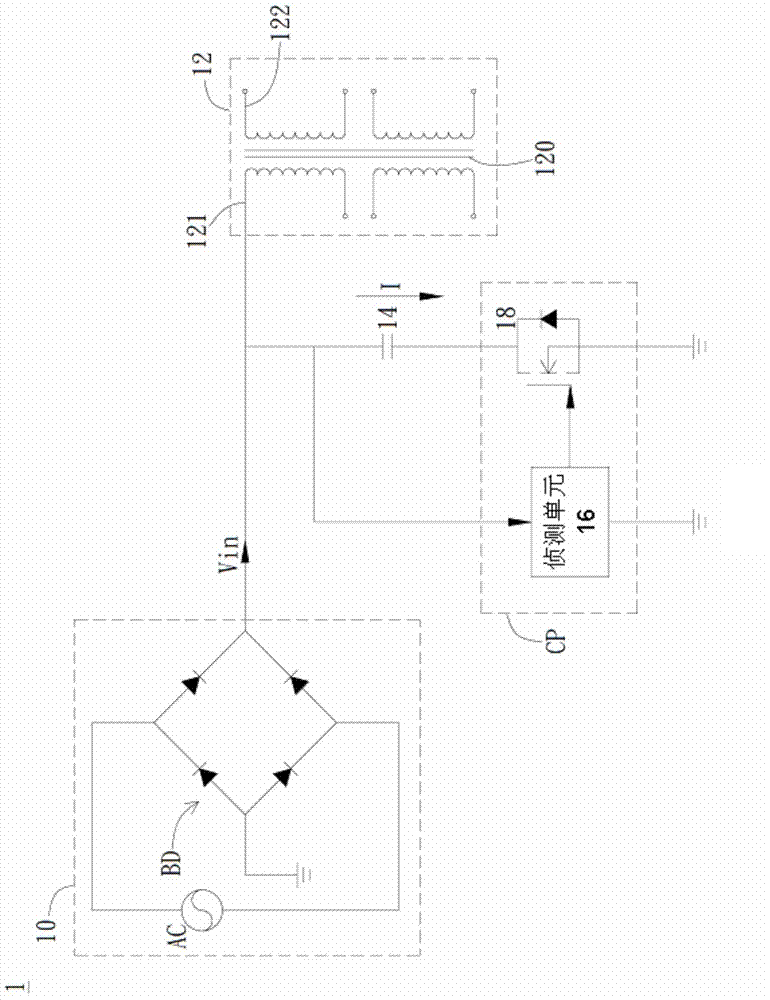

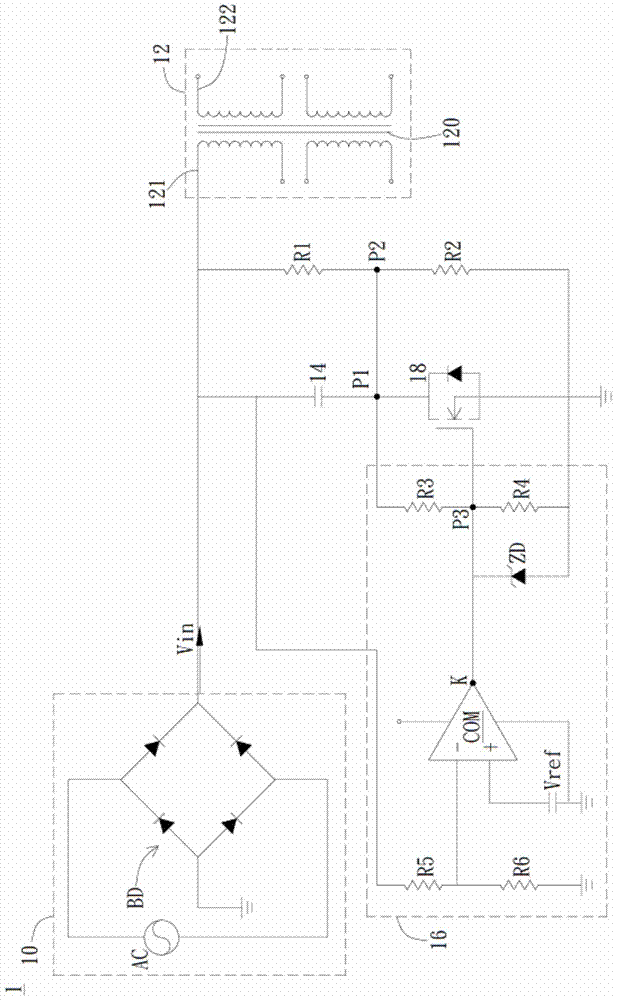

Power adapter and capacitor protection device thereof

ActiveCN103795039AAvoid the risk of burstingNo damageAc-dc conversion without reversalEmergency protective circuit arrangementsCapacitanceControl signal

The invention discloses a power adapter which comprises a capacitor and a capacitor protection device. The capacitor protection device comprises a switching unit and a detection unit. The switching unit is connected between one end of the capacitor and a grounding end in a coupled mode and the detection unit is respectively connected with the other end of the capacitor and the switching unit in a coupled mode and used for detecting the input voltage of the other end of the capacitor and judging whether the input voltage is larger than a critical voltage value or not. If yes, the detection unit outputs a control signal to the switching unit to turn off the switching unit, and therefore the voltage drop borne by the capacitor is smaller than the input voltage.

