Corrosion-resisting explosion-proof water pump

A corrosion-resistant, water-pump technology, applied in the field of water pumps, can solve problems such as failure to detect in time, poor mechanical properties, and shorten the service life of water pumps, achieve anti-corrosion and anti-cavitation wear properties, increase mechanical strength and bearing capacity, The effect of preventing the machine from idling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not used to limit the present invention.

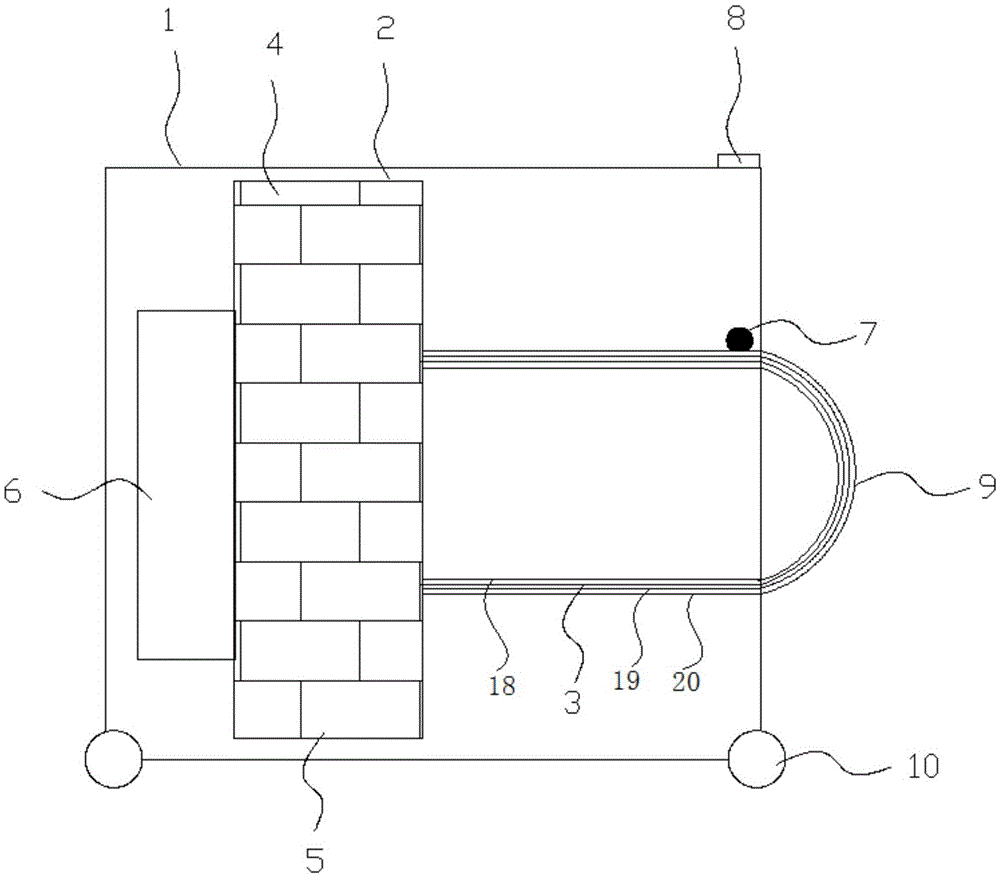

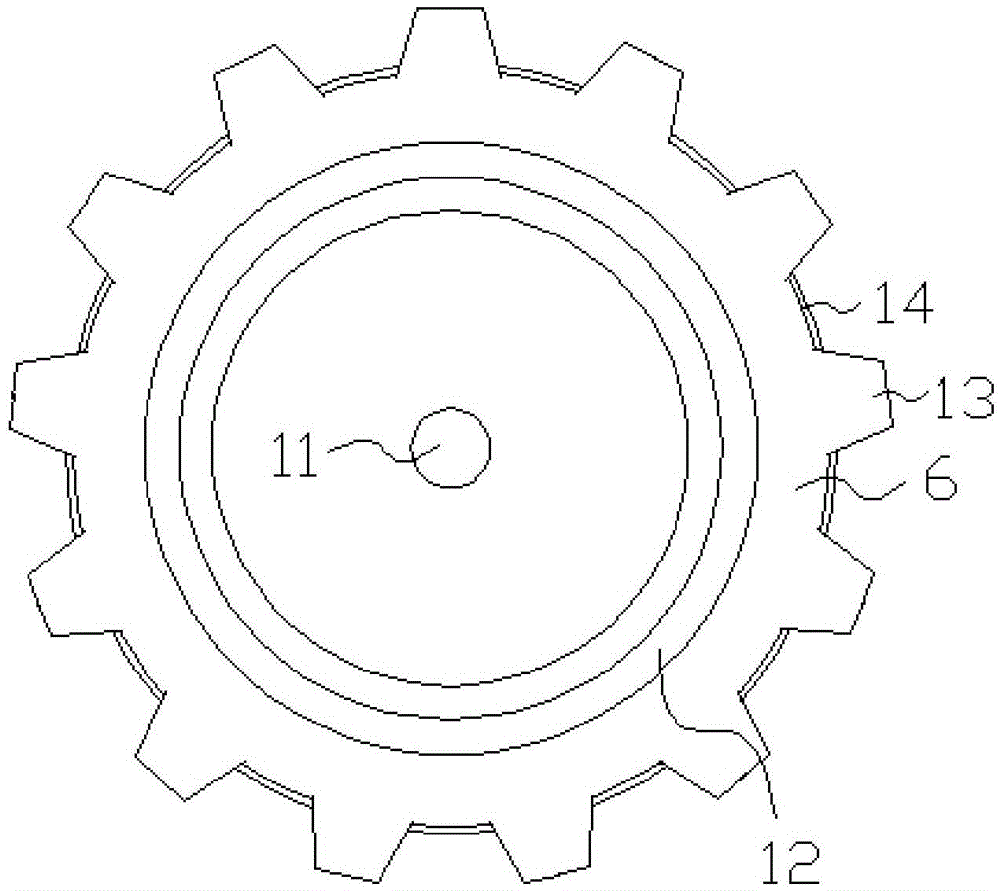

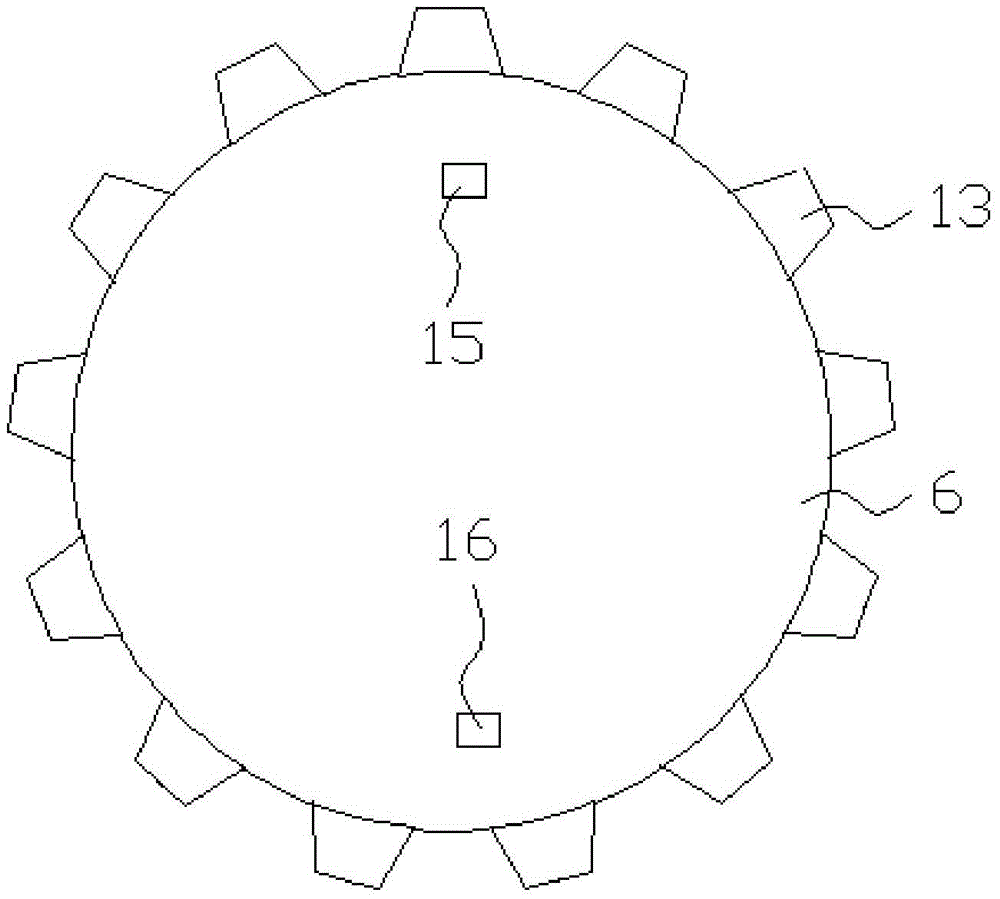

[0017] Such as Figure 1-Figure 3 As shown, the present invention provides a corrosion-resistant and explosion-proof water pump, including a housing 1, a drive motor 2 and a water pump 3. The housing 1 is fixed with a drive motor 2 and a water pump 3, and the drive motor 2 is connected to the water pump 3 in transmission , The driving motor 2 is composed of a motor body 4 and an end cover 6. The motor body 4 is fixedly connected to the end cover 6, a heat dissipation strip 5 is fixed on the motor body 4, and an annular circulating water tank 12 and an end cover 6 are fixed in the end cover 6 A trapezoidal heat sink 13 is fixed on the side of the end cover 6, a water inlet 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com