Owner:QISDA SUZHOU +1

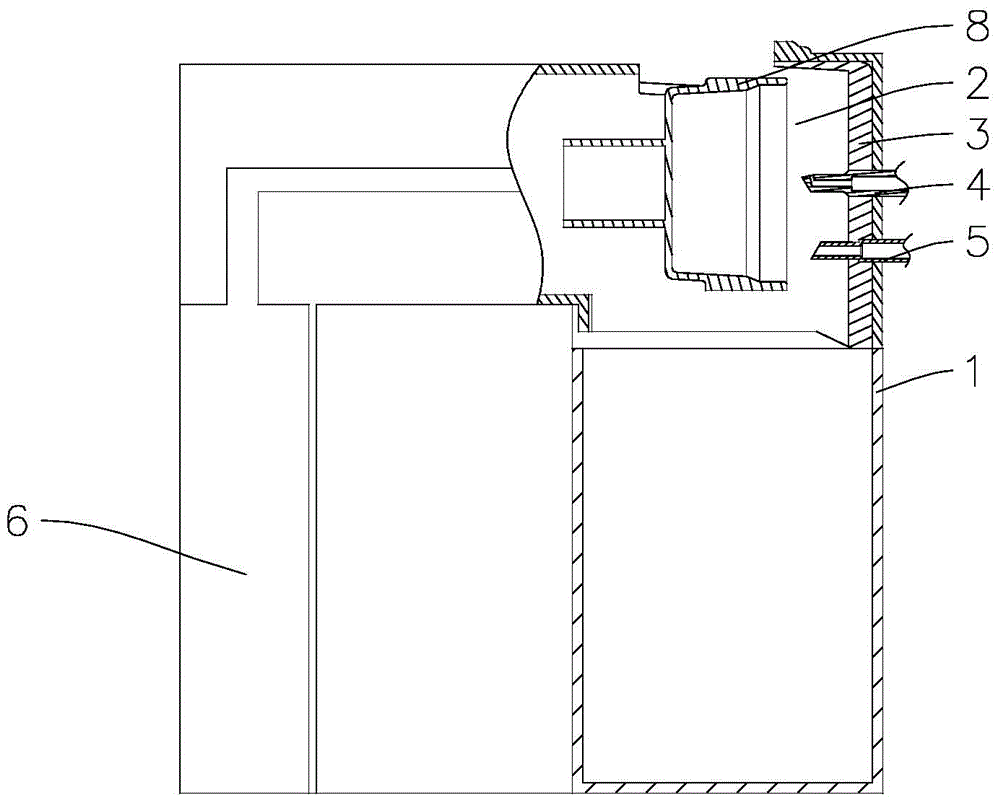

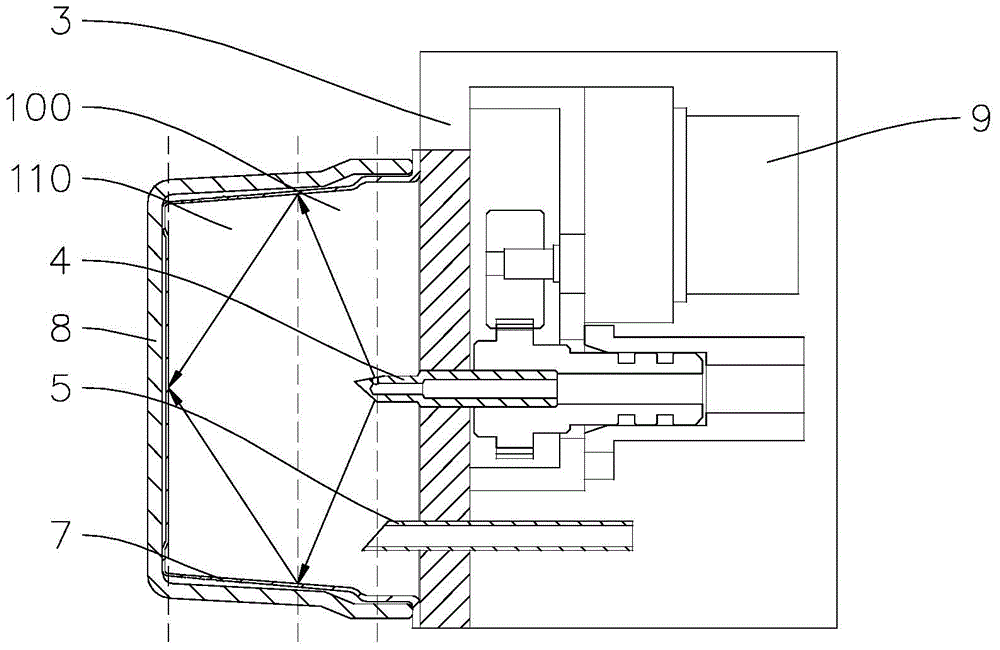

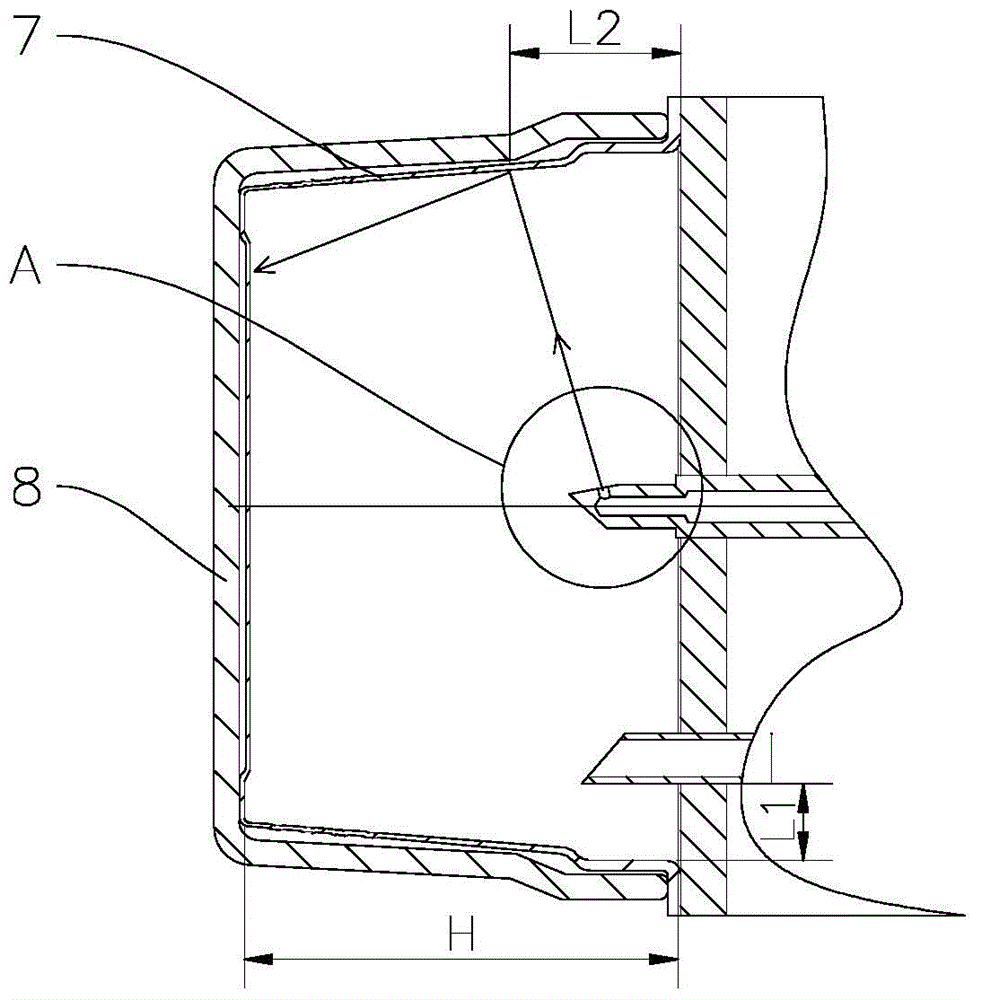

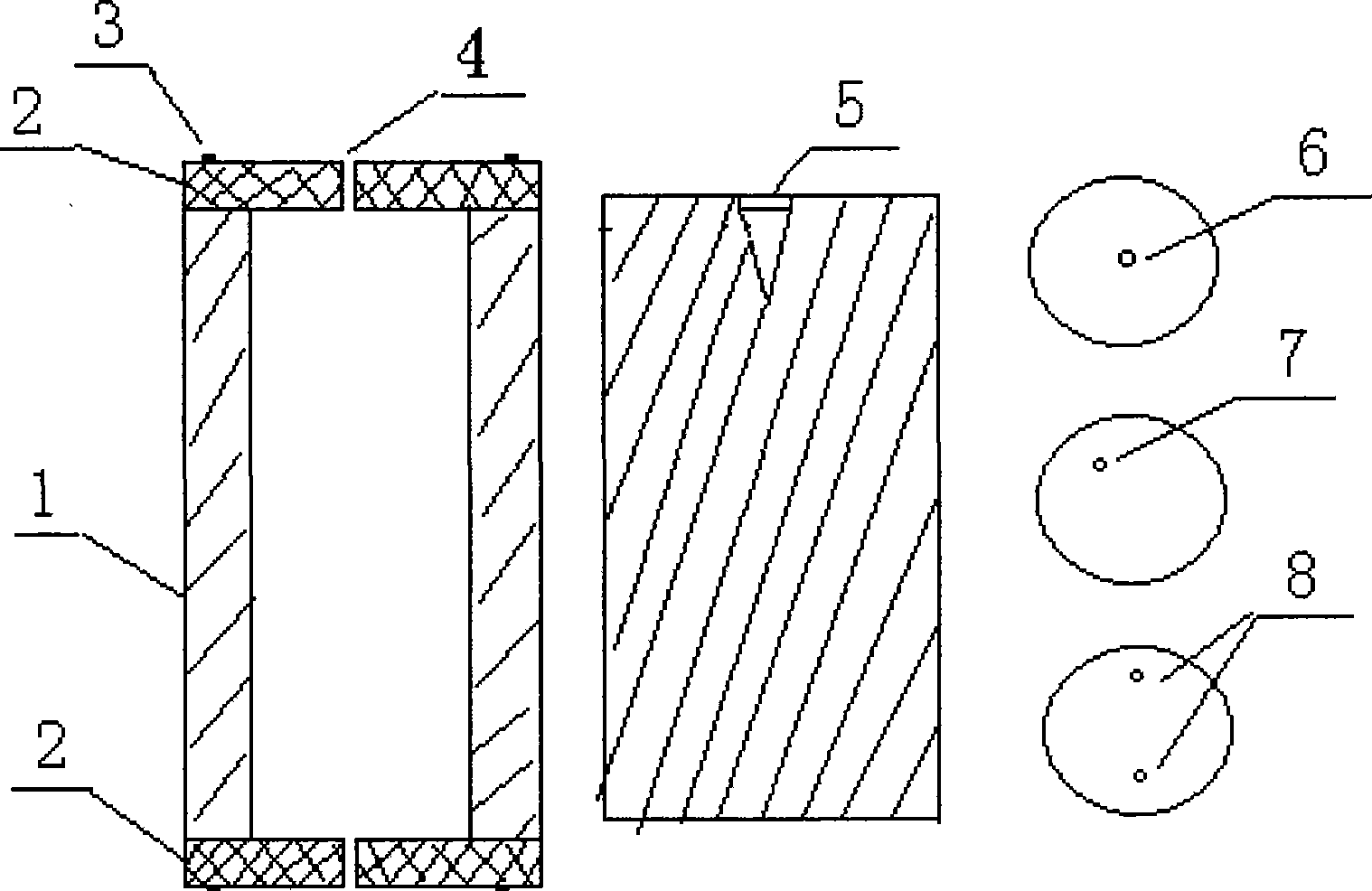

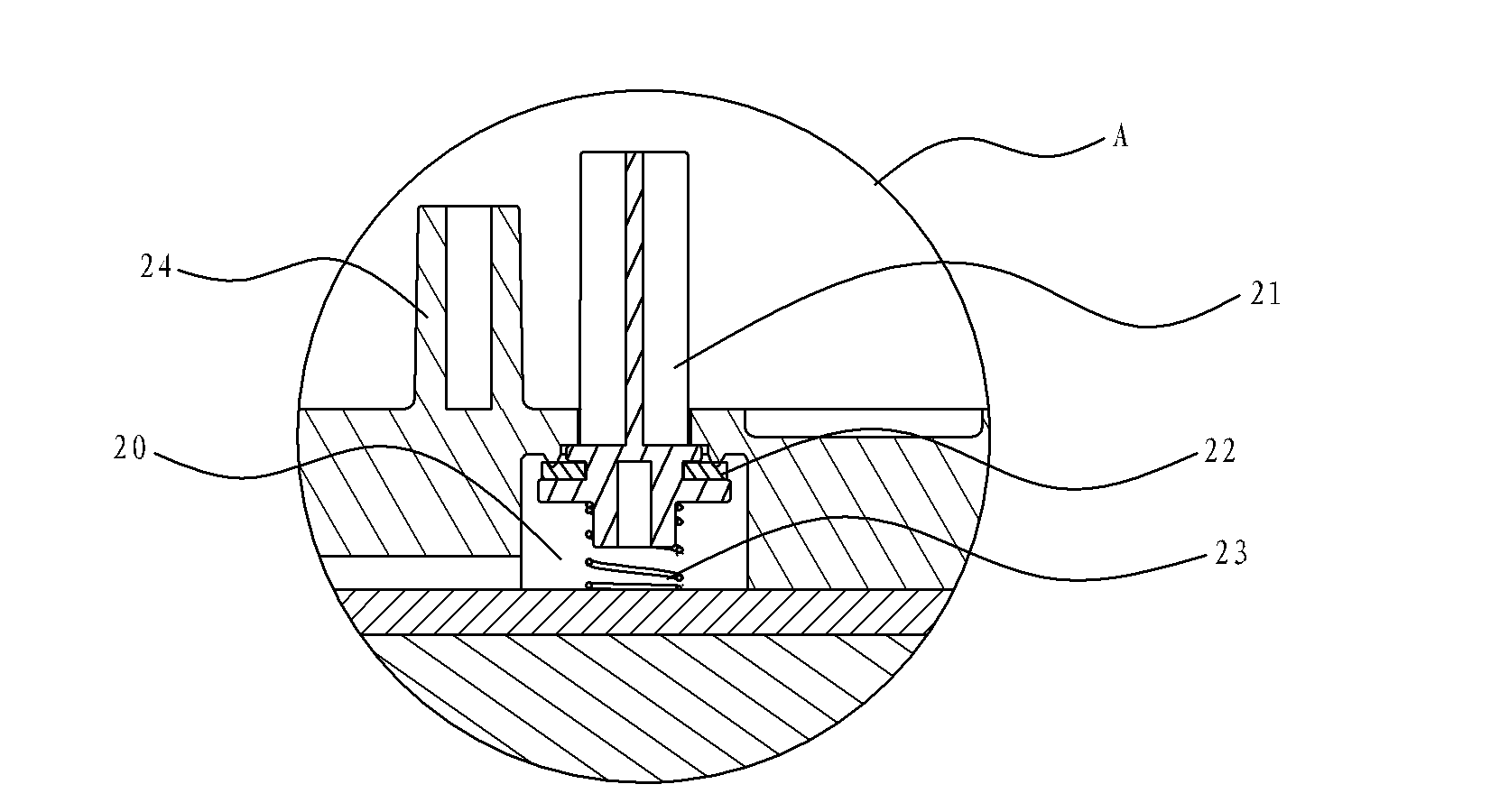

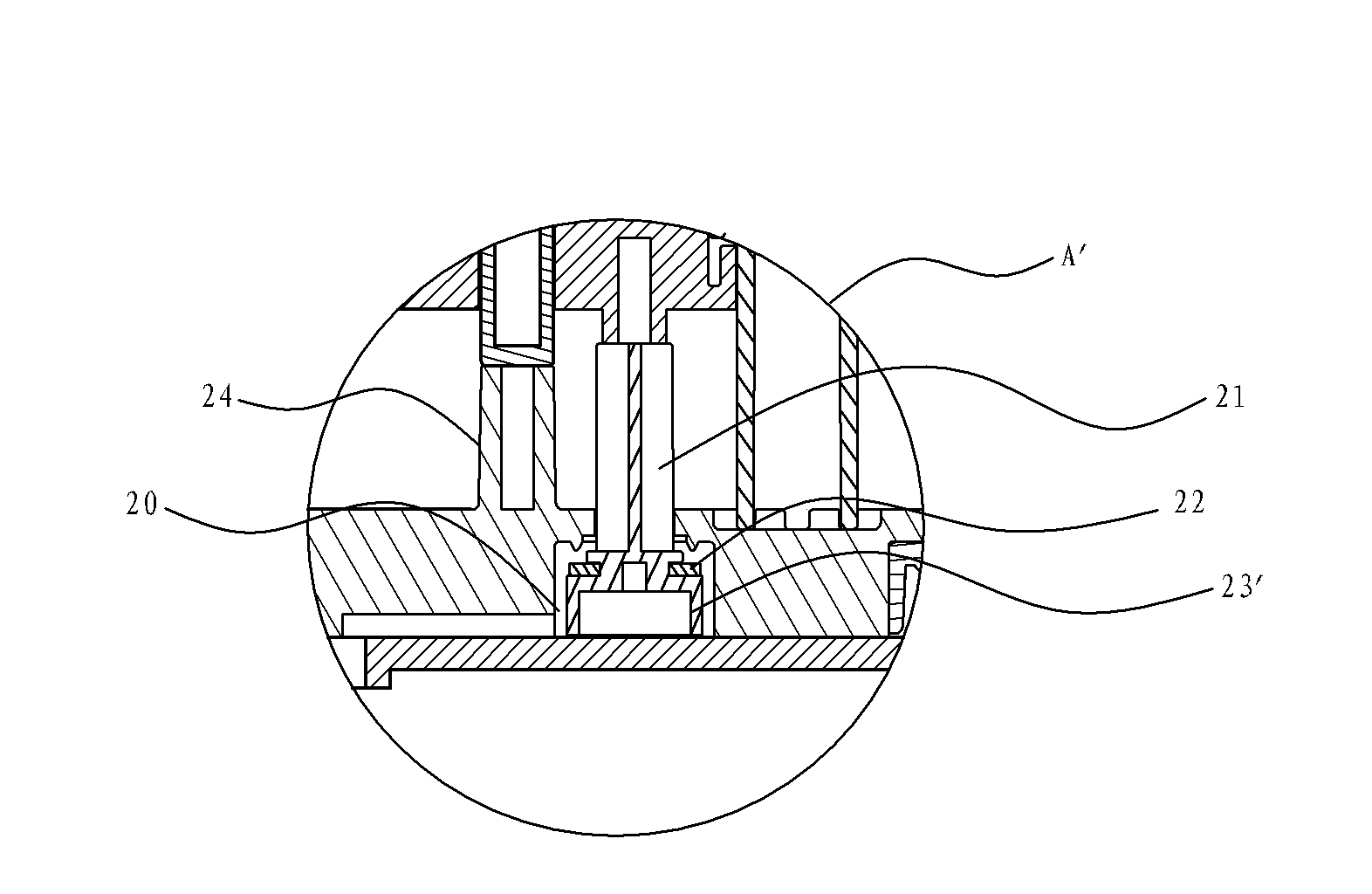

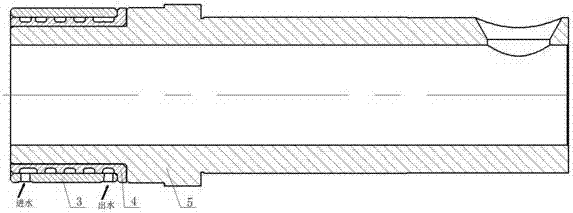

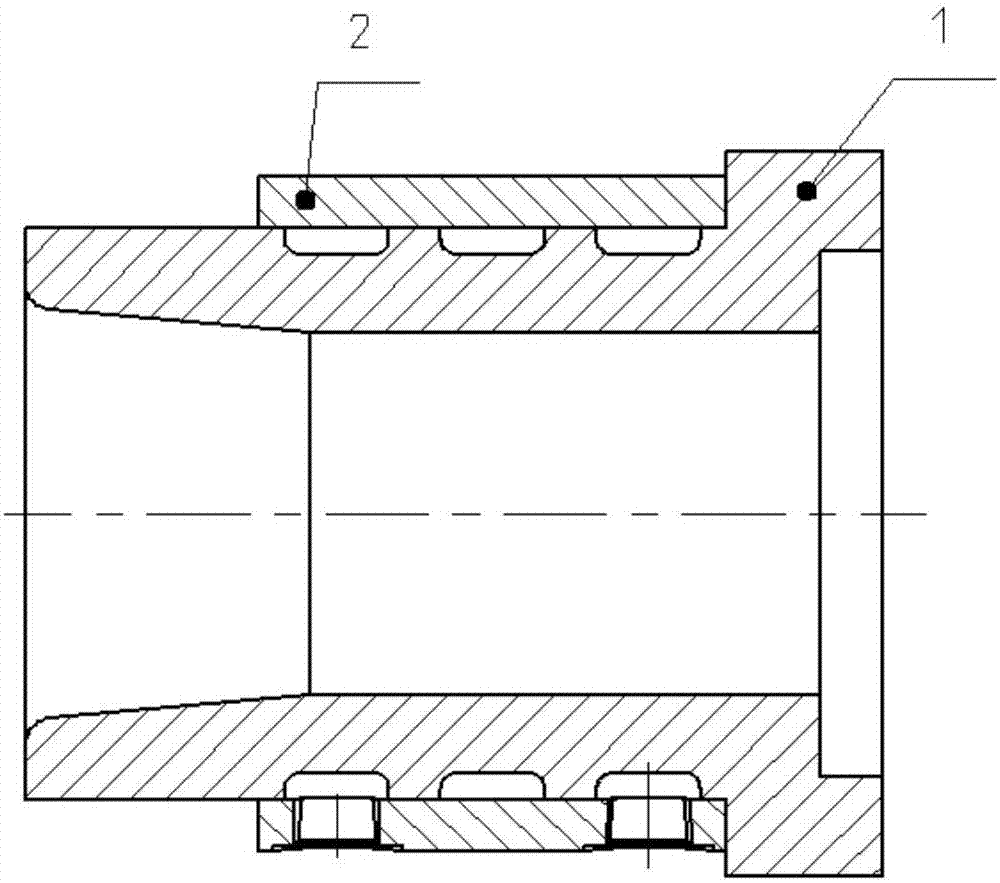

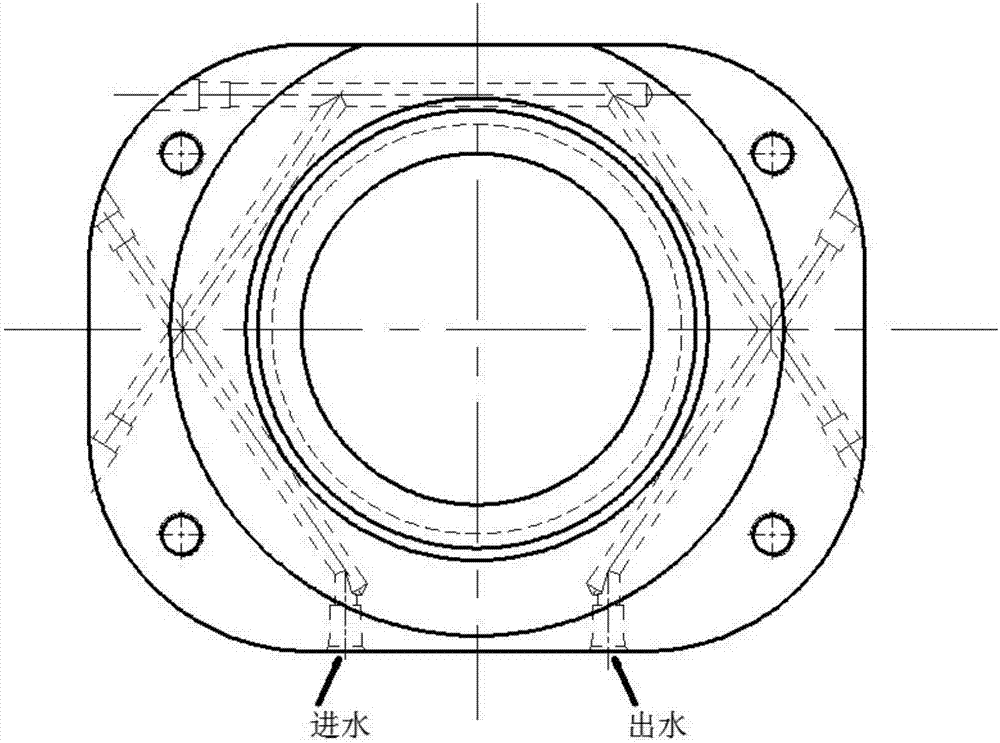

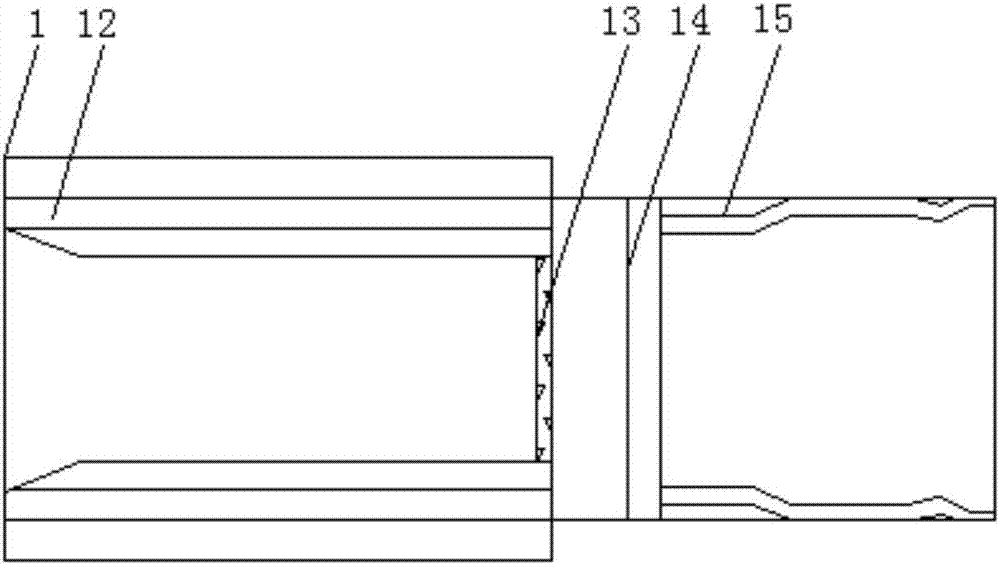

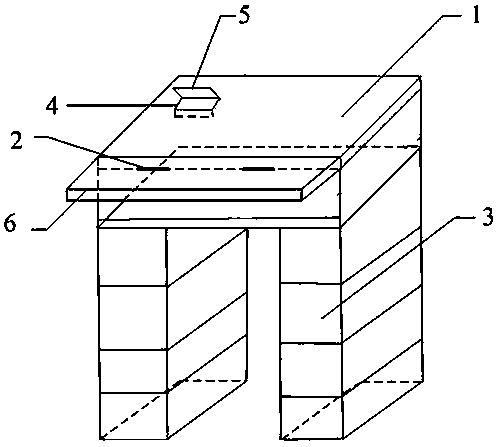

Integrated pressure casting die sprue bush

The invention discloses an integrated pressure casting die sprue bush. The integrated pressure casting die sprue bush comprises a sprue bush body and a connected material trough connected with the sprue bush, wherein the sprue bush body is of a hollow square integral structure, one end of the sprue bush body is connected with a pressure casting machine, and the other end of the sprue bush body is matched with a die pressure chamber; a plurality of cooling water channels are arranged at the front end of the sprue bush body, communicate mutually and used for introducing a coolant, so that a sprue of the die is directly cooled; the connected material trough is of a hollow square integral structure; and one end of the connected material trough comprises a cooling sleeve outer ring (3), a cooling sleeve inner ring (4) and a chute (5). The sprue bush is of the integral square structure, the multiple cooling water channels are arranged in the positions, quite close to a material cake, above the sprue, the cooling effect on the end of the sprue is remarkably improved, the bursting danger caused by poor cooling of the material cake after die opening is completely avoided, and the problems of bursting and water leaking on the matching surfaces of traditional sprues do not occur in the using process.

Owner:广东鸿图武汉压铸有限公司

Blast furnace atomization tapping technology

InactiveCN101250600AImprove cooling effectReduce wearBlast furnace componentsBlast furnace detailsInlet pressureHigh pressure water

The invention discloses a blast furnace atomization tap hole technology, which is characterized in that the water inlet pressure is 0.05-1 MPa, water yield is 1-10 L / min, water outlet pressure is 1-6MPa, air pressure is 0.4-0.6MPa, air quantity is 4-6 cubic meter / min, a water inlet pipe and a water outlet pipe are stainless steel seamless pipes whose outer diameter is 22 mm, and wall thickness is 3mm. The blast furnace atomization tap hole technology of the invention atomizes high pressure water and high pressure air under high pressure to form high pressure atomized water, directly sprays water-stem through a drill rod and a drill head of a blast furnace tap hole machine, guarantees to continuously give excellent cooling for the drill rod and the drill head in the drilling process of the tap hole machine, reduces the abrasion of the drill rod and the drill head, and decreases the consumption of the drill rod and the drill head. Water-stem which is about to be drilled is cooled down through directly spraying high pressure atomizing water on the water-stem, water-stem with high temperature is burst, which is beneficial for the drilling of the drill head, can guarantees to open the tap hole on time (usually within three minutes), prevents the stewing phenomenon, thereby not only effectively preventing the danger of the burst generation of tap hole, but also preventing iron water from reversely flowing, and guaranteeing the safety and the real-time of the blast furnace tap water.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

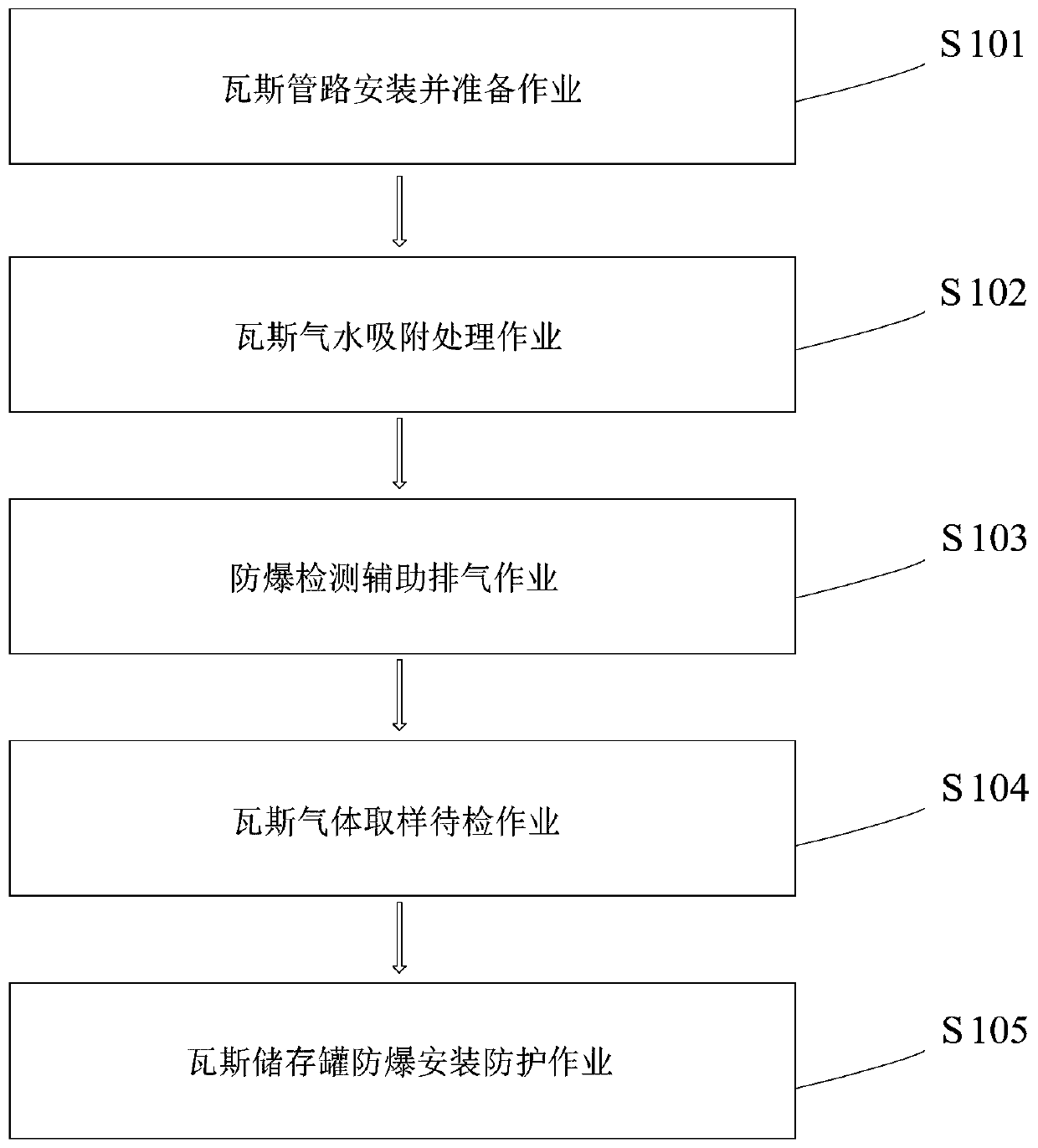

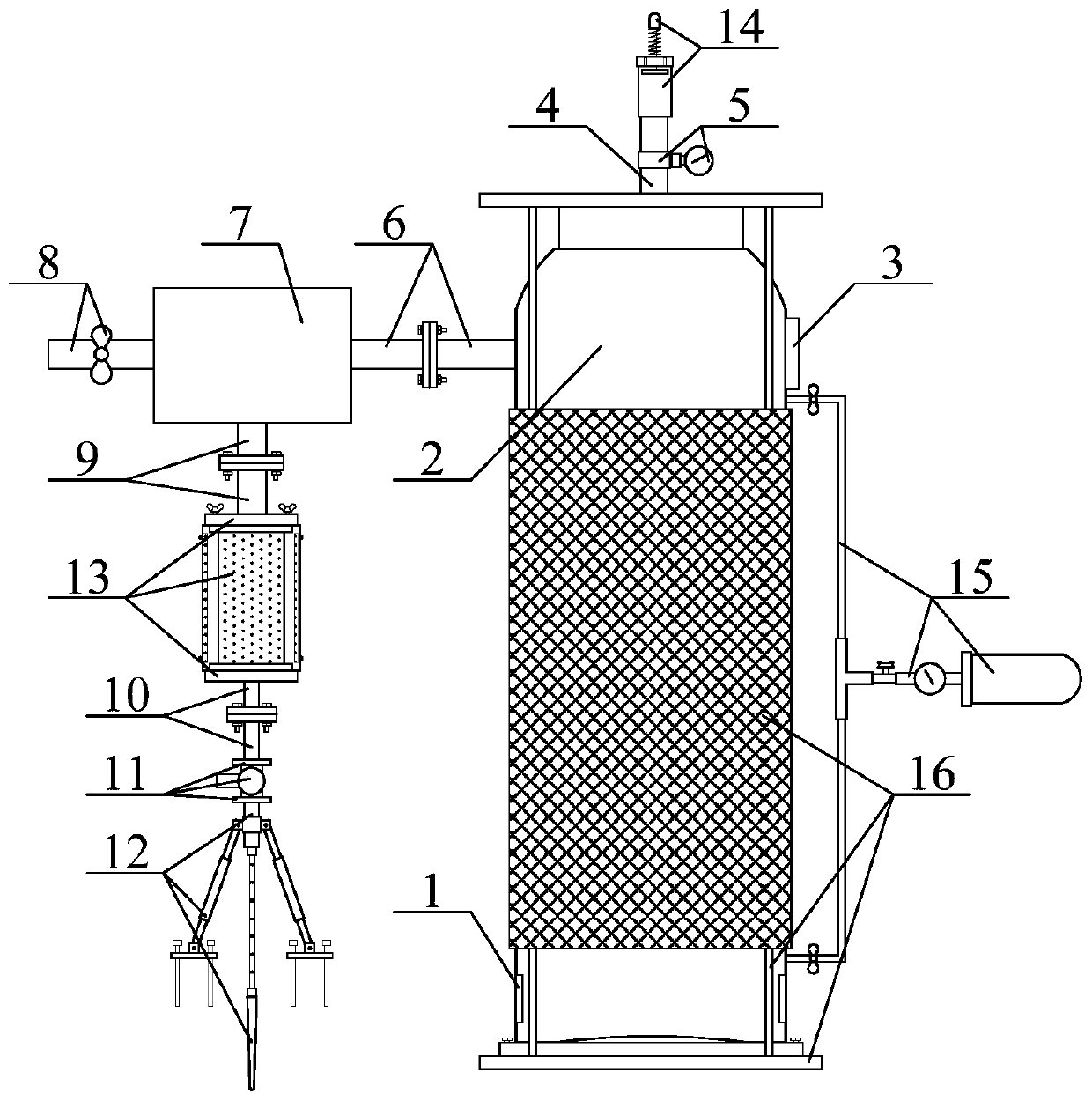

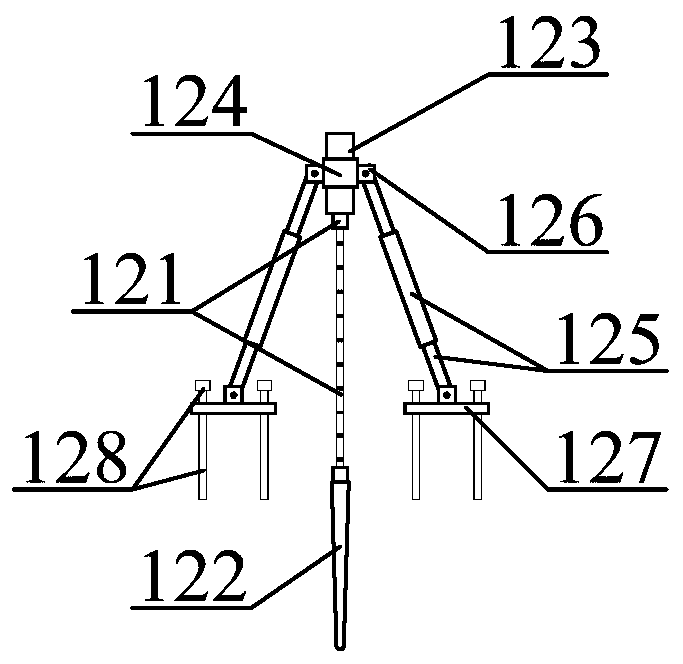

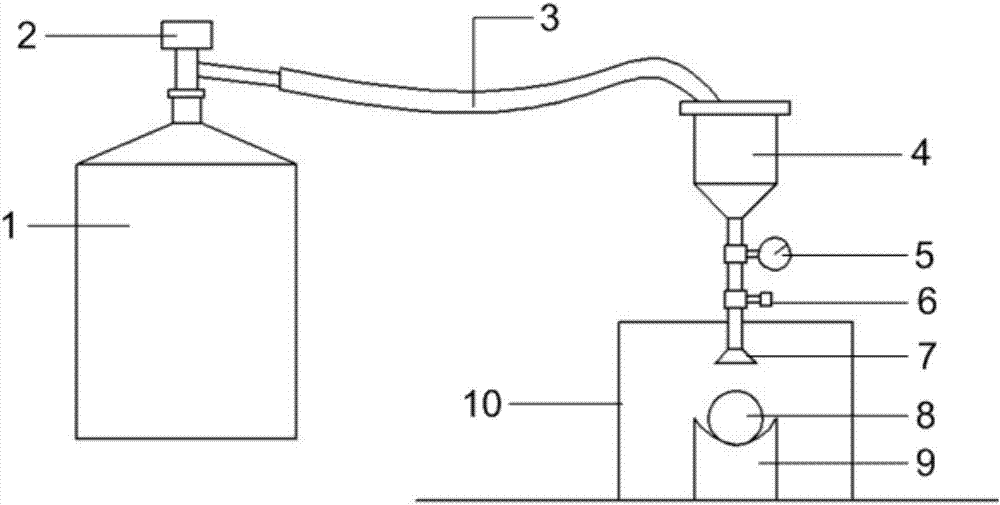

Gas pressure measuring device with high safety factor and using method of gas pressure measuring device

InactiveCN110566185AImprove support stabilityGood for adsorption and retentionSurveyFluid removalData displayProduct gas

The invention provides a gas pressure measuring device with high safety factor. The gas pressure measuring device comprises a gas pressure measuring sensor, a gas storage tank, a measuring data display screen, an exhaust pipe, a gas-pressure meter, a first flanged connecting pipeline, a gas-water separator, a valved drainage pipe, a second flanged connecting pipeline, a third flanged connecting pipeline, a suction pump, an adjustable fixed installation gas pipeline supporting frame, a detachable clearing core structure capable of adsorbing impurities, an explosion-proof auxiliary gas dischargestructure, a gas sampling to-be-inspected bottle structure capable of taking and putting and an explosion-proof auxiliary protective barrel structure. According to the gas pressure measuring device,a metal soft guide pipe, a cone-shaped suction pipe and an eduction pipe are arranged, self bending is advantageously adjusted according to the bending degree of a drilled hole, gas water can be conveniently sucked out, and the smooth progress of the gas pressure measurement work is ensured.

Owner:NORTH CHINA INST OF SCI & TECH

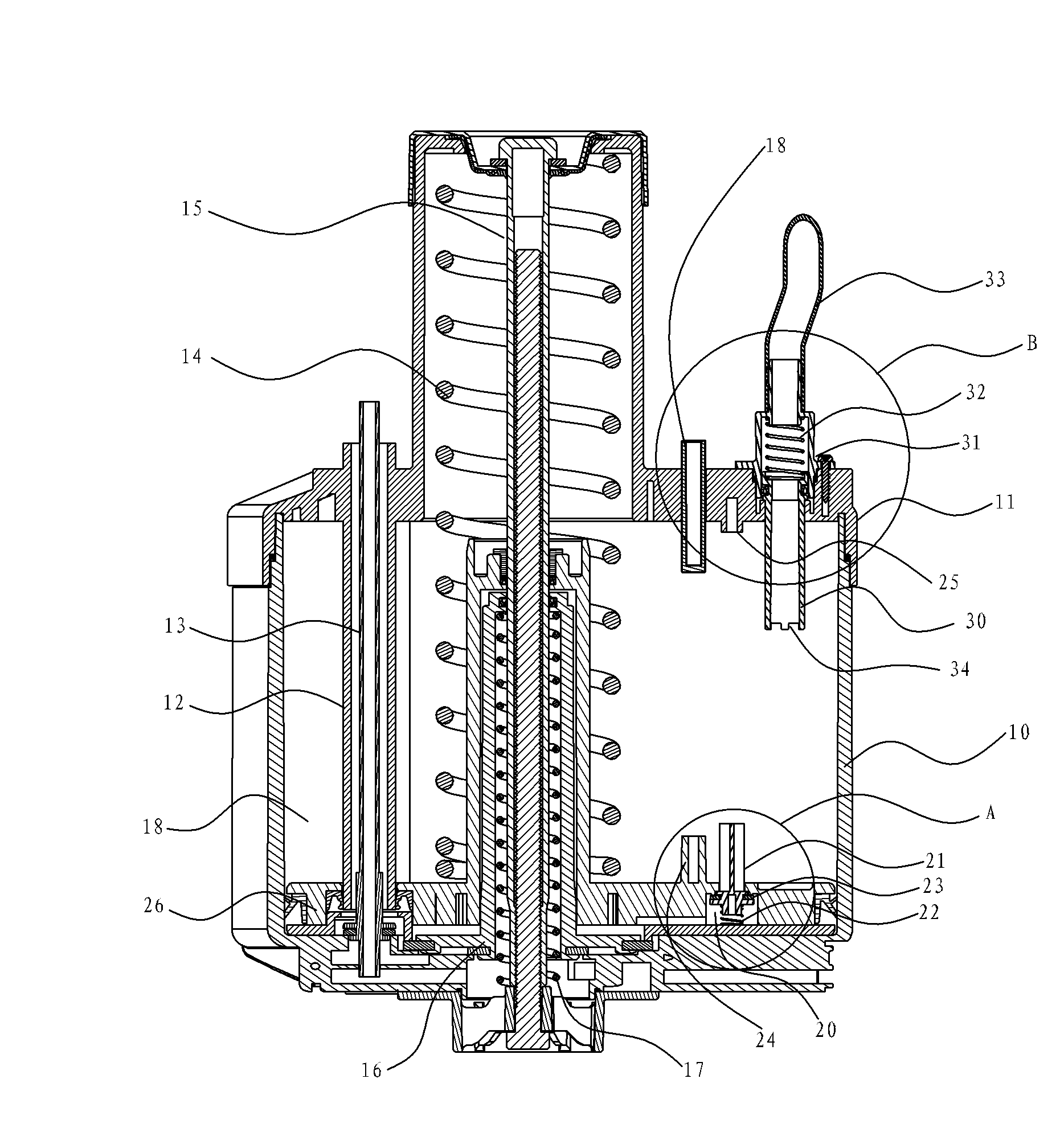

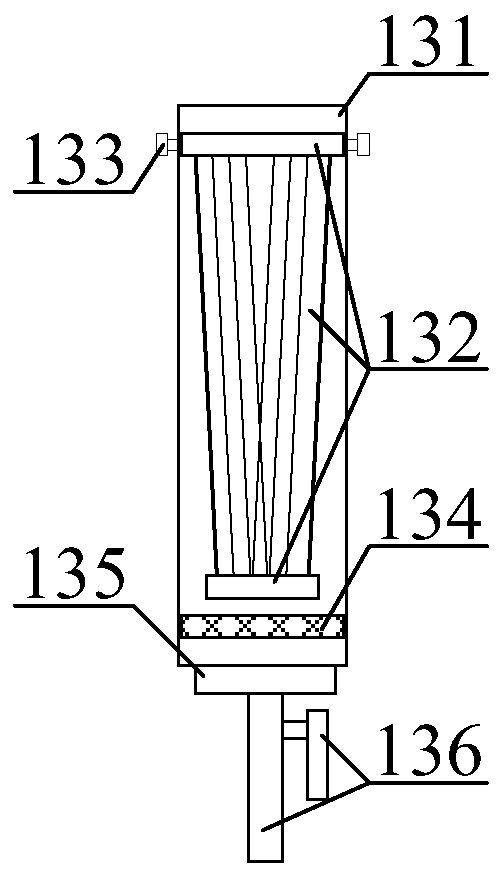

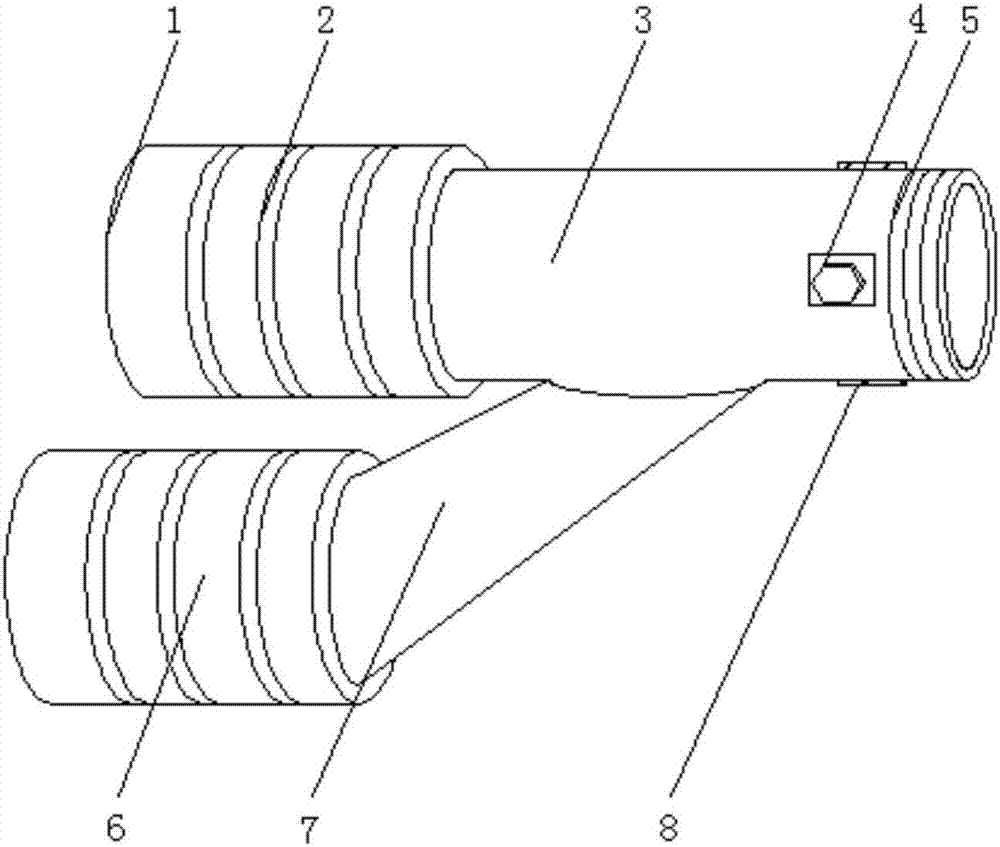

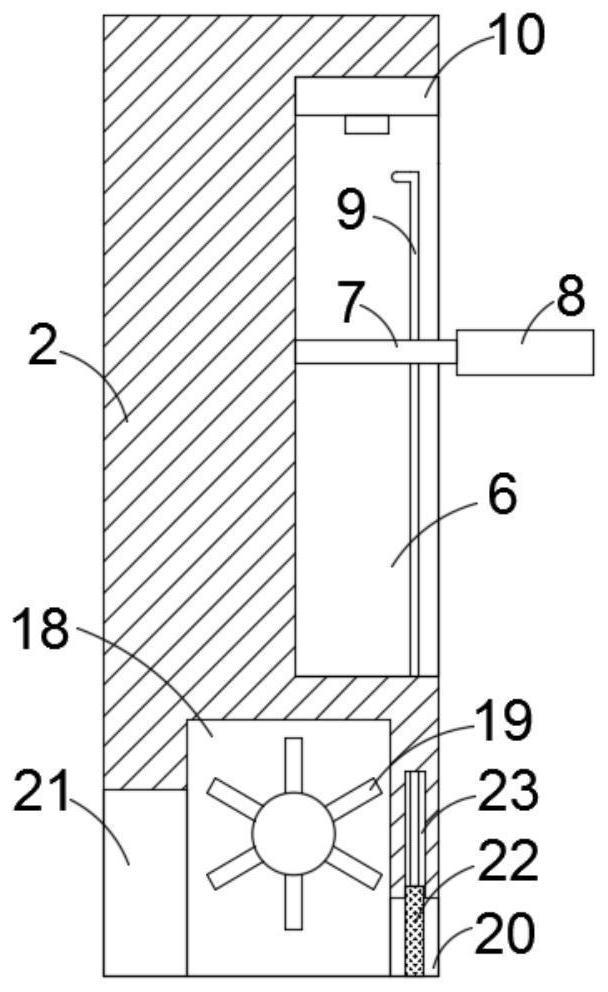

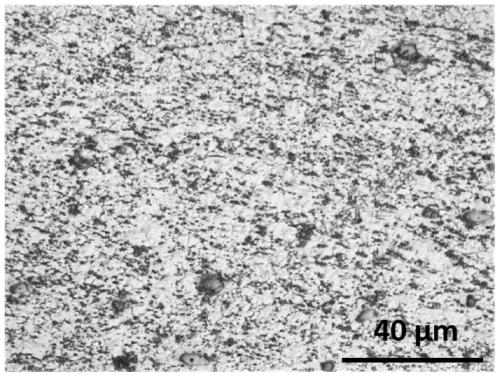

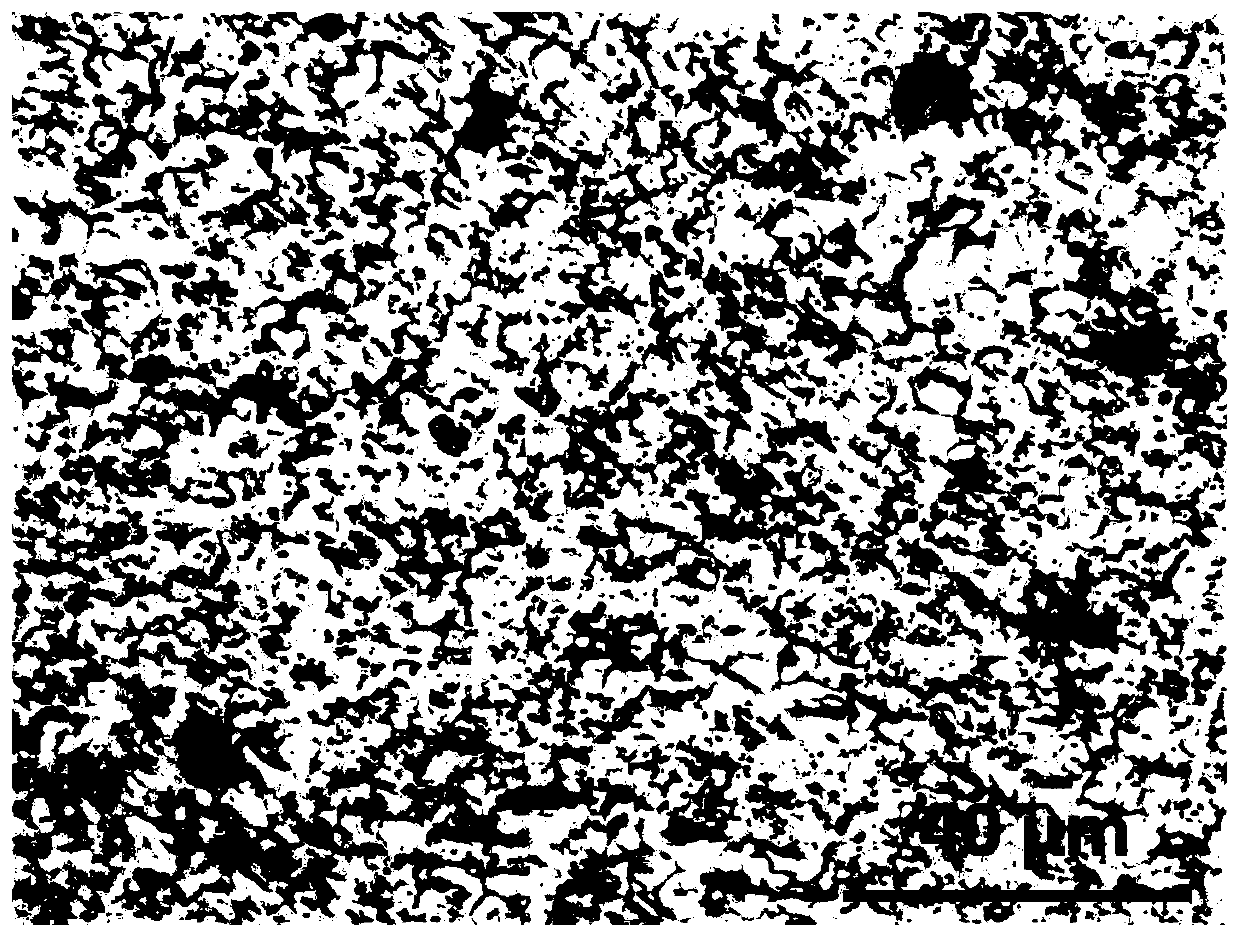

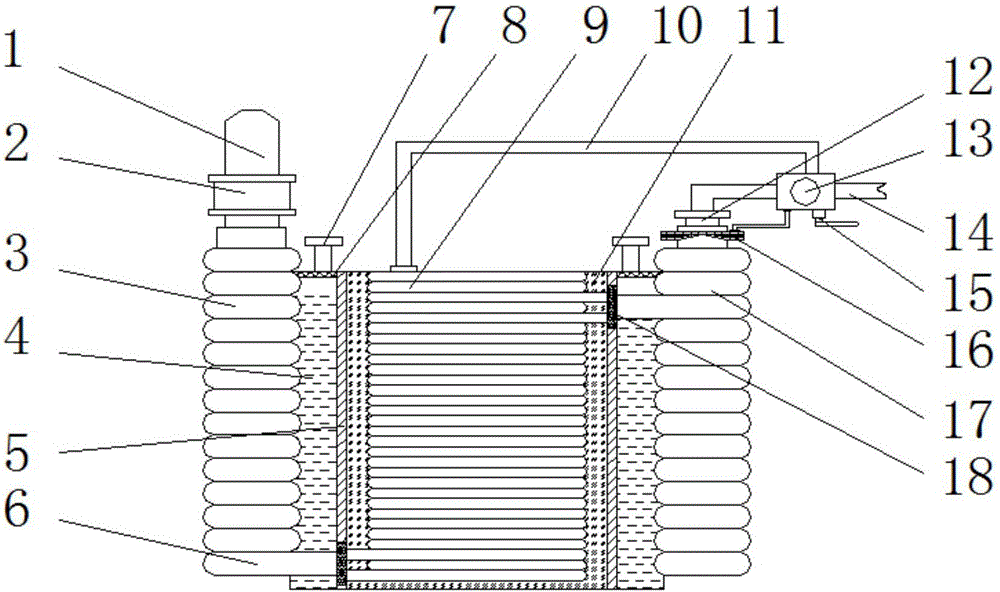

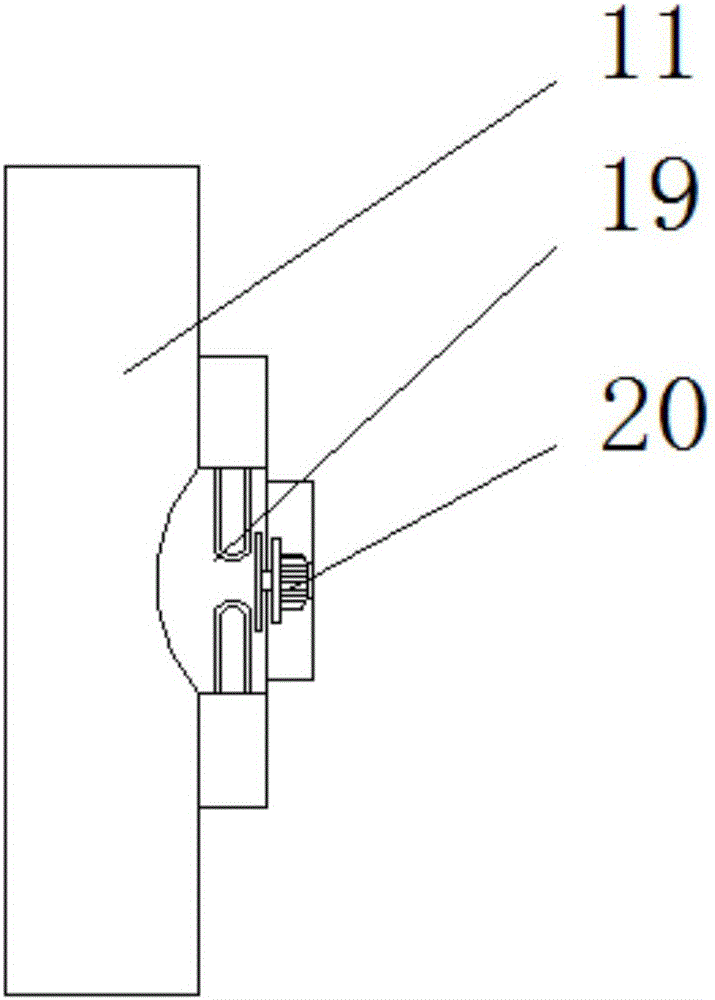

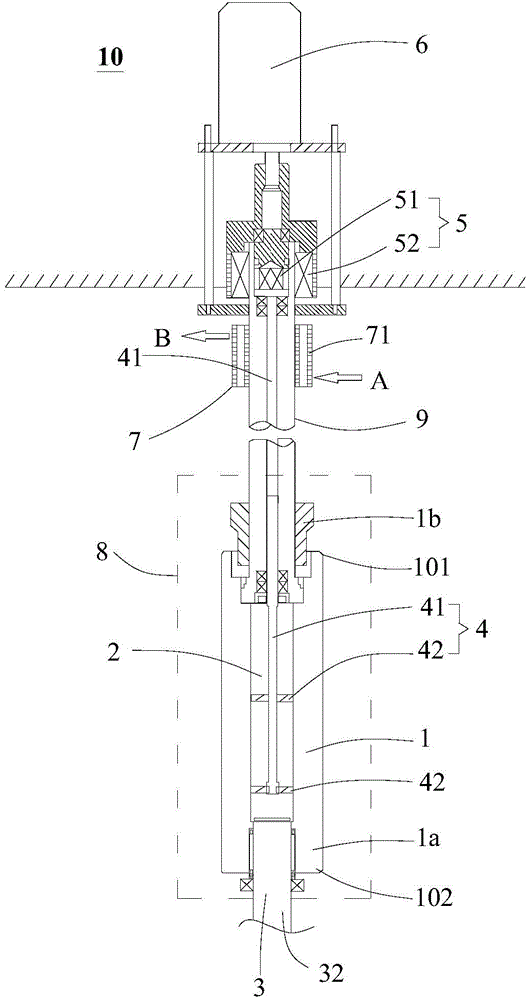

Method for refining microstructure of hot-extruded magnesium alloy

ActiveCN107299304AImprove mechanical propertiesAvoid the risk of burstingSpray nozzleLiquid nitrogen

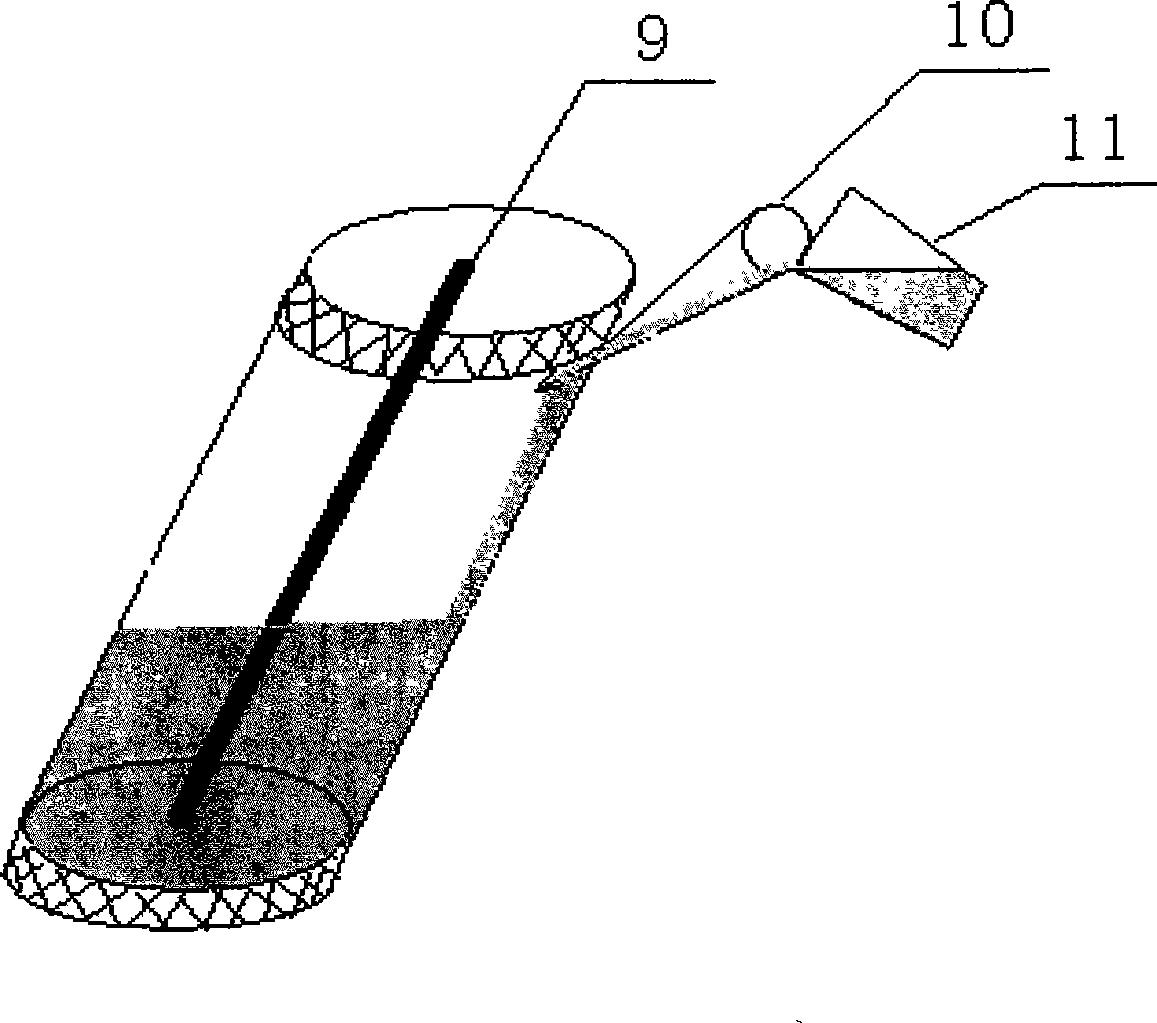

The invention provides a method for refining a structure of a hot-extruded magnesium alloy. The method comprises the step of applying liquid nitrogen to the hot-extruded magnesium alloy by adopting a cooling device so as to cool the hot-extruded magnesium alloy. The cooling device comprises a bracket (10), a liquid nitrogen storage tank (4), a spray nozzle (7) and a valve (6), wherein the bracket (10) is arranged outside a workpiece (8); the liquid nitrogen storage tank (4) is fixed on the bracket (10) and is used for storing liquid nitrogen; the bracket (10) is of an inverted-U-shaped baffle covering the outside of the workpiece (8), and the top face and two side faces of the inverted-U-shaped baffle have baffle structures; the spray nozzle (7) is arranged at an outlet of the liquid nitrogen storage tank (4) and is used for spraying the liquid nitrogen to the workpiece (8); the valve (6) is arranged between the liquid nitrogen storage tank (4) and the spray nozzle (7); the flow rate of the liquid nitrogen during cooling is 0.6m<3> / h to 1.2m<3> / h. According to the method, by adopting the specific cooling device and controlling the flow rate of the liquid nitrogen, the risks of liquid nitrogen splashing and sectional bar bursting are avoided, and the structure of the hot-extruded magnesium alloy is obviously refined.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

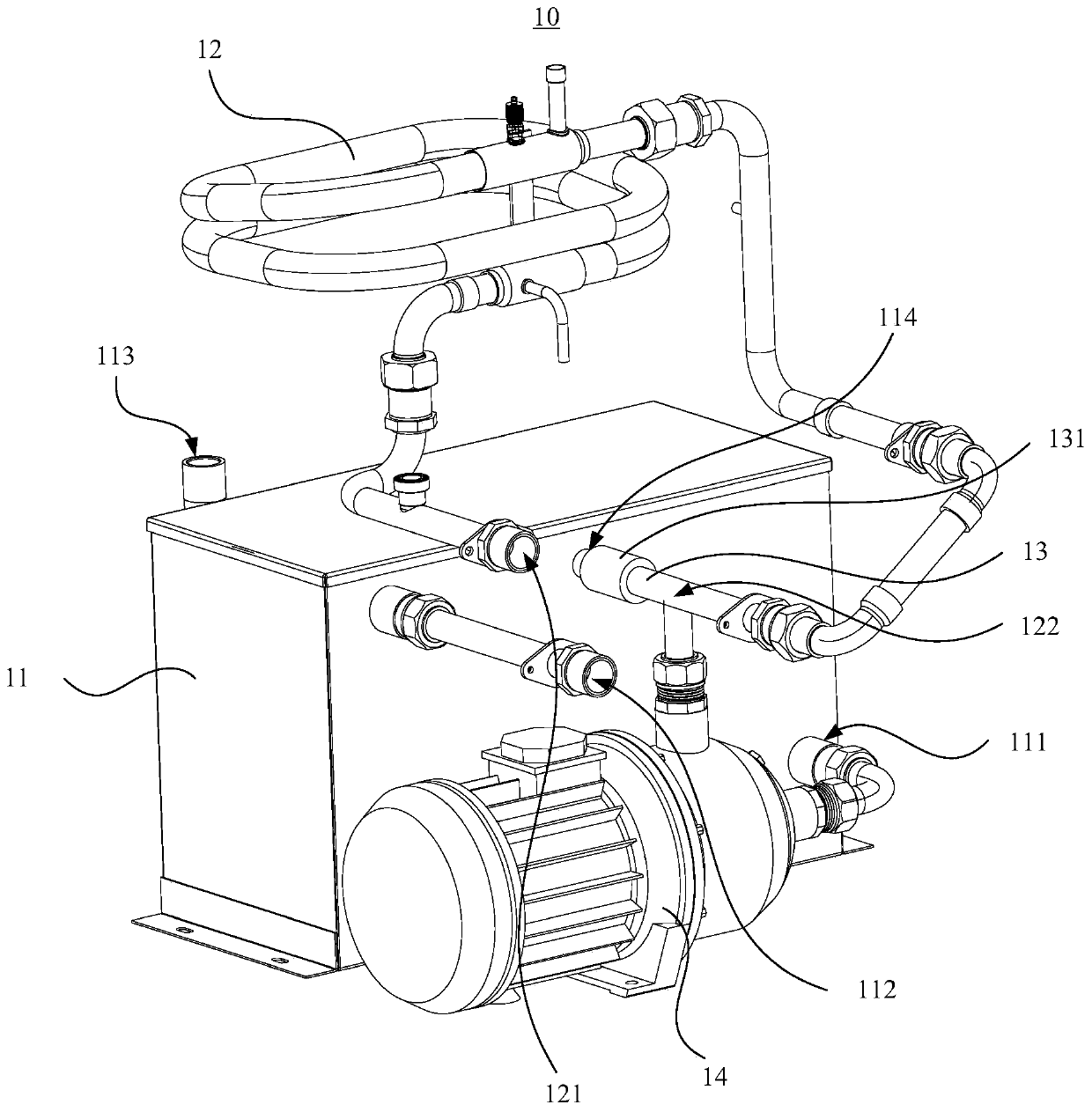

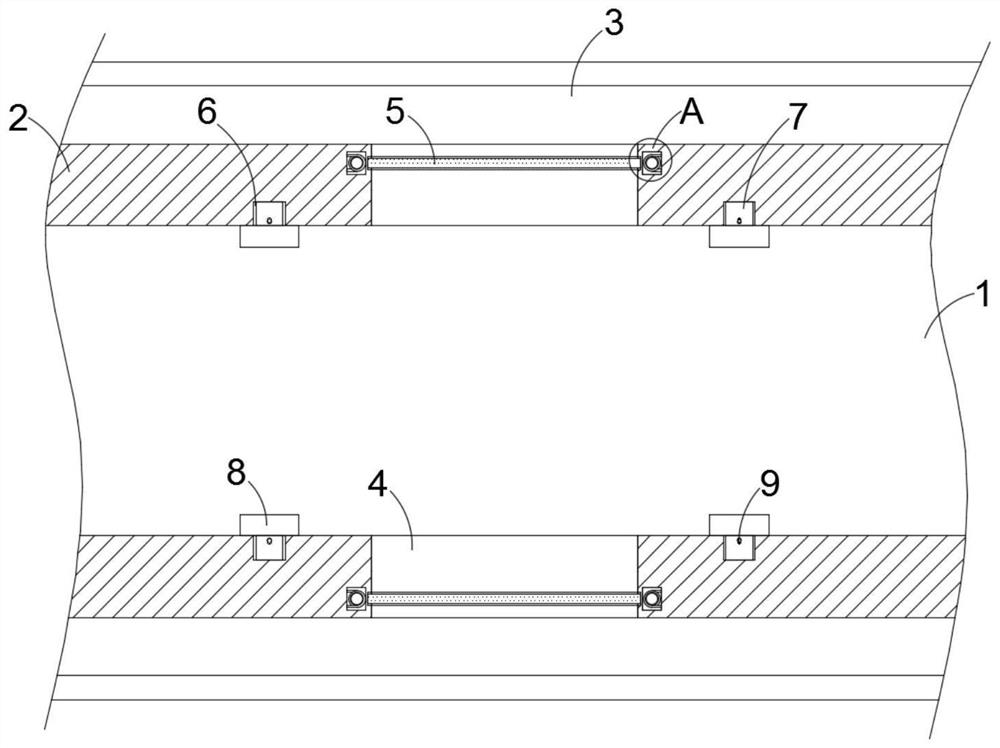

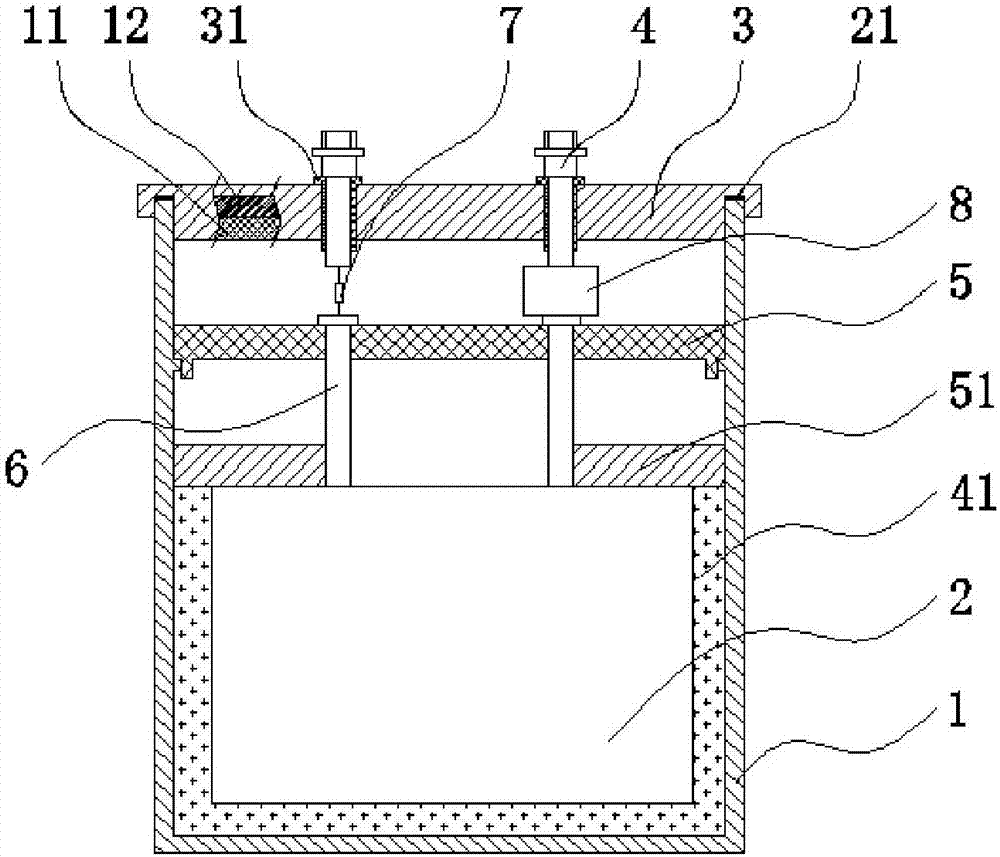

Machine tool cooler device and numerically controlled machine tool system

PendingCN110170881AAvoid the situation of water injection burstingAvoid the risk of burstingMaintainance and safety accessoriesNumerical controlEngineering

The invention relates to a machine tool cooler device and a numerically controlled machine tool system. The machine tool cooler device comprises a closed water tank, a heat exchange device and a bypass pipeline. The water tank water outlet of the closed water tank passing a unit water pump communicates to the heat exchange water inlet of the heat exchange device, the heat exchange water outlet ofthe heat exchange device communicates to the water inlet of a machine tool, the water outlet of the machine tool communicates to the water tank water inlet of the closed water tank, a water supplementing port and a bypass water outlet are formed in the closed water tank, and the water supplementing port can communicate to an external water supply device. One end of a bypass pipeline communicates to the bypass water outlet while the other end of the bypass pipeline communicates to the heat exchange device. Therefore, cooling water in the machine tool cooler device is still in a closed space during water supplementation, and meanwhile, residual water or air also can flow into the heat exchange device from the bypass pipeline, so that the condition that the closed water tank cracks is avoidedeffectively.

Owner:GREE ELECTRIC APPLIANCES INC

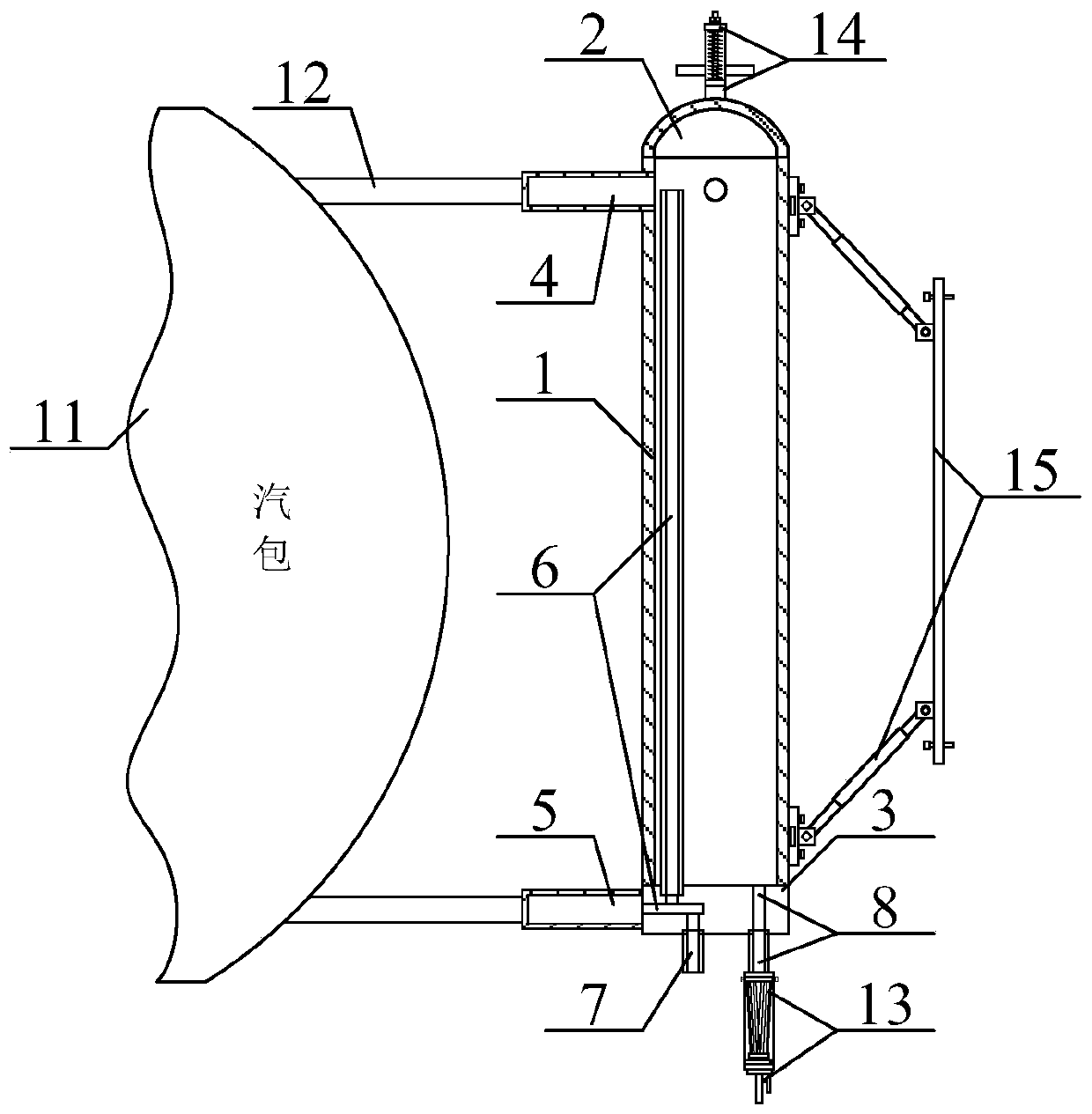

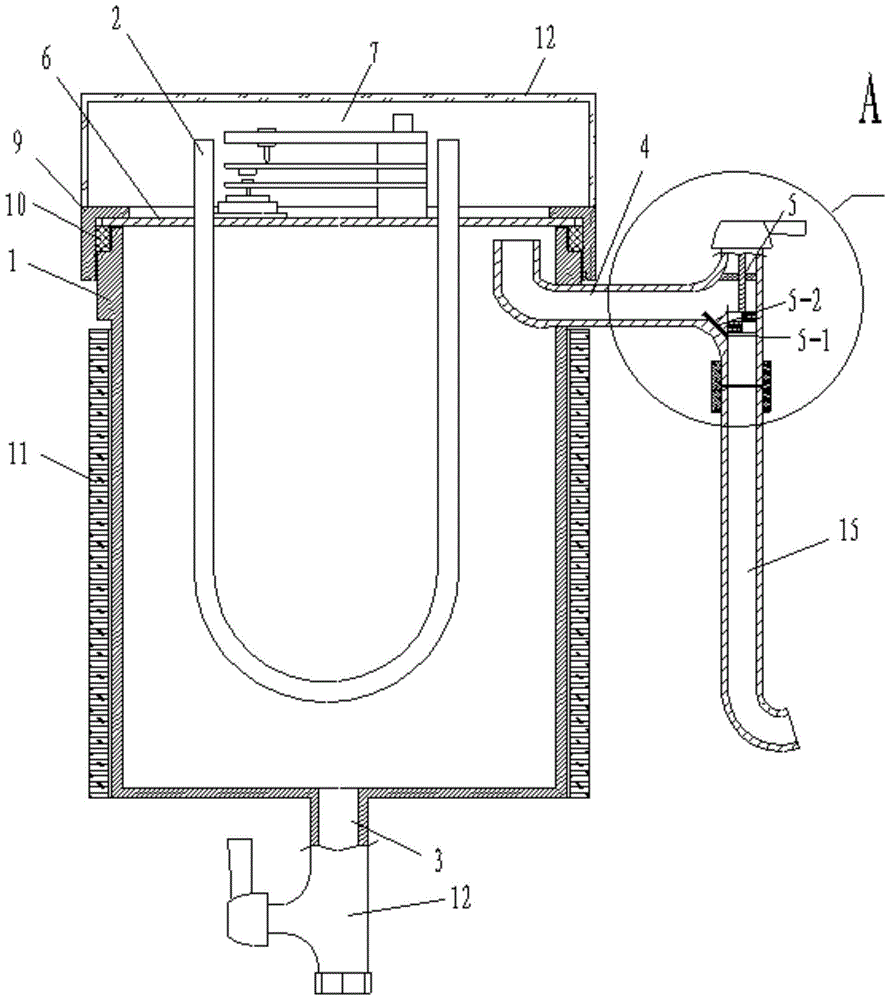

Liquid level measuring device for double-chamber balance container

ActiveCN111397688AAccurate dataReduce measurement errorSteam boilersSteam boilers componentsSteam pressureAutomatic control

The invention provides a liquid level measuring device for a double-chamber balance container. The device comprises a double-chamber balance container barrel body, an upper sealing head, a lower sealing head, an upper connecting pipe, a lower connecting pipe, a T-shaped communicating vessel, a positive pressure pipe, a blow-off pipe, a condensing coil, a negative pressure pipe, a boiler, a steam pocket steam phase guide pipe, a blow-off treatment antifouling discharge pipe structure, an automatic control release pipe structure capable of preventing steam pressure from being too high and an adjustable support mounting frame structure. According to the arrangement of the double-chamber balance container barrel, condensed water flowing back from the condensing coil can be collected and discharged into a descending pipe of a boiler, the whole container is heated and subjected to heat storage in the flowing process, it is guaranteed that the temperature in the container and the temperaturein a steam pocket are consistent, and then the accuracy of a measurement result is guaranteed. The arrangement of the T-shaped communicating vessel is beneficial to ensuring that the water level height of the communicating vessel changes along with the water level of the steam drum, so that the pressure of the positive pressure side changes along with the pressure change of the boiler steam drum,thereby ensuring the measurement accuracy, reducing the liquid level measurement error and improving the detection efficiency.

Owner:TANGSHAN CITY FENGRUN DISTRICT ZHANWANG AUTOMATION EQUIP CO LTD

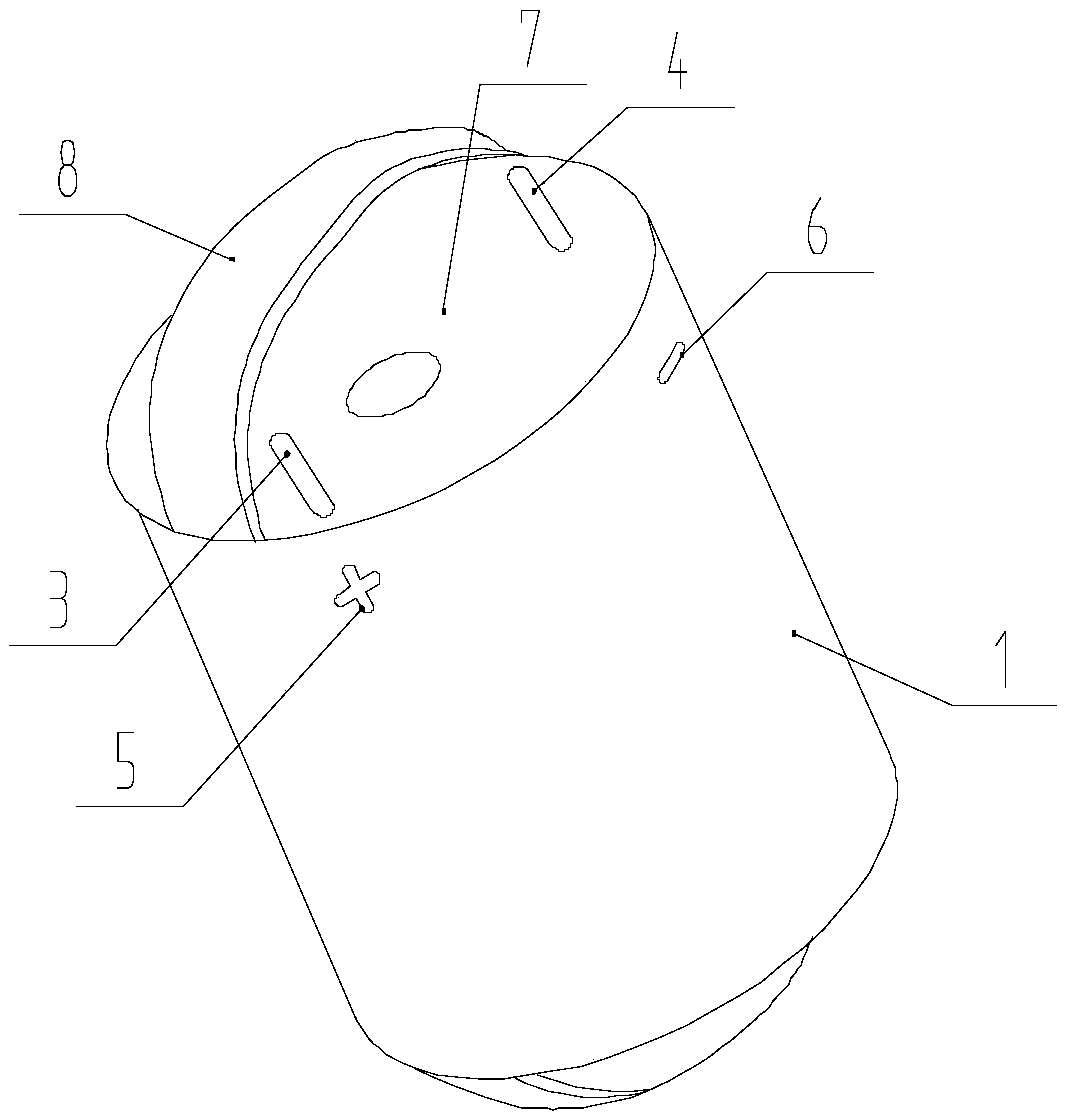

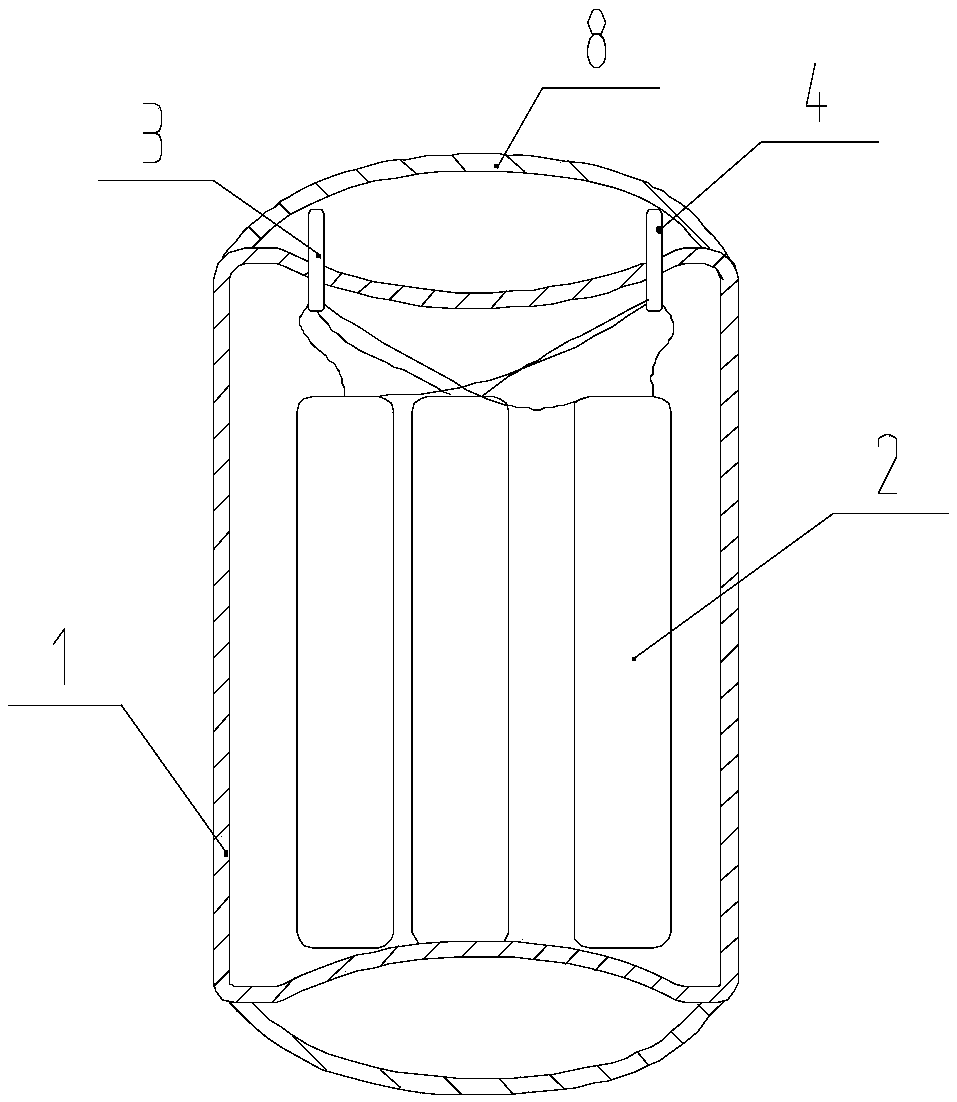

Multi-core capacitor

The invention provides a multi-core capacitor, comprising a shell and a plurality of capacitor cores sealed inside the shell. A positive pole pin and a negative pole pin are arranged on the shell; each of the capacitor cores are connected with the positive pole pin and the negative pole pin respectively; the positive pole pin side of the shell is provided with a cross-shaped groove, and the negative pole pin side is provided with an I-shaped groove; upper and lower ends of the shell are provided with anti-explosion concave parts. Bottom surfaces of the anti-explosion concave parts are spherical surfaces. The multi-core capacitor provided by the invention is firm and durable, and greatly reduces the possibility of burst. In addition, the shell is internally provided with the plurality of capacitor cores which are independently connected with the positive pole pin and the negative pole pin, even if a fault occurs in one or more capacitor cores, the capacitor can still continue to be used and work, and thus the capacitor is high in reliability. When temperature inside the capacitor is too high, a fuse is fused, a circuit is disconnected, thereby avoiding capacitor burst and occurrence of danger, and thus the capacitor is high in safety.

Owner:天津市科达斯特光电科技有限公司

Corrosion-resistant automobile tail pipe

InactiveCN107191256AImprove corrosion resistanceExplosion-proofSilencing apparatusMachines/enginesEngineeringLarge particle

The invention discloses a corrosion-resistant automobile tail pipe. A first exhaust pipe is installed on the end face of one side of a main connection tail pipe body through an installation piece. The outer wall of one side of the main connection tail pipe body is provided with a secondary connection tail pipe body. A second exhaust pipe is installed on the end face of one side of the secondary connection tail pipe body. An external thread is arranged on the outer surface of one side of the main connection tail pipe body. An outer ring is arranged on the outer portion of the first exhaust pipe, and an inner cavity is formed in the inner side of the outer ring. Vent holes are formed in the outer wall of the outer ring. An inner cavity is formed inside the first exhaust pipe. A filter is installed between the first exhaust pipe and the main connection tail pipe body. A fixed ring is fixed to the inner wall of the main connection tail pipe body. As the filter is installed at the junction of the min tail pipe body and the first exhaust pipe, large particles can be prevented from entering the main tail pipe body, an engine is protected and can operate normally, and the operation requirements are met.

Owner:CHONGQING CHANGYE AUTO PARTS

Drainage structure for flood prevention

The invention discloses a drainage structure for flood prevention. The drainage structure comprises two river levees arranged on the two sides of a river channel; flood discharge channels are arranged on the sides, away from the river channel, of the two river levees; flood discharge openings are formed in the two river levees; the two flood discharge openings communicate with the river channel and the flood discharge channels; barrier plates are arranged in the two flood discharge openings in a sliding mode; the barrier plates are made of novel rubber formed by mixing polyurethane resin and iron particles with the diameter of three micrometers; winding mechanisms corresponding to the barrier plates are arranged in the river levees; and magnetic field generating devices corresponding to the barrier plates are further arranged in the two river levees. When flood outbreaks, the flood discharge openings can be automatically opened through the change of the water level of the river channel, so that the water level of the river channel is controlled, the problem that the water level of the river channel is too high to cause levee failure is effectively avoided, and the influence of the flood on the property safety of residents along the bank is avoided.

Owner:广州欧轩机电设备有限公司

A method for refining the microstructure of hot-extruded magnesium alloy

ActiveCN107299304BImprove mechanical propertiesAvoid the risk of burstingSpray nozzleLiquid nitrogen

The invention provides a method for refining the microstructure of a hot-extruded magnesium alloy, comprising: cooling the hot-extruded magnesium alloy by applying liquid nitrogen to the hot-extruded magnesium alloy; the cooling device includes: a bracket ( 10); be fixed on the support (10) and be used for storing the liquid nitrogen storage tank (4) of liquid nitrogen; Support (10) is the inverted U-shaped baffle that covers on the workpiece (8), the inverted U-shaped baffle The top surface and two side surfaces have a baffle structure; a nozzle (7) arranged at the outlet of the liquid nitrogen storage tank (4), the nozzle (7) is used to spray liquid nitrogen onto the workpiece (8); A valve (6) arranged between the liquid nitrogen storage tank (4) and the nozzle (7); the flow rate of liquid nitrogen in the cooling process is 0.6-1.2m 3 / h. The invention adopts a specific cooling device and controls the flow rate of liquid nitrogen to avoid the risk of liquid nitrogen splashing and profile bursting, and the microstructure of the hot-extruded magnesium alloy is obviously refined.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Device for efficiently cooling hydraulic oil of drilling machine

InactiveCN106246646AAvoid the risk of burstingImprove securityFluid-pressure actuator componentsEvaporationEngineering

The invention discloses a device for efficiently cooling hydraulic oil of a drilling machine, which comprises a hot oil inlet, wherein a heat-insulating pipe sleeve is arranged below the hot oil inlet; a first cooling pipe is arranged below the heat-insulating pipe sleeve; a vapor outlet is formed above a frozen water tank; a butting sleeve is arranged at the top end of a butting pipe; a cold gas storage chamber is arranged on one side of the frozen water tank; an oil outlet is formed above a temperature detector; a flow divider is arranged above the oil outlet; an oil outlet pipe is arranged on one side of the flow divider; and a return pipe is arranged above the flow divider. The first cooling pipe is arranged on the left side of the device for efficiently cooling the hydraulic oil of the drilling machine and is used for cooling for the first time through water evaporation and heat adsorption. By the pre-cooling design, the pipe explosion danger caused by pipeline rapid cooling is avoided, so that the safety of the device is improved.

Owner:CHENGDU KECHUANGGU TECH CO LTD

Intelligent quick detection biological kit

PendingCN107991483AEasy to operateAvoid the risk of burstingPreparing sample for investigationBiological material analysisComputer moduleEngineering

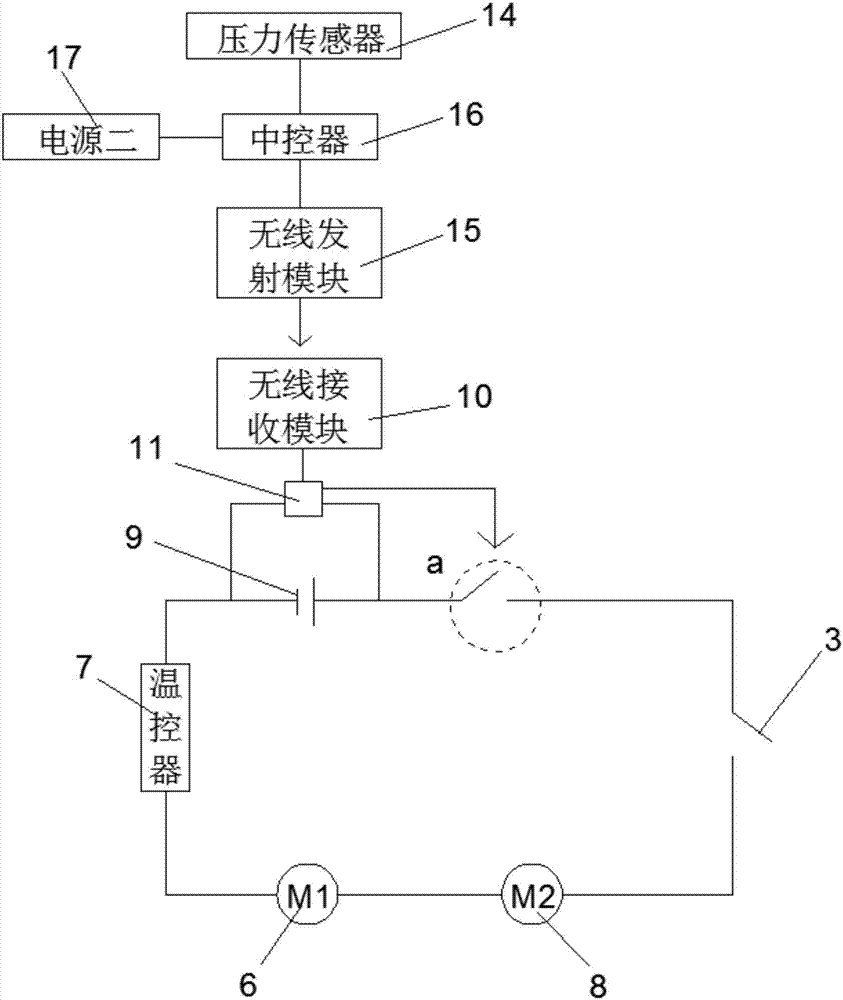

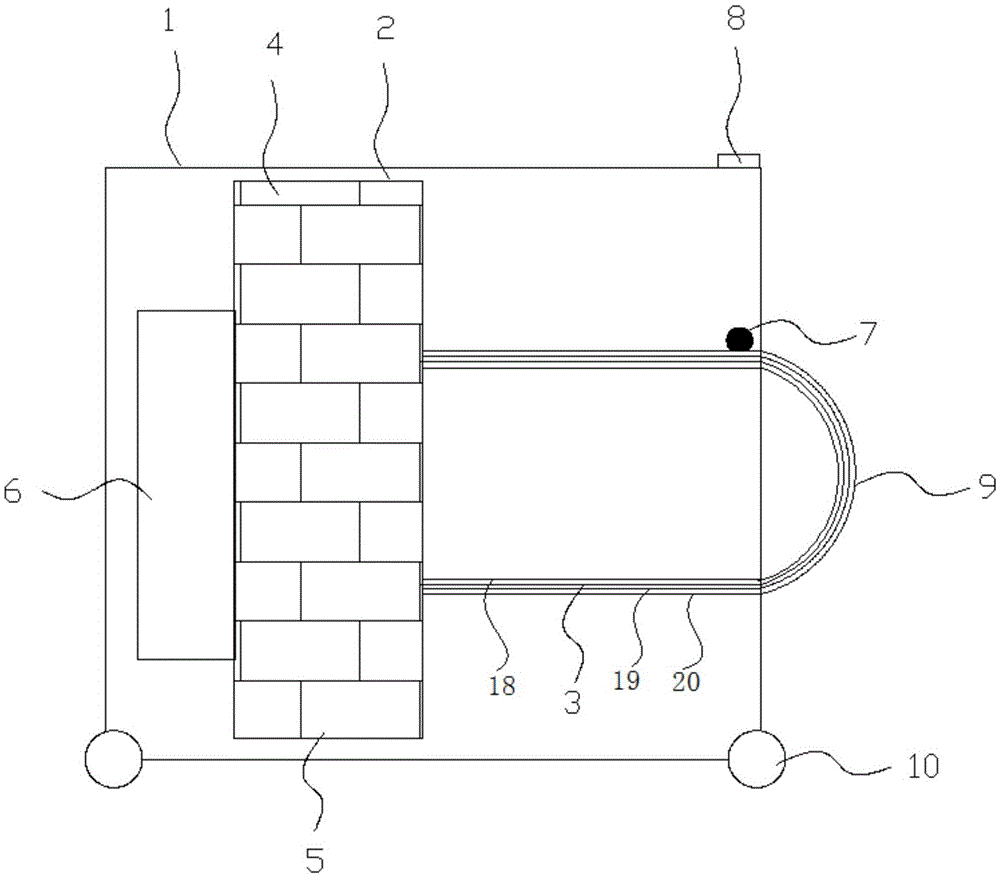

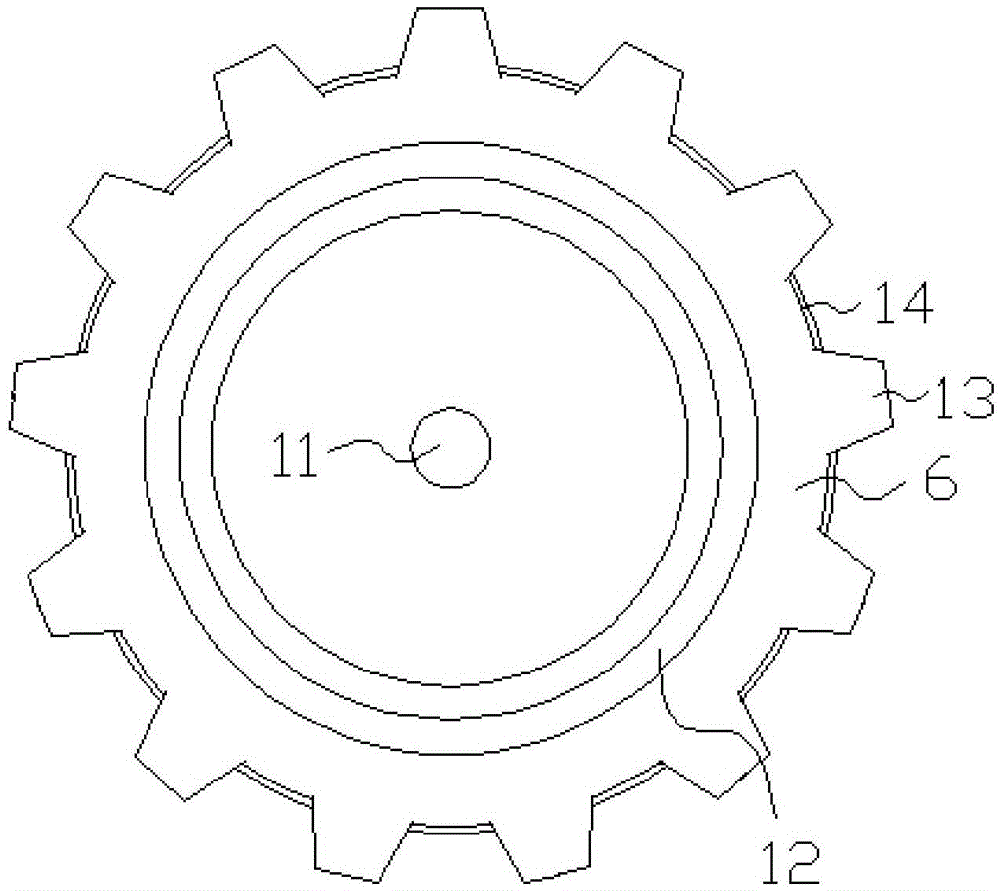

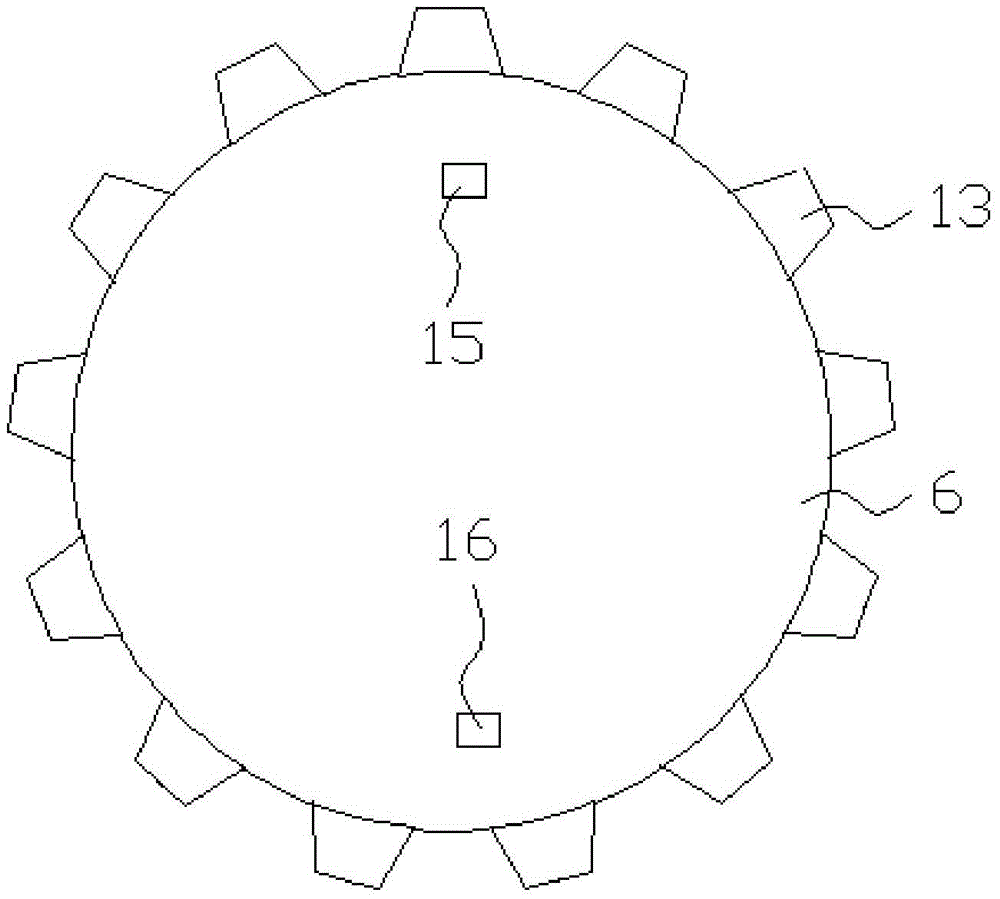

The invention relates to the technical field of biological kits, in particular to an intelligent quick detection biological kit. The intelligent quick detection biological kit comprises a kit body, akit cover, a door contact switch, a fixed block, a screw, a slide motor, a temperature controller, a rotary motor, a power source I, a wireless receiving module, a controller, a base, test tube grooves, pressure sensors, a wireless transmitting module, a central controller, a power source II, a telescopic rod, a fixed plate and clamping holes. The intelligent quick detection biological kit has theadvantages that the intelligent quick detection biological kit is suitable for clamping and fastening test tubes of different heights; the application range is broad, the intelligence degree is high,the time is shortened, the labor intensity is decreased, the loss of electric energy is reduced, the internal heating temperature is uniformly controlled, the explosion risk due to heating of local part of the test tube is reduced, the biological detection efficiency is improved, and the practicality is stronger.

Owner:天津绿禾益民生物质利用科技有限公司

Corrosion-resisting explosion-proof water pump

InactiveCN105464922AImproved corrosion and cavitation wear resistanceExtended service lifeExternal parameterPositive displacement pump componentsCorrosion resistantDrive motor

The invention discloses a corrosion-resisting explosion-proof water pump. The water pump comprises a shell, a driving motor and a water suction pump. The driving motor and the water suction pump are fixedly arranged in the shell, the driving motor is in transmission connection with the water suction pump, the driving motor is composed of a motor body and an end cover, and the motor body is fixedly connected with the end cover; an annular circulating water tank is fixedly arranged in the end cover, and a detection contact is fixedly arranged at the top end of the water suction pump; a buzzer is fixedly arranged at the top end of the shell; a wear-resisting ceramic coating is arranged on the inner wall of the water suction pump, and a teflon coating is arranged on the outer wall of the water suction pump; and a TPU layer is arranged outside the teflon coating. The wear-resisting ceramic coating is arranged on the inner wall of the shell, the anti-corrosion capability and the cavitation erosion prevention property of a filter can be greatly improved, and service life of the water pump is prolonged; the arranged teflon coating has the exposition-proof effect, and the bursting danger of a device cylinder can be prevented; and the TPU layer is arranged, and the mechanical strength and the bearing capability of the equipment are improved.

Owner:CHONGQING AMM MACHINERY MFG CO LTD

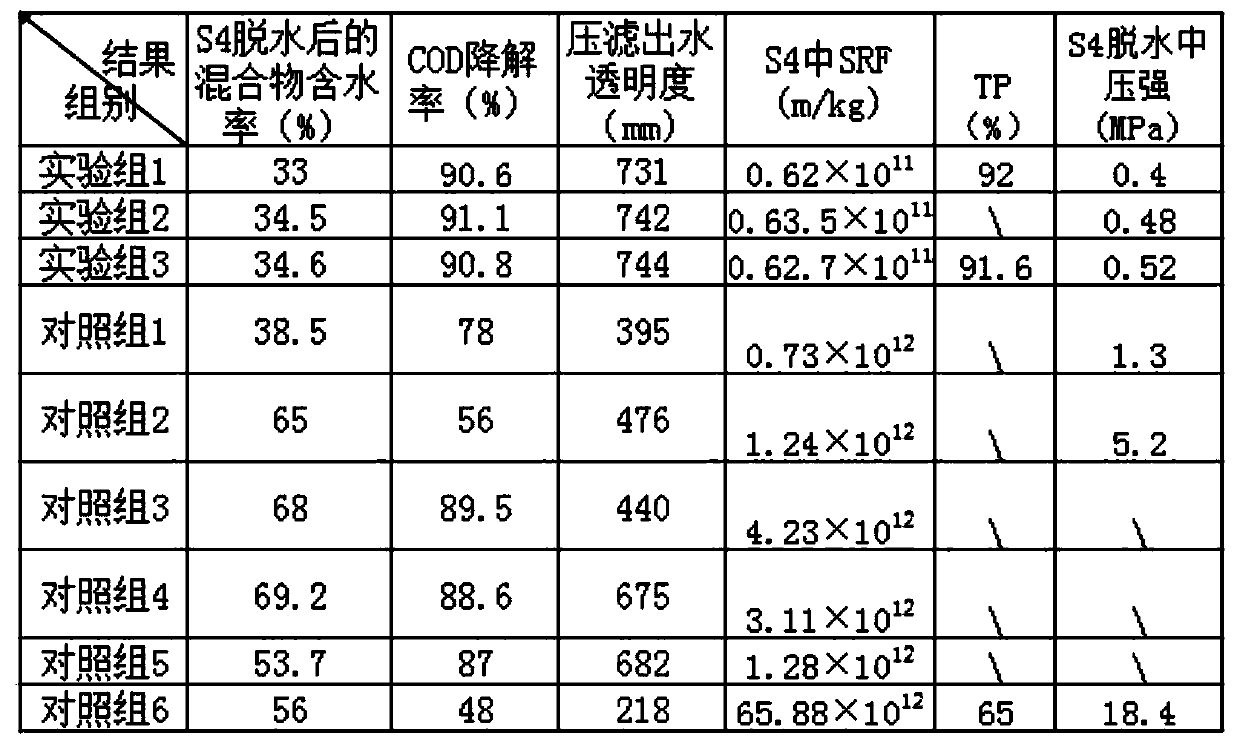

Sludge heat treatment recycling process

PendingCN111533412APromote hydrolysisImprove acidificationWater treatment parameter controlSludge treatment by thermal conditioningMicroorganismCompression molding

The invention belongs to the technical field of sludge treatment, and particularly relates to a sludge heat treatment recycling process which comprises the following steps: S1, preheating sludge, S2,carrying out heat treatment, S3, cooling, S4, dehydrating, and S5, carrying out compression molding. According to the sludge heat treatment recycling process, the sludge is deeply dewatered, the effects of disintegrating the sludge and improving organic matter dissolution can be achieved, and therefore the phosphorus release capacity of the sludge is improved, the pH value of a sludge system aftertreatment is 7, a treatment container is not corroded, and the salinity in the system cannot be improved. The process can be used for effectively sterilizing, killing germs in sludge and inhibiting fermentation microorganisms from generating a large amount of acidic biogas, so that pipeline equipment is corroded and damaged, and the burst risk caused by more biogas is avoided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Magnetic stirring apparatus

ActiveCN104888650AAvoid significant declineGuaranteed stirring effectMixersEngineeringMagnetic tension force

The present invention relates to a magnetic stirring apparatus, which comprises: a stirring kettle with a sealed stirring chamber; a stirring assembly, wherein the stirring assembly comprises a stirring shaft extending to the stirring chamber from the outer of the stirring kettle, a stirring member arranged on the stirring shaft, and a power source driving the stirring shaft through a magnetic transmission assembly; and a scattering assembly adjacent to the magnetic assembly and used for heat elimination on the magnetic assembly. According to the magnetic stirring apparatus of the present invention, the influence of the temperature on the magnetic field of the magnetic stirring apparatus can be effectively reduced so as to avoid the significant stirring effect reducing.

Owner:CHINA PETROLEUM & CHEM CORP +1

Waterproof and explosion-proof capacitor

InactiveCN106952726AImprove sealingImprove waterproof performanceCapacitorsTemperature controlThermostat

The invention relates to a waterproof and explosion-proof capacitor, which belongs to the technical field of capacitors. It includes a metal shell, capacitor core, cover, terminal block, explosion-proof plate, terminal, fuse and temperature control switch. The metal shell is fixed with an explosion-proof plate, the terminal is fixed on the explosion-proof plate, and the lower end is connected to the capacitor core. , the terminal is fixed on the cover, and connected to the upper end of the terminal through the fuse and the temperature control switch respectively. The cover is composed of three layers of materials, which are insulating layer, waterproof layer and aluminum cover layer from inside to outside. There is also a sealing gasket between the cover and the metal shell; when the temperature of the capacitor core is too high, the invention protects itself by disconnecting the temperature control switch, which not only has a good explosion-proof function, but also has good sealing and waterproof performance.

Owner:CHIZHOU RONGDA ELECTRIC CO LTD

micro water heater

The invention relates to a minitype water heater which facilitates daily washing in kitchens, is small in size and convenient to use, and has an automatic safety protection function. The minitype water heater comprises a heating container, an electric heating pipe and a safety protection switch device, wherein the electric heating pipe is inserted in the heating container, the heating container is provided with a water inlet pipe and a water outlet pipe, the water inlet pipe is arranged on the lower portion of the heating container, the water outlet pipe is arranged on the upper portion of the heating container, a water inlet valve is arranged on the water inlet pipe, a water outlet valve is arranged on the water outlet pipe, the water outlet valve is provided with a water outlet channel connected between the water inlet end of the water outlet valve and the water outlet end of the water outlet valve, and the safety protection switch device comprises a pressure sensor and / or an overheat protector.

Owner:卓元廉

High-strength wear-resistant mixing drum for constructional engineering

ActiveCN105521725AAvoid the risk of burstingImprove corrosion resistanceTransportation and packagingRotary stirring mixersWear resistantCeramic coating

The invention provides a high-strength wear-resistant mixing drum for constructional engineering. The mixing drum comprises a drum body, two sides of which are provided with driving guide rails. A stirring device is arranged inside the drum body. The stirring device comprises stirring vanes, support columns, a rotation shaft and a rotation wheel. The stirring vanes are installed on the rotation shaft through the support columns. The rotation wheel is installed on a rotation disc. A liftable anti-sediment net is arranged between the driving guide rails. The inner wall of the drum body is provided with a wear-resistant ceramic coating. The outer wall of the drum body is equipped with a Teflon coating, outside which a TPU layer is disposed. By arranging the wear-resistant ceramic coating on the inner wall of the drum body, anticorrosion capability and anti-cavitation erosion capability of a filter are greatly raised, and service life of the equipment is prolonged. The Teflon coating as an explosion-proof effect and can prevent explosion risk of the drum body. By arranging the TPU layer, mechanical strength and bearing capacity of the equipment are enhanced.

Owner:东营市柏基装饰工程有限公司

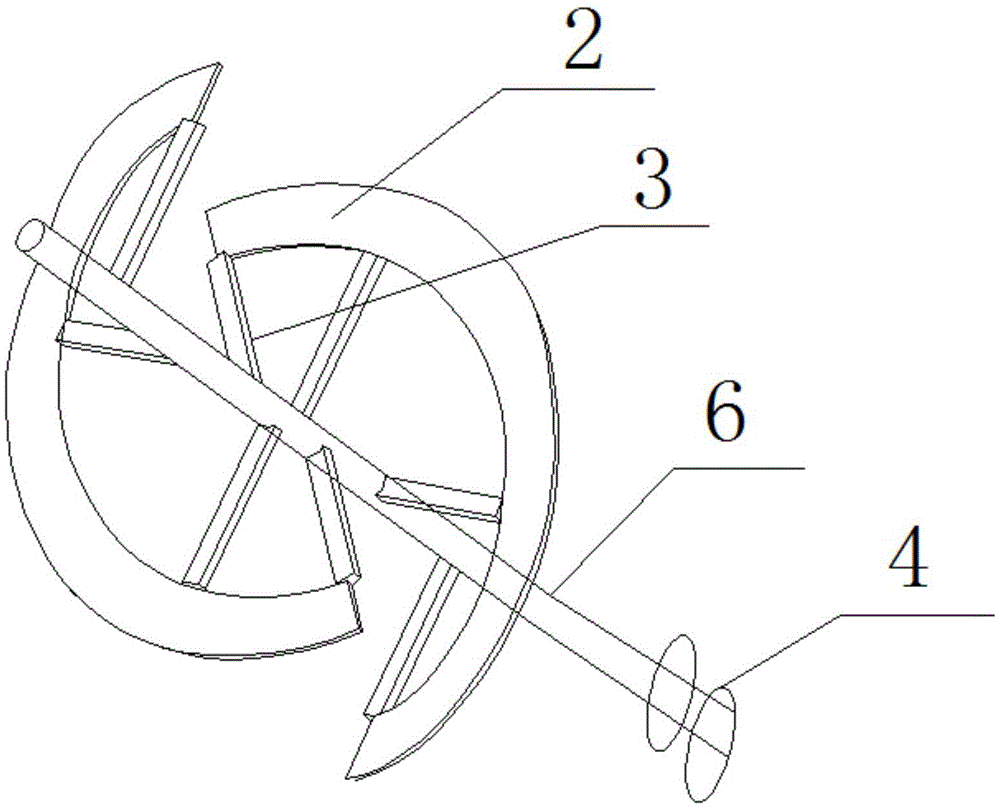

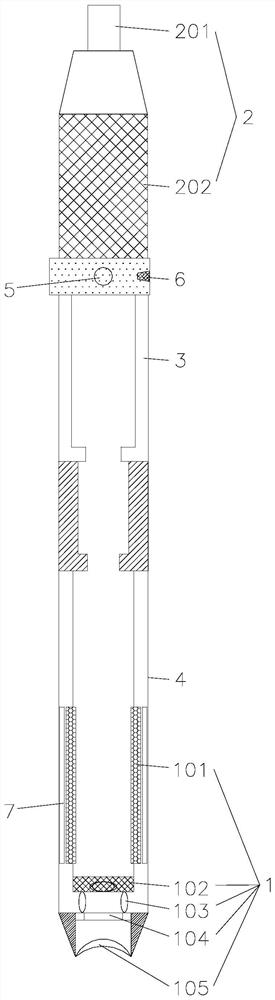

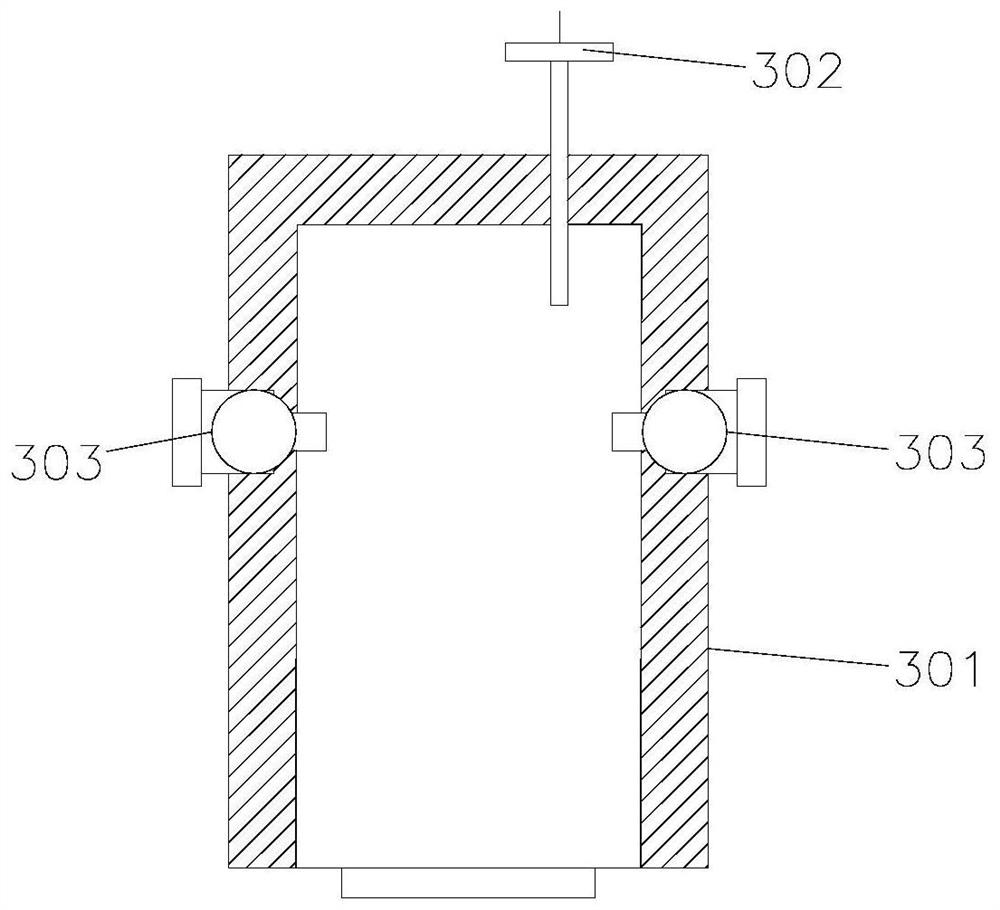

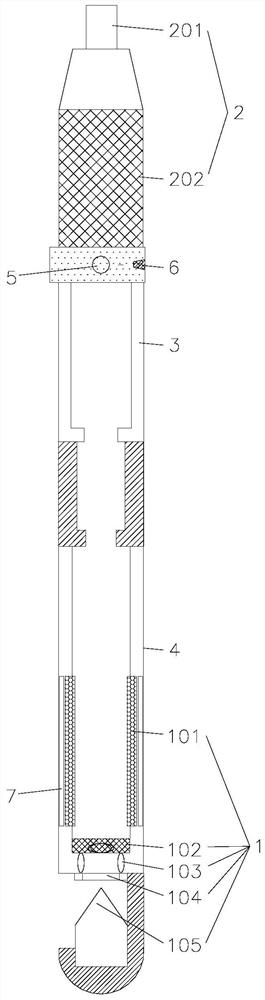

Underground video detection device suitable for high-temperature geothermal well and control method of underground video detection device

PendingCN113452880AGuaranteed differential pressureUniform differential pressureTelevision system detailsMeasurement devicesData transmissionStress sensors

The invention relates to the technical field of petroleum engineering equipment, in particular to an underground video detection device suitable for a high-temperature geothermal well and a control method of the underground video detection device. The underground video detection device comprises an image acquisition module and a communication module which is in communication and data transmission with the outside, wherein a shell is arranged outside the image acquisition module and the communication module; a cooling mechanism is arranged between the shell and the image acquisition module, a vacuum cavity is arranged between the cooling mechanism and the shell, and the communication module is in signal connection with the image acquisition module and the cooling mechanism. When the device is in use, the pressure inside the container detected by the first pressure sensor is compared with the pressure outside the shell detected by the second pressure sensor to control the opening or closing of the pressure release valve, so the pressure difference between the inside and the outside of the container is balanced, the risk of explosion caused by overlarge pressure difference between the inside of the container and the outside of the shell is prevented, and the image acquisition module is better cooled.

Owner:CHANGZHOU UNIV

A multifunctional student desk

The invention discloses a multifunctional student desk which comprises a desk body and a desk top, wherein two desk legs of the desk body both have a box-shaped structure; an air cushion, a switch and an air pump are arranged in the box-shaped structure; the air cushion is adhered to the inner surface of the box-shaped structure and is connected with the air pump; the switch is arranged on the box-shaped structure and is connected with a miniature air pump; the miniature air pump is built in the box-shaped structure. The multifunctional student desk provided by the invention is fit for various students; the use is convenient; the use area can be effectively increased; learning tools, such as pens and erasers, can be conveniently cleared up, so as to keep the desk top clean; besides, the air cushions arranged in the desk legs can be timely inflated to form a space for accommodating the student for hiding in emergency, so as to avoid hurt and achieve the function of temporary hiding; the pressure sensor can be used for avoiding the risk of air cushion explosion in the inflation process.

Owner:何永刚

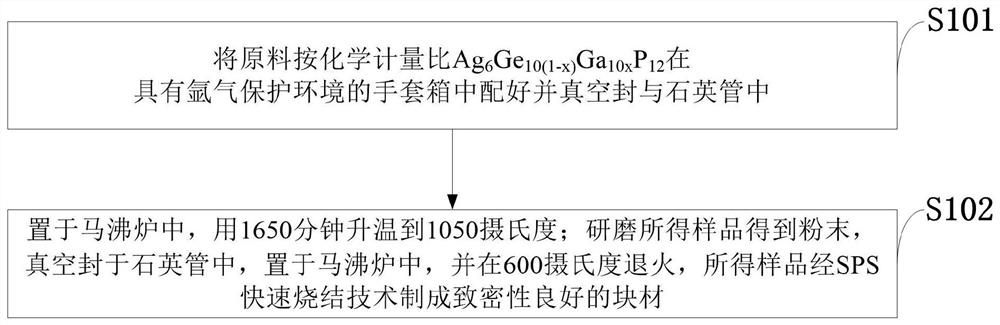

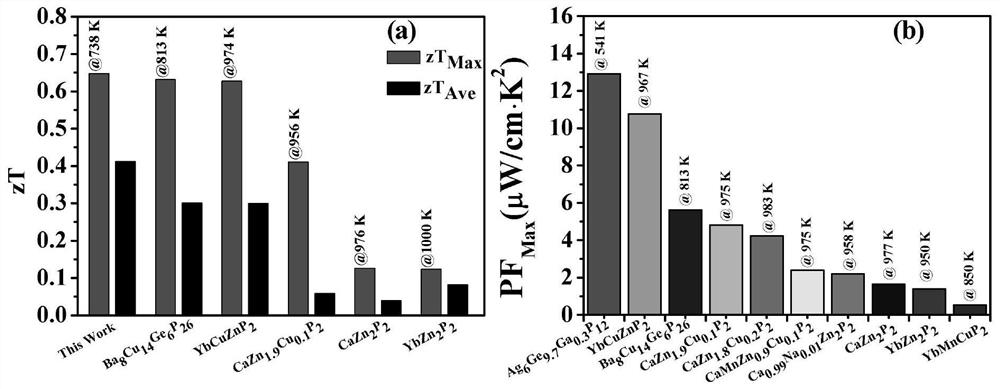

Preparation method of novel p-based compound Ag6Ge10P12 material with high thermoelectric performance

ActiveCN108425150BHigh purityImprove efficiencyPolycrystalline material growthSingle crystal growth detailsMaterial growthMetal powder

The invention belongs to the technical field of manufacturing workpieces or products from metal powder, and discloses a novel P-based compound Ag 6 Ge 10 P 12 Preparation method of high thermoelectric performance material, doped polycrystalline Ag 6 Ge 10 P 12 It has very superior thermoelectric performance, doping about 3% Ga can improve the overall performance by 2-3 times, and the time required for material growth is comparable to other traditional polycrystalline thermoelectric materials (about one week). Compared with many phosphorus-based thermoelectric materials, the highest PF (determining the electrical properties of the material) and the highest zT (determining the thermoelectric performance) or the average zT (determining the conversion efficiency) are currently the best. The present invention successfully prepares Ag 6 Ge 10 P 12 Polycrystalline bulk material; solves the problem of excessive vapor pressure generated by phosphorus during the growth process, and the explosion of the quartz tube due to excessive vapor pressure; the effective doping method of Ga element improves the thermoelectric performance of the material.

Owner:CHONGQING UNIV

Automatic safety control device for industrial waste heat recovery system

ActiveCN103486898BAvoid the risk of burstingHigh pressureHeat exchange apparatusWorking fluidControl system

The invention provides an automatic safe control device of an industrial waste heat recovery system. The automatic safe control device is based on the industrial waste heat recovery system. Temperature sensors are mounted on a heat-pipe-type cooler and are used for measuring the temperature; the port of a condenser is provided with a temperature sensor for measuring the cooling amount of the entire system, and a pressure sensor is mounted on the condenser for measuring the pressure of working fluid inside the system; signals of the sensors are inputted into the control system, and safe and effective utilization of industrial waste can be realized by controlling the number of the working fluid inside the system.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

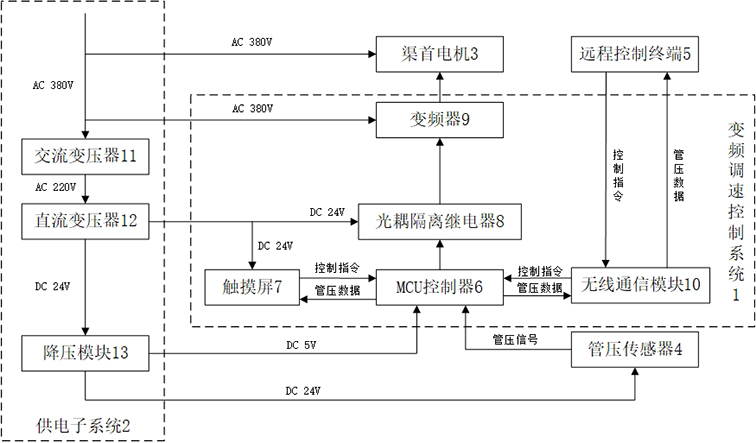

Farmland irrigation canal head motor frequency conversion speed regulation control system

PendingCN114826089AControl speedRealize remote controlAC motor controlWatering devicesFrequency changerMotor speed

A farmland irrigation canal head motor frequency conversion speed regulation control system comprises a frequency conversion speed regulation control system, a power supply subsystem, a canal head motor, a pipe pressure sensor and a remote control terminal. The frequency conversion speed regulation control system is used for controlling the rotating speed of a headstock motor and comprises an MCU controller, a touch screen, an optical coupling isolation relay, a frequency converter and a wireless communication module. The power supply subsystem is used for voltage conversion and supplying power to electrical components, a headstock motor and a pipe pressure sensor of the variable-frequency speed regulation control system. The variable-frequency speed regulation control system comprises an alternating-current transformer, a direct-current transformer and a voltage reduction module. The pipe pressure sensor is used for collecting pipeline pressure, and the MCU controller adjusts the frequency of the frequency converter according to a pipe pressure signal so as to change the rotating speed of the motor; the remote control terminal is used for an operator to remotely control and adjust the rotating speed of the motor. The pipe pressure sensor and the frequency converter are used for achieving automatic adjustment of the rotating speed of the canal head motor, the irrigation efficiency is guaranteed, and the problem of pipe explosion caused by too large pipeline water pressure is solved.

Owner:SHIHEZI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com